Lithium ion battery anode material as well as preparation method and battery thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of lithium-ion battery positive electrode materials and their preparation and batteries, and can solve problems such as agglomeration, low discharge specific capacity of materials, and low production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Since the present invention only relates to the improvement of the preparation method of the positive electrode of the lithium secondary battery, other steps are known to those skilled in the art except that the positive electrode is prepared according to the method provided by the present invention. In general, it includes disposing a separator between the positive electrode and the negative electrode to form an electrode group, accommodating the electrode group in a battery case, injecting an electrolyte solution, and sealing the battery case.

[0027] The present invention only relates to the improvement of the preparation method of the positive electrode of the battery, so there is no special limitation on the composition and structure of the lithium secondary battery (unless otherwise specified, the reagents involved in the specific embodiments of the present invention are commercially available analytical reagents) .

[0028] For example, the current collector can...

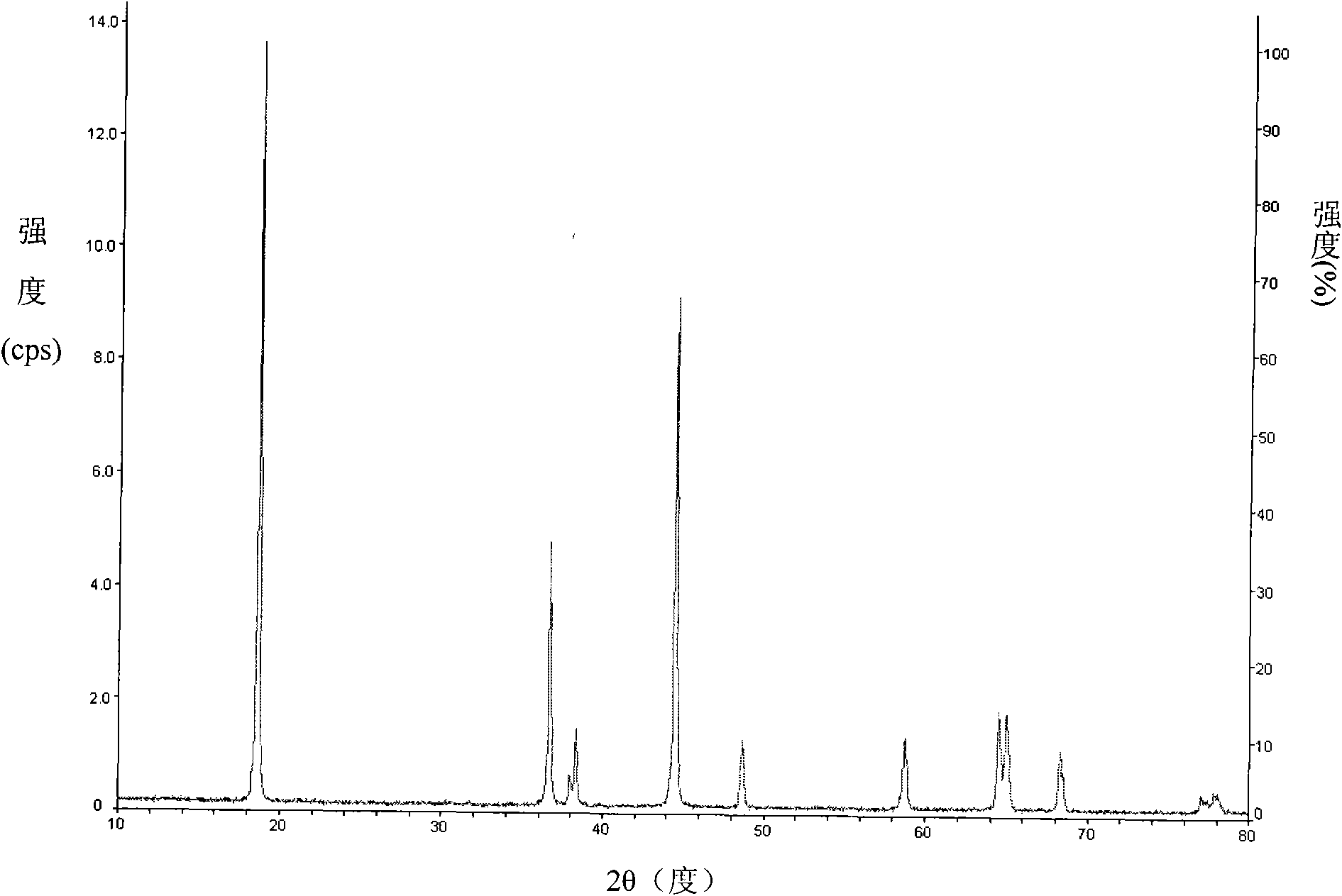

Embodiment 1

[0039] (1) Preparation of cathode material

[0040] Aluminum-containing high-cobalt spherical nickel Ni 0.80 co 0.15 al 0.05 (OH) 2 Mix well with lithium carbonate at a molar ratio of 1:0.53, calcinate the mixture at 600°C for 6 hours in an oxygen atmosphere, then sinter in situ at 800°C for 15 hours in an oxygen atmosphere, cool the product, crush it and gas crush it to obtain spherical lithium nickel cobalt Alumina material LiNi 0.80 co 0.15 al 0.05 o 2 Precursor. Will LiNi 0.8 0Co 0.15 al 0.05 o 2 The precursor was annealed and sintered for the third time at 800° C. for 4 hours in an oxygen atmosphere, and the product was cooled, crushed, and gas-crushed to obtain positive electrode material A.

