Patents

Literature

84results about How to "Less dense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

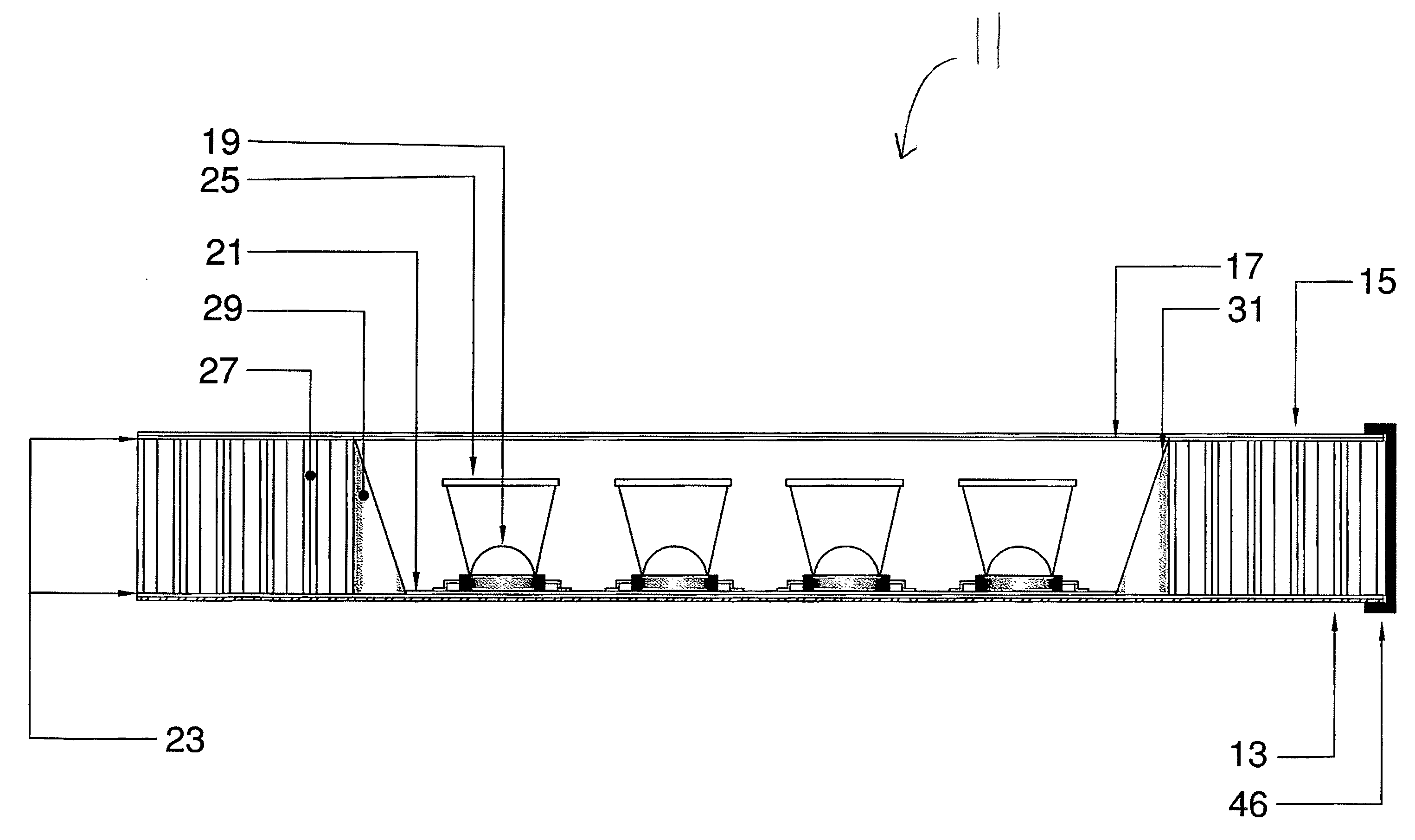

