Damper baffle for a coke oven ventilation system

a technology for ventilation systems and coke ovens, which is applied in the direction of combustible gas coke oven heating, combustion regulation, lighting and heating apparatus, etc., can solve the problems of laborious and cumbersome replacement of bulky and heavy refractory damper blocks, deterioration of refractory damper blocks, and reducing the efficiency of ventilation. , to achieve the effect of less time, less labor, and weight saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

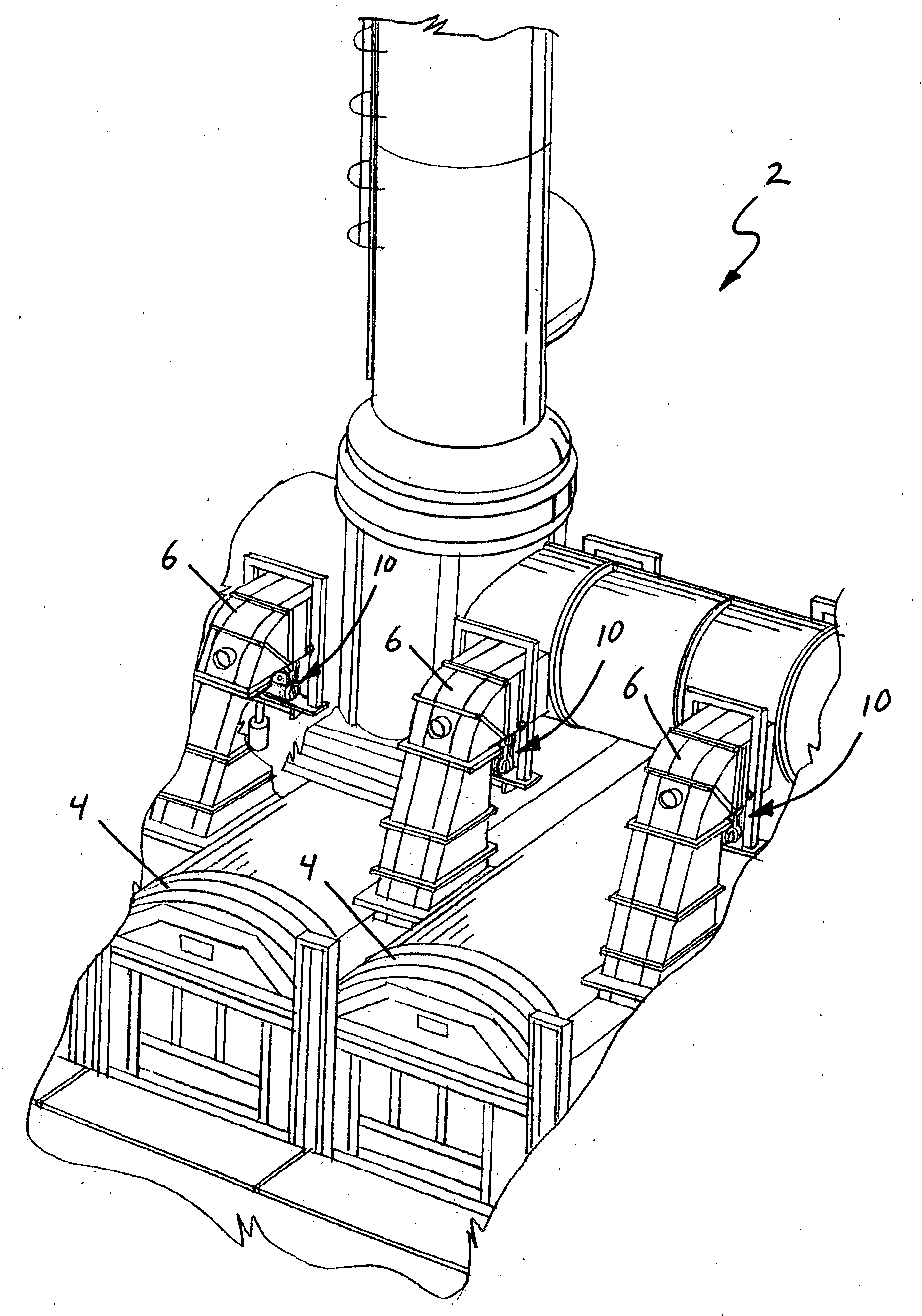

