Laser eutectic welding device for miniature LED chip and control substrate

A technology for LED chips and control substrates is applied in the field of laser eutectic welding devices for micro LED chips and control substrates, which can solve the problems of lowering the product qualification rate, labor consumption, damage to LED chips, etc., so as to reduce the process of adding solder and save production costs. , the effect of increasing the eutectic speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

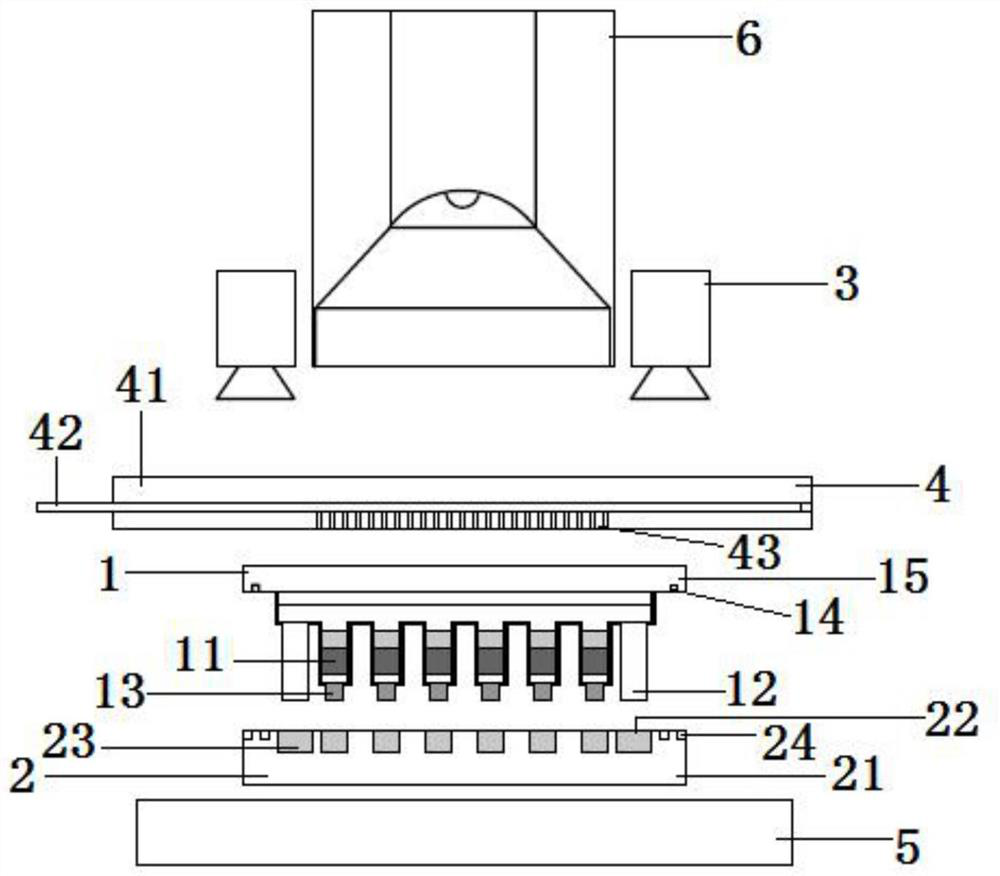

[0055] This embodiment provides a laser eutectic welding device for a micro LED chip and a control substrate, the purpose of which is to simultaneously weld multiple LED chips in the micro LED chip 1 and the control substrate 2 together by using a laser;

