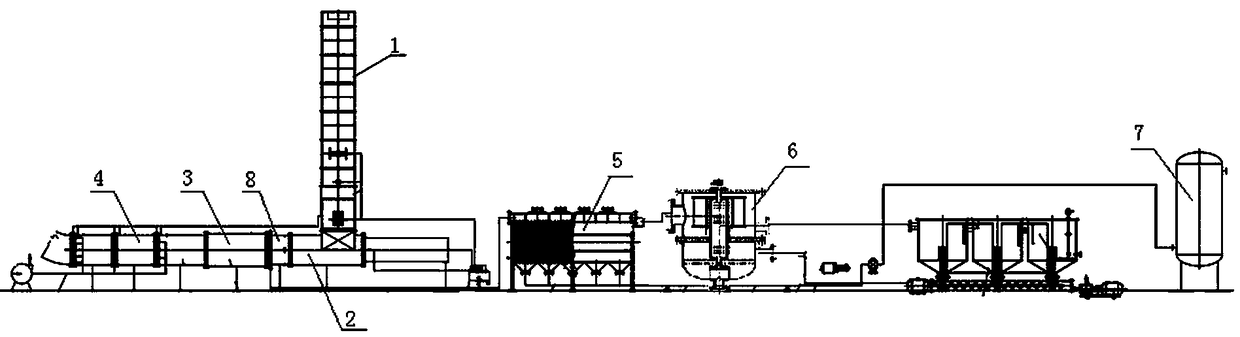

A continuous biomass decomposition process and device

A biomass and process technology, applied in the field of continuous biomass decomposition process and device, can solve the problems of large application waste, etc., and achieve energy saving and good air-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A biomass continuous decomposition process, comprising the steps of:

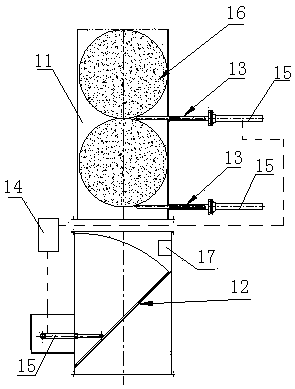

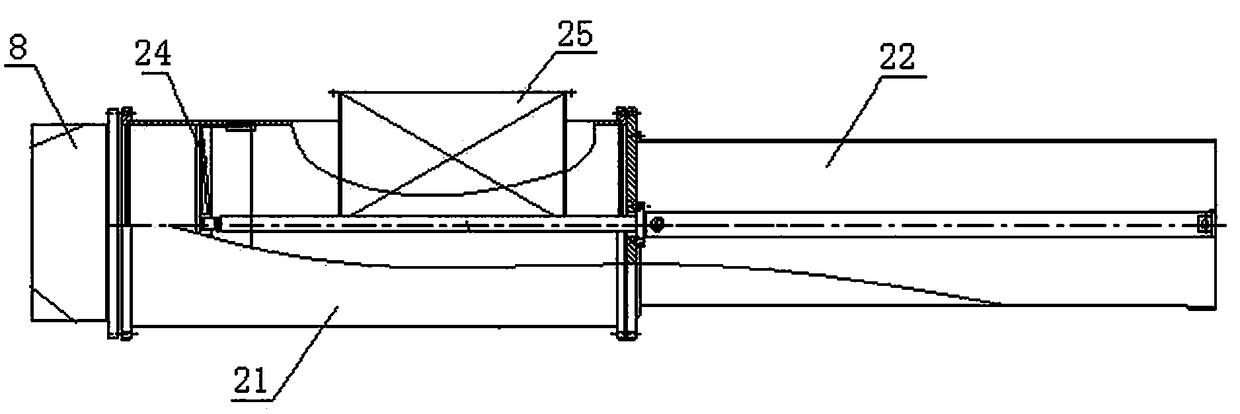

[0048] (1) The biomass raw material is sent to the air drying device for drying, and the dried biomass raw material is pushed into the carbonization furnace by the propulsion device, and the biomass raw material is compressed during the propelling process; this step also includes the biomass raw material ( Biomass raw materials refer to the steps of sorting and feeding the plant straws, and transferring the biomass raw materials to the air-drying device after sorting; the purpose of compressing the biomass raw materials (that is, straw bales) during the advancing process is to discharge the air inside. Increases the rate of decomposition into char (prevents incineration).

[0049] (2) Decompose the compressed biomass raw material in a carbonization furnace. When the biomass raw material reaches the decomposition temperature:

[0050] a. Open the gas collection valve to collect the gas produced by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com