Docking and positioning calibration method based on AGV and AGV

A small car, real-time positioning technology, applied in motor vehicles, measuring devices, instruments, etc., can solve the problems of low accuracy and deviation in picking and placing goods or materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

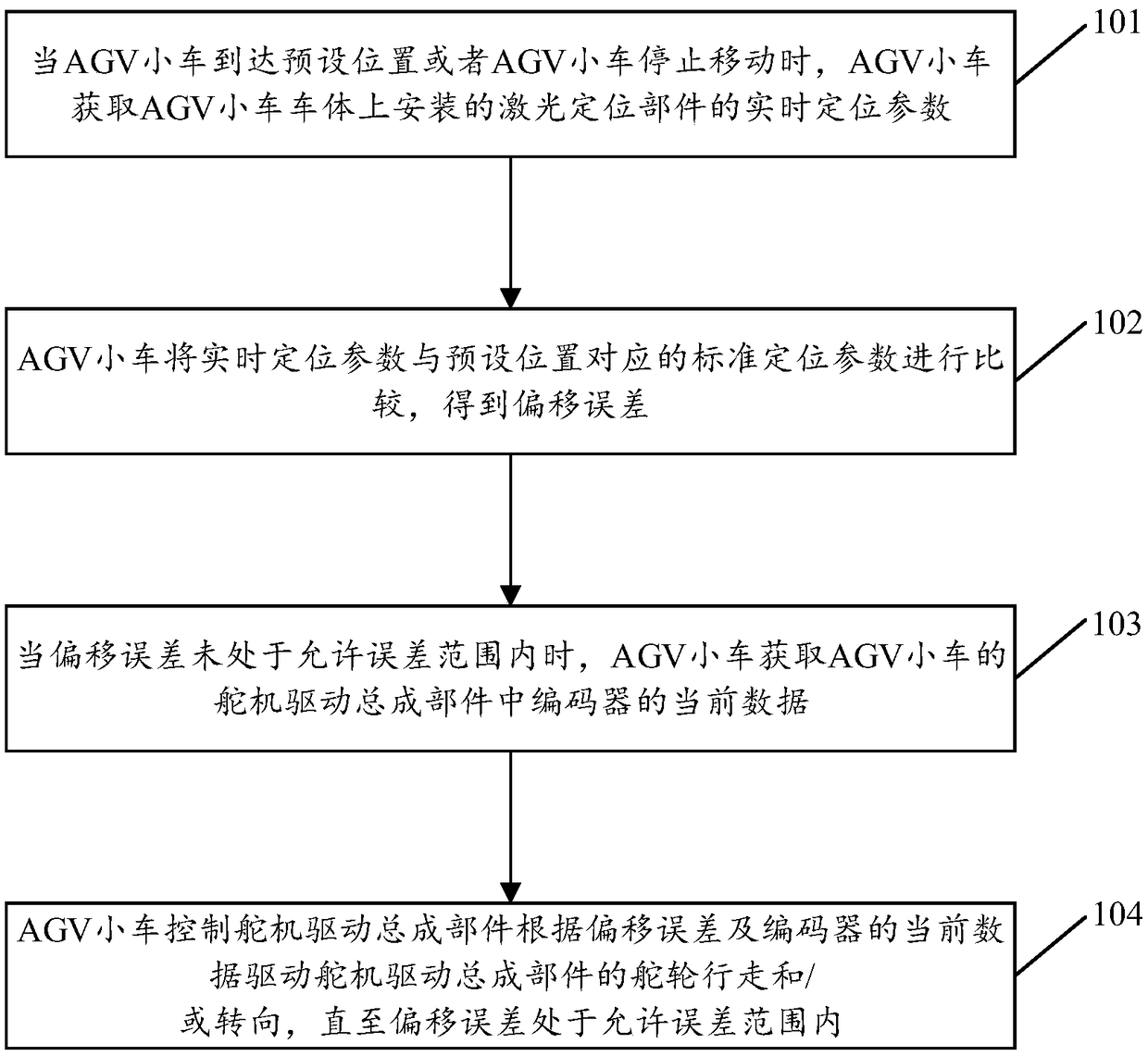

[0070] see figure 1 , figure 1 It is a schematic flowchart of an AGV-based docking positioning calibration method disclosed in an embodiment of the present invention. Such as figure 1 As shown, the docking positioning calibration method based on the AGV car can include the following steps:

[0071] 101. When the AGV car reaches the preset position or the AGV car stops moving, the AGV car obtains the real-time positioning parameters of the laser positioning components installed on the AGV car body.

[0072] In the embodiment of the present invention, the preset position can be a preset shelf position, and when the AGV trolley reaches the shelf position, it can perform the operation of picking and placing goods; when the AGV trolley reaches the shelf position, the AGV trolley automatically stops moving.

