Double-rotor-wing unmanned plane

A UAV and dual-rotor technology, applied in the direction of rotorcraft, motor vehicles, aircraft, etc., can solve the problems of unfavorable control model simplification and increased difficulty, and achieve the advantages of small structural design restrictions, large lift force, and low research cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

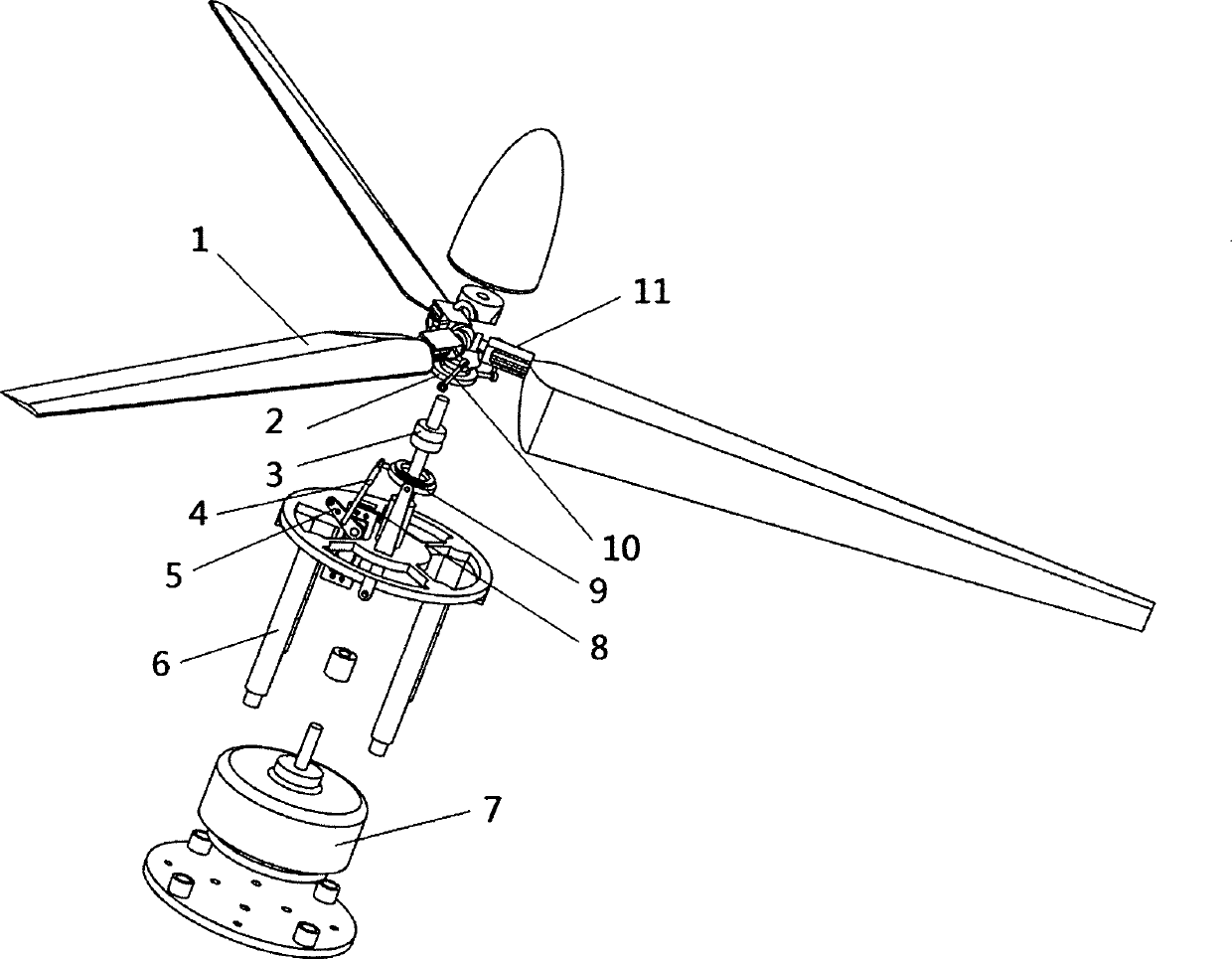

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

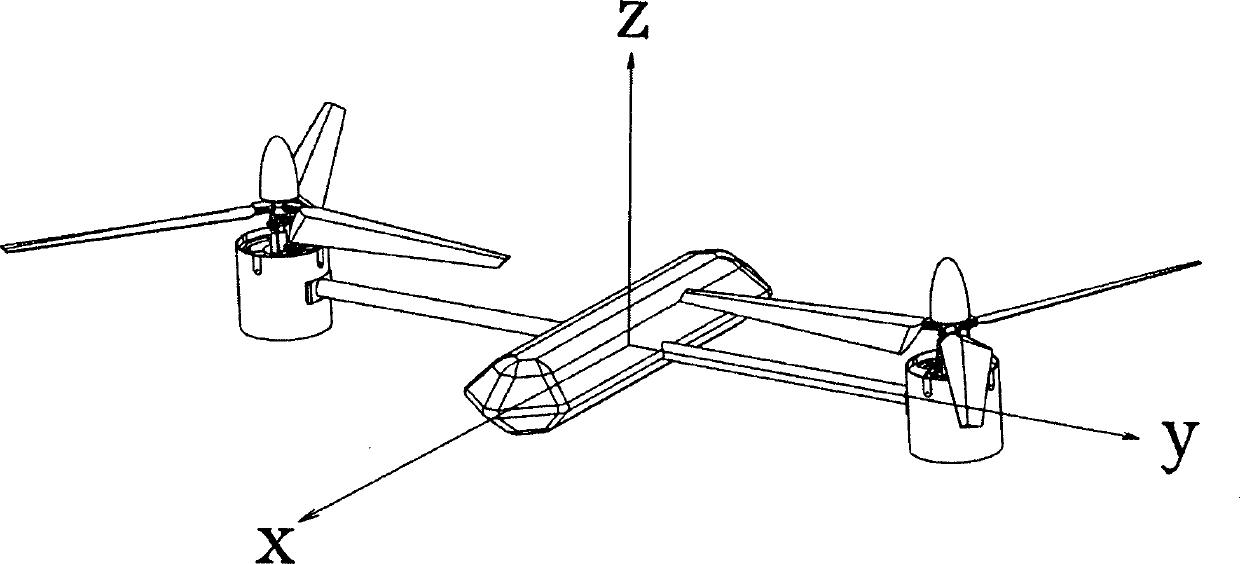

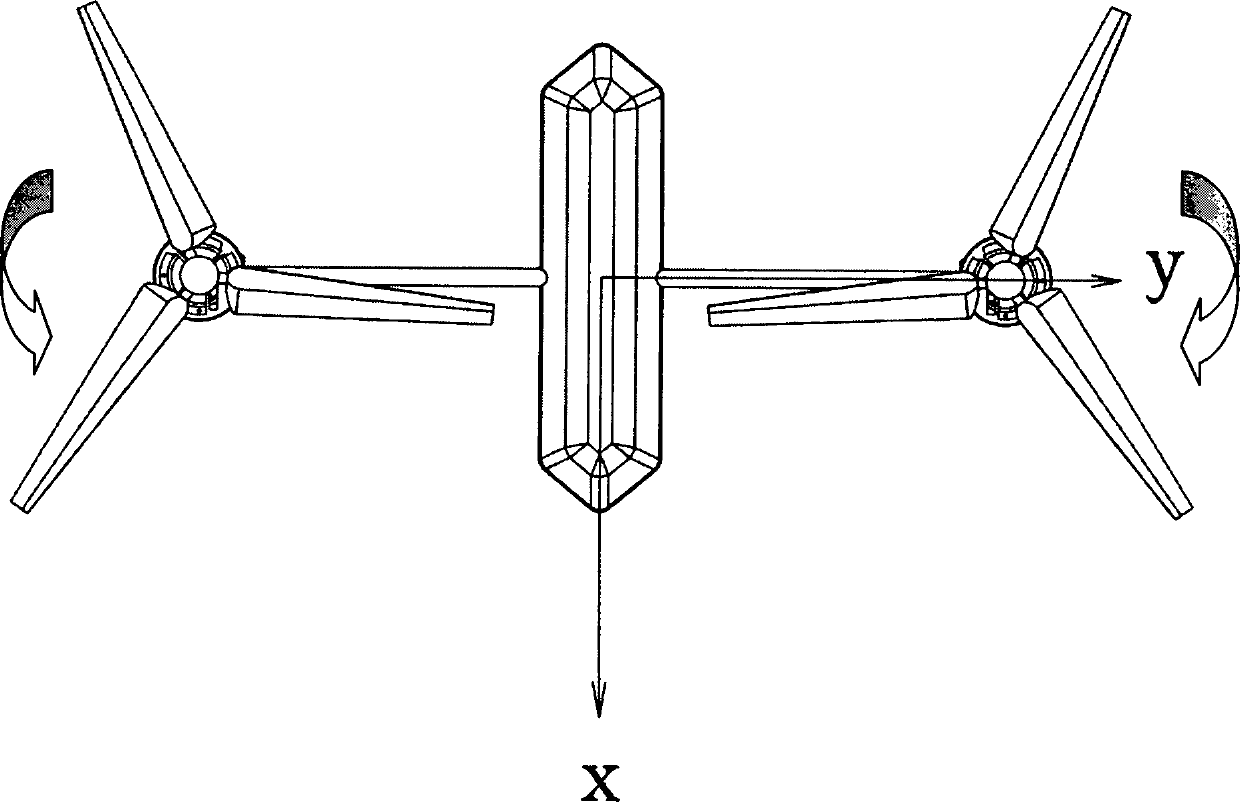

[0028] The present invention is a dual-rotor layout, and its carrier coordinate system is as follows: figure 1 . The rotors are symmetrically distributed on both sides of the fuselage, and the direction of rotation is as follows: figure 2 shown. Its flight control principle is similar to that of a quadrotor UAV. The specific method is: through the control system to control the three angles of the UAV's heading angle, roll angle and pitch angle, the attitude of the UAV can be completely controlled, so that the unmanned The machine as a whole and the horizontal plane generate a controllable inclination angle along the specified direction. The lift force perpendicular to the body of the UAV is therefore decomposed into a lift force perpendicular to the ground and a component force advancing horizontally. In addition to the altitude control, there are four c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com