Local back surface field passivation contact cell and preparation method thereof

A local back field and field passivation technology, applied in the field of solar cells, can solve the problems of unfavorable industrialization promotion and use, complicated process steps, and decreased battery yield, so as to reduce parasitic absorption, mature technology, and reduce Auger recombination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

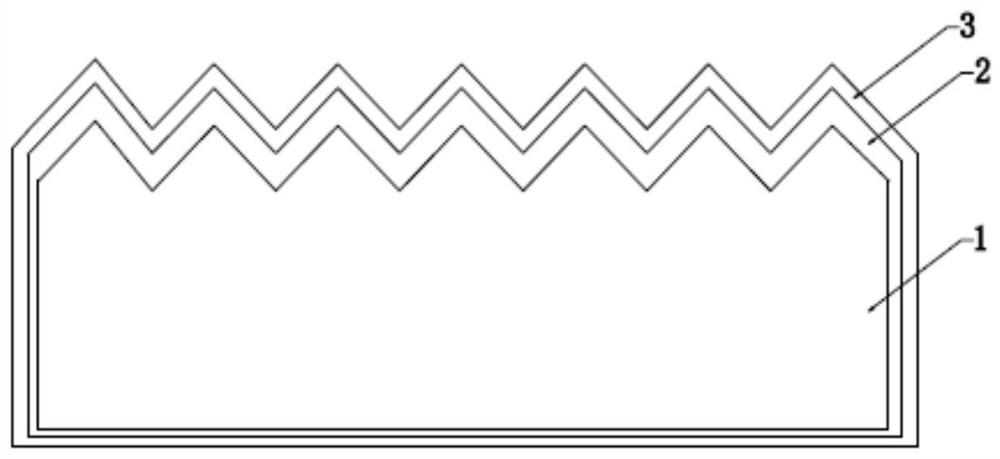

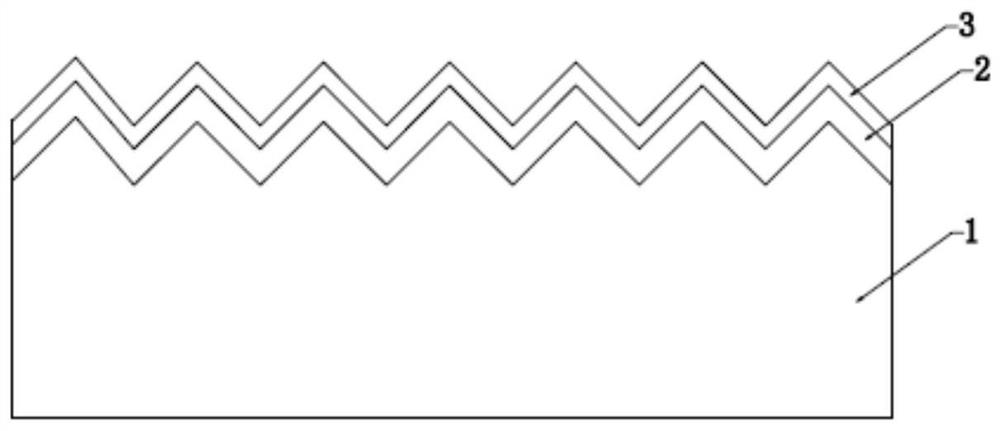

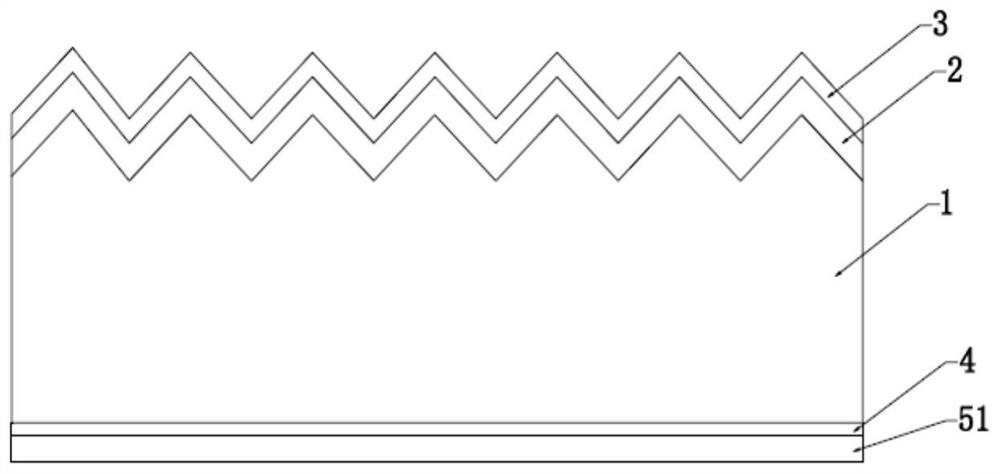

[0049] see Figure 8 , the embodiment of the present invention provides a local back field passivation contact cell, comprising a silicon wafer main body 1; a boron diffusion layer 2, a front passivation film 6 and a positive electrode 11 arranged in sequence on the front side of the silicon wafer main body 1; The tunnel oxide layer 4, the field passivation layer 5, the back passivation film 7, and the back electrode 12 are sequentially laid on the back of the chip body 1; the field passivation layer 5 is provided with a first region 501 and a second region with different doping concentrations. Area 502.

[0050]Wherein, the first region 501 is in contact with the back electrode 12 of the battery, the second region 502 is not in contact with the back electrode 12 of the battery, and the doping concentration of the first regio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com