A nitrogen oxide sensor controller

A technology of nitrogen oxides and sensors, which is applied in the direction of instruments, scientific instruments, machines/engines, etc., can solve the problems of inability to measure various indicators efficiently and accurately, so as to improve cold start performance, service life and thermal shock resistance, and realize Accurately detect and filter out the effects of noise signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

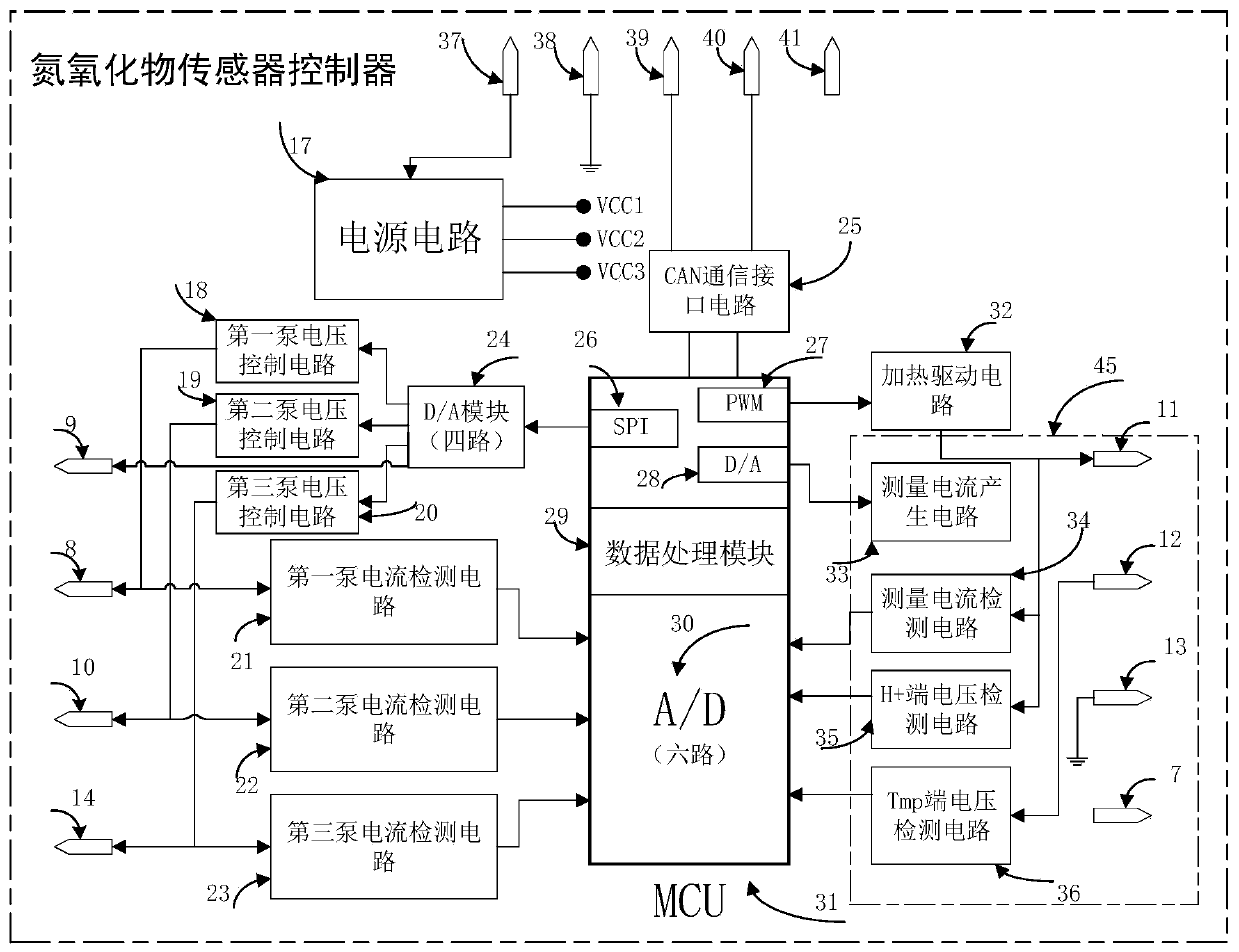

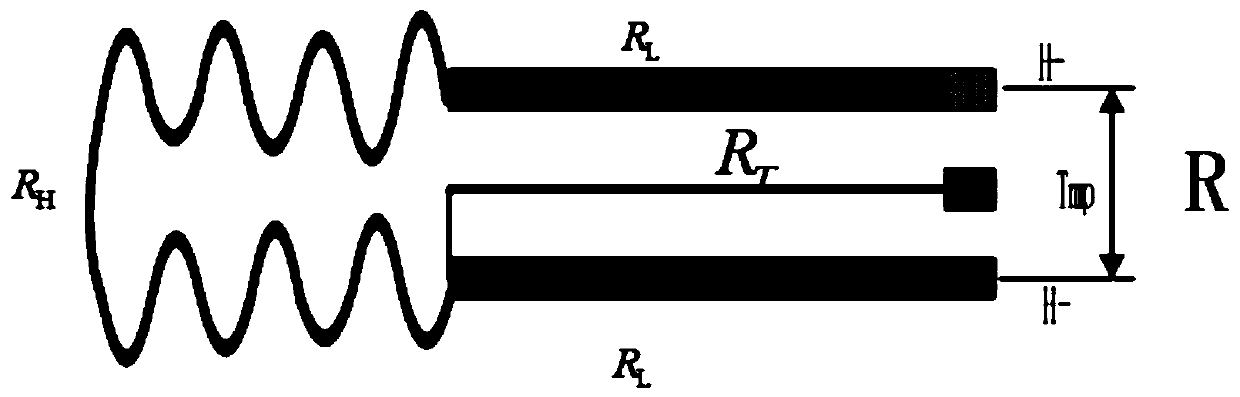

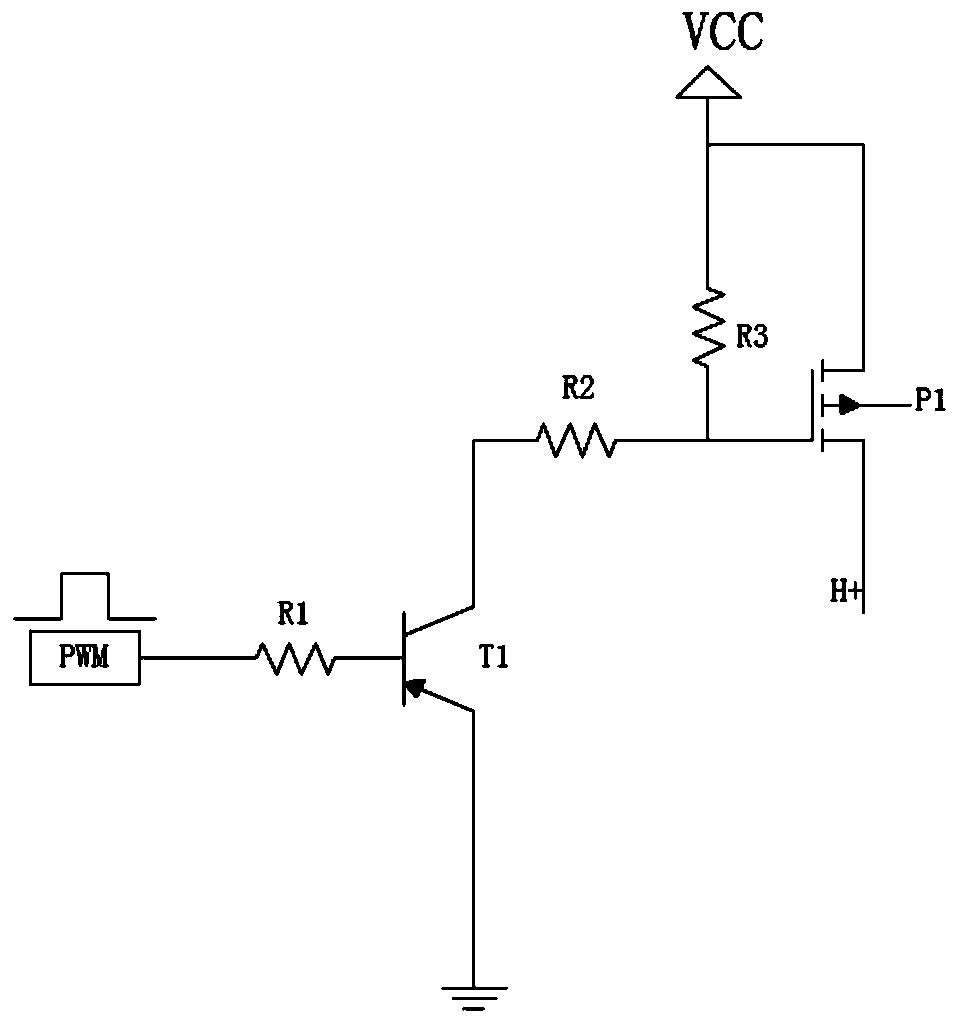

[0050] A NOx sensor controller such as figure 1 As shown, including: heater resistance measurement circuit 45, the resistance measurement circuit where the heater is located (such as figure 2 shown), micro control unit 31, heating drive circuit 32, first, second and third pump current detection circuits (including the first pump current detection circuit 21, the second pump current detection circuit 22 and the third pump current detection circuit 23) , and the first, second and third pump voltage control circuits (including the first pump voltage control circuit 18, the second pump voltage control circuit 19 and the third pump voltage control circuit 20). in,

[0051] The heater resistance measurement circuit is used to receive the current signal generated by the micro control unit through the D / A port and apply it to the heater resistance measurement circuit, measure the loop current in the loop and the voltage across the heating plate in the nitrogen oxide sensor and It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com