Three-dimensional shape characterization method for gear tooth surface

A three-dimensional topography and gear technology, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of low measurement accuracy and easy occlusion of light transmission, achieve high measurement accuracy, avoid light path occlusion, and reduce measurement costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the drawings and embodiments.

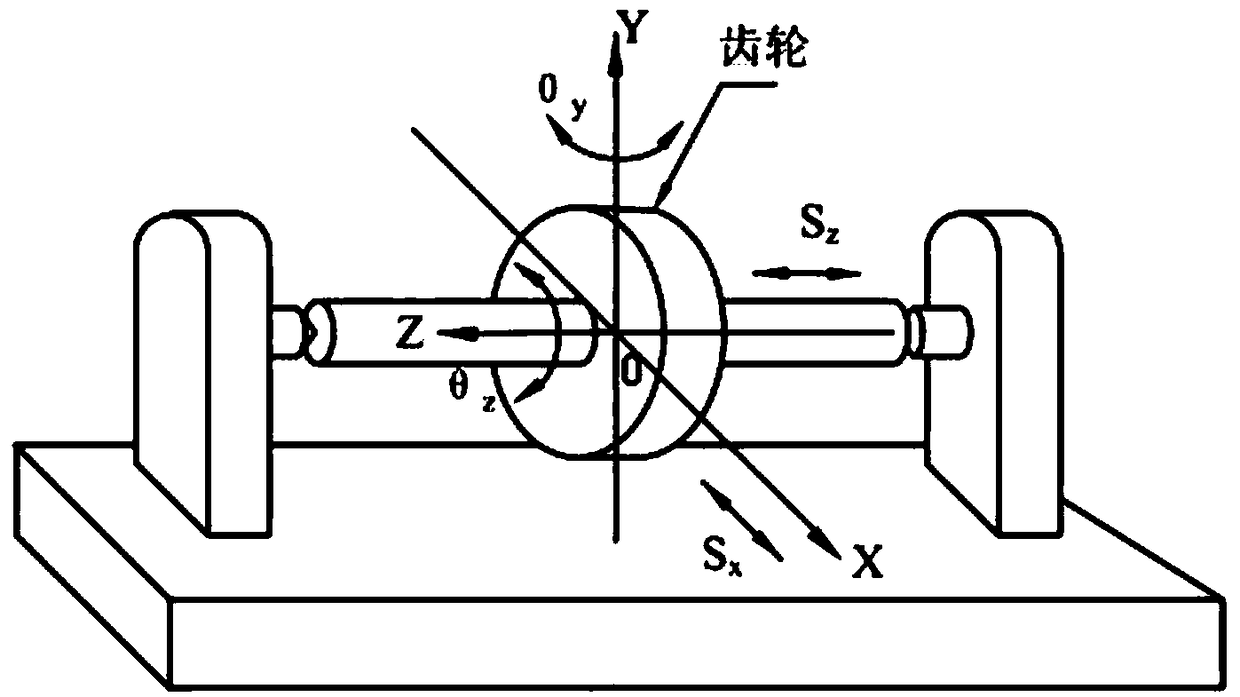

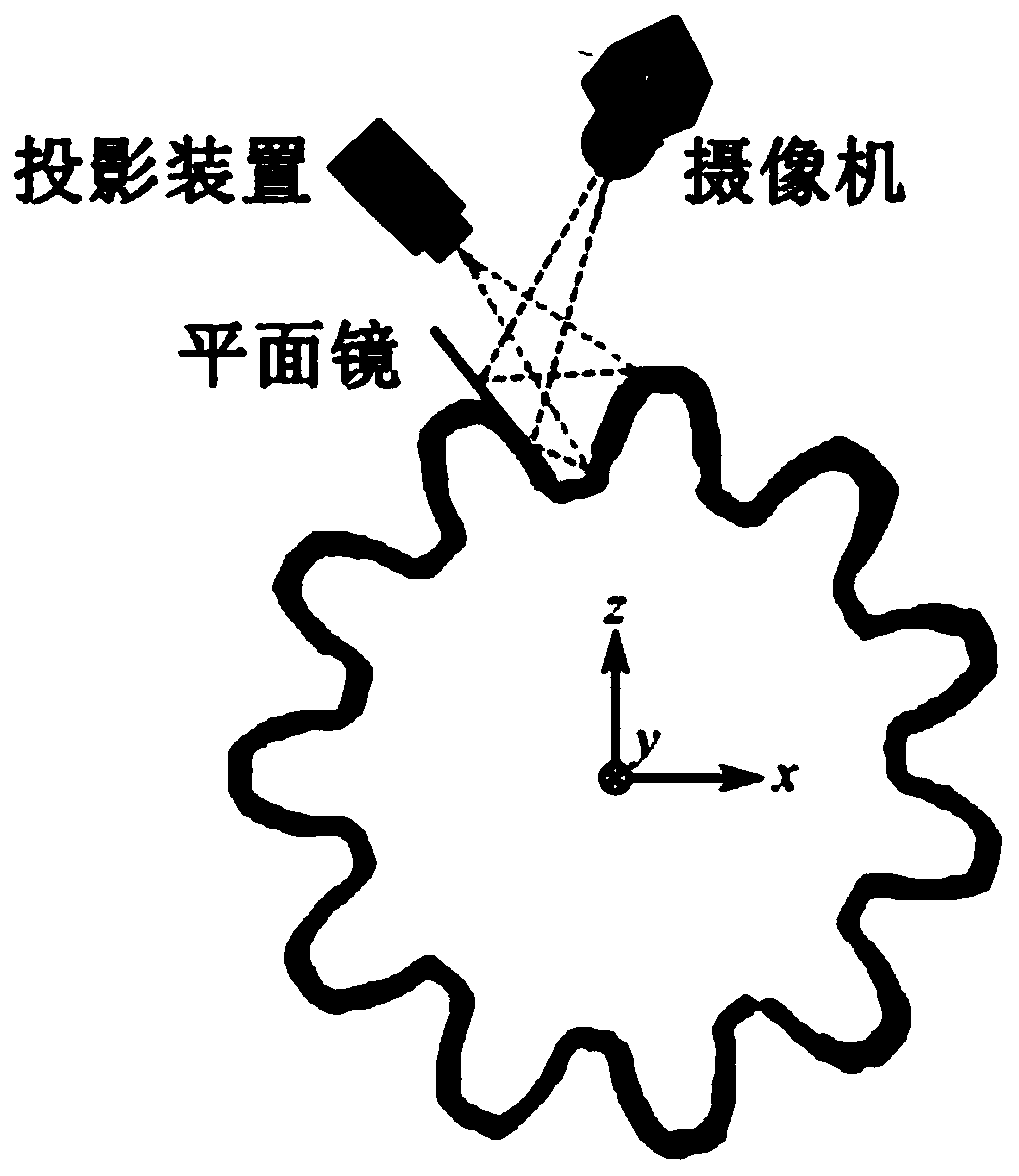

[0026] The present invention proposes a real grating projection gear tooth surface three-dimensional shape characterization method, the method introduces a uniform phase shift for the measurement field of view by moving the grating in the plane, constructs a random phase shift technology, and eliminates the misalignment error in the phase demodulation process, And take the phase as the measurement feature, and use its invariance characteristics to build a phase-height difference look-up table, quickly restore the three-dimensional measurement surface, and finally provide a way to build a fast and high-precision three-dimensional profile measurement technology for gears.