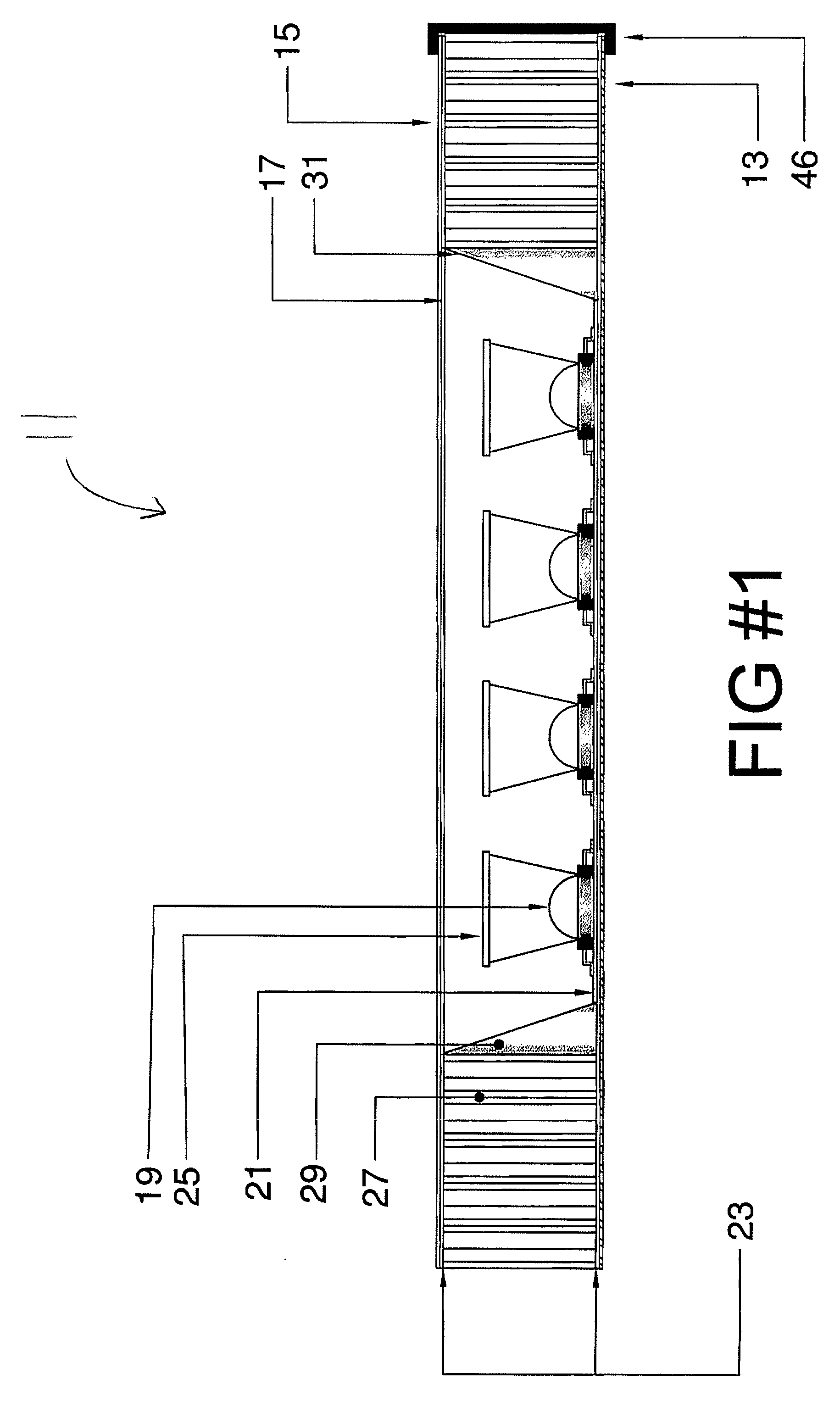

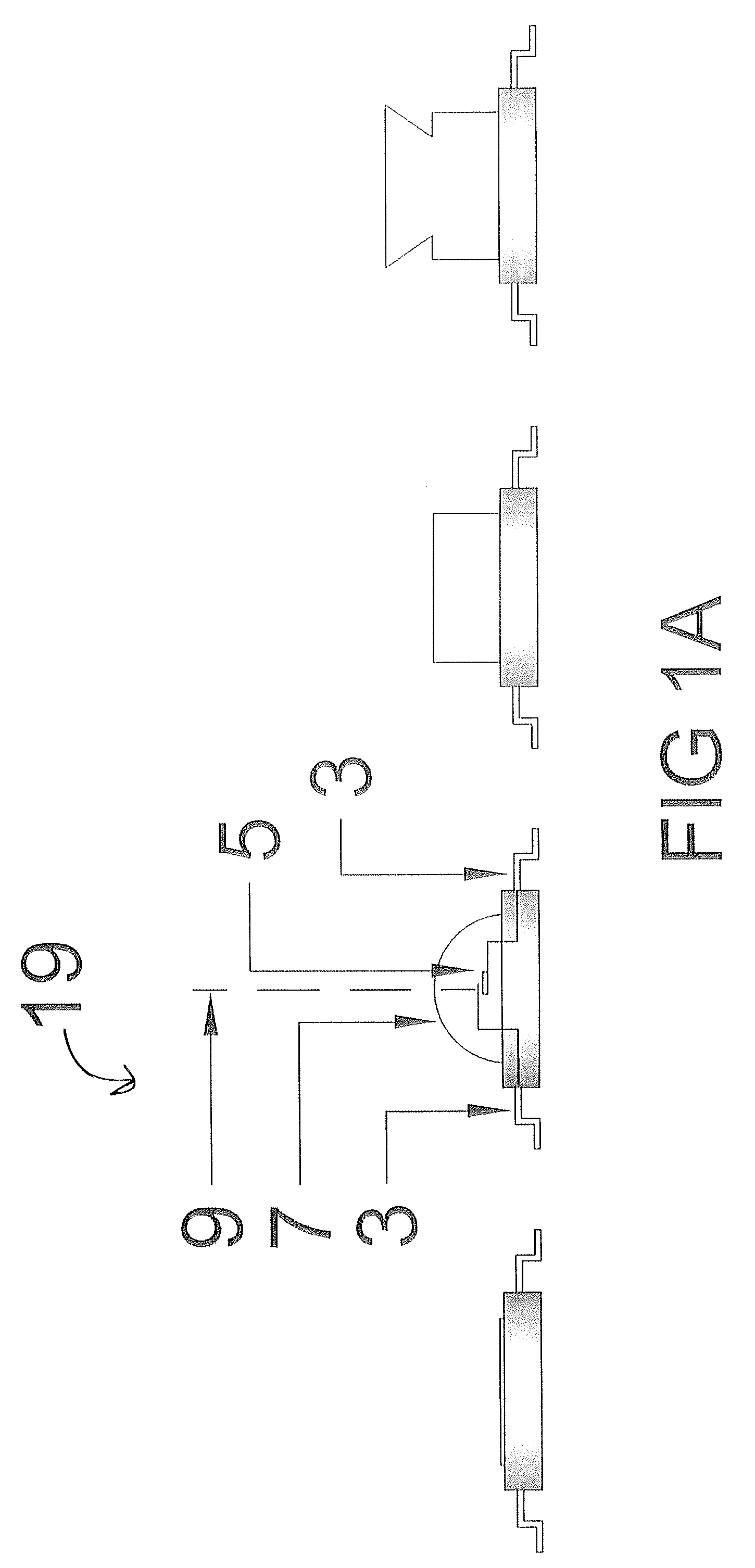

