Method for blocking pneumatic discharging valve

A kind of unloading valve, pneumatic technology, applied in the direction of valve operation/release device, lifting valve, furnace charge, etc., can solve the problems such as difficult to control, inconvenient control, safety accidents, etc., to achieve easy maintenance control, the length of the skylight minimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

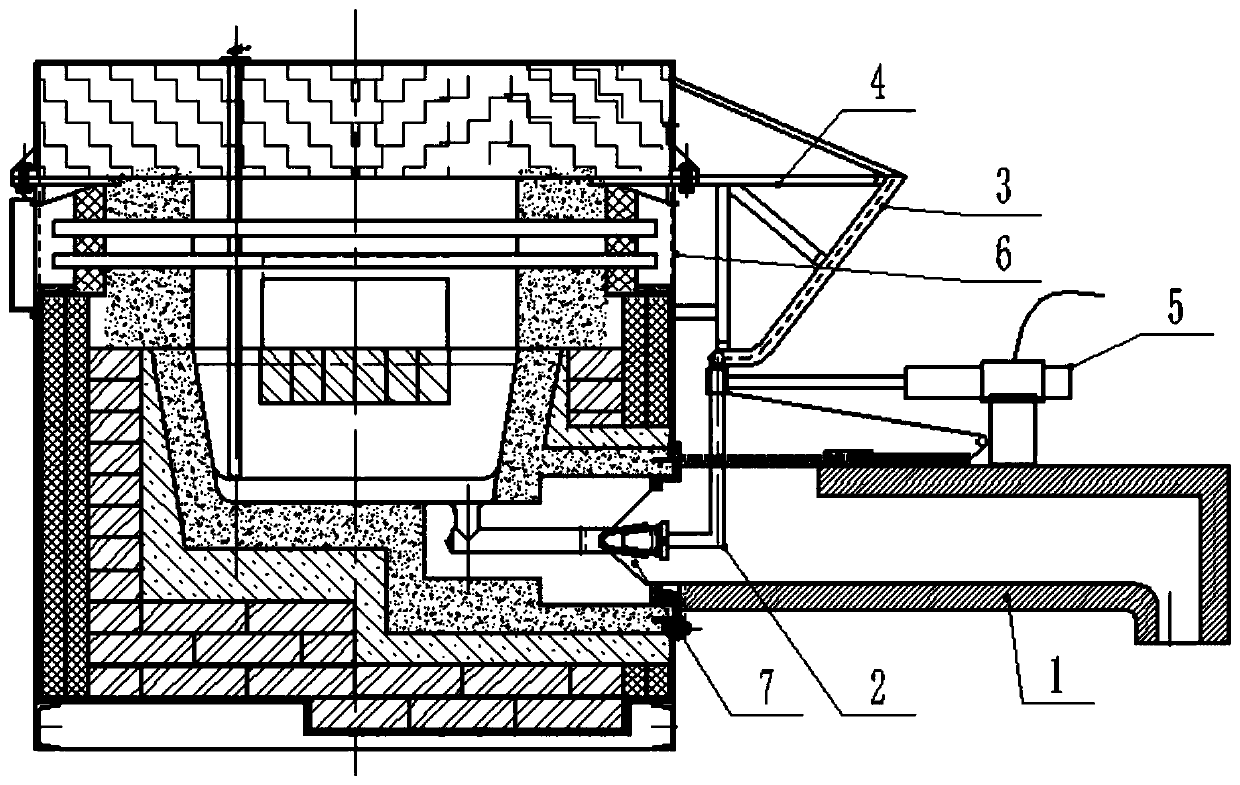

[0044] Such as Figure 3-13 Shown, the blocking method of this a kind of pneumatic unloading valve of the present invention comprises steps:

