Coke Oven Doors Having Heating Function

a technology of oven doors and coke ovens, which is applied in the direction of coke oven doors/closures, coke oven heating, retorts, etc., can solve the problems of hot coke pushed out of coke ovens, poor quality coke generated near the coke ovens at both ends, and low yield of good quality blast furnace coke, etc., to achieve easy maintenance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

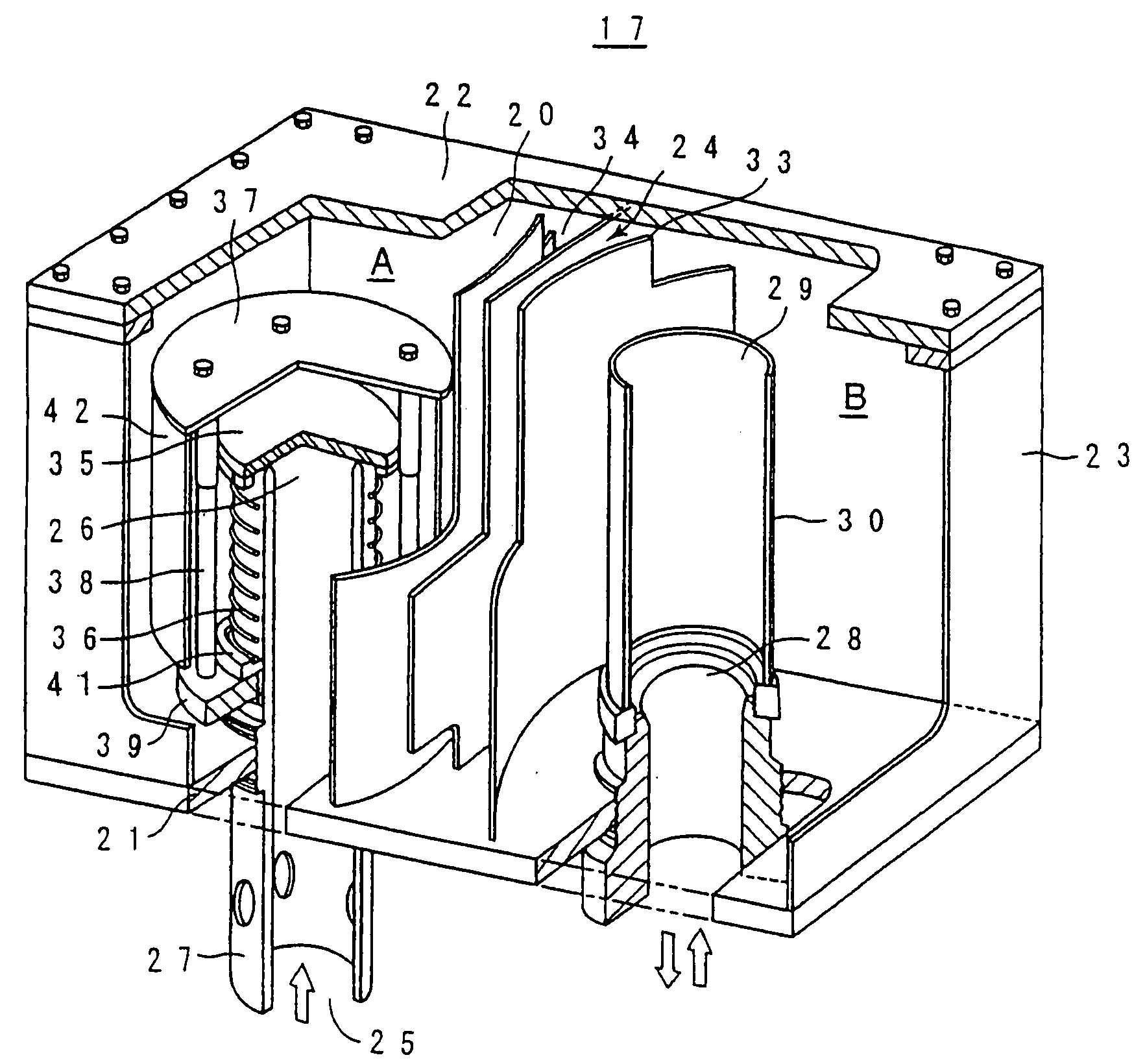

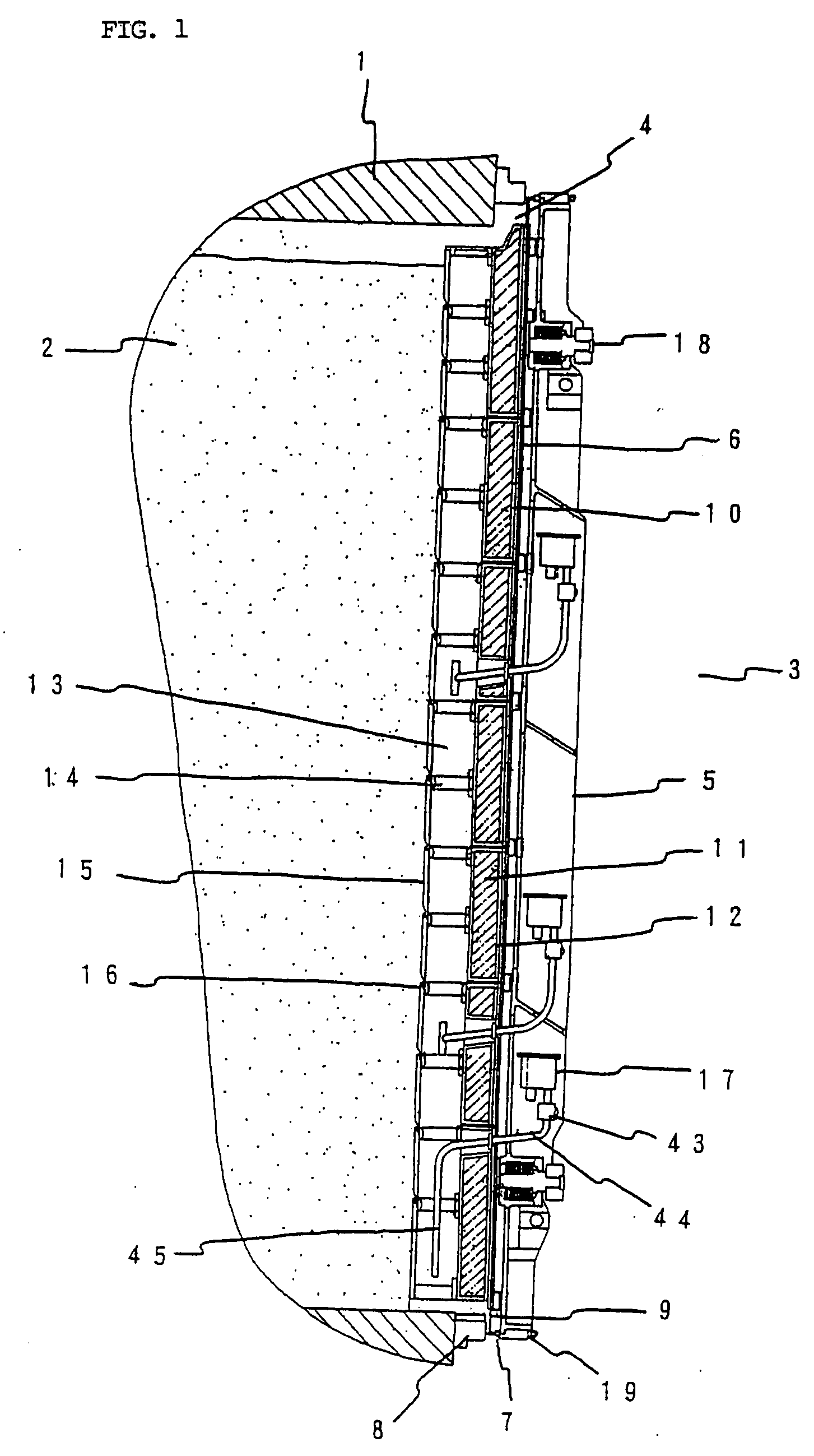