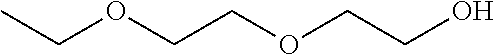

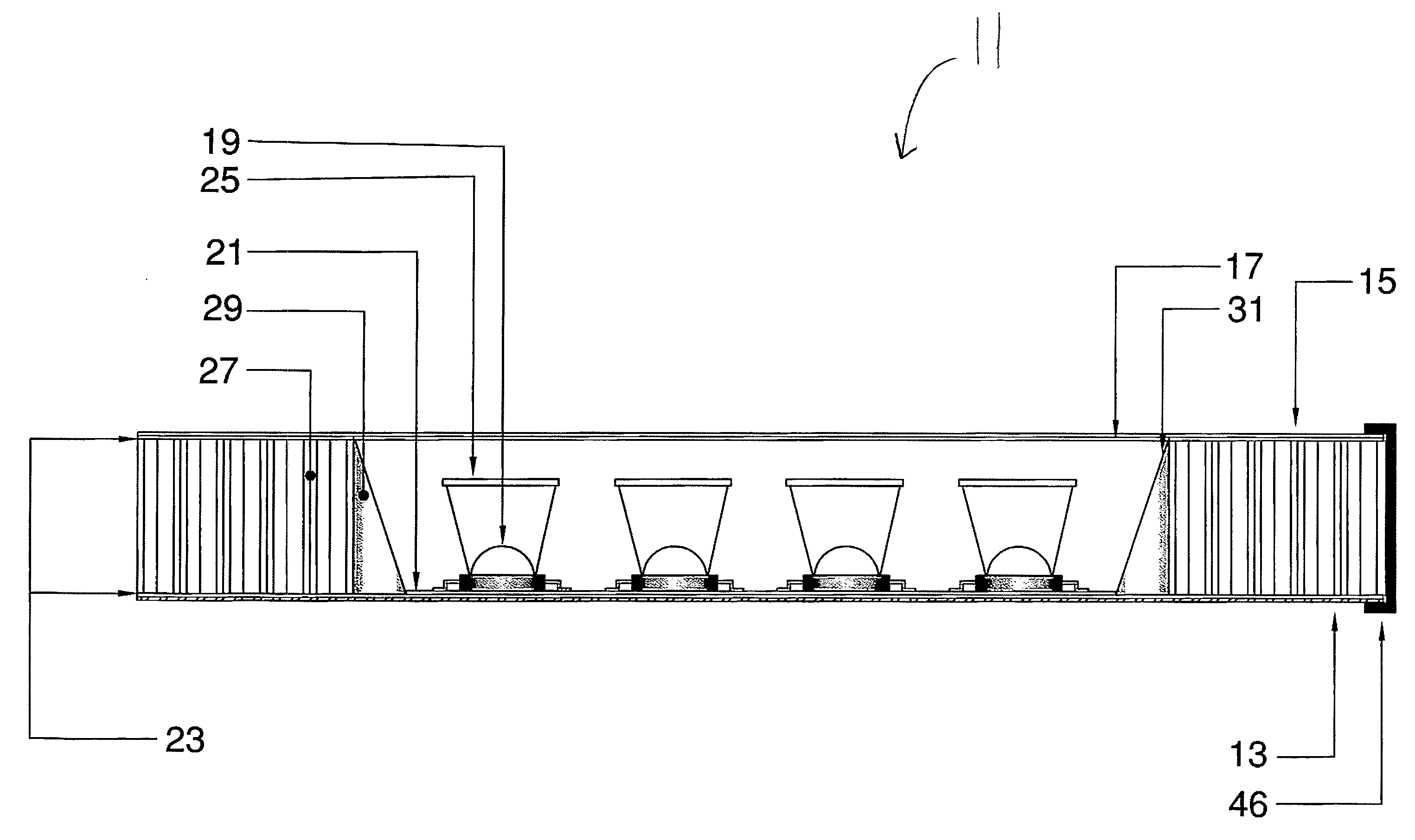

