Biomass continuous pyrolysis carbonization device and biomass continuous pyrolysis carbonization method

A pyrolysis carbonization and biomass technology, applied in combustion methods, biofuels, incinerators, etc., can solve the problems of increasing production costs and equipment quantity, increasing the investment of the overall equipment, and poor utilization of pyrolysis production capacity. Small footprint, high production efficiency and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

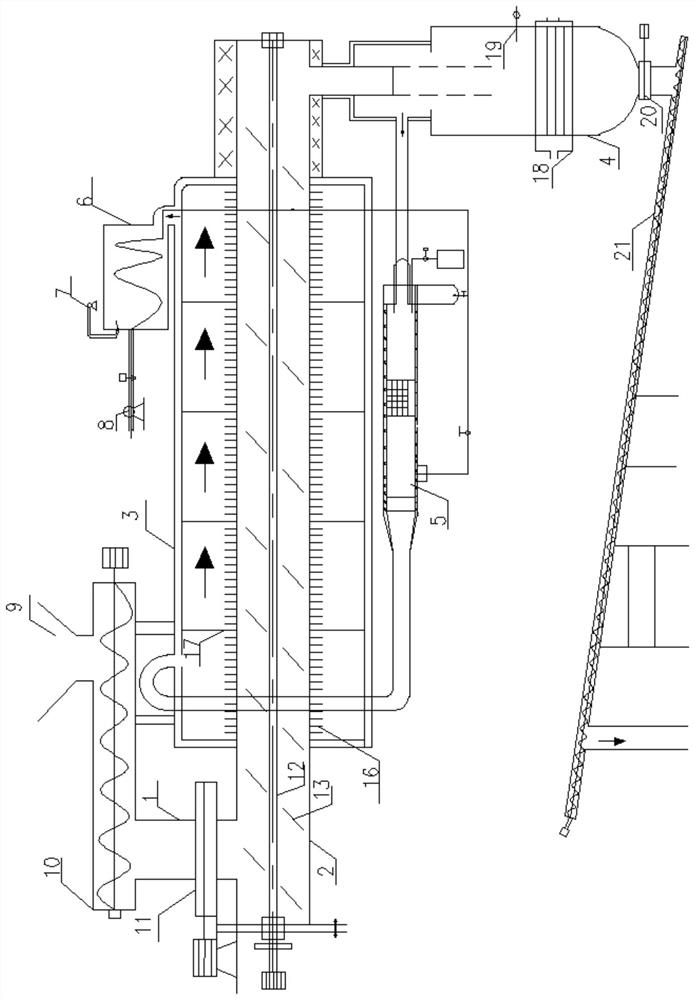

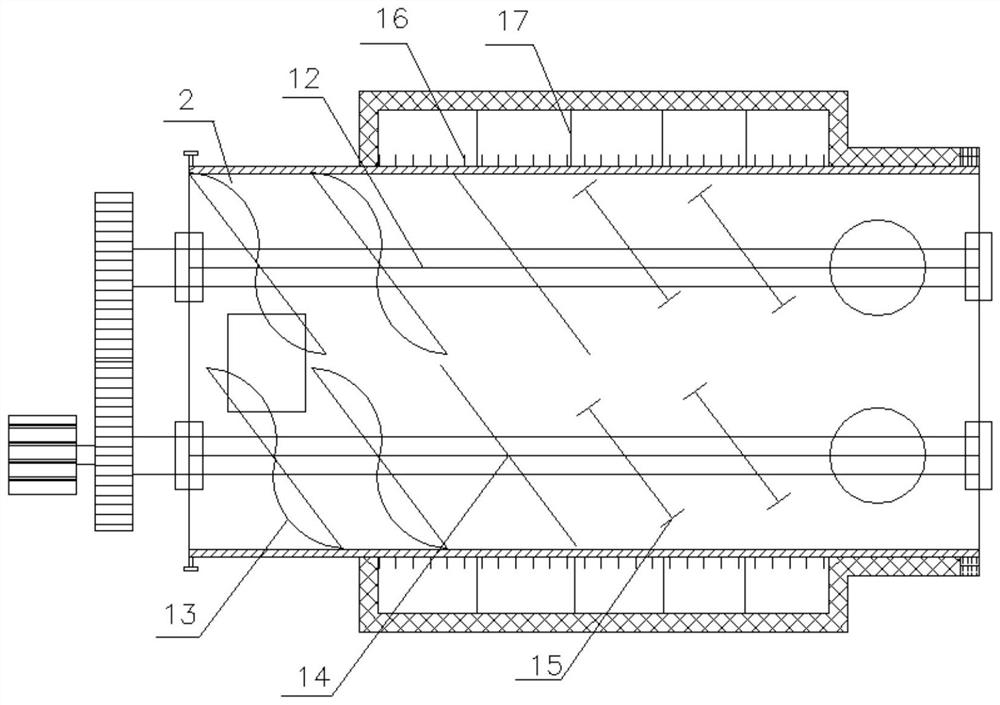

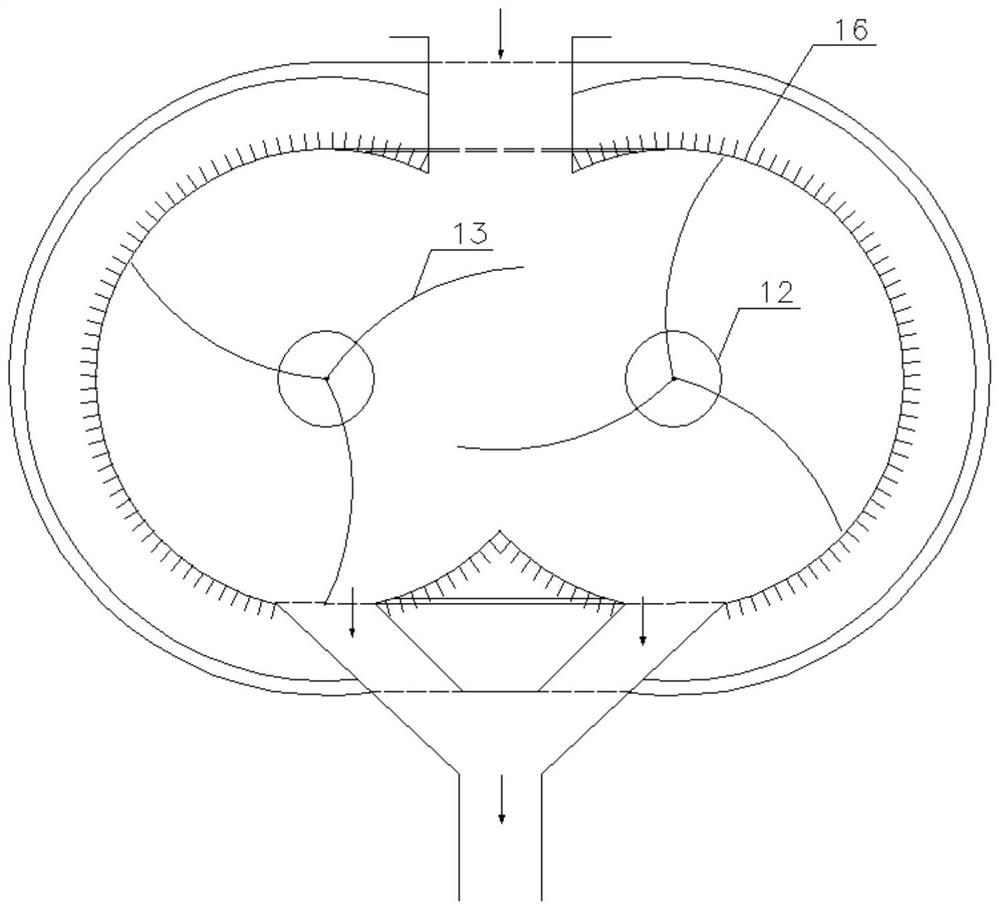

[0033] A biomass continuous pyrolysis carbonization device, the structure is as follows figure 1 As shown, the device includes a quantitative feeder 1, a pyrolysis carbonization chamber 2, a gas-solid separator 4, a burner 5, a heat exchanger 6, an induced draft fan 7, and a blower 8;

[0034] The quantitative feeder 1 is connected with the feed port of the pyrolysis carbonization chamber 2, the gas-solid separator 4 is connected with the discharge port of the pyrolysis carbonization chamber 2, the burner 5 is connected with the gas-solid separator 4 The gas outlet is connected, the burner 5 is equipped with a ceramic body, the flue gas output pipe of the burner 5 is connected to the outer heating sleeve 2, the inlet I of the heat exchanger 6 is connected to the outer heating sleeve 3 The flue gas outlet is connected, the induced draft fan 7 is connected to the outlet I of the heat exchanger 6, the blower 8 is connected to the inlet II of the heat exchanger 6, and the outlet ...

Embodiment 2

[0040] The pyrolysis carbonization method of device described in embodiment 1, described method comprises the steps:

[0041] (1) Biomass is continuously fed into the pyrolysis and carbonization chamber 2 through the quantitative feeder 1, and the material is pushed into the dehydration, pyrolysis, and carbonization areas by the pusher blade 13, the stirring blade 14, and the scraper blade 15, and is then pyrolyzed and carbonized. Finally, biochar and mixed gas are produced;

[0042] (2) Biochar and mixed gas produced after carbonization enter the gas-solid separator 4 through the discharge port of the pyrolysis carbonization chamber 2;

[0043] (3) The mixed gas is introduced into the burner by the induced draft fan 7 and burned for the first time, and the tar and wood vinegar in the mixed gas are further decomposed by the action of the ceramic body, and then burned for the second time;

[0044] (4) The high-temperature flue gas produced after combustion enters the outer hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com