Nutrient released modle of compound controlled releasing and production thereof

A production method and technology of compound fertilizer, which are applied in fertilization device, fertilizer mixture, application and other directions, can solve the problems of complex impurity composition, difficult control and high production cost, and achieve the effects of simple operation, wide selection range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

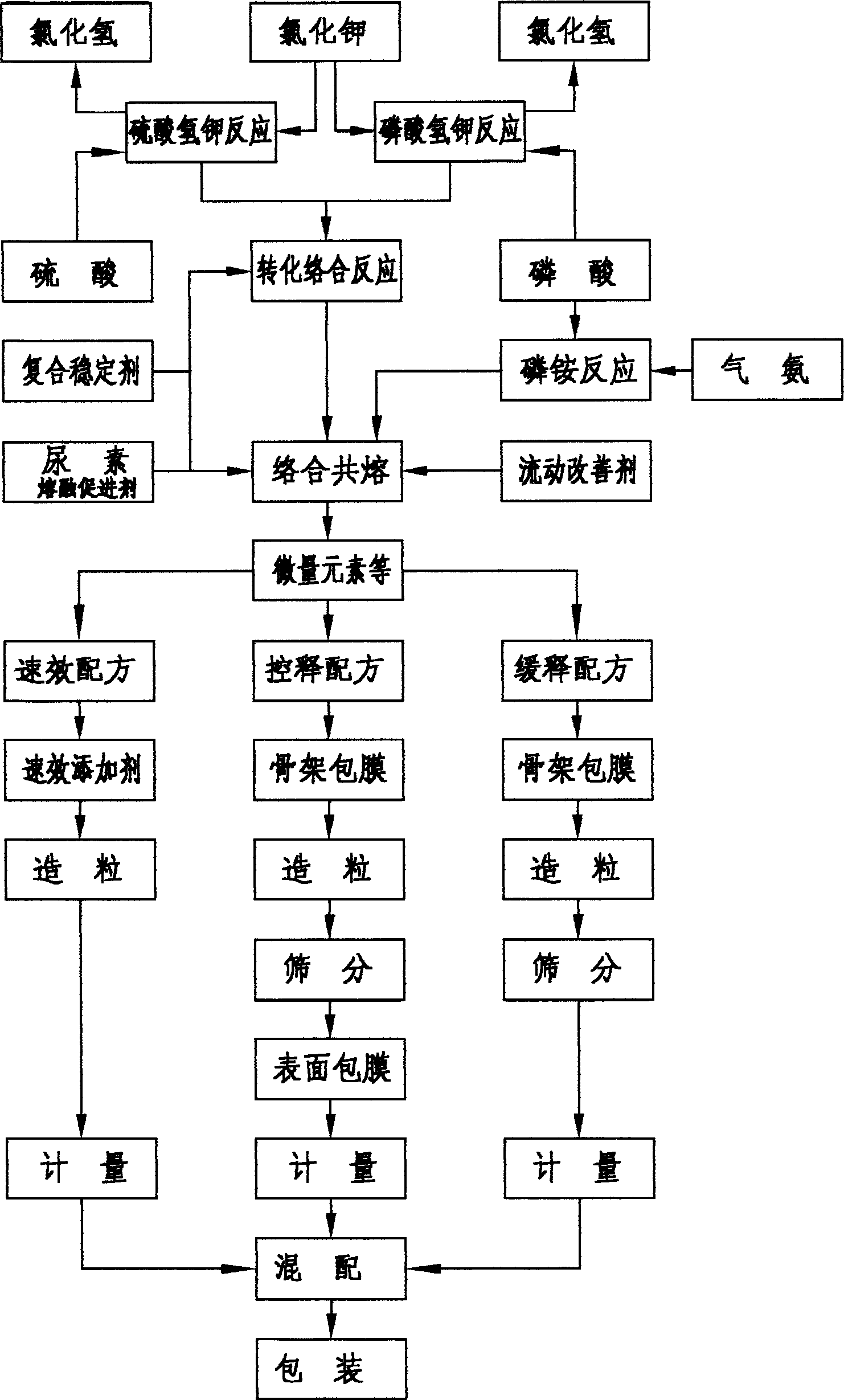

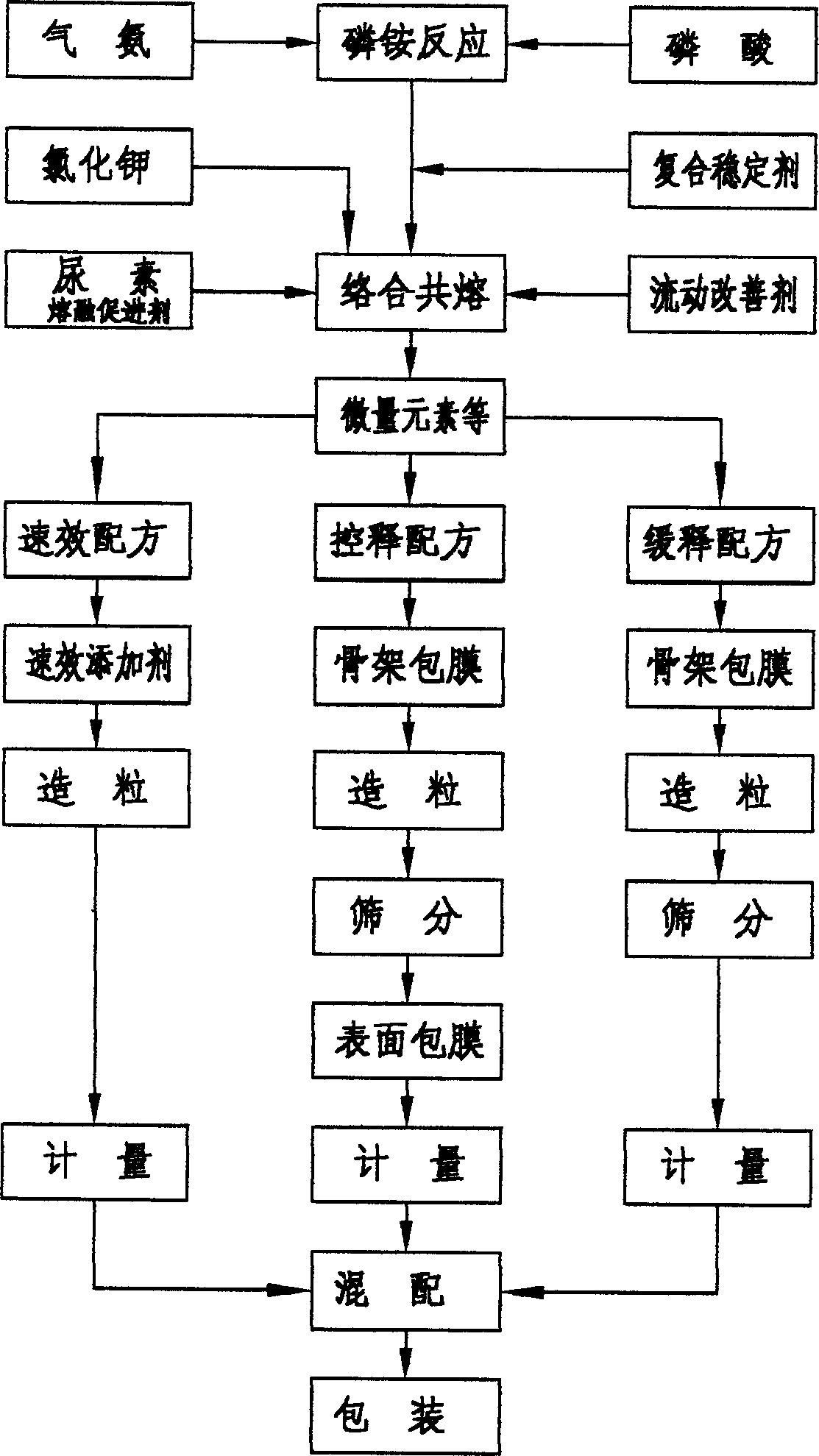

Method used

Image

Examples

Embodiment 1

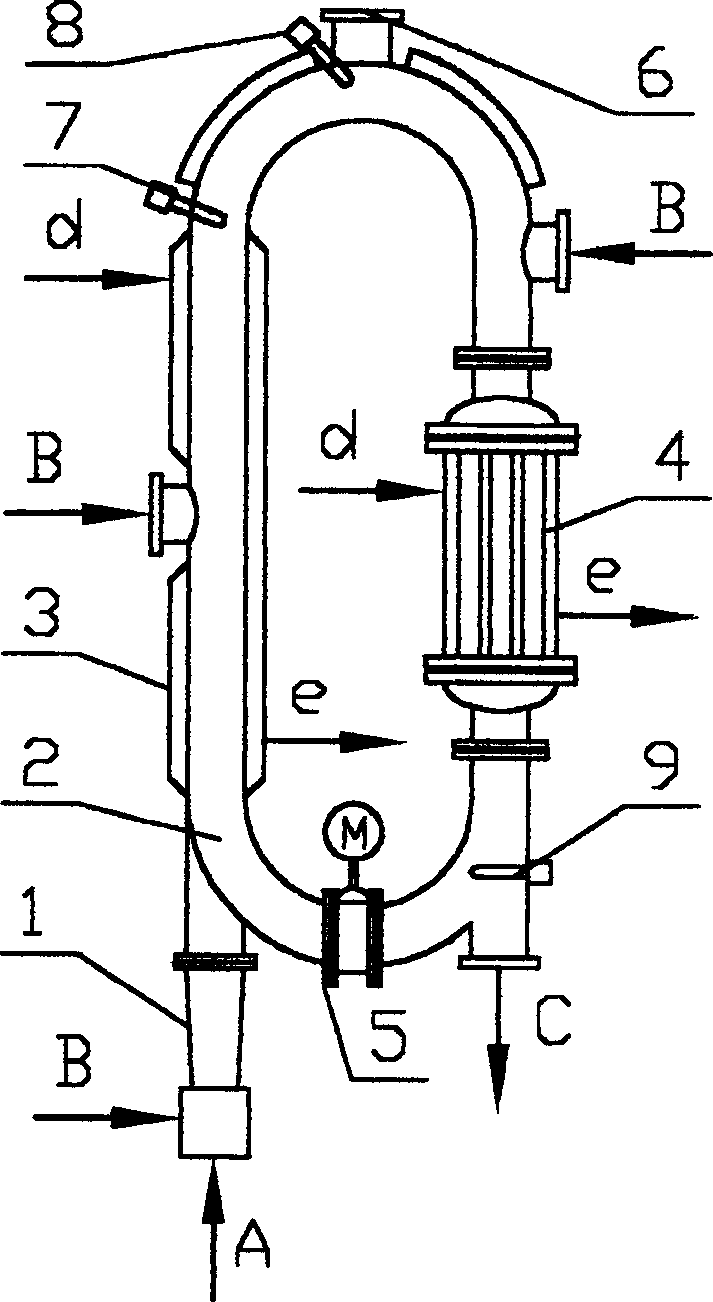

[0073] Put 165kg of 98% sulfuric acid in a 300L reactor with jacket heating and stirring, preheat to about 85°C, and add powder potassium chloride (K 2 (2≥60%) 125kg, in the reaction process, the hydrochloric acid that water jet pump circulation suction reaction process produces, maintains 115~125 ℃ of reaction temperature, reacts 60~90min, obtains potassium bisulfate feed liquid.

[0074] 317kg of 50% phosphoric acid was placed in a 500L thin-layer reaction kettle heated and stirred with a jacket, and powder potassium chloride (K 2 O≥60%) 125kg, during the reaction process, the hydrogen