Periodic curved beam structure floating raft based on wave mode conversion

A technology of structural periodicity and curved beams, applied in non-rotational vibration suppression, ships, special-purpose ships, etc., can solve problems such as inability to form broadband vibration attenuation, not fully utilizing the attenuation mechanism, and unreasonable distribution of mass and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

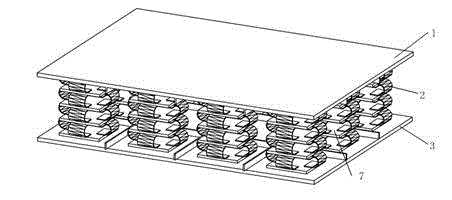

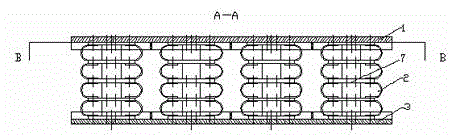

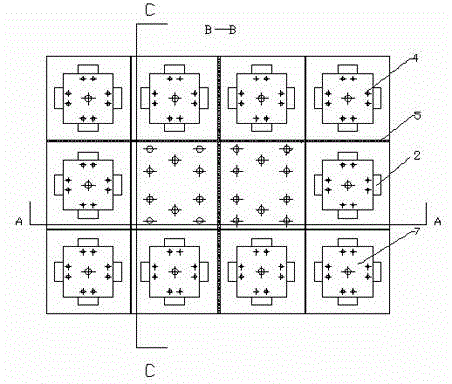

[0021] like figure 1 As shown in FIG. 4 , the curved beam structure periodic floating raft based on wave mode conversion disclosed by the present invention is mainly composed of an upper panel 1 , a plurality of curved beam periodic structures in the middle, and a lower panel 3 . The upper panel 1 and the lower panel 3 are used to install the vibration isolator, which is convenient to connect with the upper and lower connectors. The upper and lower panels should be reinforced with ribs at the place where the vibration isolator or machine foot is installed. A plurality of curved beam periodic structures are arranged side by side in the length and width directions of the panel, forming periodicity in the length and width directions. In the thickness direction of the panel, the curved beam periodic structure is a peri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com