Environment-friendly coal tar for producing waterless mud-gunstemming and application of environment-friendly coal tar

A technology of water-free gun mud and coal tar, which is applied in the field of refractory material production, can solve the problems of physical harm to workers, and achieve the effects of low price, increased strength, and slow hole expansion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

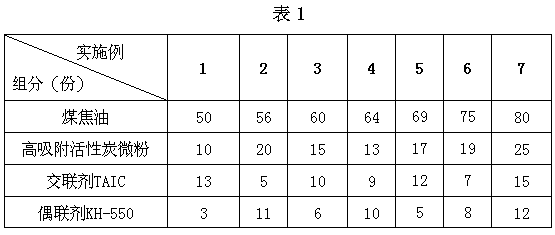

[0023] Embodiment 1~7 is used for producing the environmental protection coal tar of anhydrous taphole mud

[0024] Embodiments 1 to 7 are respectively a kind of environmentally friendly coal tar used to produce anhydrous taphole mud, and the active ingredients thereof are specifically shown in Table 1

[0025]

[0026] Mix and stir the above-mentioned ingredients evenly to obtain the environmentally friendly coal tar for producing anhydrous taphole clay as described in any one of Examples 1-7.

Embodiment 8

[0027] Embodiment 8 is used for the application of the environment-friendly coal tar of producing anhydrous taphole mud

[0028] This embodiment provides an application of using any one of the embodiments 1-7 to produce the environmentally friendly coal tar of anhydrous taphole clay. It is used to prepare tar-pitch combined Al2O3-SiO2-SiC-C anhydrous tapped clay system. The production of anhydrous taphole mud is changed to the environmentally friendly coal tar used in the production of anhydrous taphole mud according to any one of Embodiments 1 to 7, and the asphalt ratio can be reduced to 3%. Utilize the anhydrous gun mud that the coal tar in the embodiment 1~7 produces in Liaoning Yingkou Iron and Steel Works 1350m 3 The test on the blast furnace and the 1080m³ blast furnace of Shengbao Steel, the effect is satisfactory, there is no unpleasant smell during the production and use of the gun mud, the concentration of yellow smoke in front of the furnace is reduced from 85% to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com