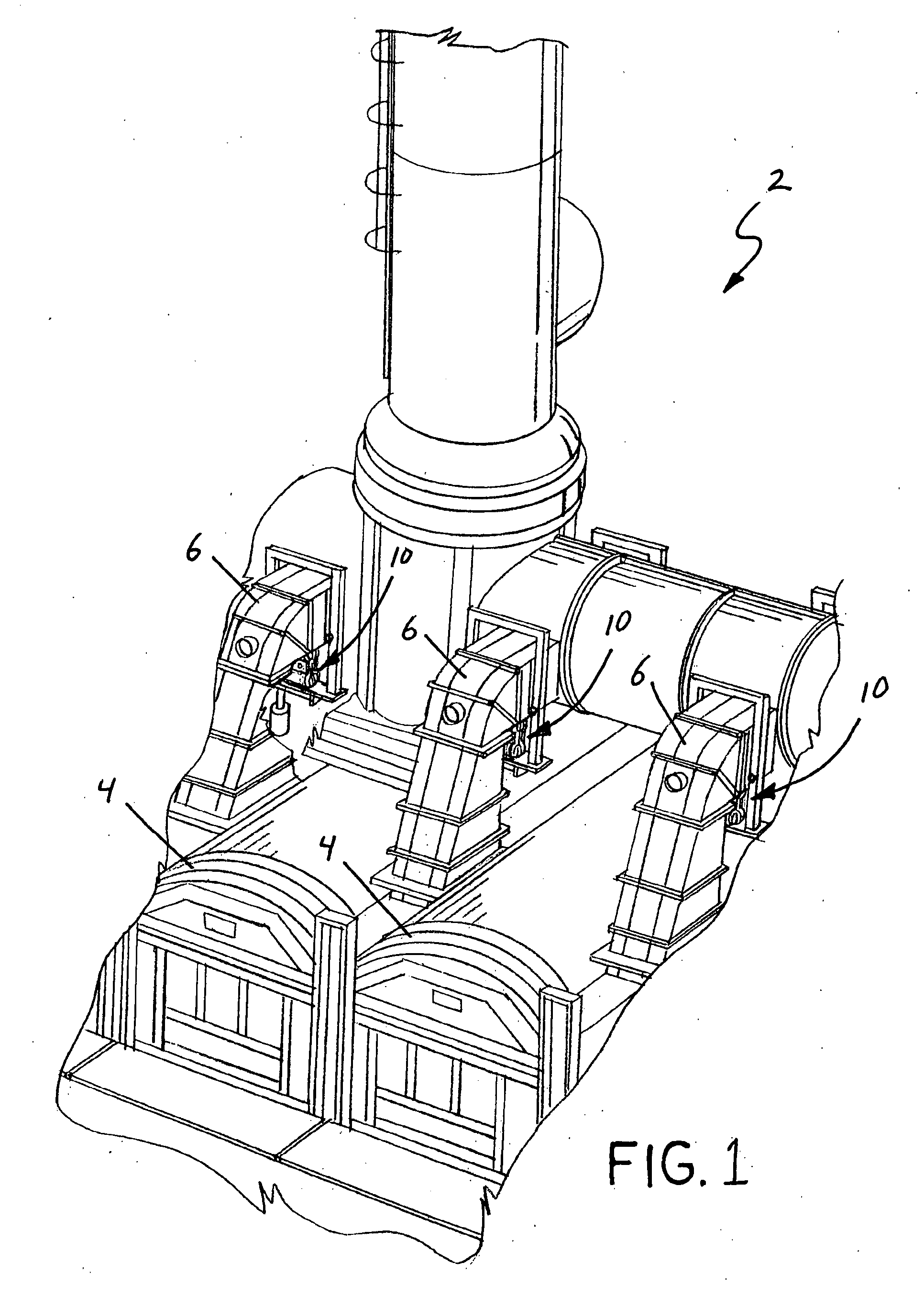

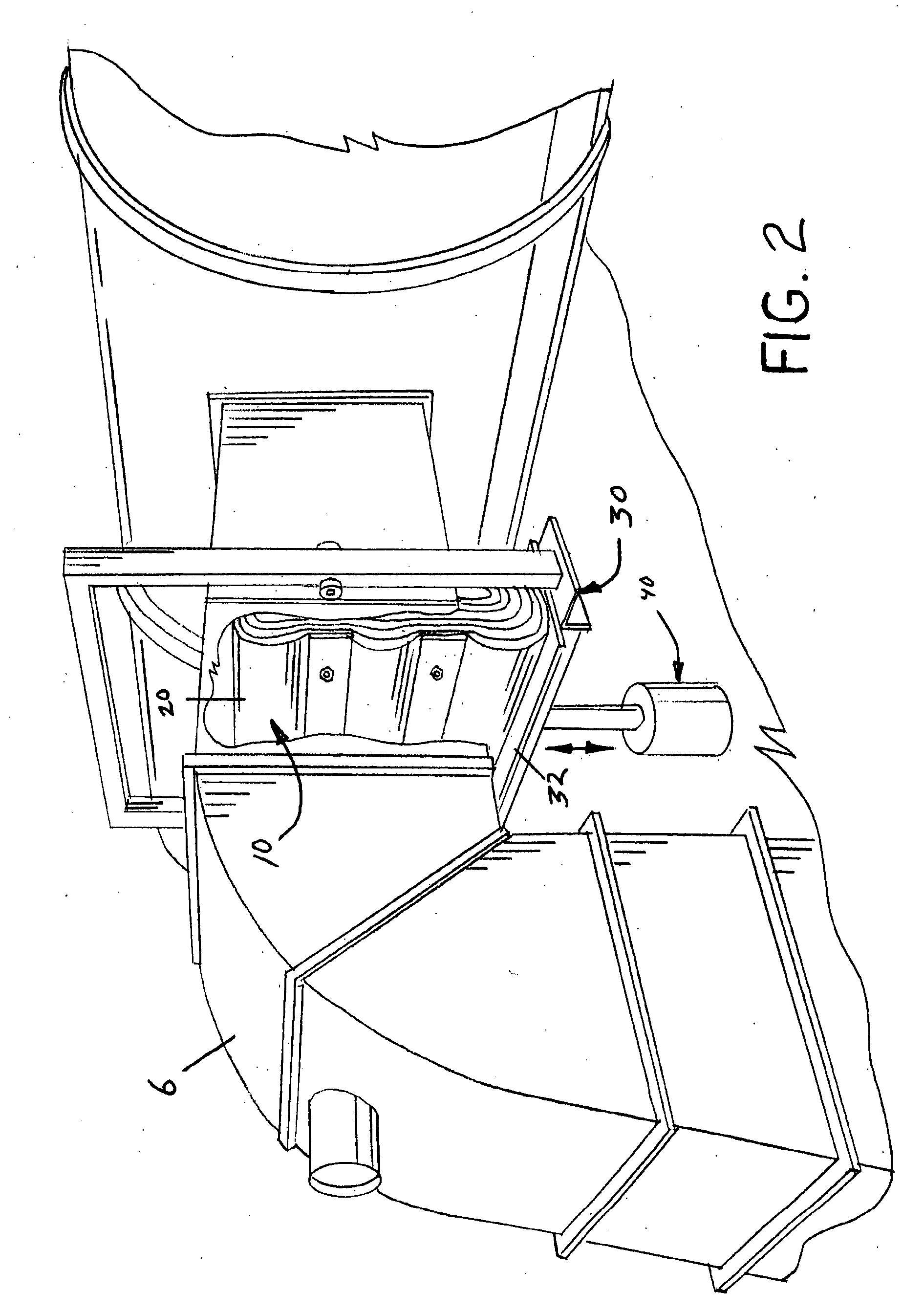

[0012]FIGS. 1-5 illustrate an embodiment of the present invention where reference numeral 10 generally designates a damper baffle for use in the ventilation system of a coke oven. FIG. 1 illustrates a conventional coke oven battery 2 incorporating damper baffle 10 into the ventilation duct 6 of each coke oven 4. For the sake of simplicity, only those parts of the coke oven and ventilation system necessary for the explanation of the present invention are explained and discussed; however, the present invention can be incorporated into any coke oven ventilation system. As shown in FIG. 2-5, damper baffle 10 is designed to replace conventional damper block baffles, while still using the conventional lift frame 30 and hydraulic lifts 40. Damper baffle 10 is mounted to a conventional base plate 32 of lift frame 30. As shown in FIGS. 4 and 5, a hydraulic lift 40 mounted under lift frame 30 raises and lowers damper baffle 10 into ventilation duct 6.

[0013]As best shown in FIG. 3, damper baff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com