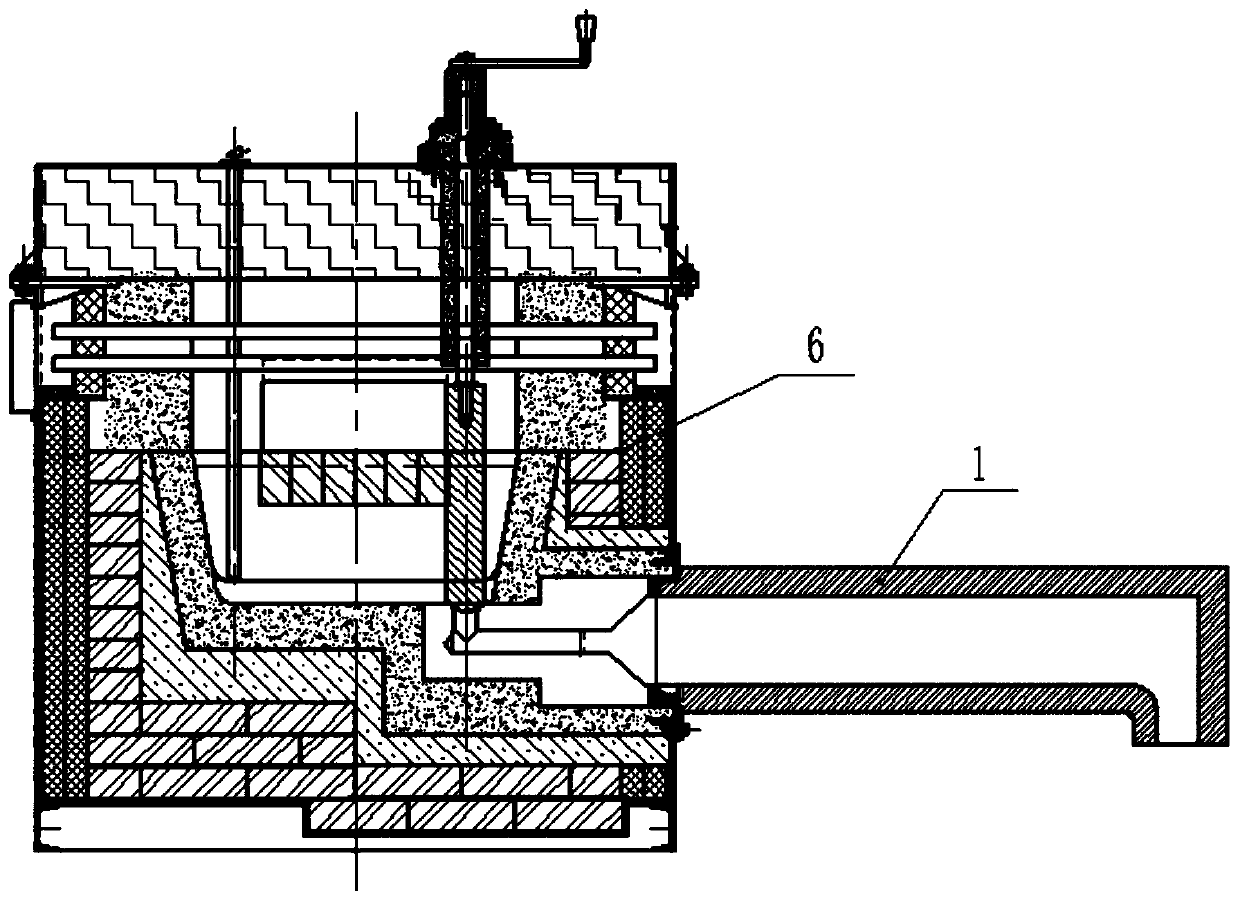

[0045] A guide tube 1 is installed on the discharge port 7 of the furnace body 6, and a skylight 8 is provided on the top surface of the inner end of the guide tube 1;

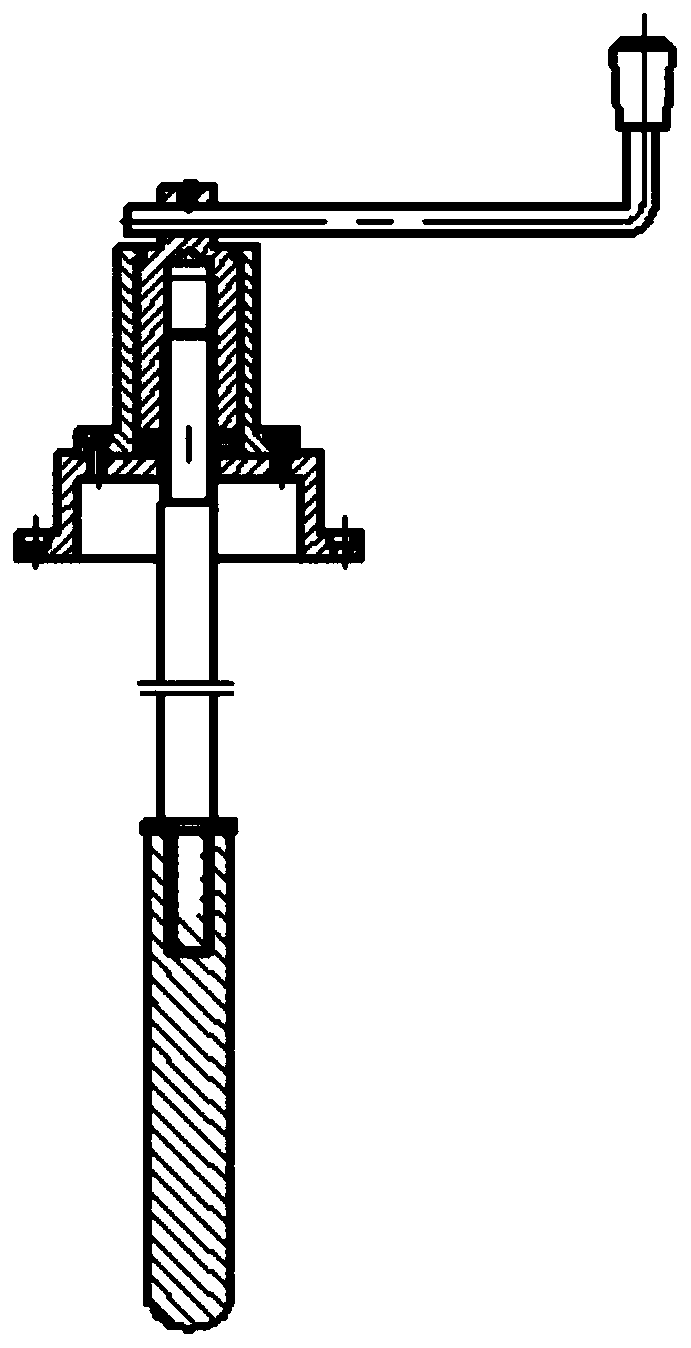

[0046] The valve stem guide frame 3 is fixedly installed on the furnace body 6 corresponding to the skylight 7 through the guide installation frame 4; the valve stem guide frame 3 includes a valve stem guide groove 9 and a connecting cross bar 10, and the valve stem guide groove 9 includes The valve stem guide groove 11 of the horizontal section and the valve stem guide groove 12 of the inclined section, the angle between the valve stem guide groove 11 of the horizontal section and the valve stem guide groove 12 of the inclined section is 125°-130°; the two valve stem guide grooves 9 The notch is relatively mirror image set through a plurality of connecting bars 10 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com