Full-highland-barley compressed biscuit and processing technology thereof

A technology for compressing biscuits and production processes, applied in baking, dough processing, baked food and other directions, can solve the problems of inconvenience to carry and eat, limit the geographical scope of highland barley consumption, and cannot be widely promoted, etc. Absorption, short heating time and less loss of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

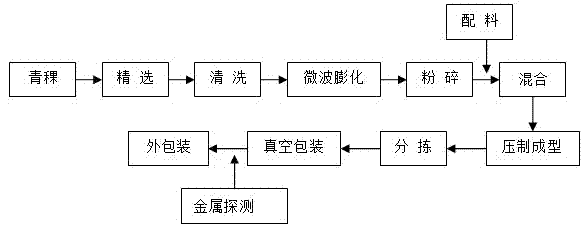

[0041] Such as figure 1 Shown, a kind of production technology of full highland barley compressed biscuit comprises the steps:

[0042] Step (1), raw material collection and storage: select the highland barley produced by the green food raw material base, the quality of impurities in the highland barley is not higher than 1% of the total mass, and the grains are full;

[0043] Step (2), selection: the highland barley is selected, and the selected highland barley raw material should be guaranteed to be shell-free and free of impurities;

[0044] Step (3), cleaning: Soak the highland barley obtained in step (3) in water for not less than 12 hours, then wash with water to remove dust on the surface of the highland barley, and at the same time, the moisture content of the highland barley after cleaning is required to be 38-42% ;

[0045] Step (4), microwave curing: the highland barley cleaned in step (3) is subjected to microwave curing at a temperature of 135-140°C for 6 minut...

Embodiment 2

[0053] Such as figure 1 Shown, a kind of production technology of full highland barley compressed biscuit comprises the steps:

[0054] Step (1), raw material collection and storage: select the highland barley produced by the green food raw material base, the quality of impurities in the highland barley is not higher than 1% of the total mass, and the grains are full;

[0055] Step (2), selection: the highland barley is selected, and the selected highland barley raw material should be guaranteed to be shell-free and free of impurities;

[0056] Step (3), cleaning: Soak the highland barley obtained in step (3) in water for no less than 12 hours, then wash with water to remove the dust on the surface of the highland barley. At the same time, the moisture content of the highland barley after cleaning is required to be 39-41% ;

[0057] Step (4), microwave curing: the highland barley cleaned in step (3) is subjected to microwave curing at a temperature of 138-142°C for 7 minute...

Embodiment 3

[0065] Such as figure 1 Shown, a kind of production technology of full highland barley compressed biscuit comprises the steps:

[0066] Step (1), raw material collection and storage: select the highland barley produced by the green food raw material base, the quality of impurities in the highland barley is not higher than 1% of the total mass, and the grains are full;

[0067] Step (2), selection: the highland barley is selected, and the selected highland barley raw material should be guaranteed to be shell-free and free of impurities;

[0068] Step (3), cleaning: Soak the highland barley obtained in step (3) in water for not less than 12 hours, then wash with water to remove the dust on the surface of the highland barley, and at the same time, the moisture content of the highland barley after cleaning is required to be 40-42% ;

[0069] Step (4), microwave curing: the highland barley cleaned in step (3) is subjected to microwave curing at a temperature of 141-145°C for 8 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com