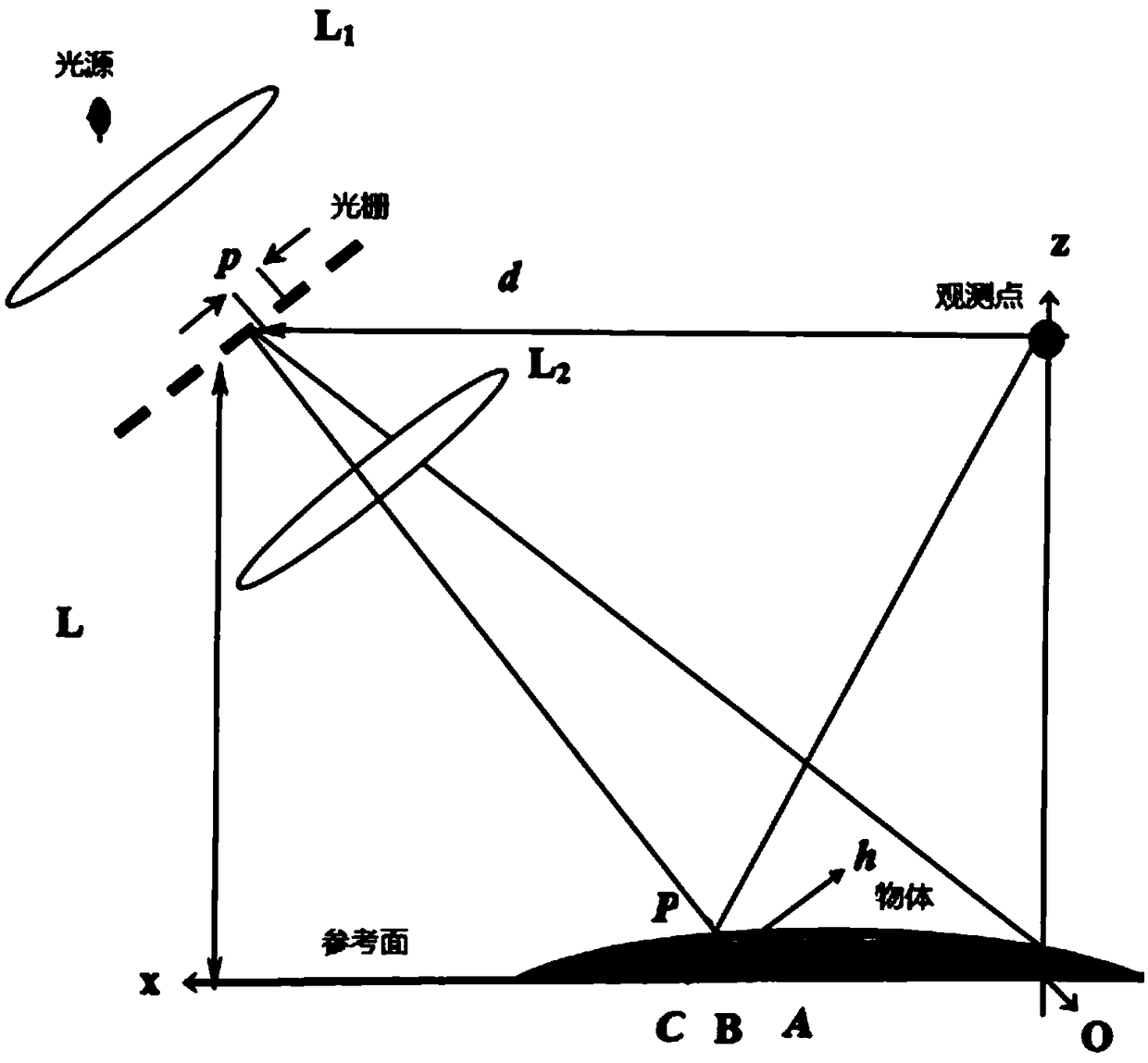

[0027] see figure 1 with figure 2 , which is the device used in the well-known surface structured light measurement method. It includes: (1) a point light source, (2) a CCD camera, (3) a Roche g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com