Parallel link robot

一种机器人、连杆的技术,应用在机械手、机械设备、程序控制机械手等方向,能够解决吸盘易与工件W干涉、加长安装部件190与吸盘780距离、电缆卷绕在其它部件上等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The same reference numerals are assigned to the same components in the following figures. In order to facilitate understanding, these drawings are appropriately changed in scale.

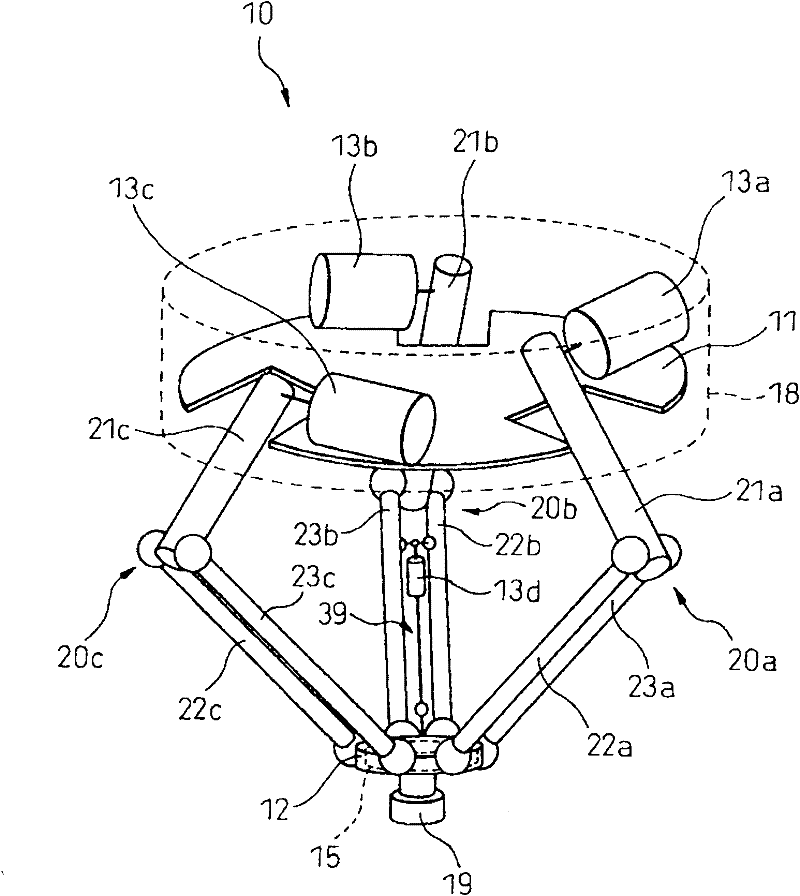

[0041] figure 1 It is a perspective view of a parallel link robot according to a typical embodiment of the present invention. exist figure 1 Among them, the parallel link robot 10 mainly includes: a base part 11 installed in a casing 18 ; a movable plate 12 ; and three link parts 20 a - 20 c connecting the base part 11 and the movable plate 12 . A mounting member 19 is provided under the movable plate 120 , and an unshown end effector is mounted on the mounting member 19 .

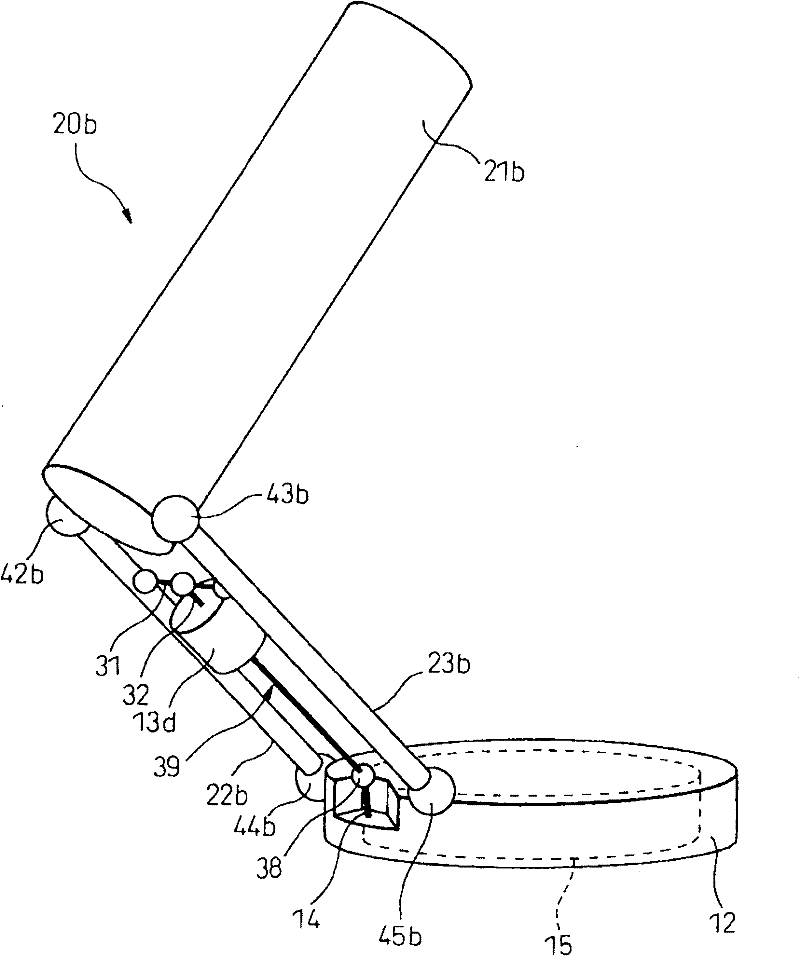

[0042] figure 2 yes figure 1 A partial perspective view of the parallel-link robot shown. Such as figure 2 As shown, the link portion 20b includes a drive link 21b and two driven links 22b, 23b extending from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com