[0073] As an optional implementation manner, before performing step 101, the following steps may also be performed:

[0074] The AGV car uses the RFID reader installed on t...

Embodiment 2

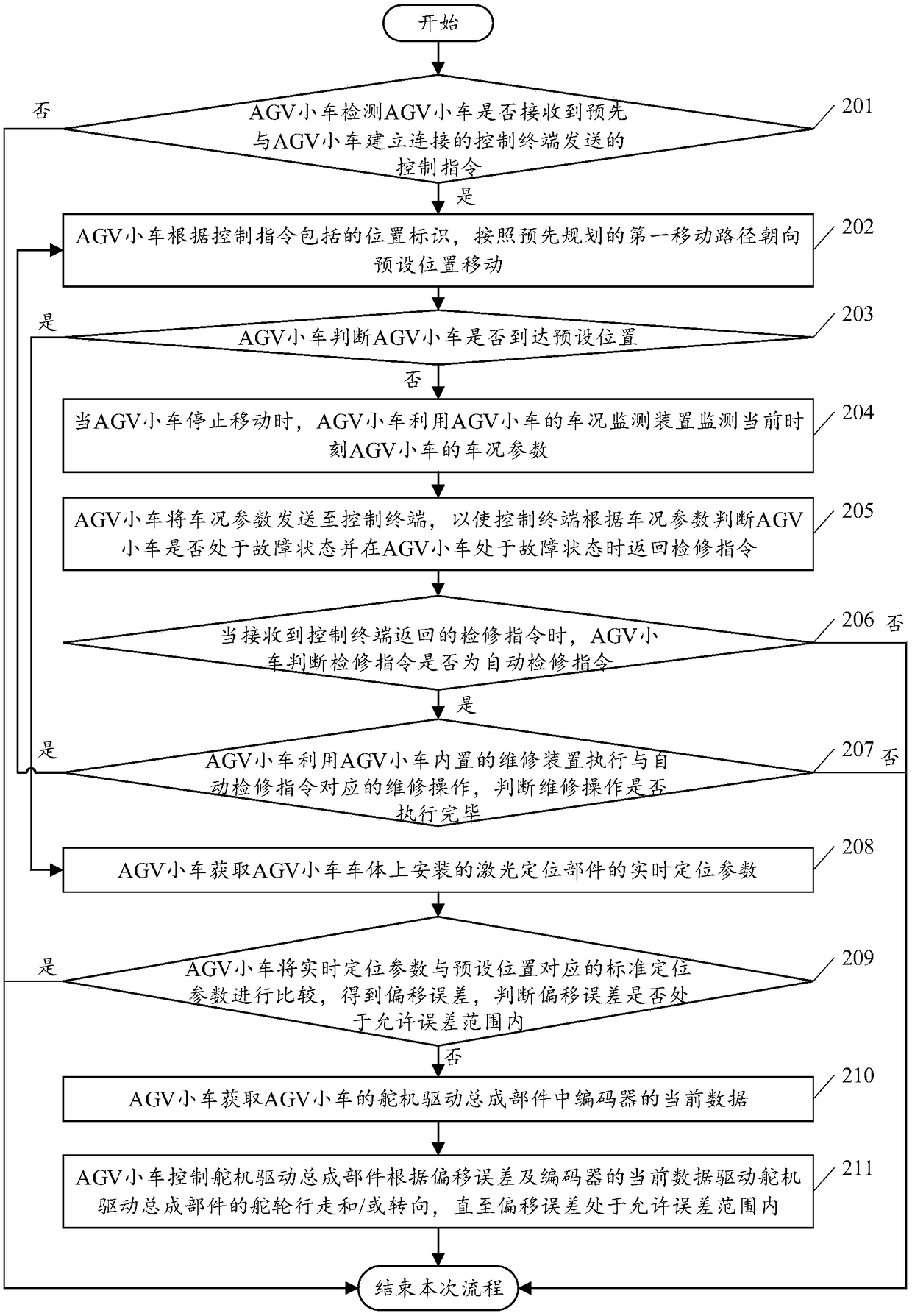

[0097] see figure 2 , figure 2 It is a schematic flowchart of another AGV-based docking positioning calibration method disclosed in the embodiment of the present invention. Such as figure 2 As shown, the docking positioning calibration method based on the AGV car can include the following steps:

[0098] 201. The AGV detects whether the AGV has received the control command sent by the control terminal that has previously established a connection with the AGV. If yes, execute steps 202 to 203. If not, end this process.

[0099] In the embodiment of the present invention, the control instruction at least includes a position identification of a preset position and a preset operation, and the preset operation includes a material fetching operation or a material putting operation.

