Device for processing side pin hole of front shaft

A technology of side pins and front axles, which is applied in the field of devices for processing front axle side pin holes, can solve the problems of low product qualification rate, high labor intensity, and low work efficiency, and achieve fast feed, reduce labor intensity, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

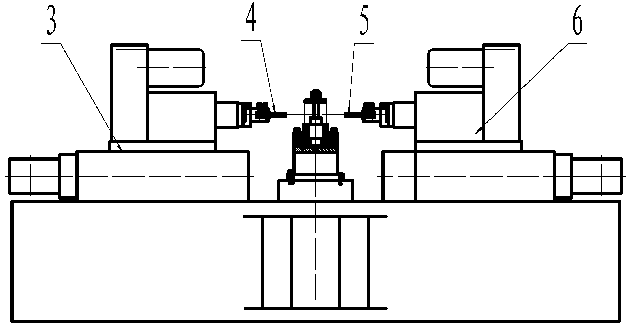

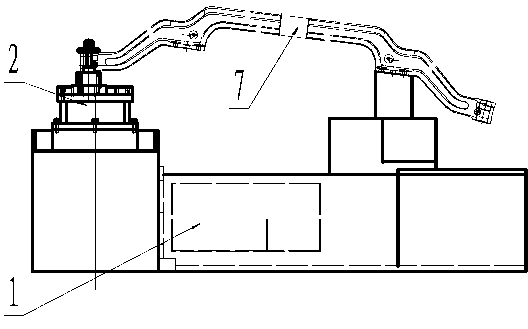

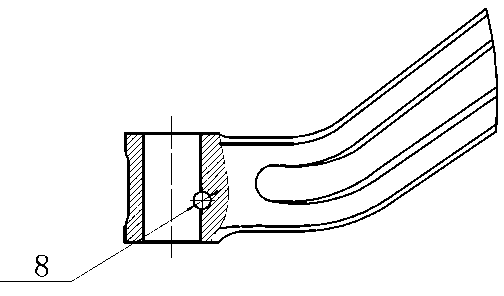

[0013] A device for processing pin holes on the side of the front axle, comprising a combined bed 1, tooling 2, a first power feed unit 3, a first shallow hole drill 4, a second shallow hole drill 5, a second power feed unit 6 and The workpiece 7, the first power feed unit 3 and the second power feed unit 6 are respectively arranged on both sides of the combined bed 1, on the first power feed unit 3 and the second power feed unit 6 respectively The first shallow hole drill 4 and the second shallow hole drill 5 for processing the pin hole 8 on the side of the front axle are provided. Between the drills 5, a workpiece 7 is clamped on the frock 2.

[0014] During processing, firstly adjust the coaxiality of the two boring shafts of the counter boring machine to 0.01. During boring: the first power feed unit 3 drives the first shallow hole drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com