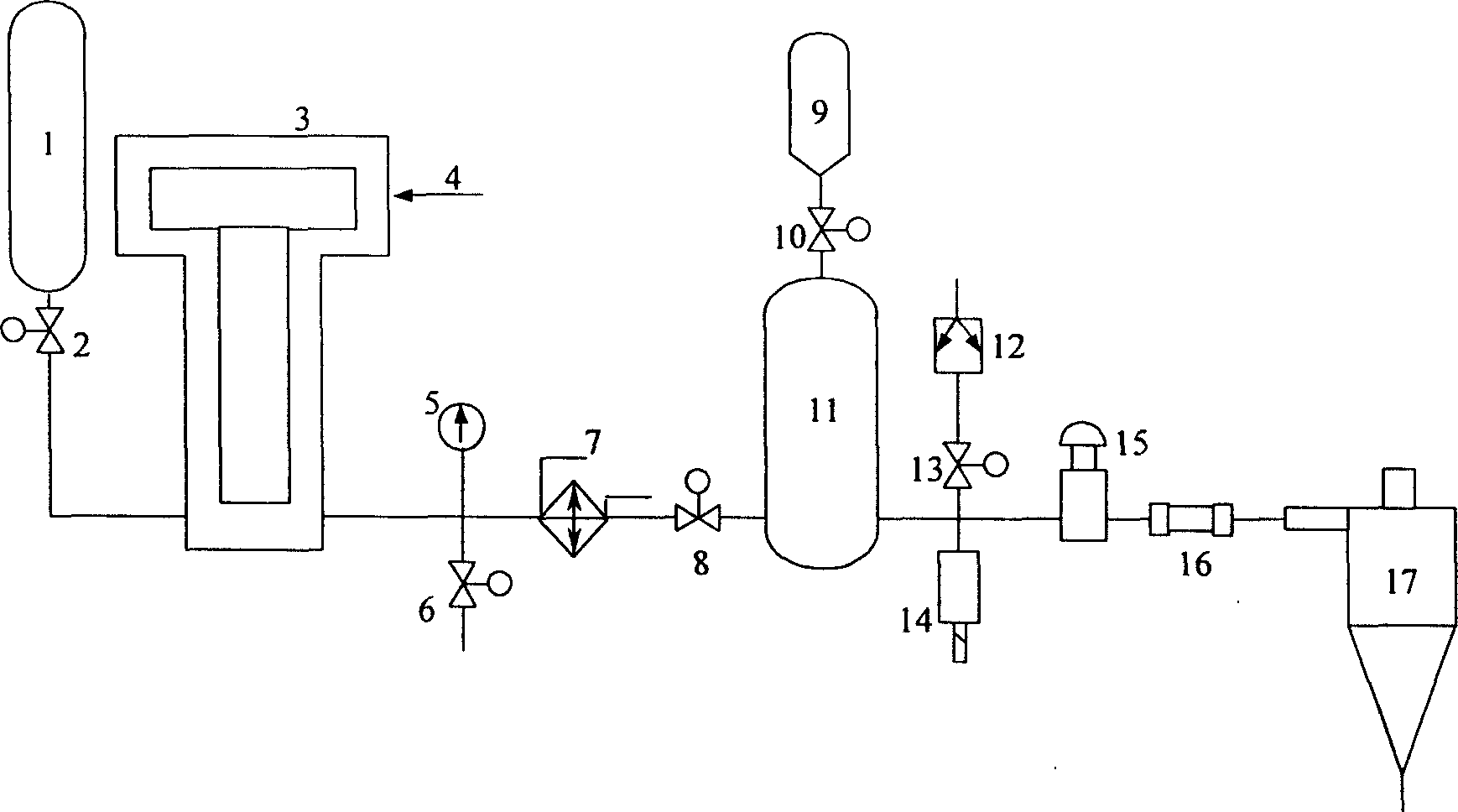

Method and apparatus for preparing superfine powder by super high pressure supercritical fluid micro jetting technology

A technology of supercritical fluid and ultrafine powder, applied in the field of ultrafine powder, can solve the problems of reducing product purity, separation energy consumption and energy reduction, etc., achieving simple final separation, improving pulverization effect, and energy The effect of increased utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

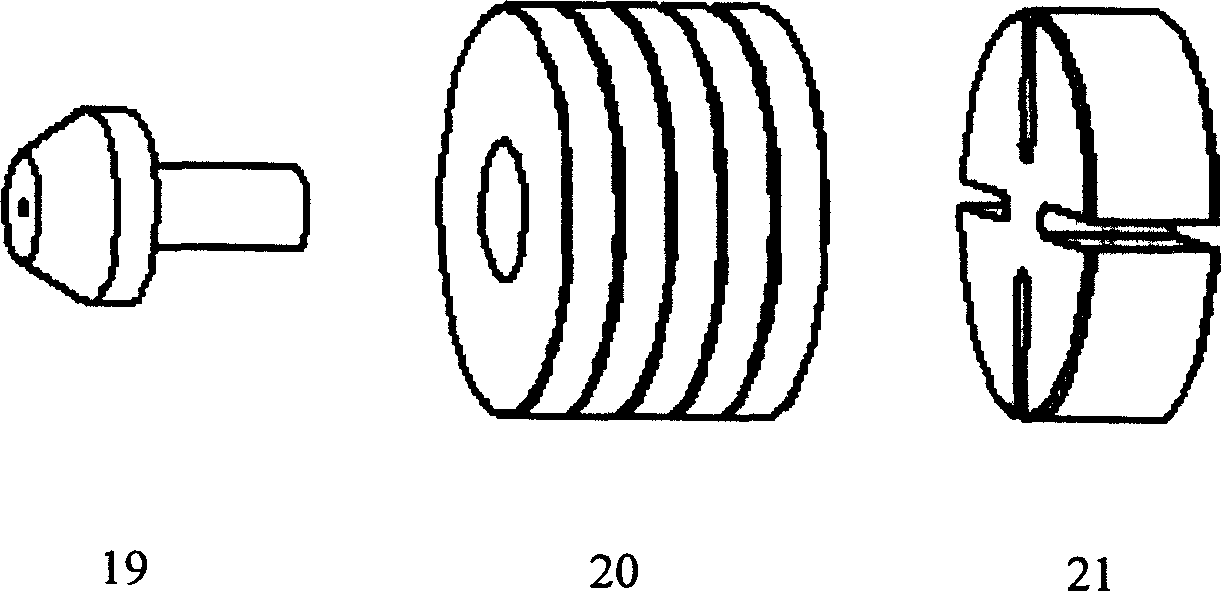

Method used

Image

Examples

Embodiment

[0051] Embodiment: under 300MPa, 250 ℃ (the temperature of the outer wall of the raw material mixing tank), the ultra-high pressure supercritical micro-jet pulverizing system of the present invention is used to carry out the ganoderma spore crushing experiment. out, pulverize in a micro jet pulverizer, and obtain the final product in a cyclone separator. Observed under a microscope, the original size of the Ganoderma lucidum spore powder is 7-10 μm, and the wall breaking rate of the crushed spore powder reaches 88.48%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| critical point | aaaaa | aaaaa |

| critical point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com