Hydrothermal preparation method of magnetic carbon micro-spheres

A carbon microsphere and hydrothermal technology, applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems of long reaction cycle, etc., and achieve the effects of low production cost, convenient reuse and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

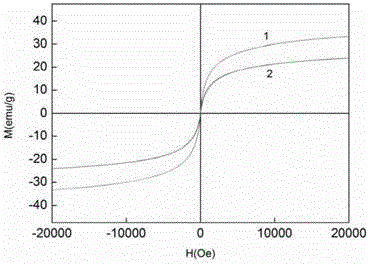

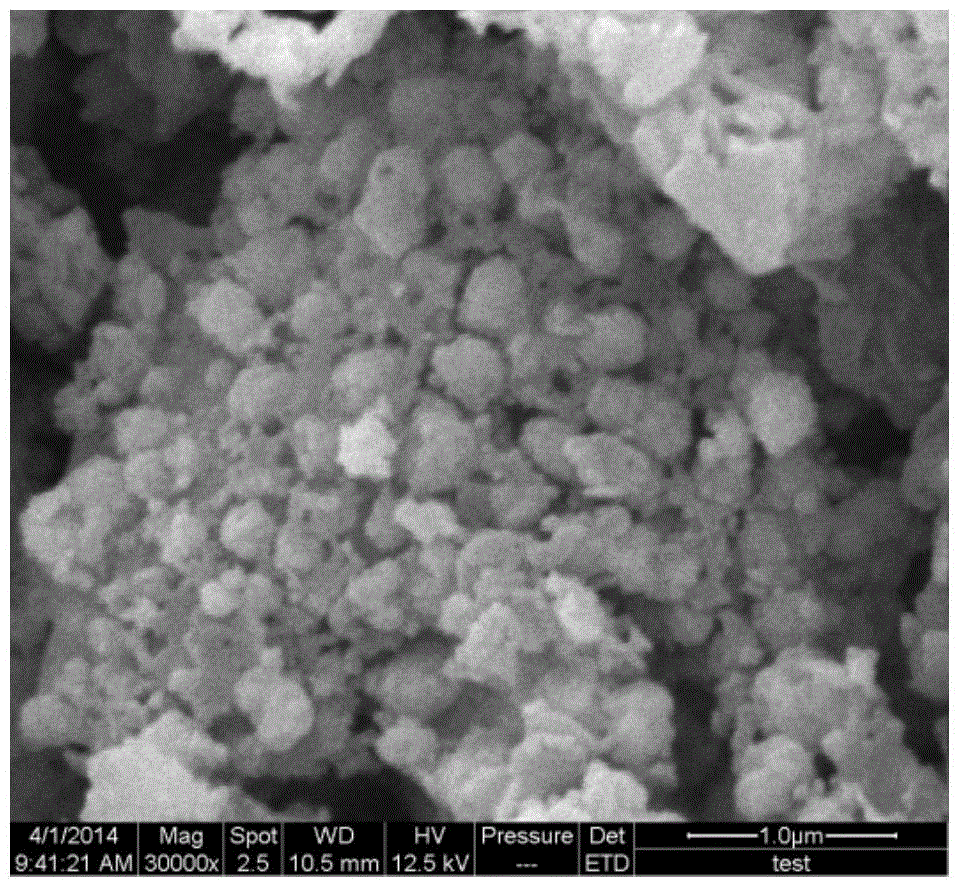

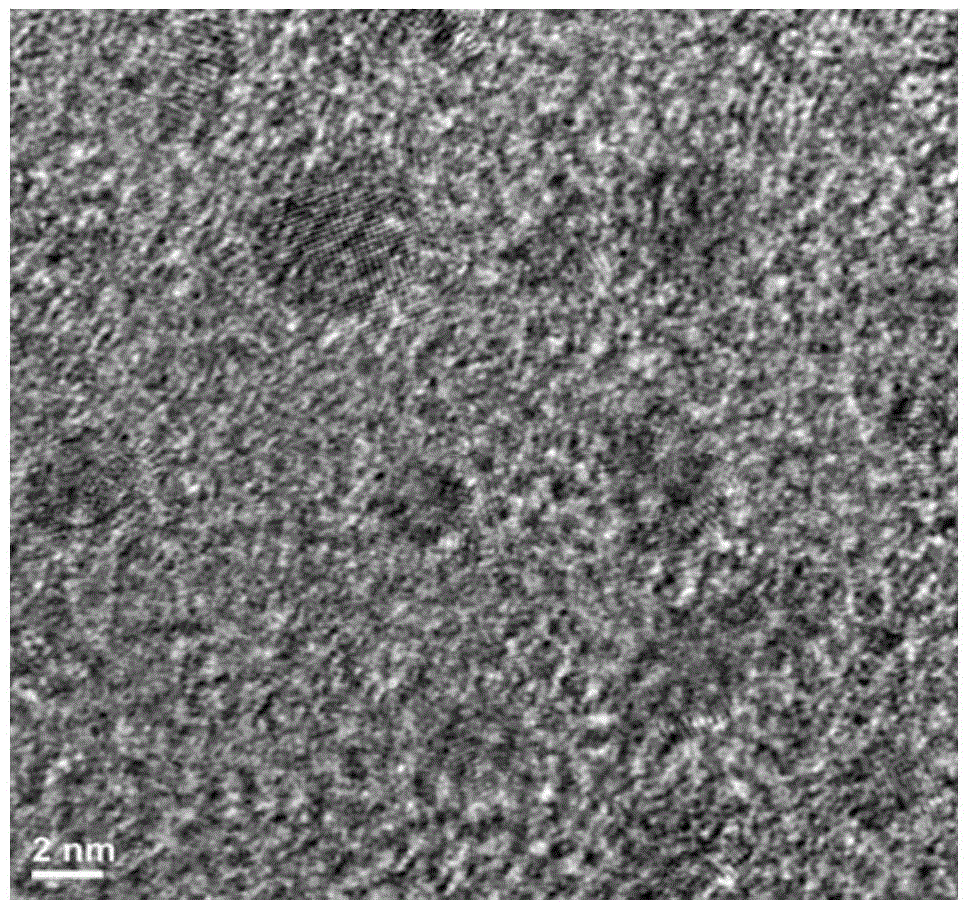

Embodiment 1

[0025] Add 1.5g microcrystalline cellulose to 45mL aqueous solution, use nickel acetate tetrahydrate as the nickel source, the concentration is 0.1mol / L, put it into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and ensure that the volume of the solution and the volume of the kettle are 13:20, put it into a high-temperature reactor, heat up to the target temperature of 230°C at a rate of 10°C / min, keep the temperature for 14 hours, cool down to room temperature, and centrifuge twice at a speed of 9000r / min to obtain a brown solid product. It was washed with distilled water and absolute ethanol three times successively, and vacuum-dried at 100°C for 6 hours to obtain a nickel-doped hydrothermal carbon product precursor. Put the dried carbon sample into a tubular resistance furnace, raise the temperature at 5°C / min to the target temperature of 950°C, and keep the temperature constant for 2 hours to obtain carbon microspheres with a well-developed pore structure. ...

Embodiment 2

[0029]Add 2.5g microcrystalline cellulose to 40mL aqueous solution, use nickel acetate tetrahydrate as the nickel source, the concentration is 0.2mol / L, put it into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and ensure that the volume of the solution and the volume of the kettle are 6:7, put it into a high-temperature reactor, raise the temperature to the target temperature of 250°C at a rate of 10°C / min, keep the temperature for 11 hours, cool down to room temperature, and centrifuge twice at a speed of 12000r / min to obtain a brown solid product. It was washed with distilled water and absolute ethanol three times successively, and vacuum-dried at 80°C for 6 hours to obtain a nickel-doped hydrothermal carbon product precursor. Put the dried carbon sample into a tubular resistance furnace, raise the temperature at 5°C / min to the target temperature of 850°C, and keep the temperature constant for 2 hours to obtain carbon microspheres with well-developed pore str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com