Processing method of gear reducer

A technology of gear reduction box and processing method, which is applied in the direction of belt/chain/gear, transmission box, elements with teeth, etc., can solve the problem of easy deformation, equipment status and personnel status, gear box production efficiency and yield can not be satisfied Production requirements and other issues to achieve the effect of improving processing efficiency and reducing the accumulation of machine tool system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

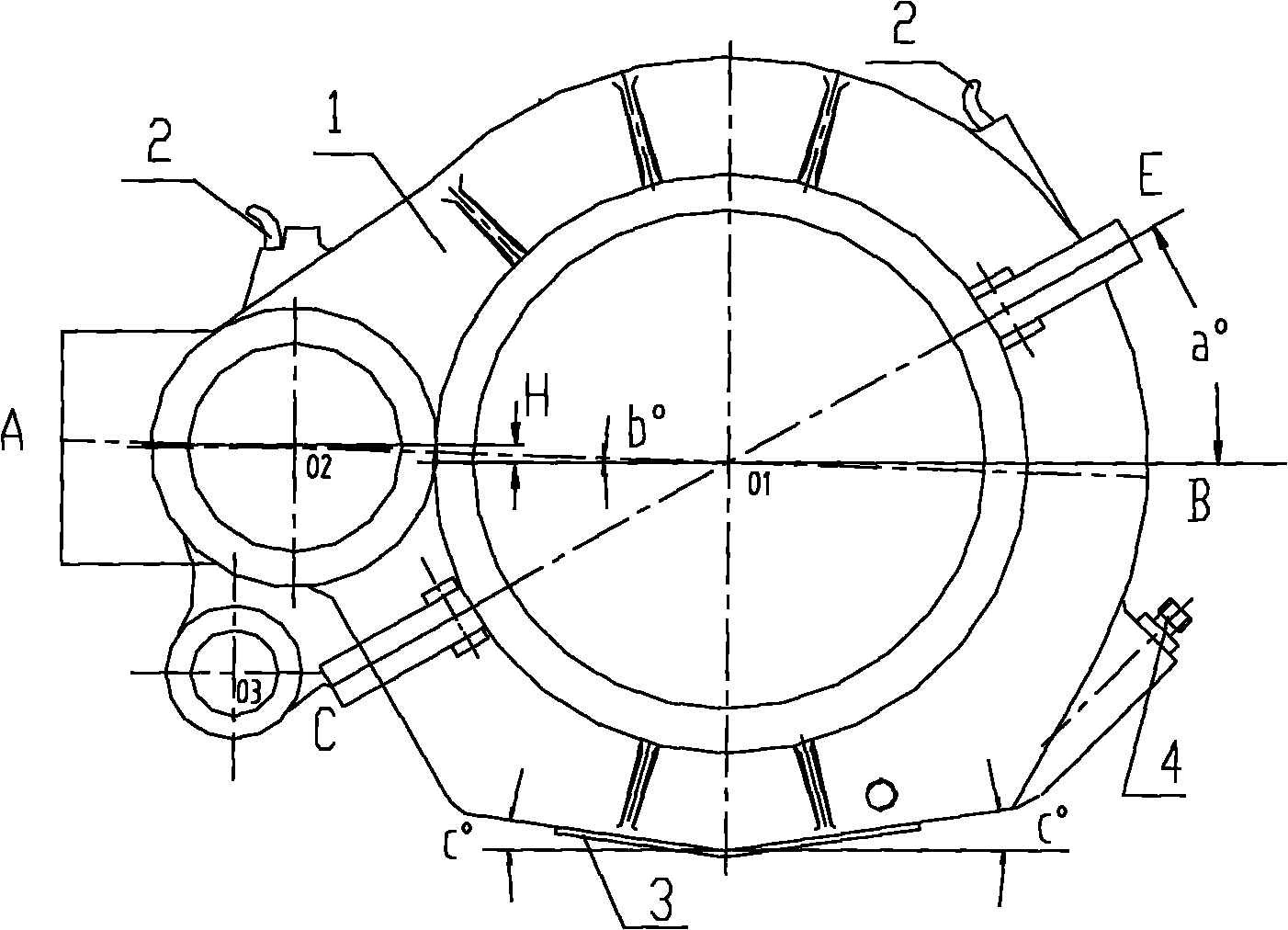

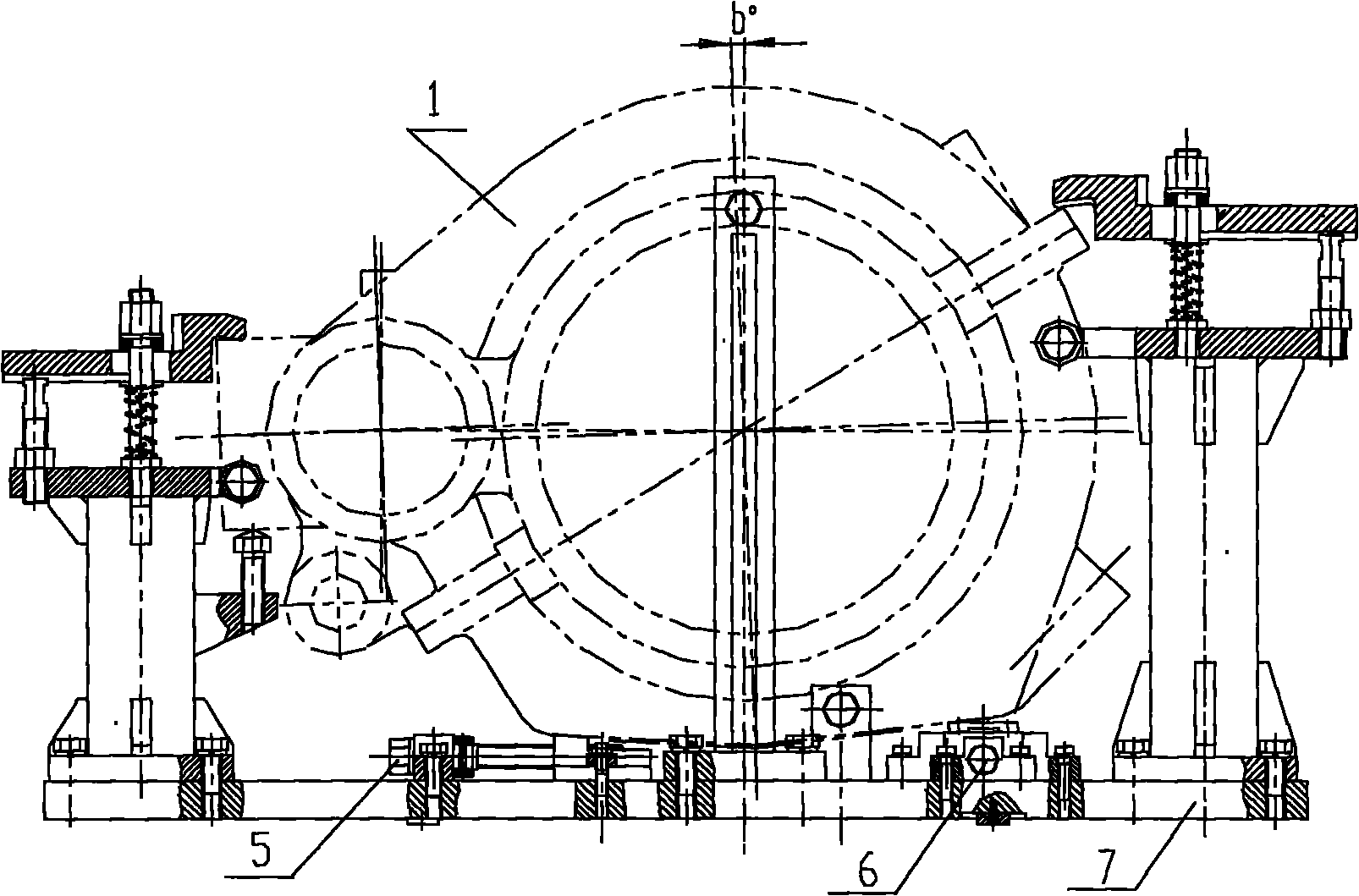

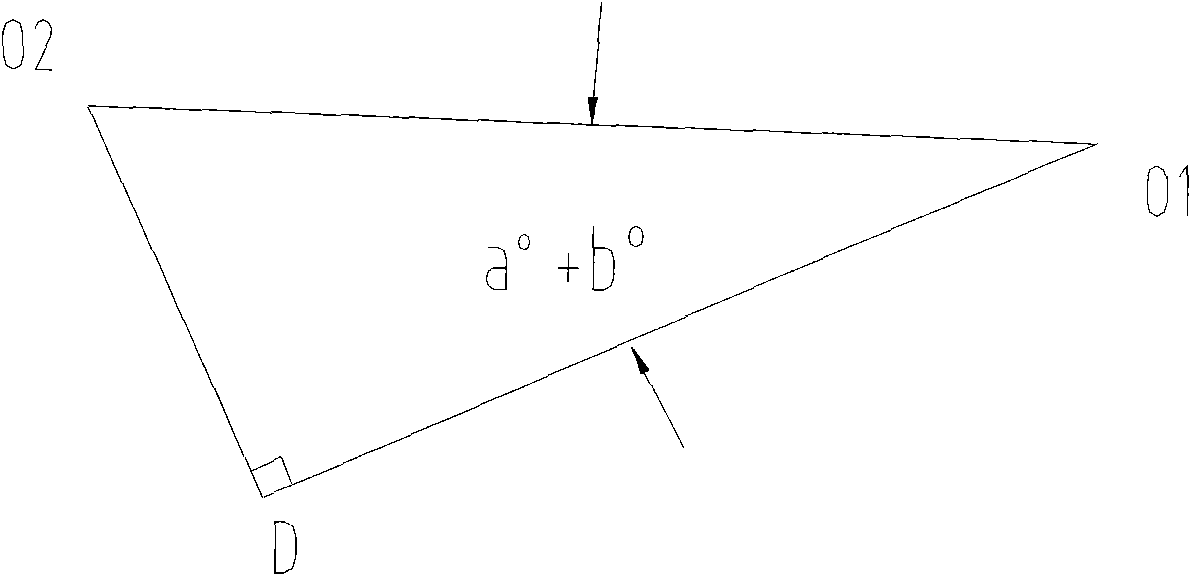

[0021] 1. Reference figure 1 , image 3 , Figure 9 , use the adjustable top 18 in the center support plate to fix the center support plate 19 in the driving gear hole and the driven gear hole of the gear reduction box, and draw the driving gear hole with the planning plan based on the outer wall of the driving gear hole of the gear reduction box Center O 2 . Then use the dash template O 2 o 1 D Draw out the center of the driven gear hole of the gear reducer O 1 , O 1 D must be separated from the gearbox surface C O 1 E is aligned. The marking template can pass through the center of the driving gear hole O 2 To the gearbox side C O 1 E makes a vertical line O 2 D, angle C O 1 o 2 Equal to a°+b°, the overall rotation angle b° of the gearbox can pass through the vertical distance H and the center distance O between the centers of the driving gear hole and the driven gear hole 2 o 1 It is calculated that sin b°=H / O 2 o 1 . Then connect the line O between the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com