Fine-crushing soybean milk machine

A soymilk maker and micro-grinding technology, applied in milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of difficulty in obtaining slag-free soymilk, reduced crushing efficiency, and single crushing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

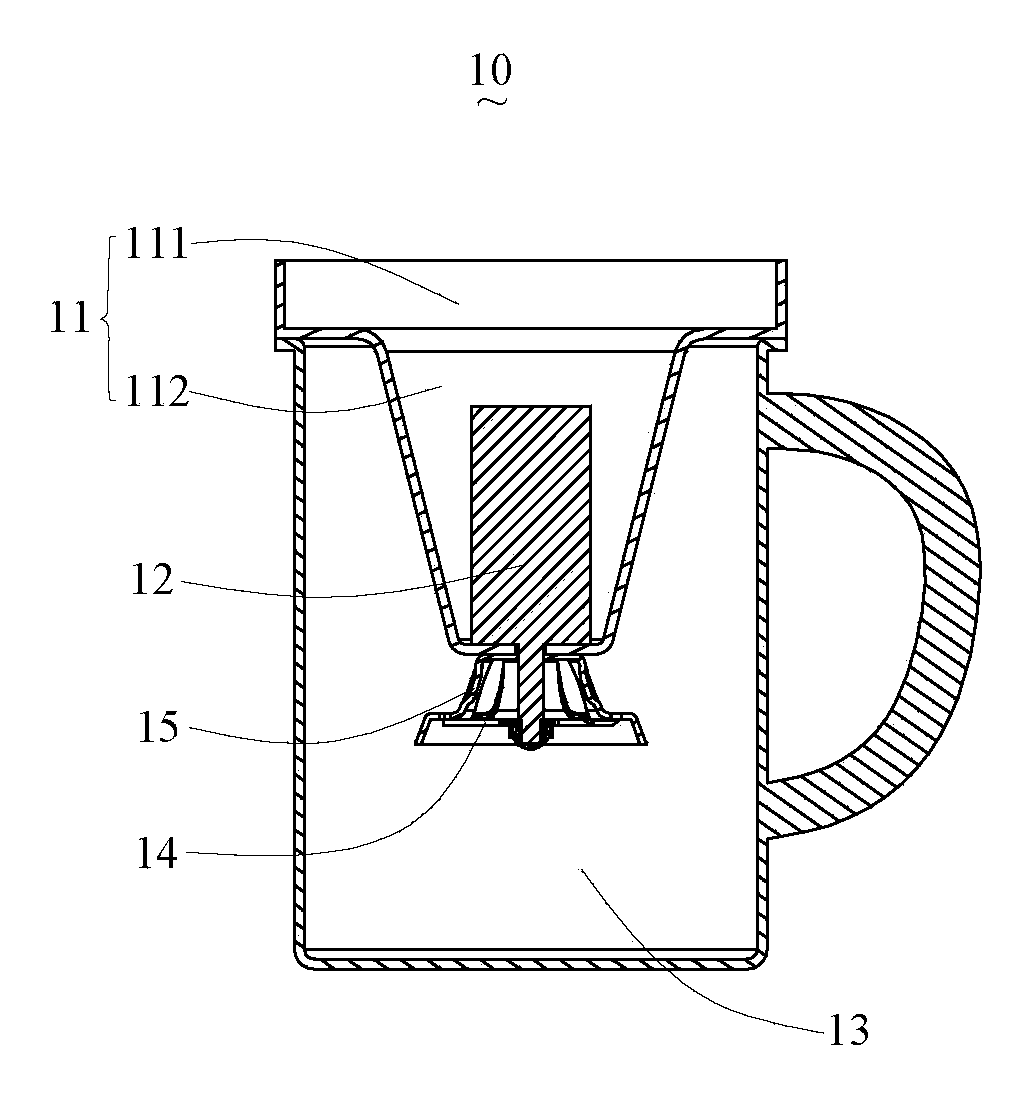

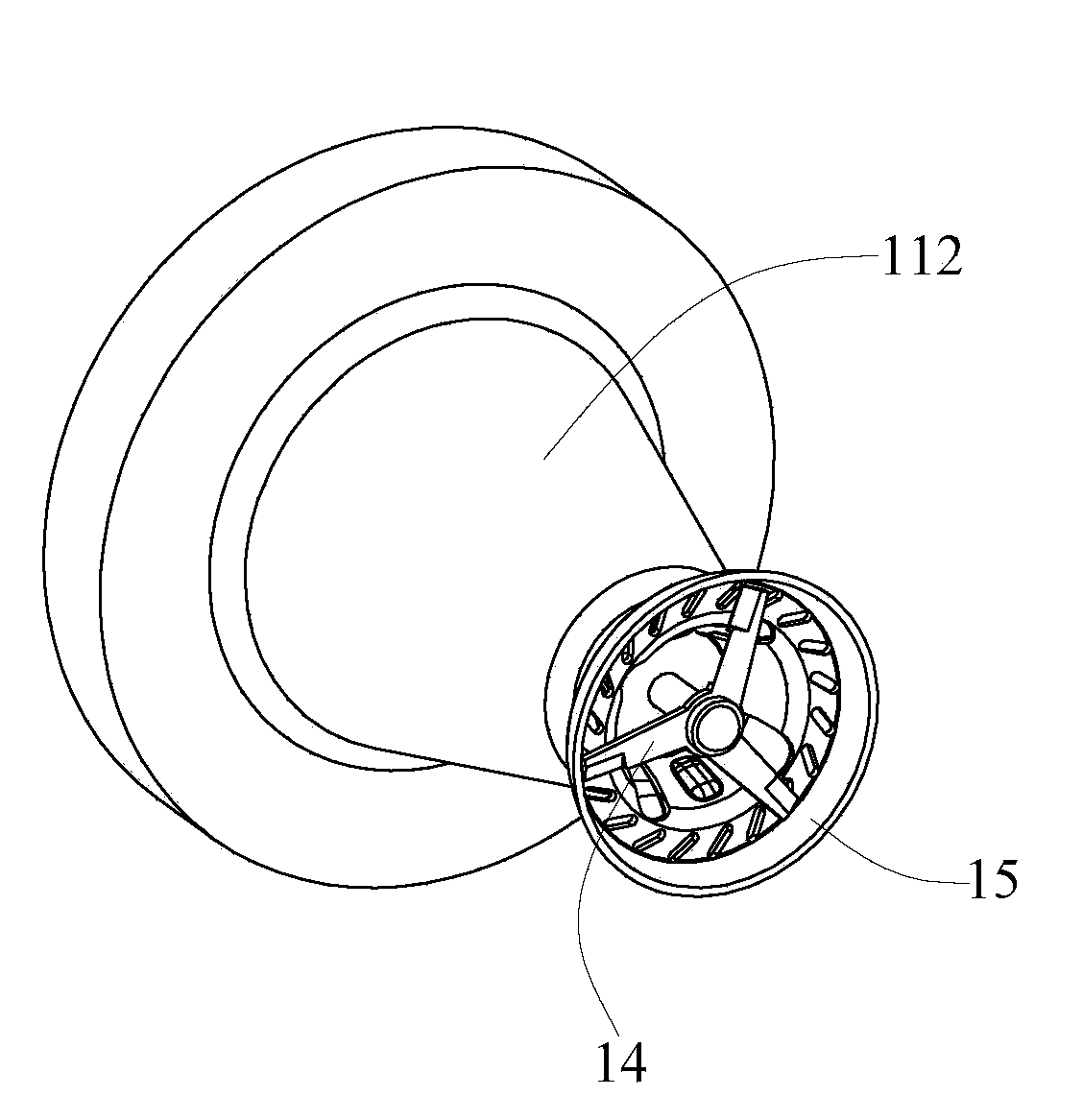

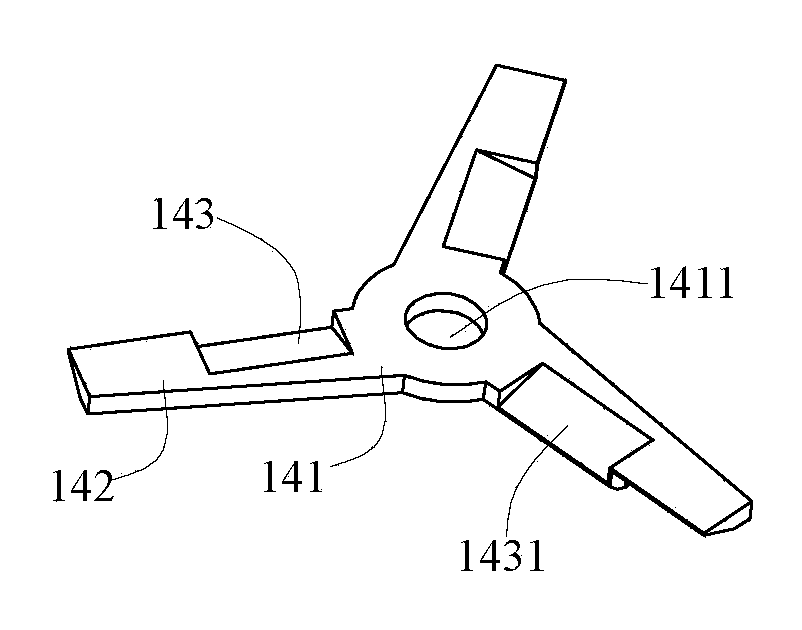

[0042] Please also refer to figure 1 and figure 2 Shown is the first preferred embodiment of the finely pulverized soybean milk machine of the present invention. The finely pulverized soybean milk machine 10 includes a head 11 , a motor 12 , a cup body 13 , a crushing cutter 14 and a control unit (not shown). The machine head 11 is fastened on the cup body 12 . The motor 12 is installed in the machine head 11 . The motor 12 is electrically connected with the control unit, and the motor 12 drives the crushing cutter 14 to rotate. A crushing cover 15 is also fixed on the machine head 11 . The crushing tool 14 is located in the crushing cover 15 .

