Single-degree-of-freedom ultralow frequency vertical vibration isolation system

A vibration isolation system and ultra-low frequency technology, applied in non-rotational vibration suppression and other directions, can solve the problems of reduced versatility, poor environmental adaptability, and unadjustable rigidity, achieving low natural frequency, low vibration transmissibility, and weakened impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

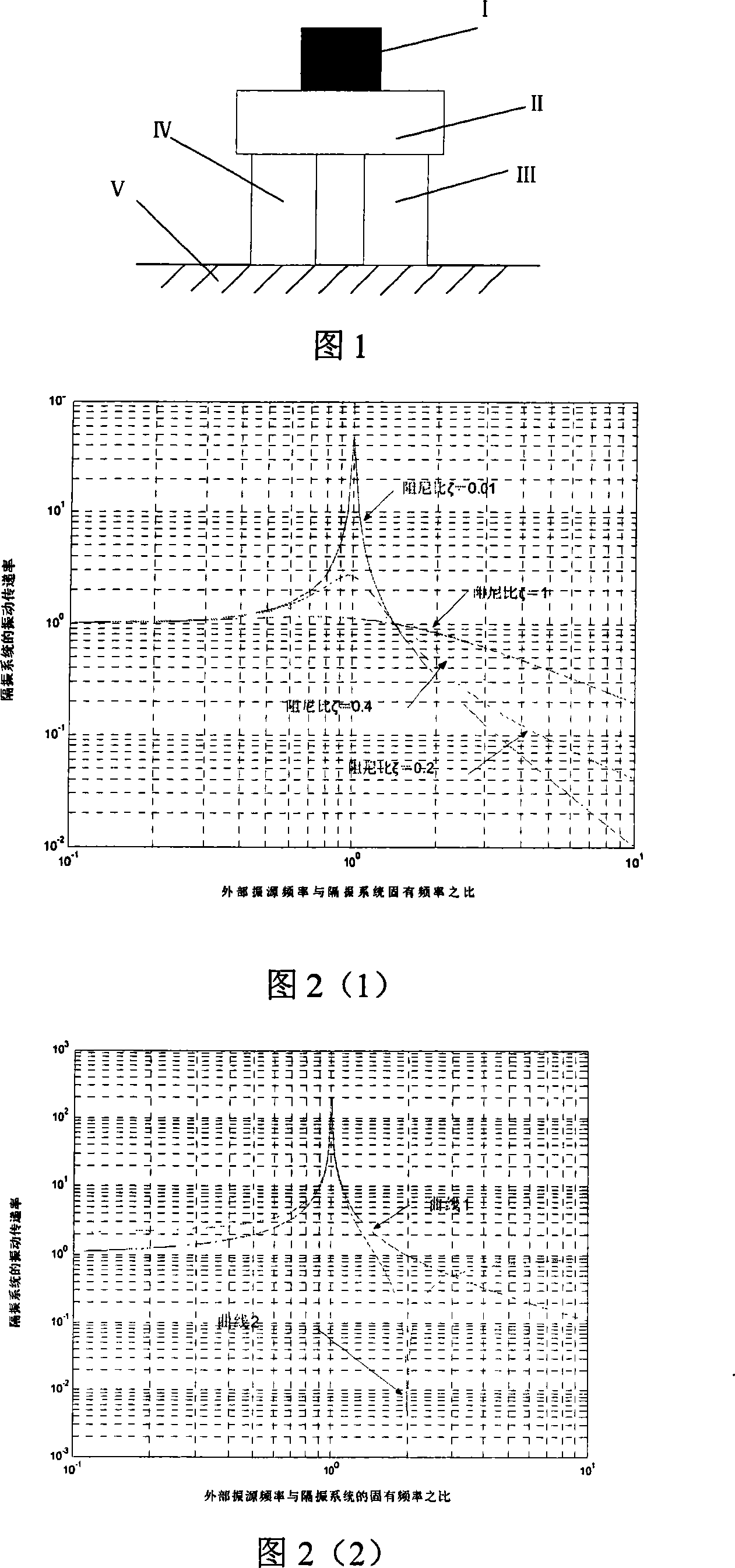

[0013] Referring to Fig. 1, the present invention is made up of mass block I (actual object), intermediate mass mass block II, zero point generating mechanism III, zero stiffness mechanism IV (which can realize the theoretical value of dynamic stiffness equal to zero), and rigid foundation V. The intermediate mass II is located on the zero-stiffness mechanism IV and the zero point (an anti-resonance frequency point, characterized by zero vibration transmissibility of the system) generating mechanism III; the mass I is located directly above the intermediate mass II.

[0014] The main structures of the present invention are zero-point generating mechanism III and zero-stiffness mechanism IV. The zero stiffness mechanism IV reduces the dynamic stiffness value of the system structure of the present invention, greatly reduces the natural frequency of the system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com