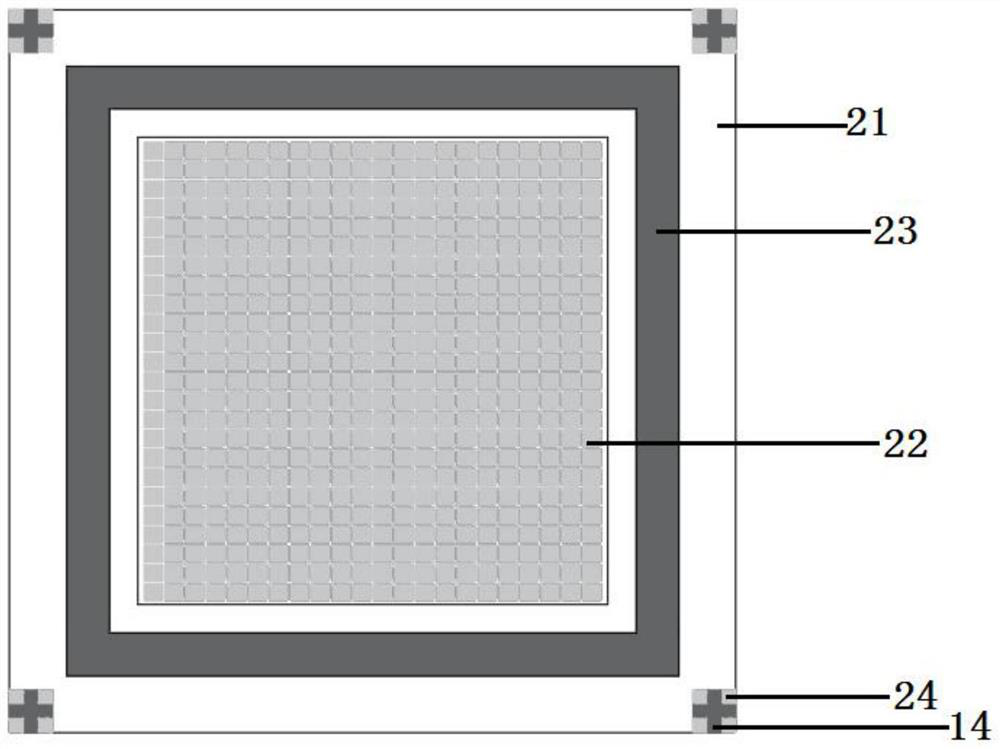

[0056] The micro LED chip 1 includes a chip substrate 15 and a plurality of LED chips 11 fixed on the chip substrate 15; a plurality of LED chips 11 have a common first negative electrode 12, and a plurality of LED chips 11 have independent a first positive electrode 13;

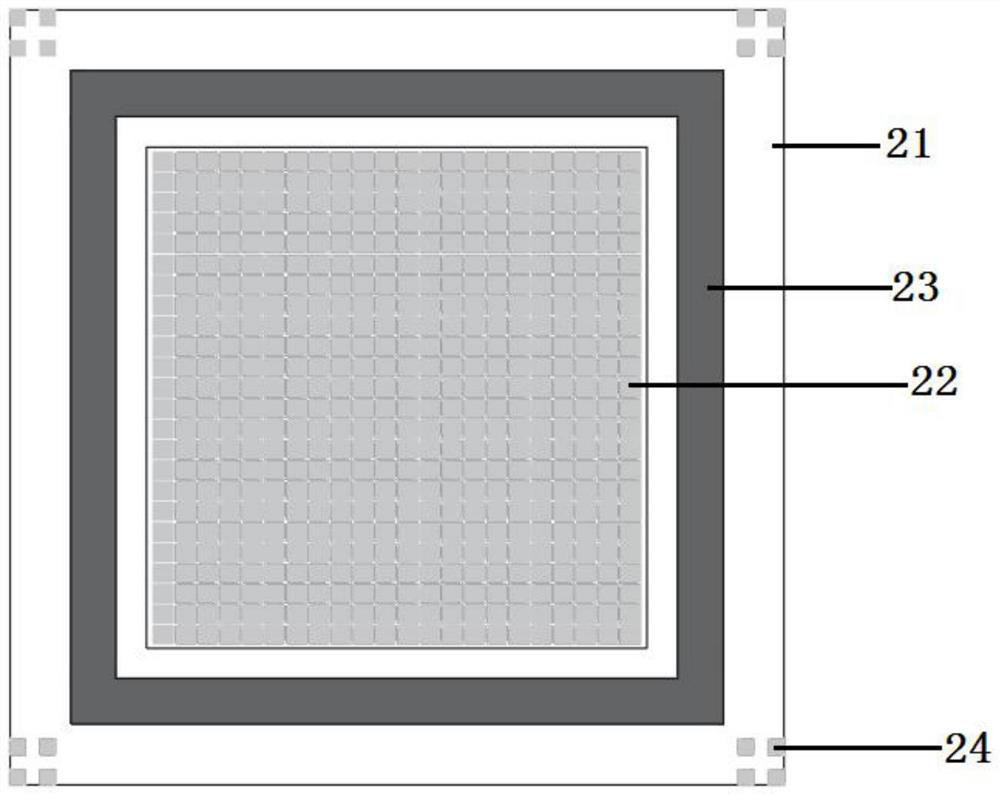

[0057] The control substrate 2 is located below the micro LED chip 1, and it includes a control substrate main body 21 and a plurality of second positive electrodes 22 and a second negative electrode 23 located on the control substrate main body 21;

[0058] The laser eutectic welding device includes:

[0059] a negative pressure adsorption unit 4, which is used to absorb the micro LED chip 1 and place it on the control substrate 2;

[0060] The laser em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com