[0043] The machine head 11 includes an upper head cover 111 and a lower head cover 112 . Described motor 12 is installed in the machine head lower cover 112, and the motor shaft of this motor 12 stretches out from the machine head lower cover 112. The cutter shaft is the motor shaft, and the crushing cutter 14 is directly fixed...

Embodiment approach 2

[0059] see Figure 9 The second preferred embodiment of the finely pulverized soymilk maker of the present invention is shown. The difference between the finely pulverized soymilk maker 20 and the finely pulverized soymilk maker 10 is that the finely pulverized soymilk maker 20 is a motor-mounted soymilk maker, and the finely pulverized soymilk maker Machine 20 comprises machine base 21, motor 22, cup body 23, pulverizing cutter 24, and cup body 23 is fastened on the machine base 21, and motor 22 is installed in the machine base 21, and motor 22 drives pulverizing knife 24 to rotate, and described cup body 23 bottoms are also fixed with a crushing cover 25, and the crushing cutter 24 is located in the crushing cover 25.

[0060] In this embodiment, the crushing tool 24 is fixed on the cutter shaft 241, and the cutter shaft 241 penetrates the bottom of the cup body 23 and extends into the cup body 23. One end of the cutter shaft 241 is fixed with the crushing tool 24, and the o...

Embodiment approach 3

[0064] Please also refer to Figure 10 and Figure 11 The third preferred embodiment of the finely pulverized soymilk machine of the present invention is shown. The difference between the finely pulverized soymilk machine 30 and the pulverized soymilk machine 10 is that the crushing cover 61 includes a mounting part 611 and a shearing device connected to the mounting part 611. A shearing hole 613 is opened on the shearing plane 612, and the shearing plane 612 is perpendicular to the motor shaft.

[0065] understandable, see Figure 12 , the shearing surface may also be provided with a shearing groove 614 .

[0066] In this implementation manner, other structures and beneficial effects are the same as those in the first implementation manner, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com