Tensile test fixture used for tubular product sample

A tensile test and fixture technology, applied in the direction of applying stable tension/pressure to test the strength of materials, analyzing materials, measuring devices, etc., can solve problems such as easy deviation, avoid slippage, avoid pipe performance changes, The effect of reliable material mechanical properties parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This embodiment is a tensile test fixture for a pipe sample, through which accurate mechanical property parameters of the pipe can be obtained.

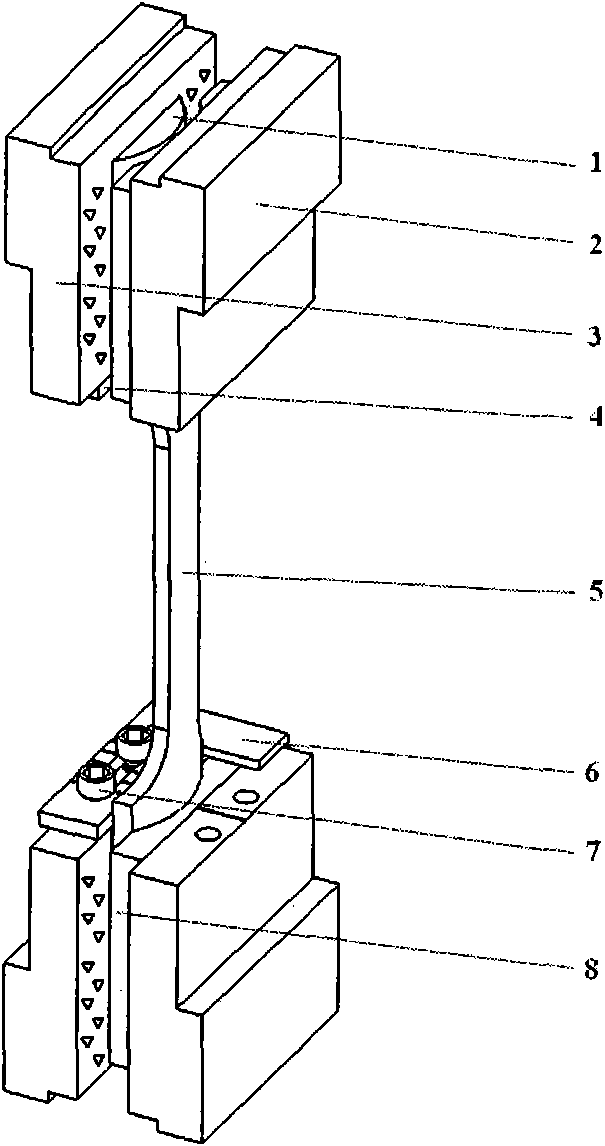

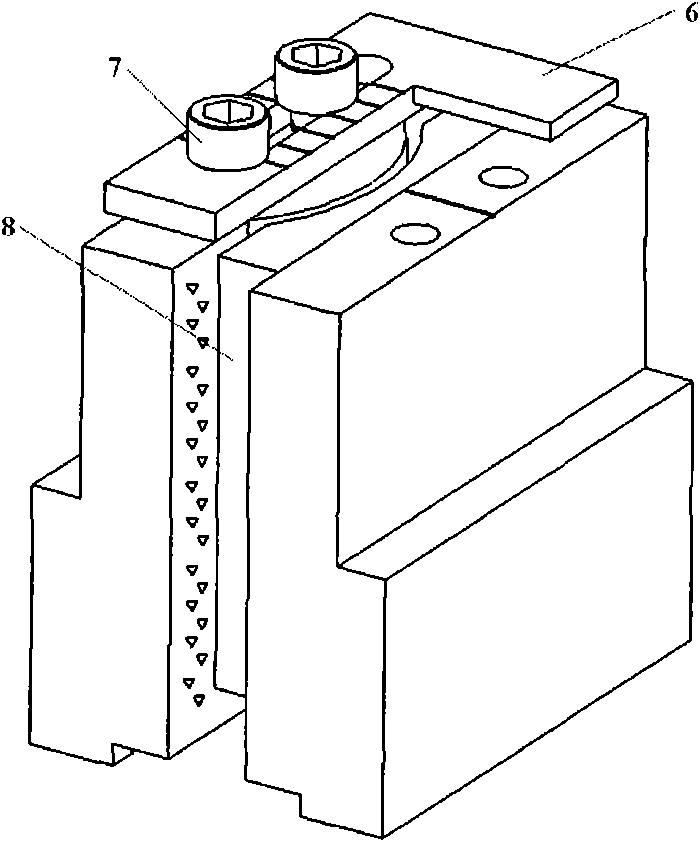

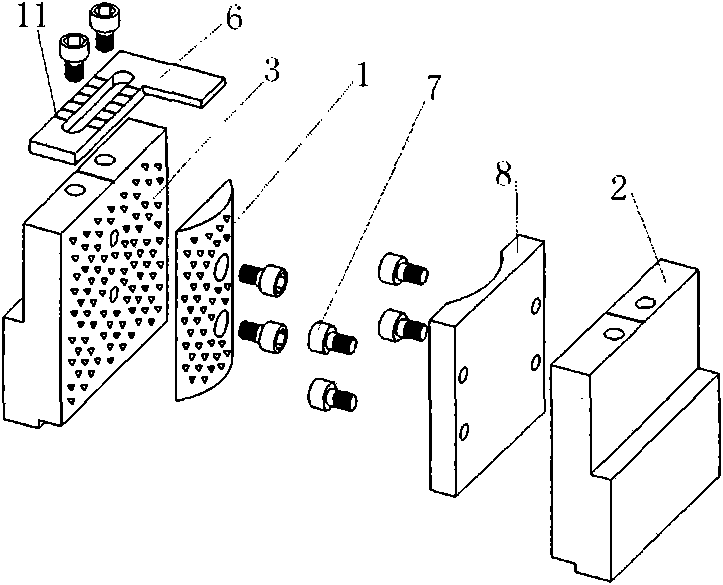

[0022] Such as figure 1 and figure 2 As shown, this embodiment includes an integral fixture composed of two die clamps 2, two die pads 8, two punch clamps 3 and two punch pads 1, as well as an upper positioning plate 4 and a lower positioning plate. Plate 6 and screw 7.

[0023] Wherein, a die clamp 2 and a punch clamp 3 cooperate with each other to form a pair of clamps; the shape and structure of the die clamp 2 and the punch clamp 3 are the same, and the directions are opposite; One surface is flat, and there are mounting holes for the die pad 8 on the plane of the die clamp 2, and there are mounting holes for the punch pad 1 on the plane of the punch clamp 3; the die clamp 2 and the punch clamp The other surface of 3 is a stepped surface, forming the flange 10 of the die fixture and the flange 9 of the fixture of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com