Real-time grinding and polishing method based on dynamic interferometer

A dynamic interference, polishing liquid technology, applied in grinding/polishing equipment, control of workpiece feed movement, grinding machine parts, etc. problems, to save time, reduce the impact of grinding accuracy, and avoid machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

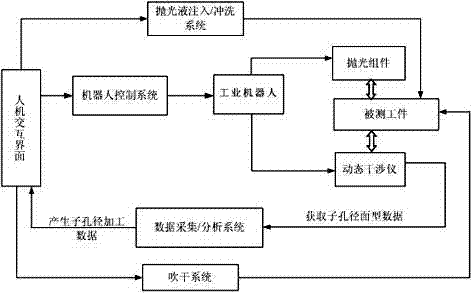

[0028] In this embodiment, the real-time grinding and polishing system based on the dynamic instrument is used to carry out the specific process of polishing ( figure 1 )as follows:

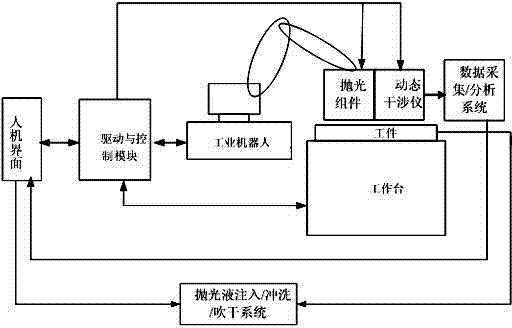

[0029] 1. If figure 2 As shown, the dynamic interferometer is installed at the front end of the polishing assembly and bundled with the polishing assembly. When installing, ensure that the polishing assembly is level with the dynamic interferometer.

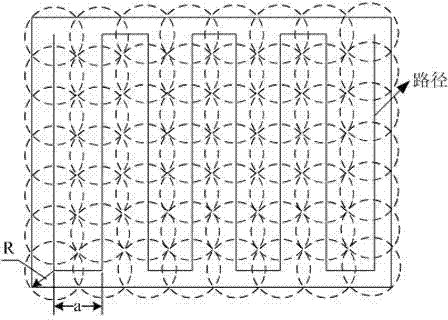

[0030] 2. Input the geometric parameters of the surface to be measured, such as surface equation, effective aperture, off-axis, etc., into the analysis program

[0031] In the system, the number, relative position, size and distribution of the apertures required to be measured / processed are analyzed to complete a complete grinding / polishing, and then the movement path required for dynamic interferometer measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com