Robot revolute joint module with single degree of freedom

A technology of rotary joints and robots, which is applied in the field of robots, can solve the problems of unsatisfactory weight-torque ratio, difficulty in meeting a wide range of needs, and many degrees of freedom of modules, and achieve the effects of light weight, small axial size, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the model will be further described below in conjunction with the accompanying drawings.

[0019] like figure 1 Shown is the appearance of this joint module. There is no direct connection between the joint base 02 and the output sleeve 07 in the figure, but the two can relatively rotate around the central axis through other parts.

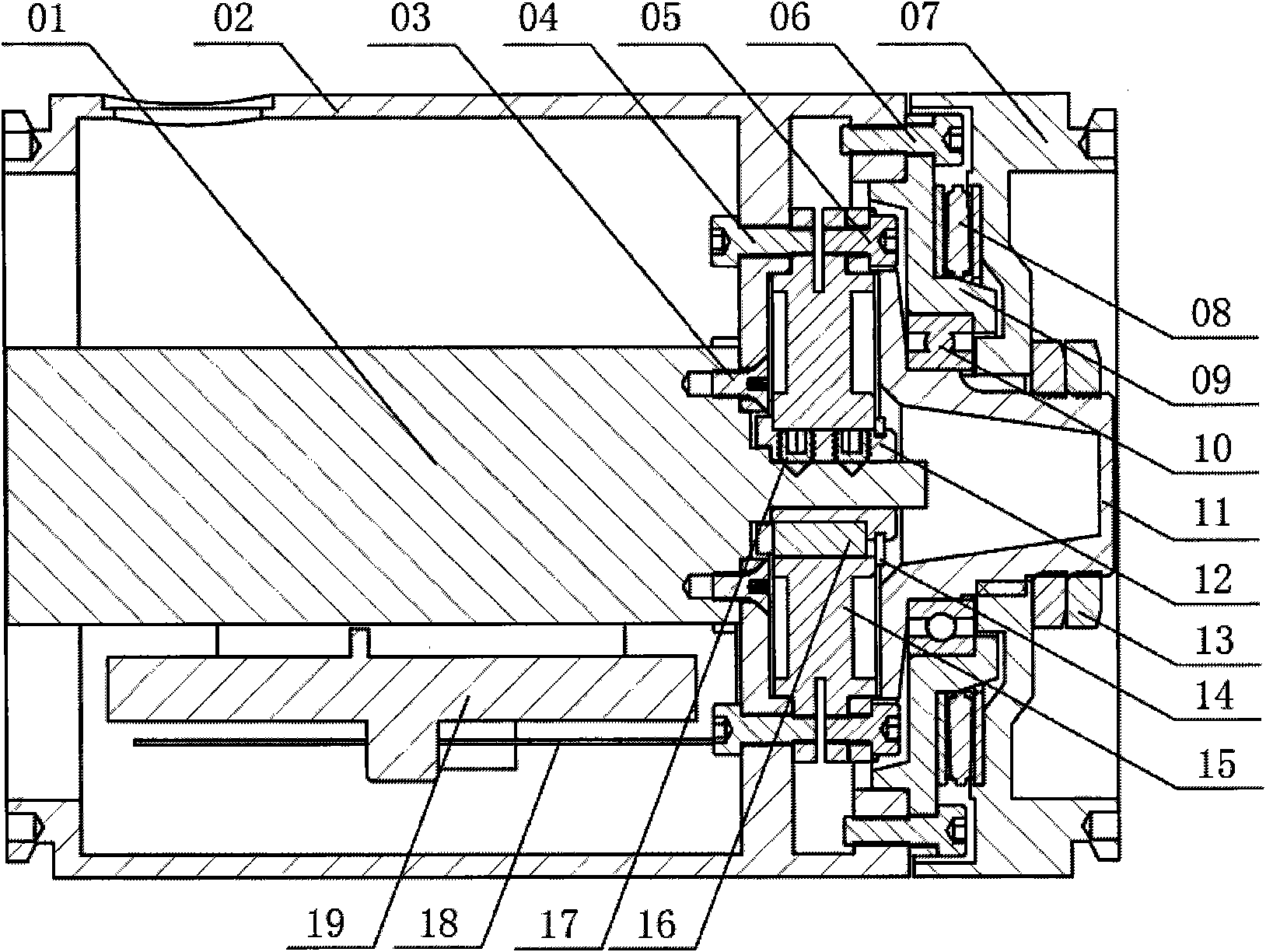

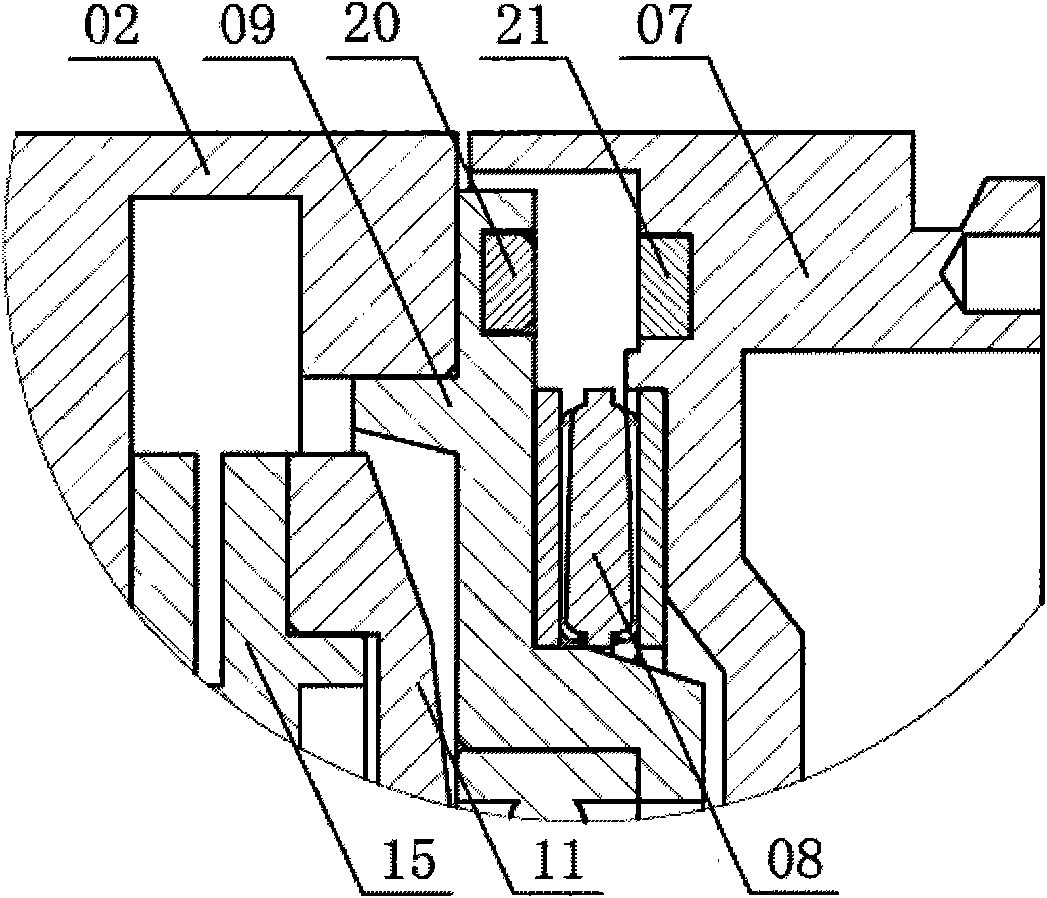

[0020] like figure 2 Shown is a cross-sectional view of this joint module. exist figure 2 In , the relative rotation axis of the joint module coincides with the central axis of the module itself. Parts include: servo motor and photoelectric encoder assembly 01, joint base 02, motor fixing screw 03, harmonic reducer input axial fixing screw 04, harmonic reducer output axial connecting screw 05, hexagon socket screw 06. Output sleeve 07, needle roller one-way thrust bearing 08, end cover bearing seat 09, deep groove ball bearing 10, harmonic reducer output disc 11, shaft sleeve 12, ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com