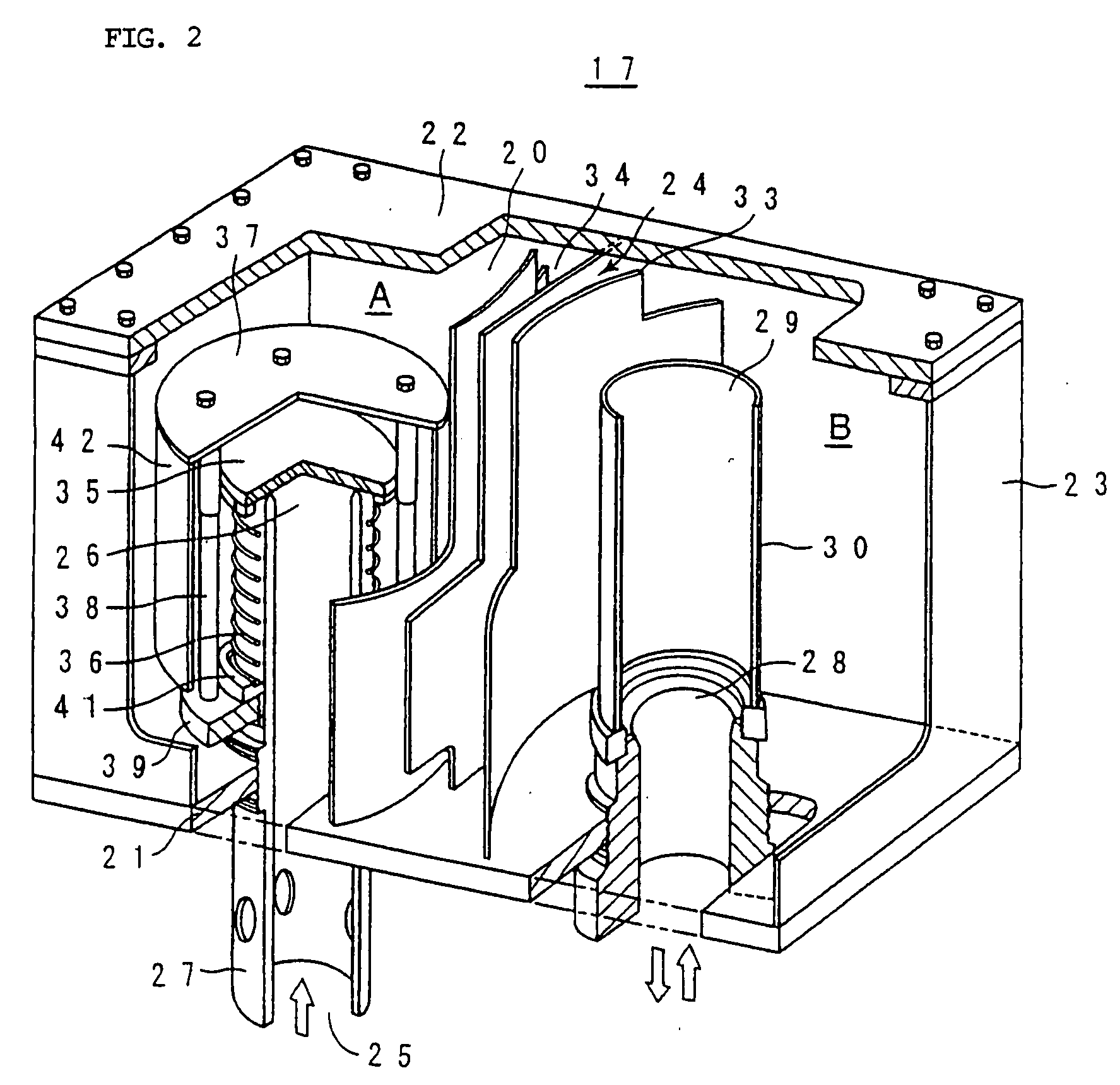

[0028]Details of this invention will be described by reference to the drawings. FIG. 1 is a cross-sectional view in the vicinity of coke oven opening of coke delivery or pushing side illustrating an embodiment of this invention in the direction of oven height. In FIG. 1 reference numeral 1 designates a coke oven, 2 coal particles charged in the coke oven 1. On both sides of coke oven 1 combustion chambers (not shown) are located. They give heat through heating wall to coke oven 1 to produce coke.

[0029]Reference numeral 3 is an oven door structure that opens and closes an opening 4 of coke oven 1. The oven door structure 3 comprises a sturdy cast iron or steel frame 5, slide plate 6 on coke oven side of frame 5, flanges with knife-edge cross section 7 that contact to door jamb 8, seal plate 9 made of heat-resistant metal plate that works as a gas sealing member in conjunction with flanges 7, inner plate 10, heat-insulation box 12 filled with insulating material 11 such as alumina sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com