Pit structure mounting method

An installation method and bottom pit technology are applied in infrastructure engineering, transportation and packaging, elevators in buildings, etc., which can solve problems such as rough and simple installation methods, deviation errors, and unstable connections, and achieve the elimination of potential safety hazards, The effect of reducing deviation error and preventing landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

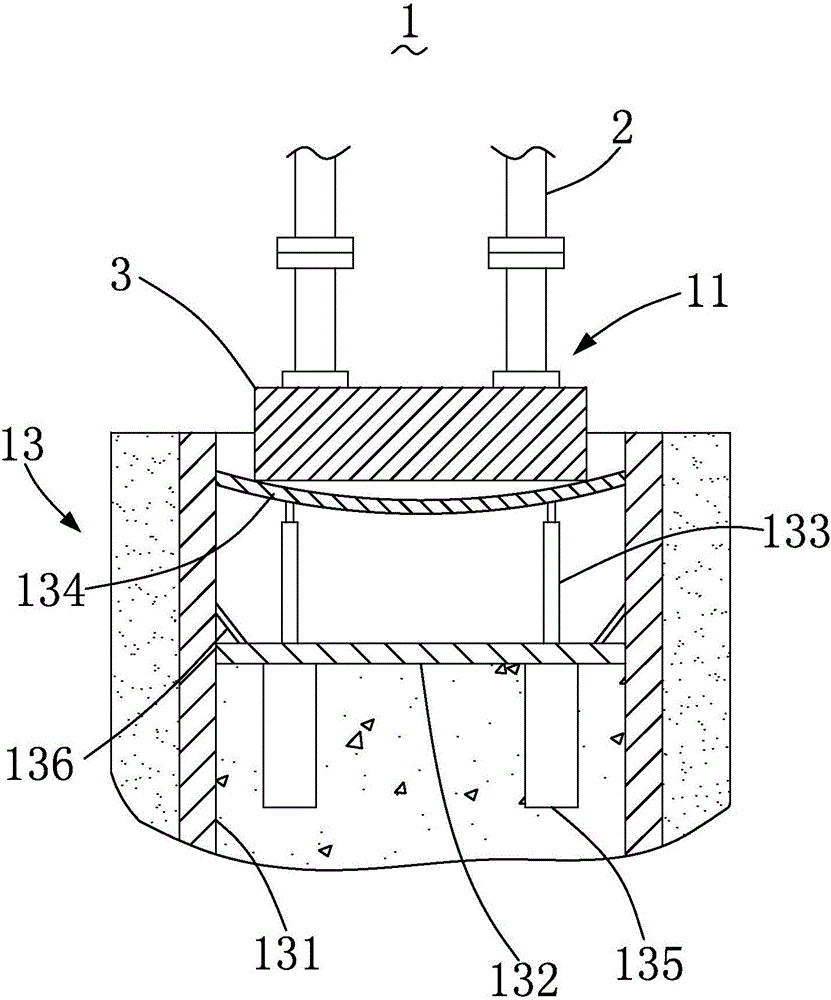

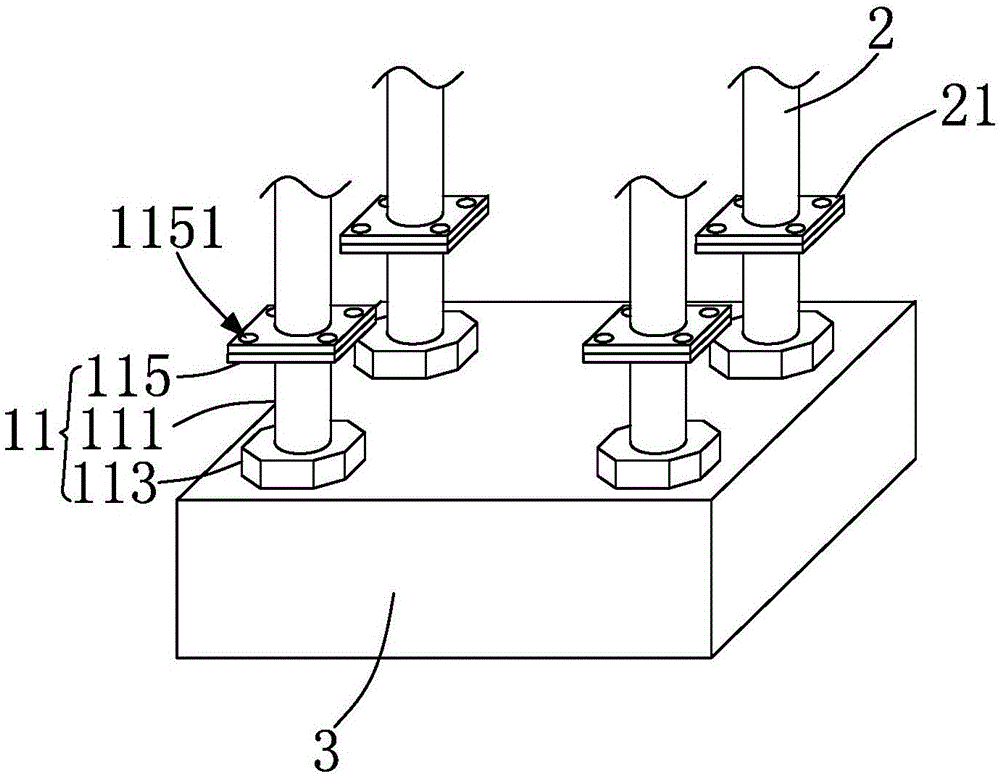

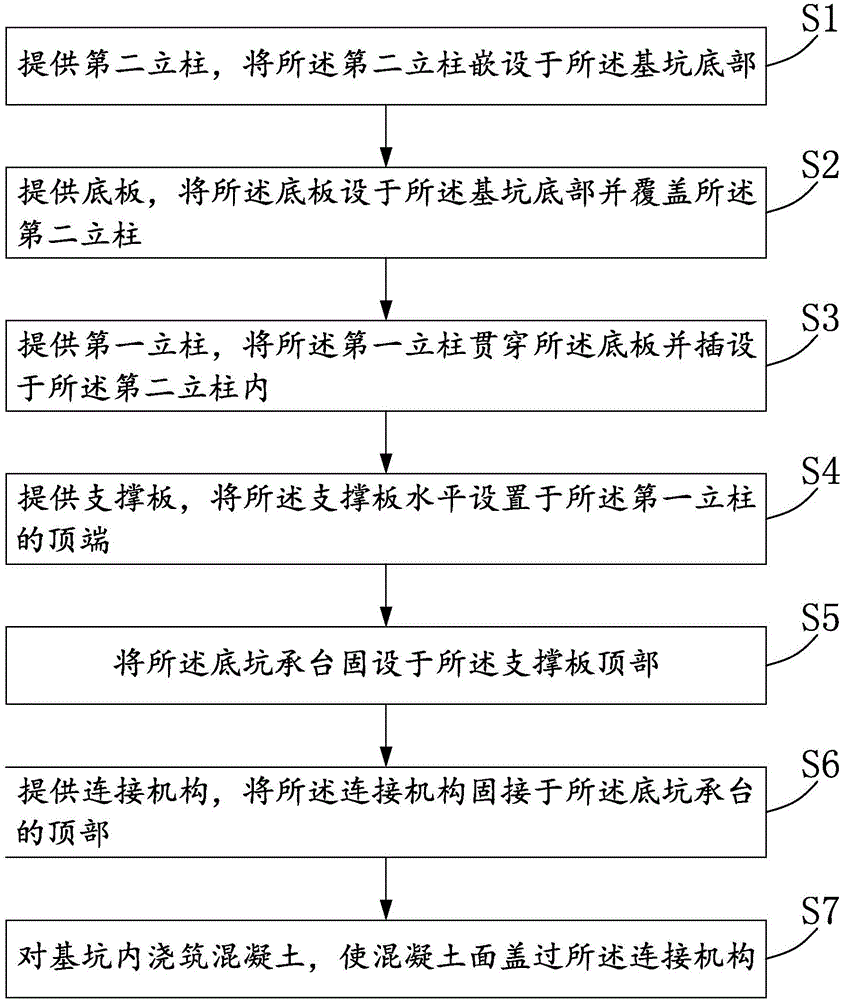

[0034] see figure 1 , is a flow chart of the steps of the pit structure installation method of the present invention. The installation method of the pit structure, through the fixing mechanism arranged at the bottom of the pit cap and the connecting mechanism arranged at the top of the pit cap, fixes the pit cap and connects the hoistway frame, comprising the following steps :

[0035] Step S1, providing a second column, and embedding the second column in the bottom of the foundation pit;

[0036] Step S2, providing a bottom plate, setting the bottom plate on the bottom of the foundation pit and covering the second column;

[0037] Step S3, providing a first column, passing the first column through the bottom plate and inserting it into the second column;

[0038] Step S4, providing a support plate, and horizontally setting the support plate on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com