[0041] (2) Preparation of positive electrode sheet

[0042] Dissolve 30 grams of polyvinylidene fluoride (PVDF) in 450 grams of N-methylpyrrolidone (NMP) solvent to prepare a binder solution, then add 940 grams of positive active material and 30 grams of acetylene blac...

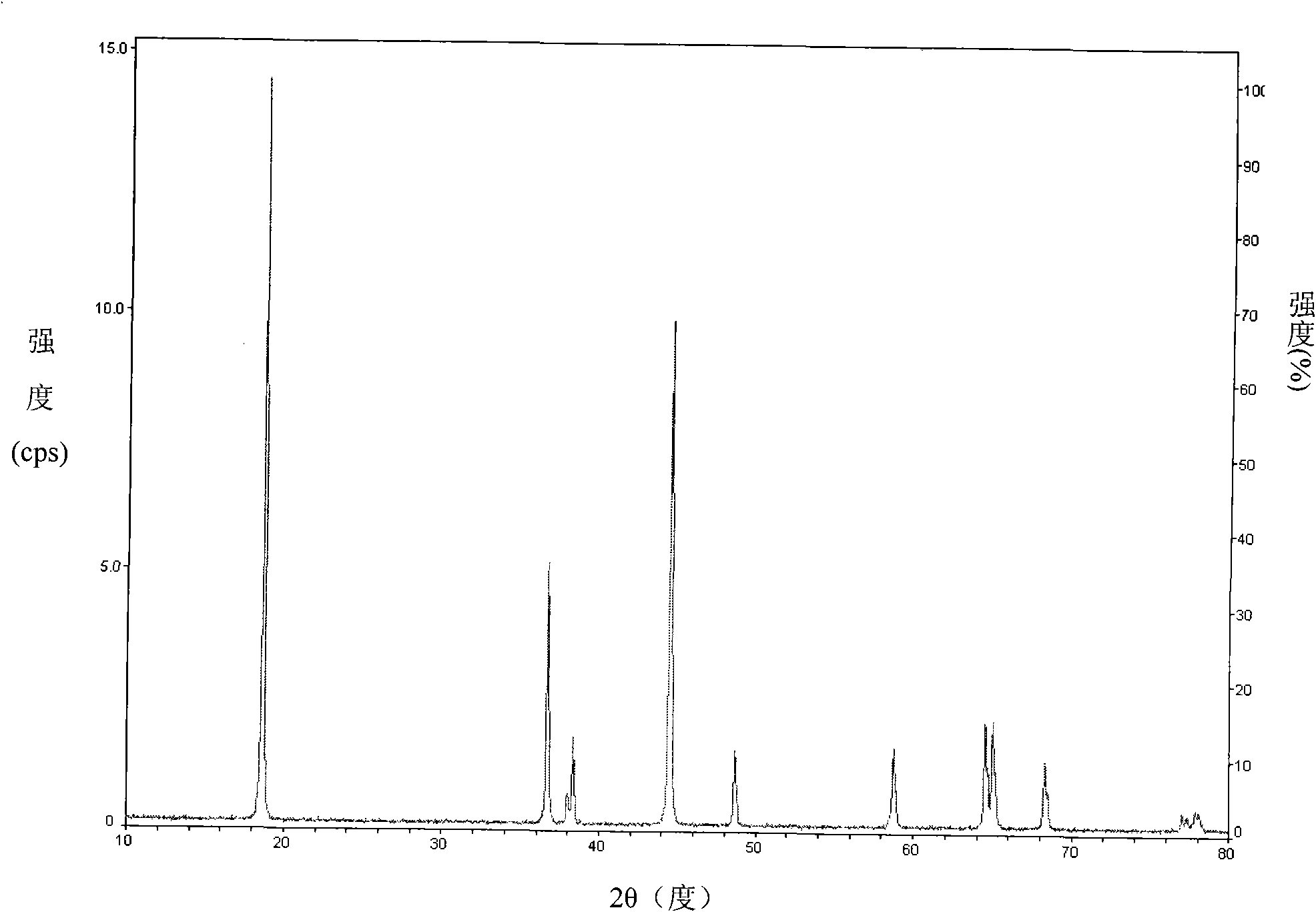

Embodiment 2

[0051] The synthesis method and battery manufacturing method are the same as in Example 1, except that the Ni 0.80 co 0.15 Al 0.05 (OH) 2 Replaced with manganese-containing high-cobalt spherical nickel Ni 0.80 co 0.16 mn 0.04 (OH) 2 , the prepared cathode material is LiN i0.80 co 0.16 mn 0.04 o 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com