straw propulsion device

A propulsion device and straw technology, which is applied in the direction of charging device, special form of dry distillation, application, etc., can solve the problem of uncontrollable propulsion speed, achieve the effect of improving the air discharge effect, increasing the carbonization rate, and slowing down the running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

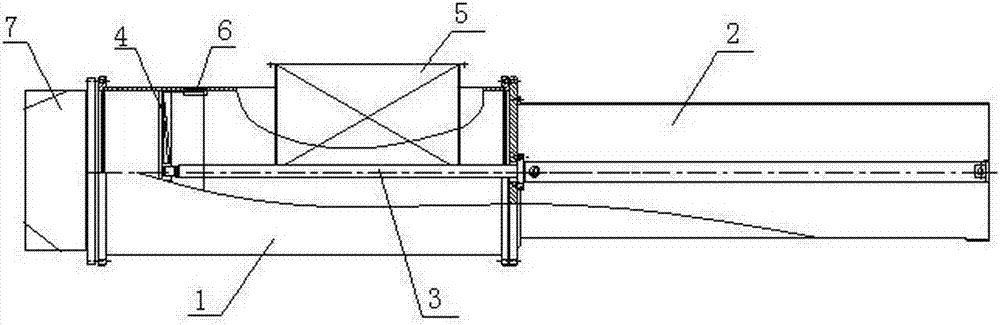

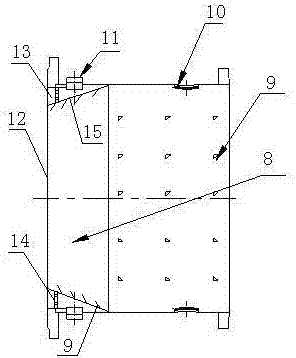

[0023] Such as figure 1 , figure 2 As shown, a straw propulsion device includes a cylinder body 1, a hydraulic cylinder 2 and a compression device 7. The two ends of the cylinder body 1 pass through flanges, the hydraulic cylinder 2 and the compression device 7 respectively, and the side wall of the cylinder body 1 is provided with The feed port 5, the other end of the compression device 7 is the discharge port 12, the cylinder 1 is provided with a piston 4 for pushing the straw bales, the piston 4 is connected with the hydraulic cylinder 2 through the connecting rod 3, and the hydraulic cylinder 2 drives the piston 4 Do reciprocating motion in the cylinder body 1, send the air-dried straw bales from the feed port 5 into the carbonization furnace for carbonization, the compression device 7 is a cylinder body, and a cone cylinder 15 is arranged inside the cylinder body, and the cone A compression chamber 8 is formed inside the shaped cylinder 15, the small diameter end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com