[0100] In the embodiment of the present invention, the movement of the AGV car can be controlled through the control terminal that has established a connection with the AGV car in advance, wherein...

Embodiment 3

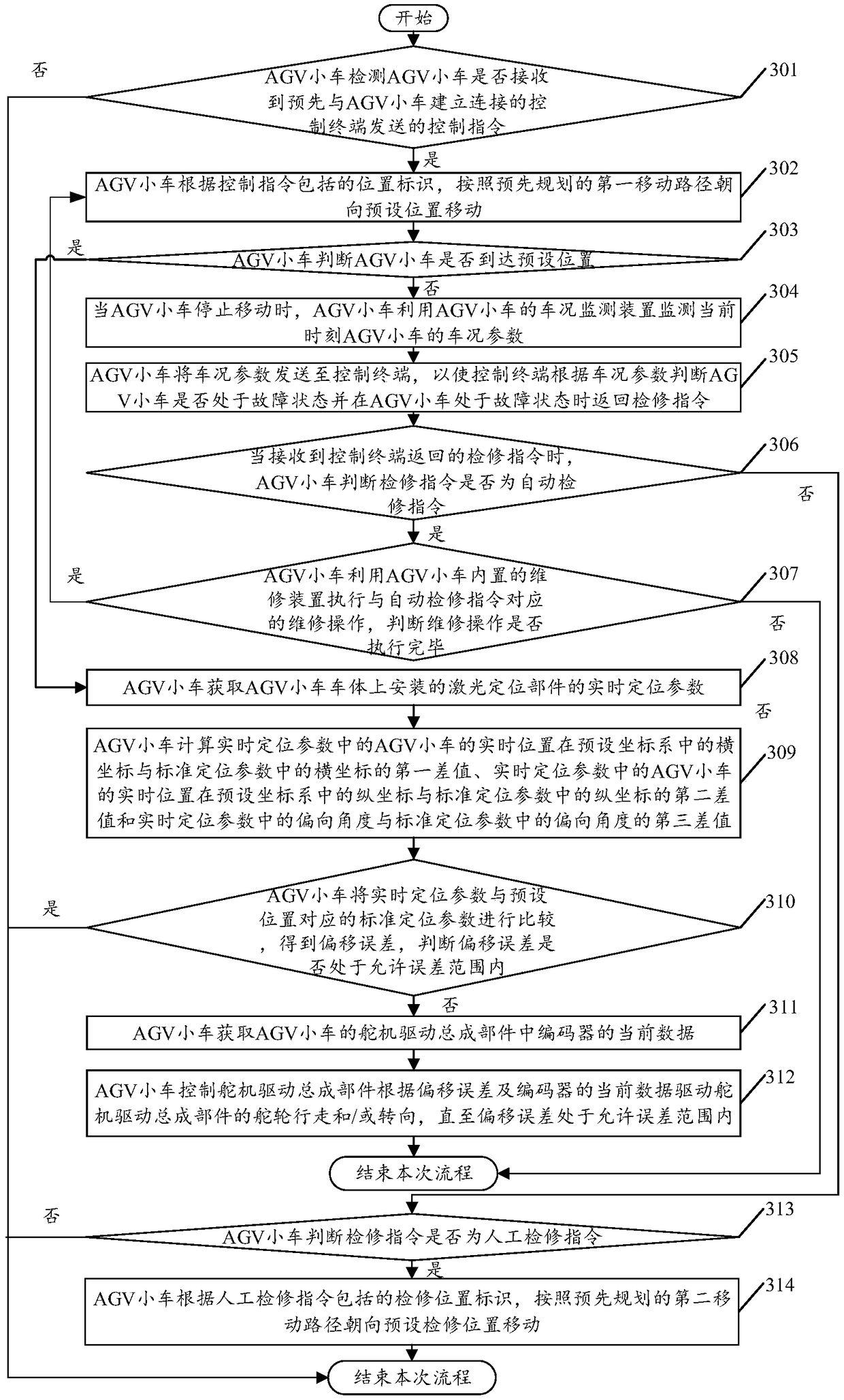

[0130] see image 3 , image 3 It is a schematic flowchart of another AGV-based docking positioning calibration method disclosed in the embodiment of the present invention. Such as image 3 As shown, the docking positioning calibration method based on the AGV car can include the following steps:

[0131] 301. The AGV detects whether the AGV has received the control command sent by the control terminal that has established a connection with the AGV in advance. If yes, execute steps 302 to 303. If not, end this process.

[0132] In the embodiment of the present invention, the control instruction at least includes a position identification of a preset position and a preset operation, and the preset operation includes a material fetching operation or a material putting operation.

[0133] 302. The AGV moves toward a preset position according to a pre-planned first movement path according to the position identifier included in the control instruction.

[0134] 303 . The AGV jud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com