Dynamic characteristic parameter test device and method of sliding guide rail junction surface

A technology for sliding guide rails and dynamic characteristics, which is applied in the field of testing devices for dynamic characteristic parameters of the joint surface of sliding guide rails. It can solve the problems of complex contact state, lack of precision guarantee, and many influencing factors on the joint surface of sliding guide rails, and achieve the elimination of foundation displacement and avoid torsion. And rollover, simple effect of test device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

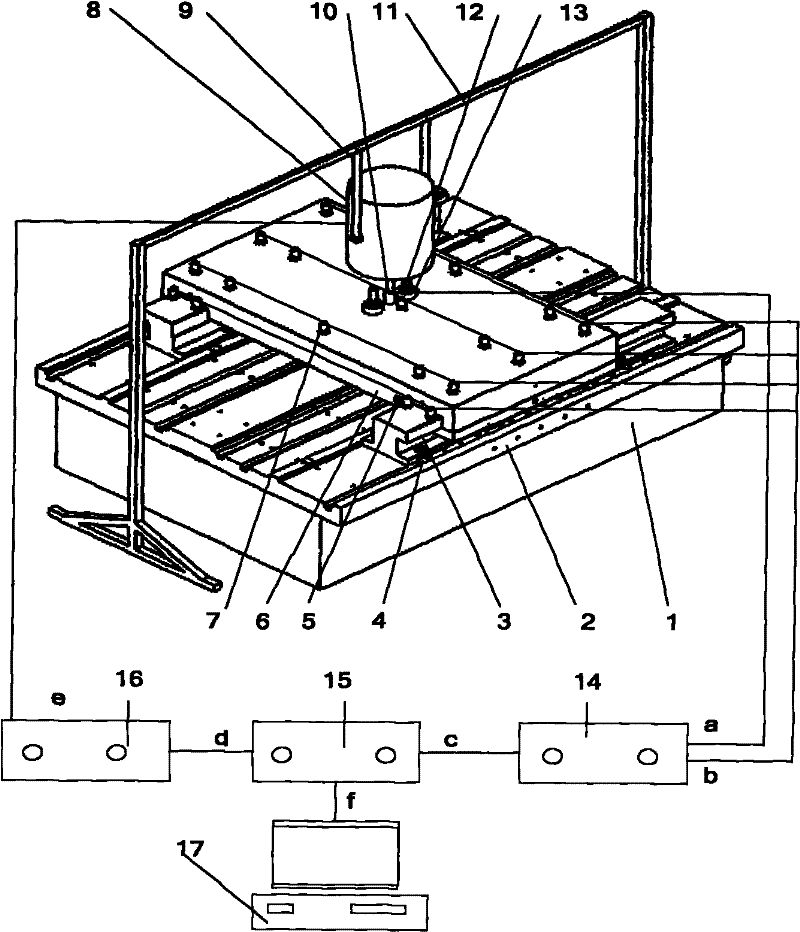

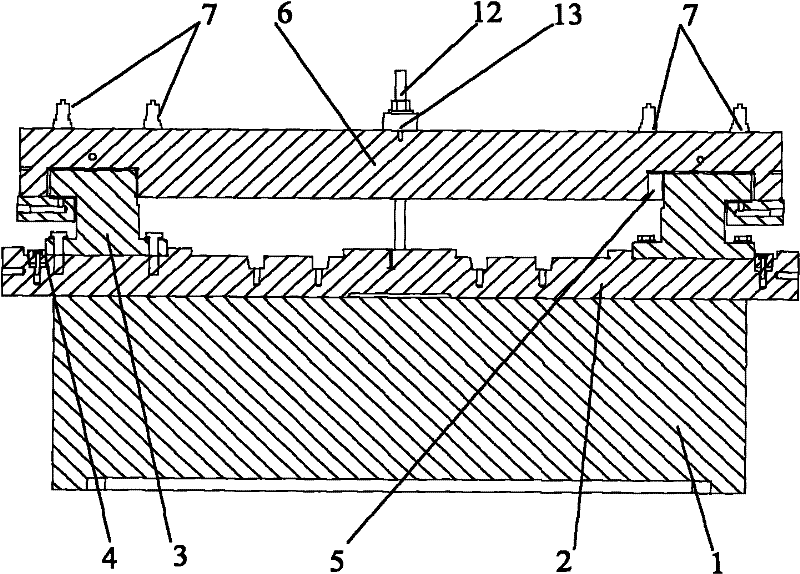

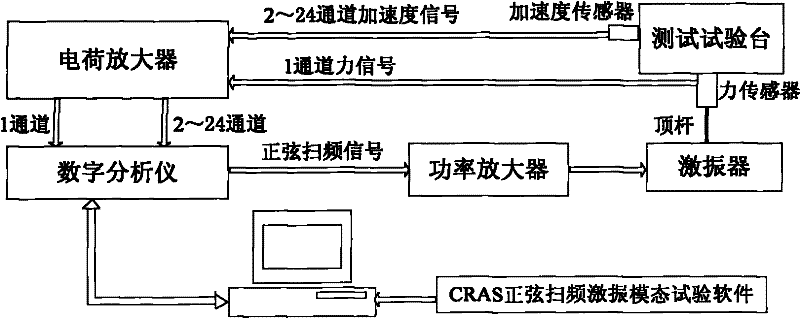

[0025] A device for testing dynamic characteristic parameters of a joint surface of a sliding guide rail, comprising a measurement platform, a charge amplifier 14, a data collector 15, a power amplifier 16, and an electronic computer 17, wherein the measurement platform includes a base 1, an installation platform 2, a fixed guide rail 3, Wedge block 4, inlay 5, slider 6, several piezoelectric acceleration sensors 7, vibrator 8, elastic cord 9, impedance head 10, shelf 11, normal force applying bolt 12 and rubber ring 13;

[0026] The installation platform 2 is located above the base 1. The fixed guide rail 3 is fixedly connected to the installation platform 2. The fixed guide rail is pressed and positioned by the wedge block 4. The fixed guide rail 3 is provided with a rectangular slider 6, which is adjusted by the inlay 5. Lateral clearance, the normal force bolt 12 presses the slider 6 on the installation platform 2, a rubber ring 13 is set between the normal force force bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com