Five-degree-of-freedom artificial hand mechanism

A technology of degrees of freedom and prosthetic hands, applied in the direction of manipulators, program-controlled manipulators, artificial arms, etc., can solve problems such as single degrees of freedom and inability to realize individual movements of each finger, so as to increase degrees of freedom, improve finger flexibility, and use safely and reliably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

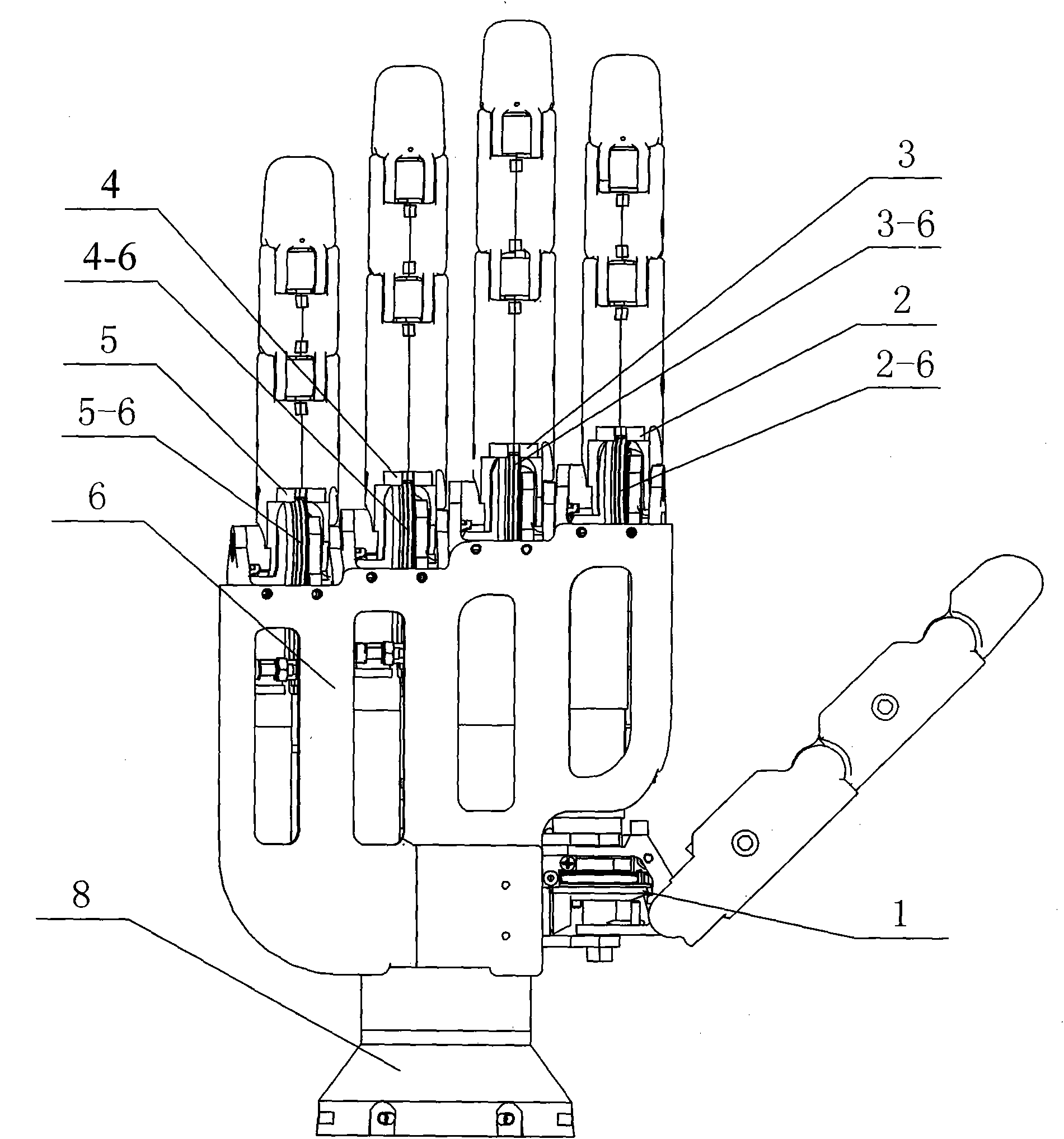

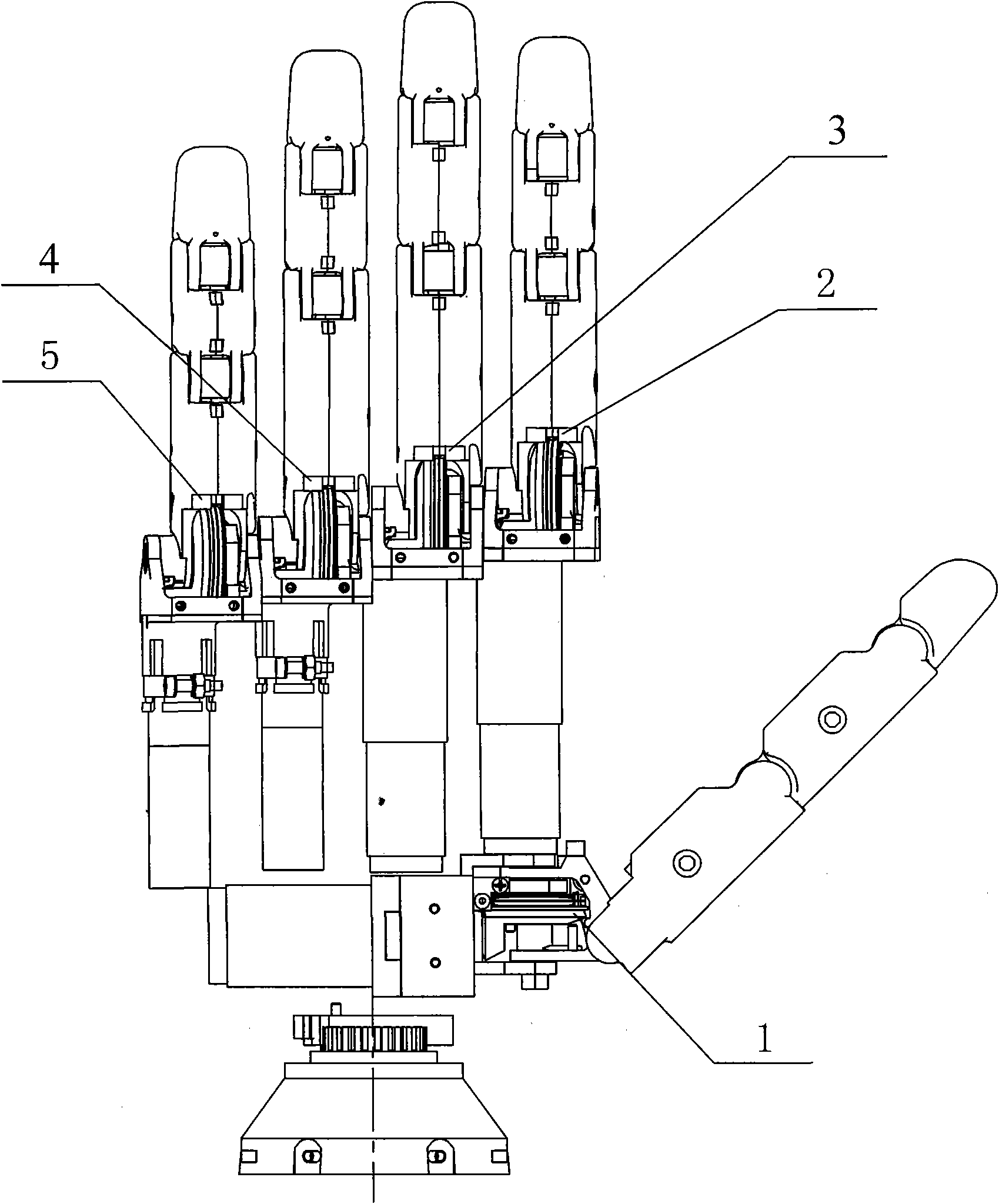

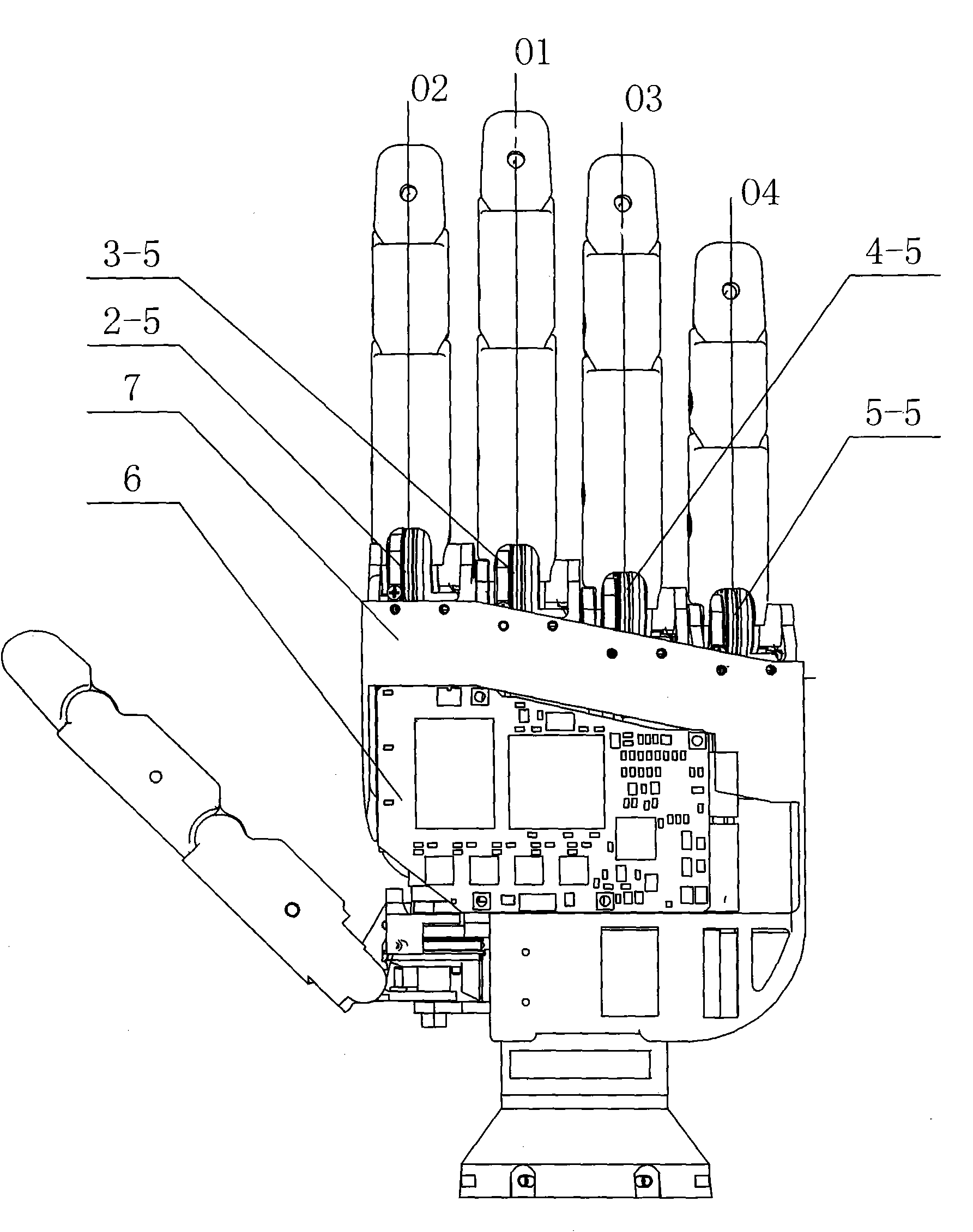

[0008] Specific implementation mode one: combine Figure 1-Figure 17 Describe this embodiment, the prosthetic hand mechanism of this embodiment is made up of palm 6, five drivers, five speed reducers, five transmission mechanisms, five potentiometers, five bases, palm circuit board 7 and wrist 8; The five drivers are respectively thumb driver 1-1, index finger driver 2-1, middle finger driver 3-1, ring finger driver 4-1 and little finger driver 5-1, and the five reducers are respectively thumb reducer 1-2, Index finger reducer 2-2, middle finger reducer 3-2, ring finger reducer 4-2 and little finger