Loach settling-type puffing mixed feed and preparing method thereof

An extruded compound feed, sinking technology, applied in the field of loach feed and its preparation, loach sinking extruded compound feed and its preparation field, can solve the problems of increased loach incidence, affecting loach feeding, poor water resistance, etc., to achieve The effect of increasing breeding benefits, improving the body's anti-stress ability, and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

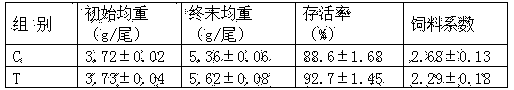

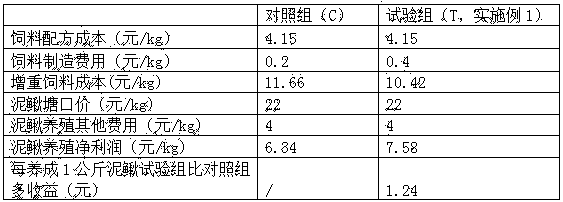

Examples

Embodiment 1

[0030] A loach sinking extruded compound feed comprises the following raw materials in parts by weight:

[0031] 5 parts of fish meal, 6 parts of meat meal, 5 parts of corn gluten meal, 2 parts of hemoglobin powder, 4 parts of fermented soybean meal, 5 parts of soybean, 10 parts of soybean meal, 18 parts of rapeseed meal, 6 parts of DDGS, 15 parts of flour, soybean oil 1.5 parts, 2 parts of calcium dihydrogen phosphate, 2 parts of bentonite, 0.3 parts of 98.5% lysine hydrochloride, 0.05 parts of 99% DL-methionine, 0.05 parts of choline chloride, 0.3 parts of multivitamin premix, 35% vitamin C Phosphate ester 0.02 part, compound mineral premix 1.0 part, sodium butyrate 0.05 part.

[0032] Preferably, the fish meal is imported fish meal, the meat meal is first-grade meat meal, and the DDGS is imported DDGS.

[0033] Preferably, the multivitamin premix is the omnivorous fish vitamin premix of Tongwei Co., Ltd. Sichuan Premix Factory; the multivitamin premix is Tongwei Co., L...

Embodiment 2

[0035] A loach sinking extruded compound feed comprises the following raw materials in parts by weight:

[0036] 3 parts of fish meal, 5 parts of meat meal, 6 parts of corn gluten meal, 3 parts of hemoglobin powder, 6 parts of fermented soybean meal, 4 parts of soybean meal, 8 parts of soybean meal, 20 parts of rapeseed meal, 15 parts of DDGS, 20 parts of flour, soybean oil 2 parts, 2 parts of calcium dihydrogen phosphate, 2 parts of bentonite, 0.25 parts of 98.5% lysine hydrochloride, 0.1 part of 99% DL-methionine, 0.1 part of choline chloride, 0.25 parts of multivitamin premix, 35% vitamin C Phosphate ester 0.03 part, compound mineral premix 1.5 part, sodium butyrate 0.15 part.

[0037] Preferably, the fish meal is imported fish meal, the meat meal is first-grade meat meal, and the DDGS is imported DDGS.

[0038]Preferably, the multivitamin premix is the omnivorous fish vitamin premix of Tongwei Co., Ltd. Sichuan Premix Factory; the multivitamin premix is Tongwei Co., L...

Embodiment 3

[0040] A loach sinking extruded compound feed comprises the following raw materials in parts by weight:

[0041] 4 parts of fish meal, 6 parts of meat meal, 6.5 parts of corn gluten meal, 3.5 parts of hemoglobulin powder, 4.5 parts of fermented soybean meal, 7.5 parts of soybean, 12.5 parts of soybean meal, 21.5 parts of rapeseed meal, 10.5 parts of DDGS, 17.5 parts of flour, soybean oil 2.25 parts, 2.5 parts of calcium dihydrogen phosphate, 2 parts of bentonite, 0.3 parts of 98.5% lysine hydrochloride, 0.15 parts of 99% DL-methionine, 0.1 part of choline chloride, 0.45 parts of multivitamin premix, 35% vitamin C Phosphate ester 0.04 part, compound mineral premix 1.5 part, sodium butyrate 0.15 part.

[0042] Preferably, the fish meal is imported fish meal, the meat meal is first-grade meat meal, and the DDGS is imported DDGS.

[0043] Preferably, the multivitamin premix is the omnivorous fish vitamin premix of Tongwei Co., Ltd. Sichuan Premix Factory; the multivitamin premi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com