Quantitative powder-filling device for sintering-type heat pipes

A sintering, heat pipe technology, used in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of waste of raw materials such as copper powder, uneven thickness of copper powder, affecting the performance of heat pipes, etc., to reduce the flying and distribution of dust. The effect of uniform and improved heat pipe performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

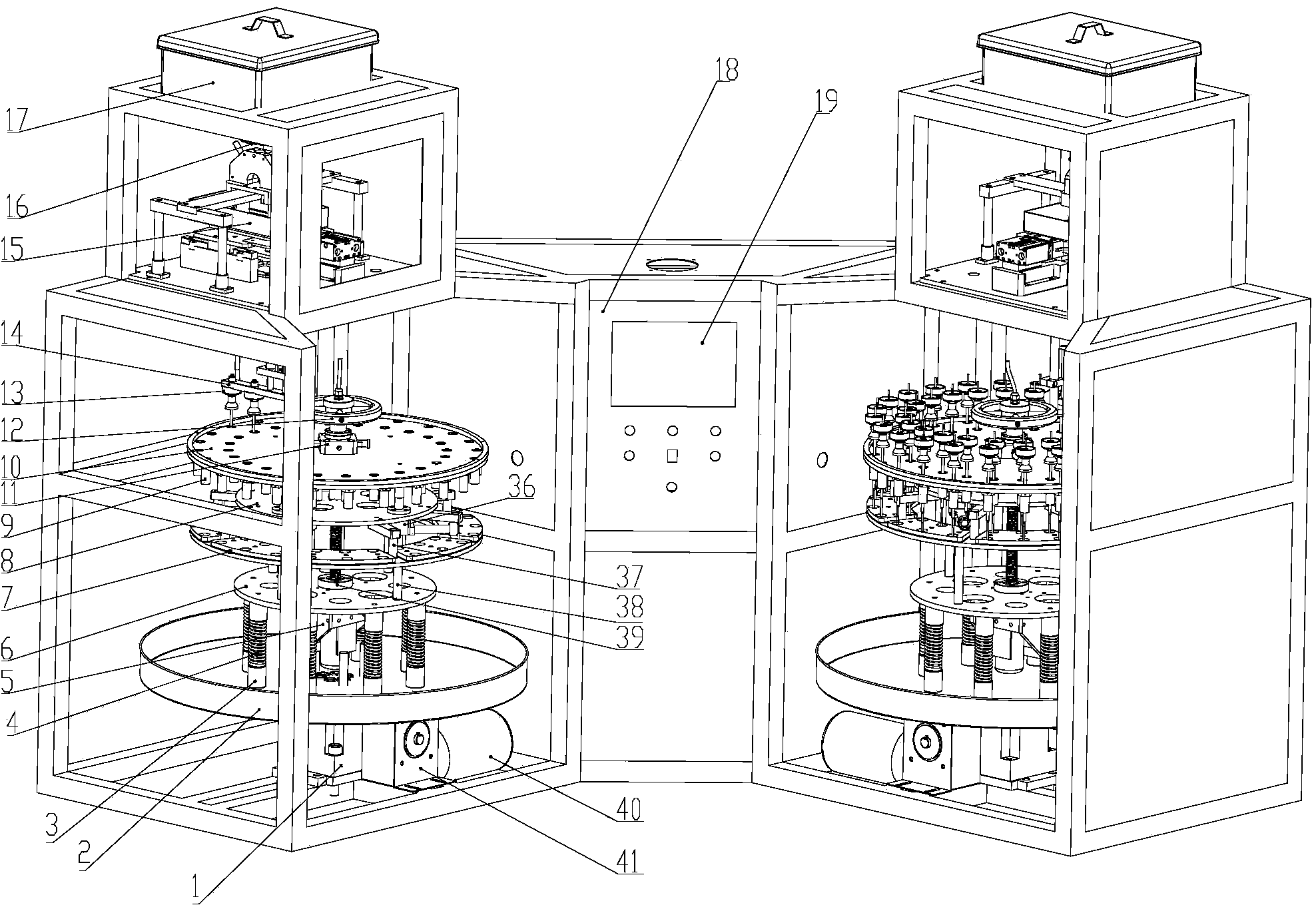

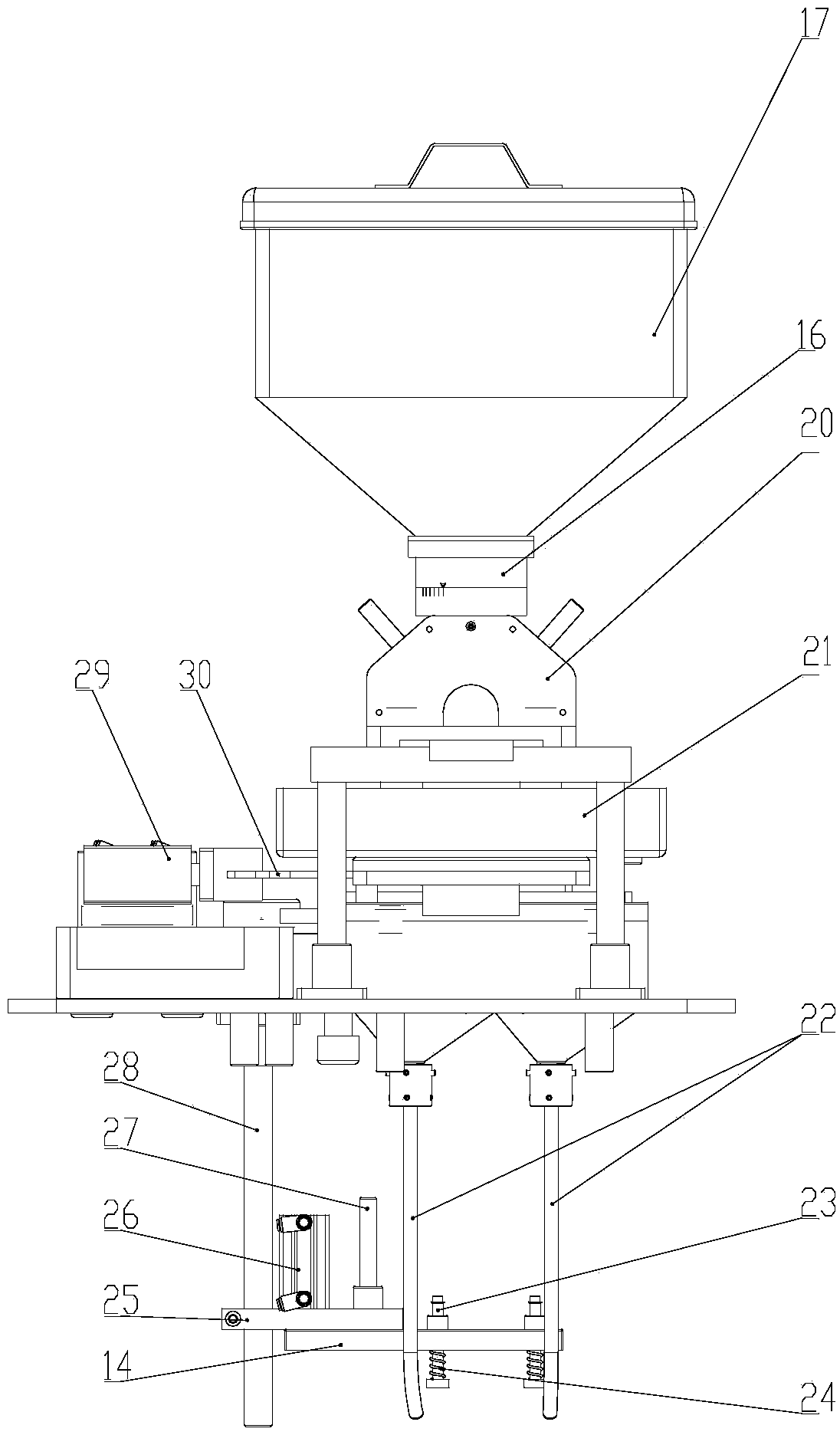

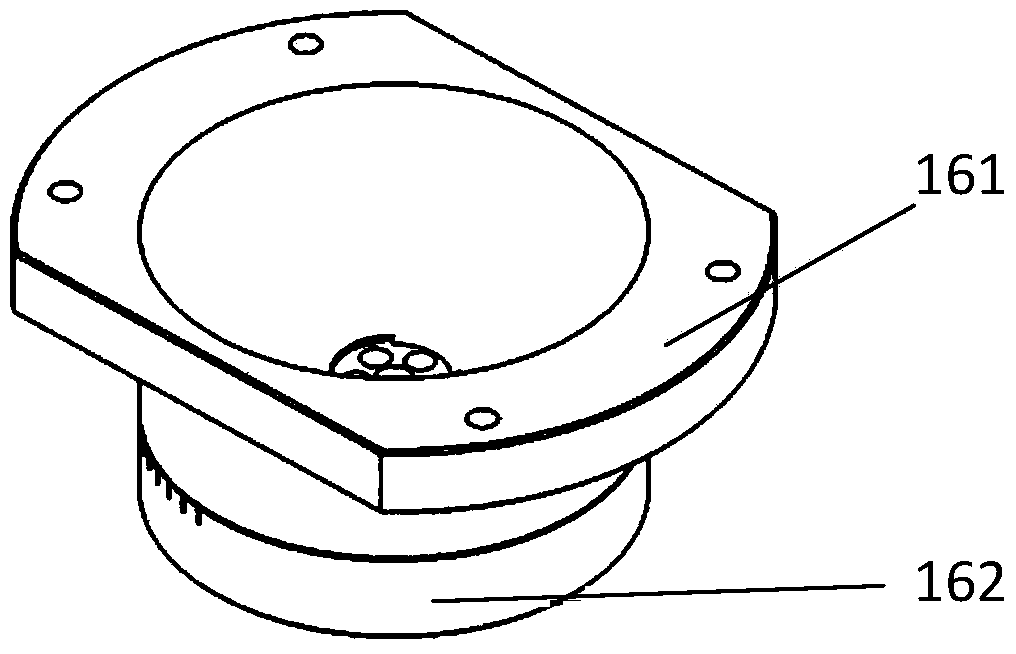

[0036] like Figures 1 to 6As shown, a sintered heat pipe quantitative powder filling equipment includes a left-right symmetrical V-shaped frame 18 and a touch screen control panel arranged in the middle of the frame 18, and also includes a funnel positioning device and a left-right symmetrically arranged on the frame 8. Two sets of powder filling core mechanisms, the powder filling core mechanism includes a powder storage tank 17 arranged on the frame 18 from top to bottom, an automatic powder feeding mechanism 15, and a pressing mechanism for pressing the mandrel 31 , the main panel 10 of the powder filling platform for placing the heat pipe 33,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com