Microwave-enhanced biomass carbonization treatment method

A technology of biomass charcoal and treatment method, which is applied in the direction of biofuel, special carbonization, petroleum industry, etc. It can solve the problems of complicated operation and low acid concentration, and achieve carbonization treatment with reduced reaction steps, large specific surface area and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

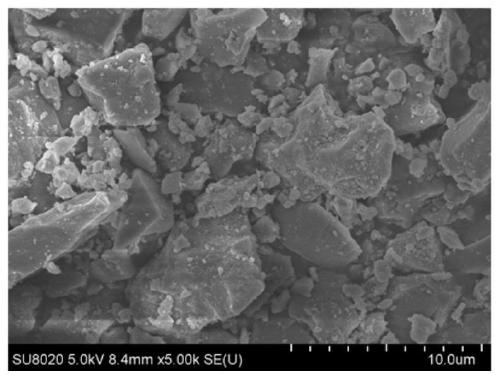

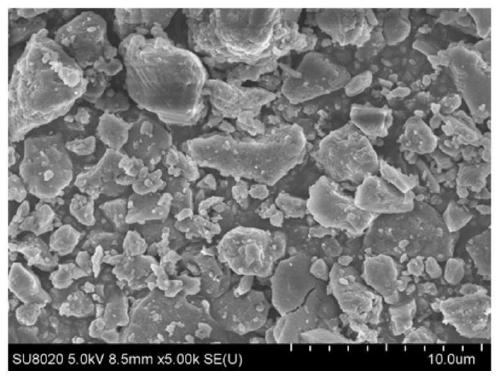

Image

Examples

Embodiment 1

[0050] The invention provides a treatment method for microwave-enhanced biomass carbonization, said method comprising the following steps:

[0051] The method comprises the steps of:

[0052] (1) Mix biomass (rice husk), acid and catalyst to obtain a mixture; wherein, the particle size of the biomass is ≤100mm; the mixing is the first mixing of the biomass and the acid, followed by the second mixing with the catalyst Two mixing; the temperature of the first mixing is 85°C; the time of the first mixing is 1h; the temperature of the second mixing is 140°C; the time of the second mixing is 2h; the acid is alkane Alkylation waste sulfuric acid, the mass concentration of the alkylation waste sulfuric acid is 89.2%; the mass ratio of the acid and the biomass is 5:1; the catalyst is 1-butylsulfonic acid-3-methylimidazole sulfuric acid Hydrogen salt ionic liquid; the addition of the catalyst is 0.3% of the acid mass;

[0053] (2) The mixture obtained in step (1) is subjected to micr...

Embodiment 2

[0056] The invention provides a treatment method for microwave-enhanced biomass carbonization, said method comprising the following steps:

[0057] (1) Mix biomass (rice husk), acid and catalyst to obtain a mixture; wherein, the particle size of the biomass is ≤100mm; the mixing is the first mixing of the biomass and the acid, followed by the second mixing with the catalyst Two mixing; the temperature of the first mixing is 65°C; the time of the first mixing is 3h; the temperature of the second mixing is 100°C; the time of the second mixing is 3h; the acid is alkane Alkylation waste sulfuric acid, the mass concentration of the alkylation waste sulfuric acid is 89.2%; the mass ratio of the acid and the biomass is 4:1; the catalyst is 1-butylsulfonic acid-3-methylimidazole sulfuric acid Hydrogen salt; the addition of the catalyst is 1% of the acid mass;

[0058] (2) The mixture obtained in step (1) is subjected to microwave treatment to obtain a carbon material; wherein, the po...

Embodiment 3

[0061] The invention provides a treatment method for microwave-enhanced biomass carbonization, said method comprising the following steps:

[0062] (1) Mix biomass (reed), acid and catalyst to obtain a mixture; wherein, the particle size of the biomass is less than or equal to 100mm; the mixing is the first mixing of the biomass and the acid, followed by the second mixing with the catalyst Mixing; the temperature of the first mixing is 90°C; the time of the first mixing is 3h; the temperature of the second mixing is 95°C; the time of the second mixing is 3h; the acid is an alkyl The mass concentration of the waste sulfuric acid of the alkylation is 89.2%; the mass ratio of the acid and the biomass is 6.7:1; the catalyst is N-sulfonic acid butylpyridine bisulfate; the catalyst The addition amount is 0.5% of acid mass;

[0063] (2) The mixture obtained in step (1) is subjected to microwave treatment to obtain a carbon material; wherein, the power of the microwave treatment is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com