40-type whole-water-jacket automatic turning ultrafine pulverizer

An ultrafine pulverizer and automatic turning technology, which is applied in grain processing and other directions, can solve the problems of not being able to meet the production requirements of customers, unreasonable structural design, and difficulty in reaching customers, so as to save labor costs, prolong the service life, The effect of lowering the operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the examples.

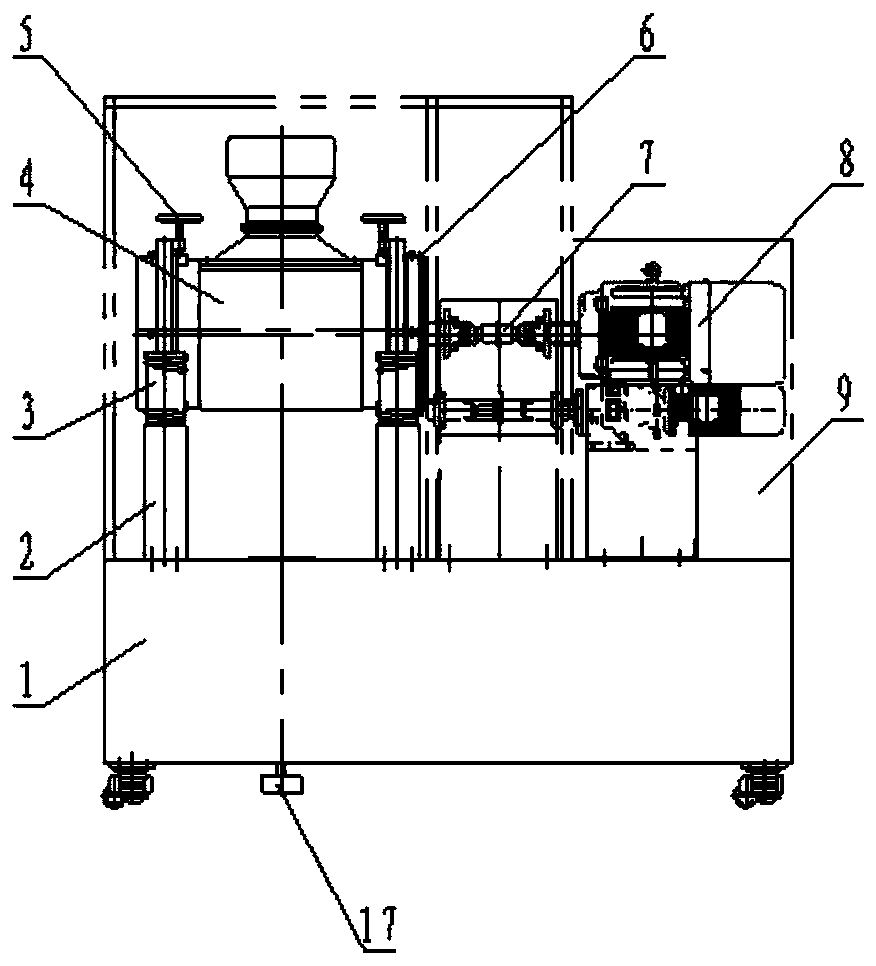

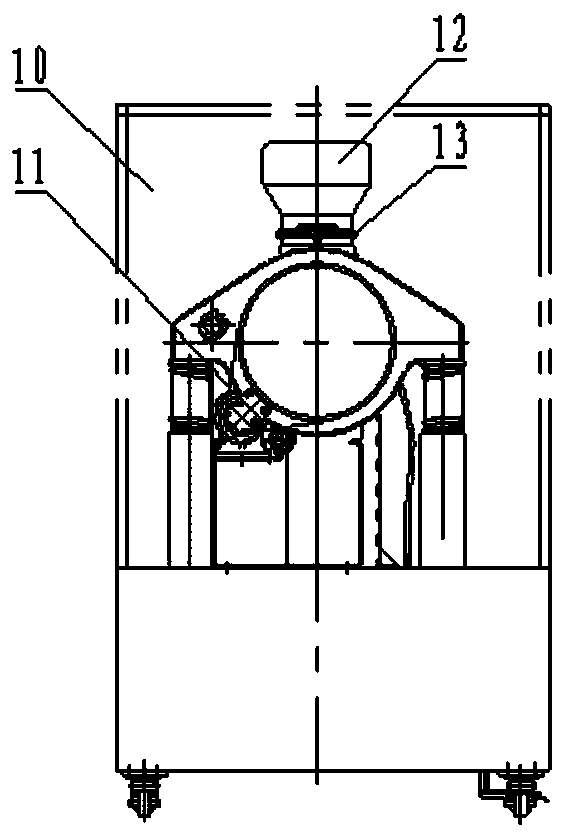

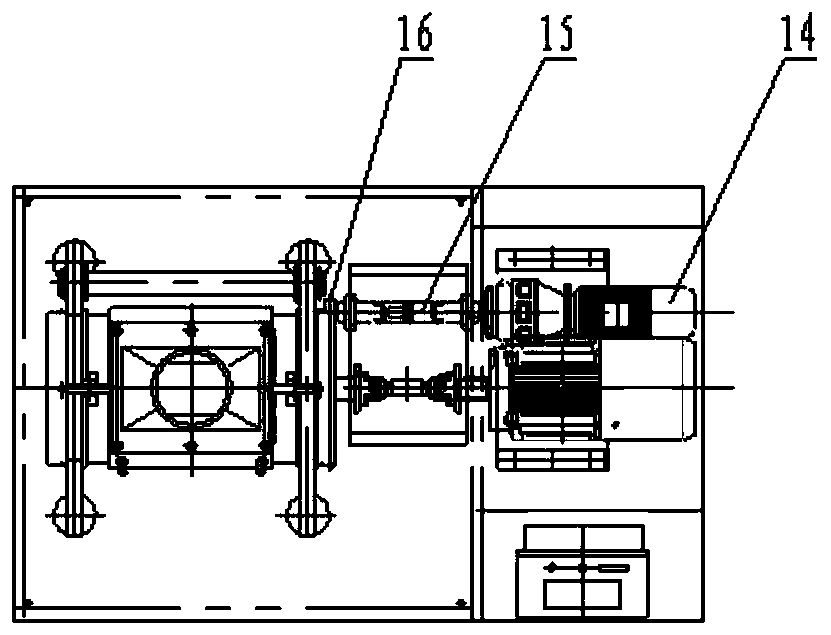

[0032] The invention discloses a 40-type full-water jacket automatic flip ultrafine pulverizer, which includes a full-water jacket grinding cylinder device, a grinding cylinder turning device, and a lifting device 17, wherein:

[0033] The full water jacket grinding cylinder device includes a table 1, a column 2 arranged on the table 1, a vibration isolation spring 3 installed on the column 2, a stand installed on the vibration isolation spring 3, and the upper and lower vibration isolation springs respectively 3 and the full water jacket grinding cylinder 4 on the vertical frame, the locking device 5 that is arranged on the vertical frame and connected with the full water jacket grinding cylinder 4, and the clamp 13 that is movably connected with the feed inlet of the full water jacket grinding cylinder 4 , material box 12 movably connected with clamp 13, transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com