reducer 5-2, the five transmission mechanisms are respectively thumb transmission mechanism 1-5, index finger transmission mechanism 2-5, Middle finger transmission mechanism 3-5, ring finger transmission mechanism 4-5 and little finger transmission mechanism 5-5, the five potentiometers are thumb potentiometer 1-3, index finger potentiometer 2-3, middle finger potentiometer 3-3, ...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 14-Figure 17Describe this embodiment, the thumb speed reducer 1-2 of this embodiment is a harmonic reducer (Harmonic reducer), the thumb driver 1-1 is a DC motor, and the thumb transmission mechanism 1-5 is composed of a thumb small bevel gear 1-5-1 , connecting shaft 1-5-2, thumb big bevel gear 1-5-3, first pin 1-5-4, thumb connecting sleeve 1-5-5, thumb big bevel gear shaft 1-5-6 and thumb steel wire The wheel is composed of 1-5-7; the rigid wheel of the thumb reducer 1-2 is connected with the thumb base 1-4, and the flexible wheel of the thumb reducer 1-2 and the thumb bevel gear 1-5-1 are connected by a connecting shaft 1-5-2 transmission connection, the thumb small bevel gear 1-5-1 meshes with the thumb bevel gear 1-5-3, and the thumb connecting sleeve 1-5 is housed in the inner hole of the thumb bevel gear 1-5-3 -5, the thumb connection sleeve 1-5-5 is set on the thumb bevel gear shaft 1-5-6, the thumb bevel g...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 , Image 6 and Figure 7 Describe this embodiment, the index finger speed reducer 2-2 of this embodiment is a planetary gear reducer (Planetary gearhead), the index finger driver 2-1 is a DC motor, the index finger transmission mechanism 2-5 is formed by the index finger small bevel gear 2-5-1 , the index finger bevel gear 2-5-2, the second pin 2-5-3, the index finger connecting sleeve 2-5-4, the index finger bevel gear shaft 2-5-5 and the index finger wire wheel 2-5-6; The index finger base 2-4 is composed of the index finger support seat 2-4-1 and the index finger fixing plate 2-4-2, and the index finger driver 2-1 and the index finger reducer 2-2 are connected with the index finger fixing plate 2-4. -2 connection, the index finger fixed plate 2-4-2 is connected with the index finger support seat 2-4-1 (connected by screws in the present embodiment), the output end of the index finger reducer 2-2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com