chloride produced in the reaction process is circulated by the water jet pump, the reaction temperature is maintained at 95~125°C, the pressure is -0.6~-0.8Mpa, the reaction is 60min, and the phosphoric acid with a water content of 5~8% is obtained Potassium dihydrogen liquid.

[0075] Put 217 kg of potassium hydrogen sulfate and potassium dihydrogen phosphate obtained from the reaction into ...

Embodiment 2

[0081] Embodiment two (high nitrogen type N: P 2 o 5 : K 2 O=25:10:10)

[0082] Place 111kg of 98% sulfuric acid in a 300L jacketed heating and stirring reactor, preheat to about 85°C, and add powder potassium chloride (K 2 (2≥60%) 84kg, in the reaction process, the hydrochloric acid that water injection pump circulation suction reaction process produces, maintains 115~125 ℃ of reaction temperature, reacts 60~90 minutes, obtains potassium bisulfate feed liquid.

[0083] With 50% phosphoric acid 213kg, place in the thin-layer reactor of 300L band jacket heating and stirring, add powder potassium chloride (K 2 (O≥60%) 84kg, in the reaction process, the hydrochloric acid that the hydrojet pump circulation suction reaction process produces, maintains reaction temperature 95~110 ℃, pressure-0.6~-0.8Mpa, reacts for 60 minutes, obtains water content 5~8% Potassium dihydrogen phosphate liquid.

[0084] Put the potassium hydrogen sulfate and potassium dihydrogen phosphate obtain...

Embodiment 3

[0085] Embodiment three (high potassium type N: P 2 o 5 : K 2 O=15:10:20)

[0086] Put 280kg of 50% phosphoric acid in a 200L jacketed thin-layer reactor for heating and stirring, add 86kg of molten urea while stirring, maintain the reaction temperature at 95-110°C, and react for 40 minutes to obtain phosphoric acid with a water content of 8-15%. urea.

[0087] Potassium chloride powder (K 2 (0≥60%) 334kg is added to 1200L melting and complexing reactor, is mixed with the melting urea (241kg) that is added with complexing accelerator in the reactor and co-melts, and then the urea phosphate that above-mentioned reaction obtains is pumped in, promotes in complexing Partially generate the translucent mixed slurry of urea complex under the action of the agent, then add the slurry fluidity improver (15kg), trace elements 107kg, and functional additive 94kg. Prepared to contain N:P 2 o 5 : K 2 O=15:10:20, mixed molten slurry containing about 5-8% water. Then add 40kg of ske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com