Fork four-freedom parallel connection robot mechanism

A degree of freedom, robot technology, applied in the field of robotics, to achieve the effect of easy control, decoupling of movement and rotation, and good processing and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

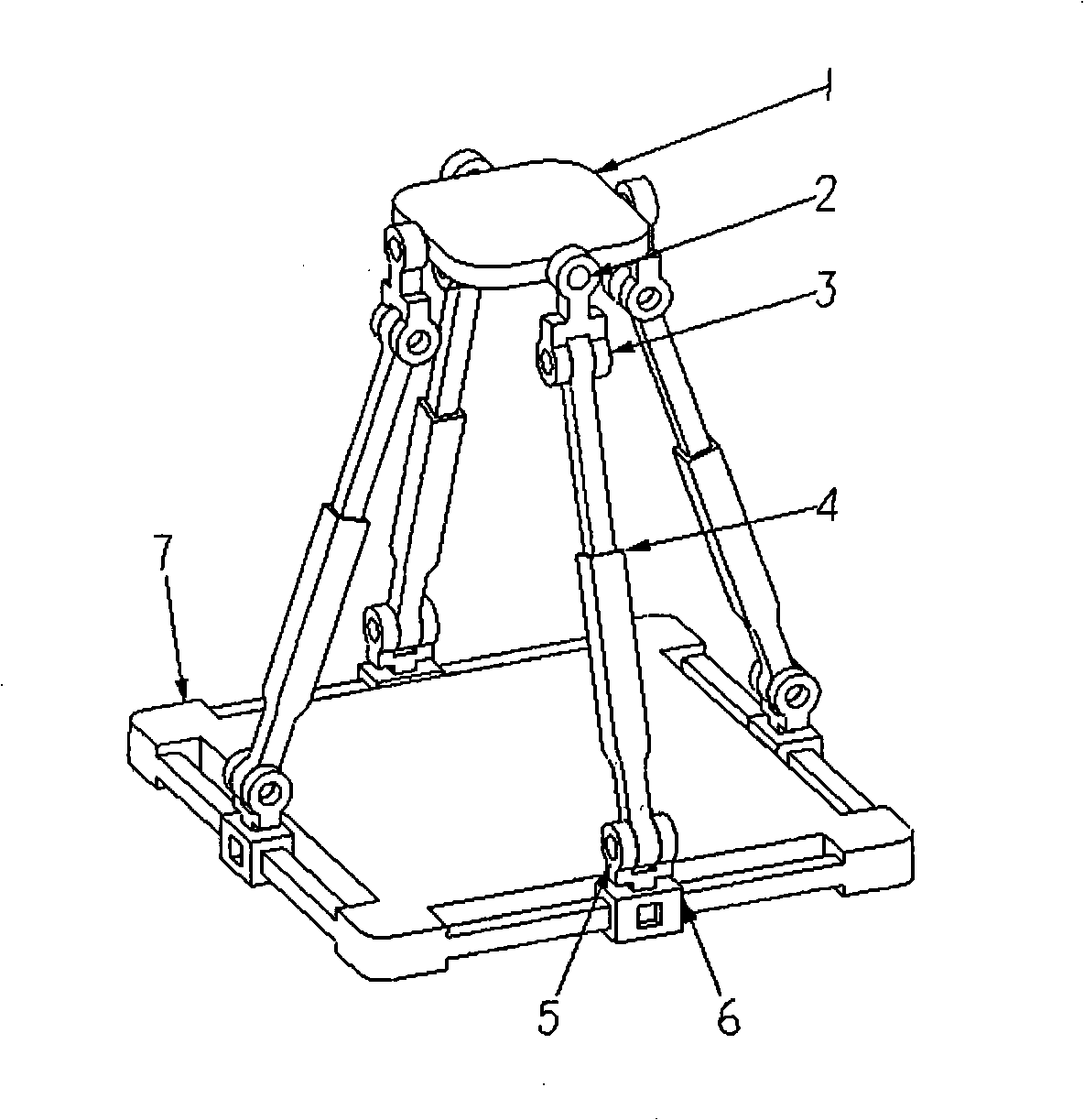

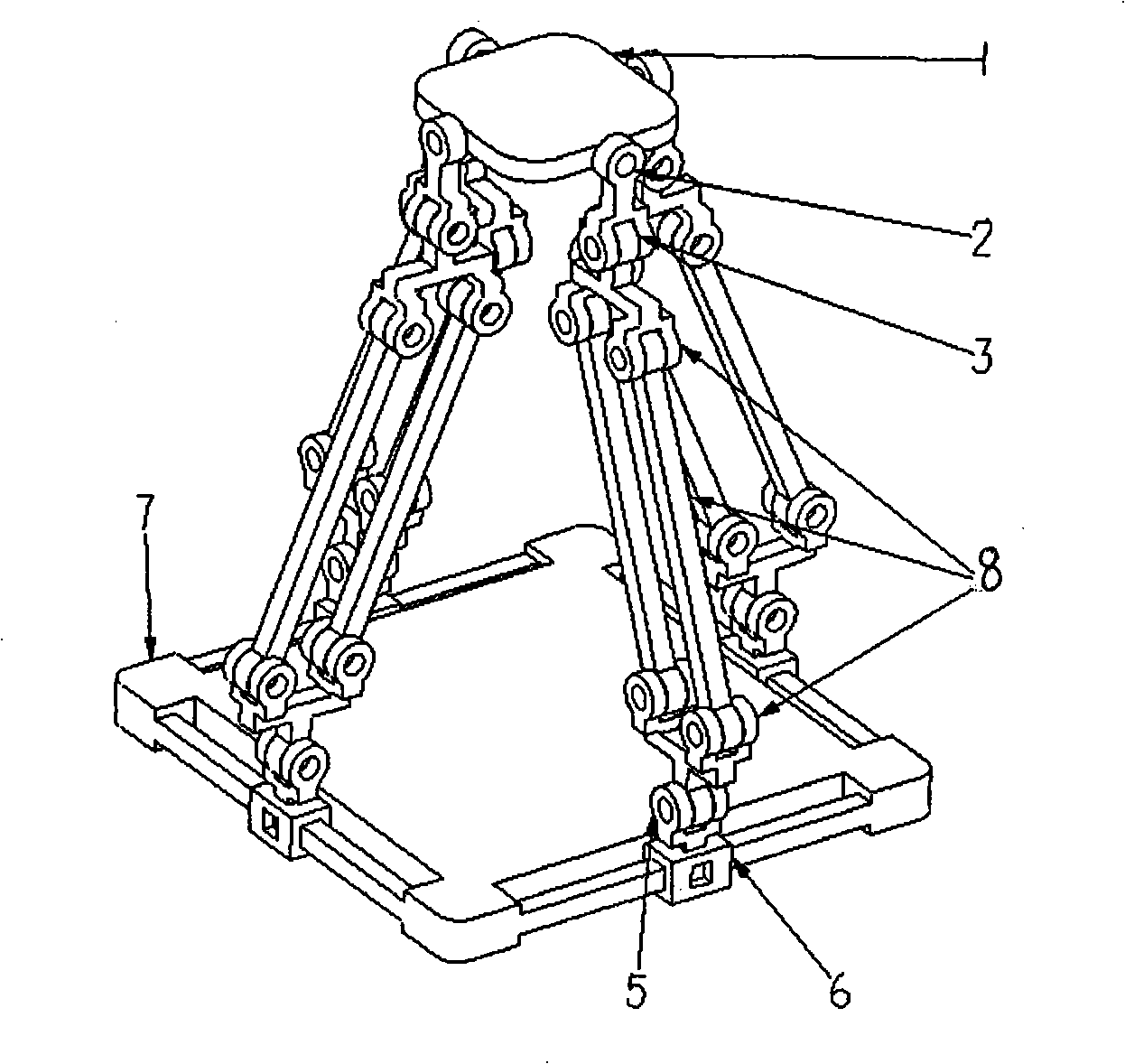

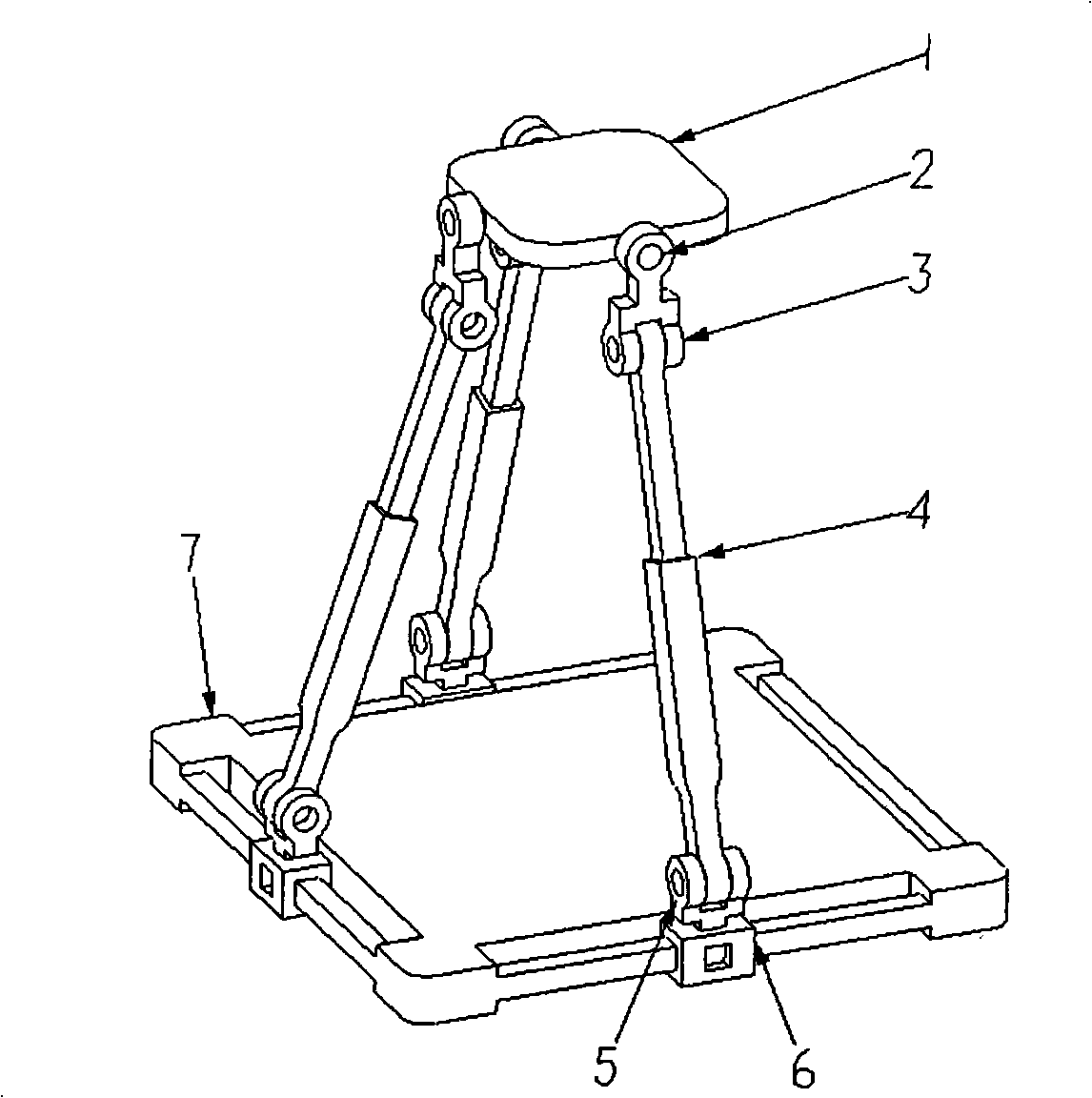

[0020] Such as figure 1 Shown is a schematic structural diagram of the first embodiment of the present invention. It is composed of moving platform 1, fixed platform 7 and 2 to 4 moving branch chains with the same structure connecting moving platform 1 and fixed platform 7; said moving branch chain is composed of three rotating pairs 2, 3, 4 and one moving pair 6 and a single degree of freedom movement pair; the movement branch chain from the fixed platform 7 to the moving platform 1 is the moving pair 6, the first rotation pair 5, the single degree of freedom movement pair, the second rotation pair 3 and the third rotation pair 2 The axis of the moving pair 6 is parallel to the axis of the first and second rotating pair 5, 3, and perpendicular to the axis of the third rotating pair 2; in the initial assembly configuration, the moving platform 1 is parallel to the fixed platform 7. The single-degree-of-freedom movement pair in the middle of the kinematic branch is the moving pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com