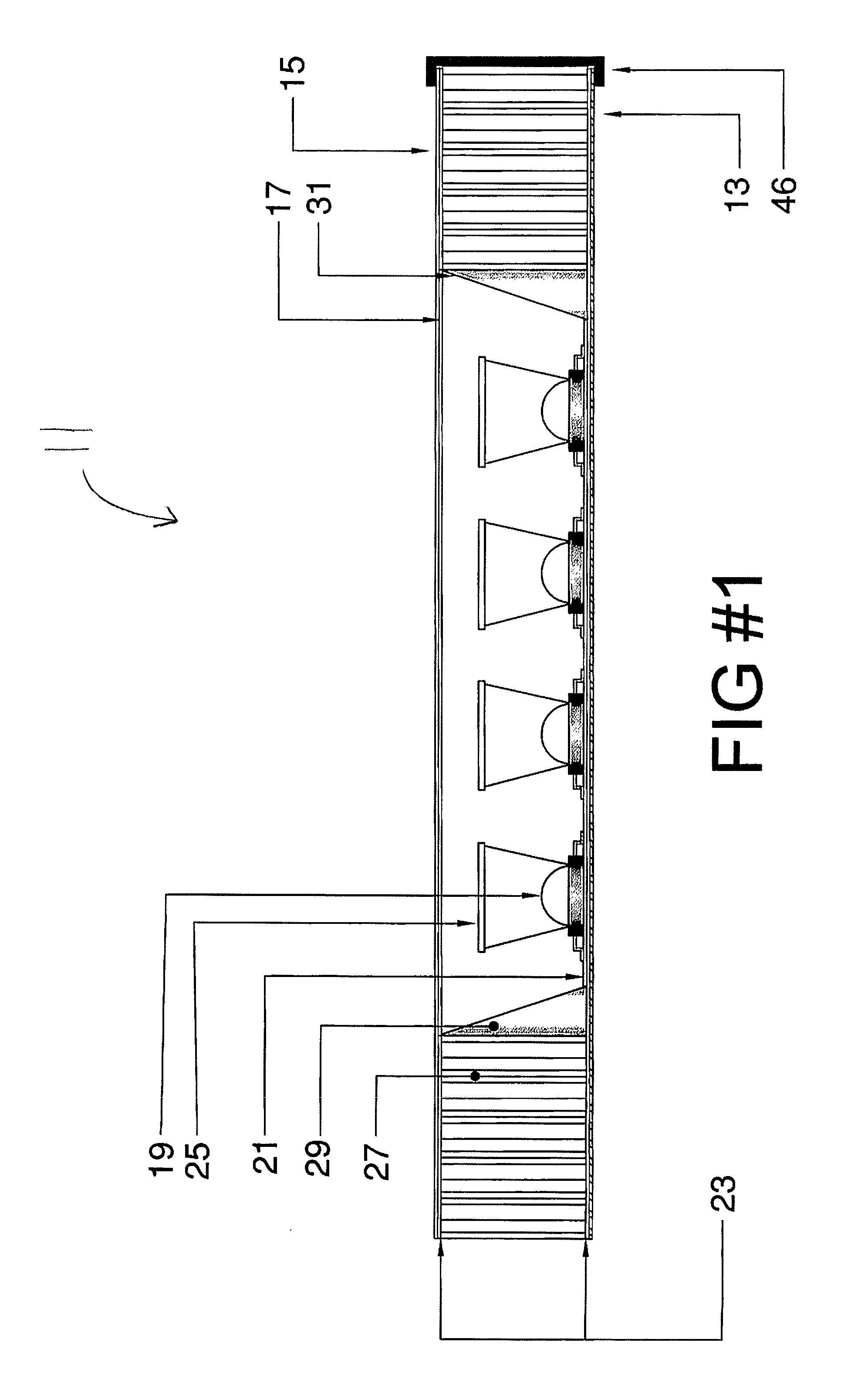

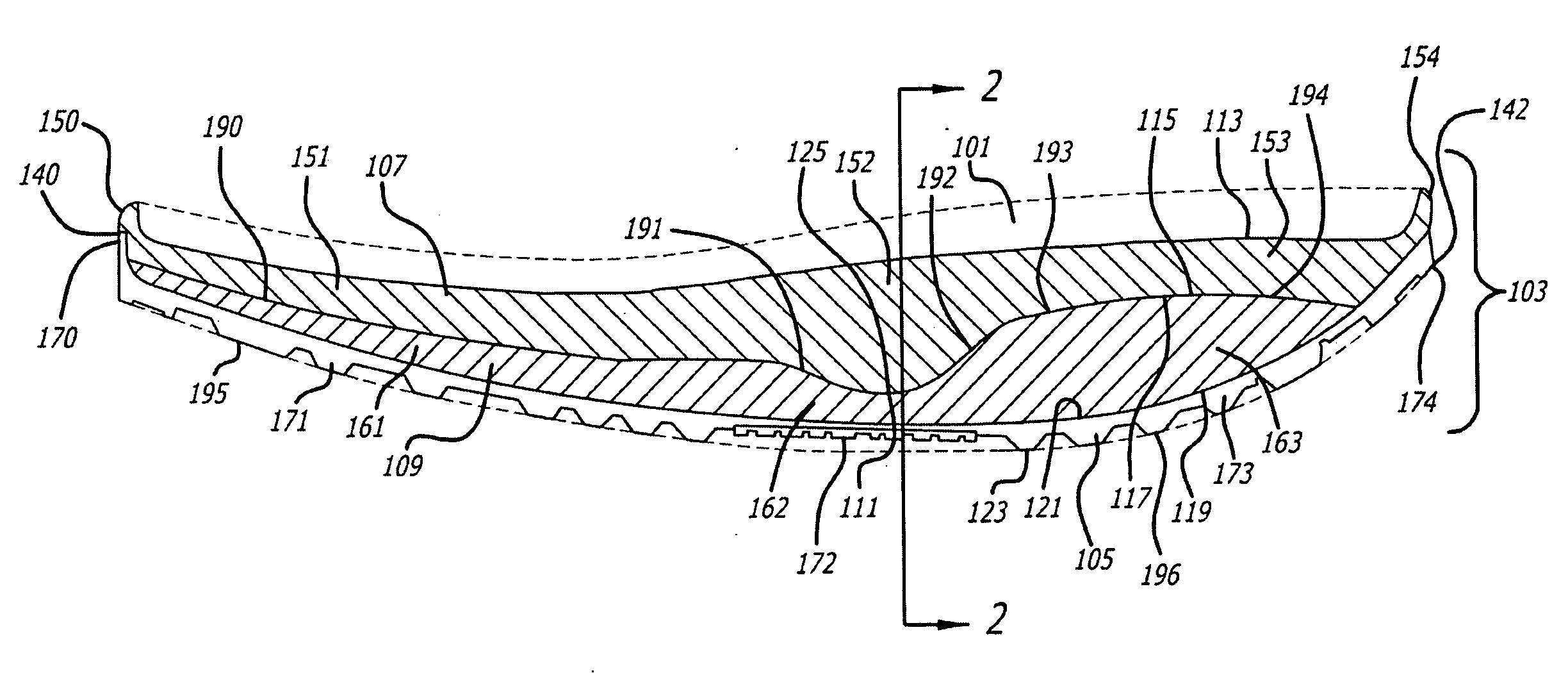

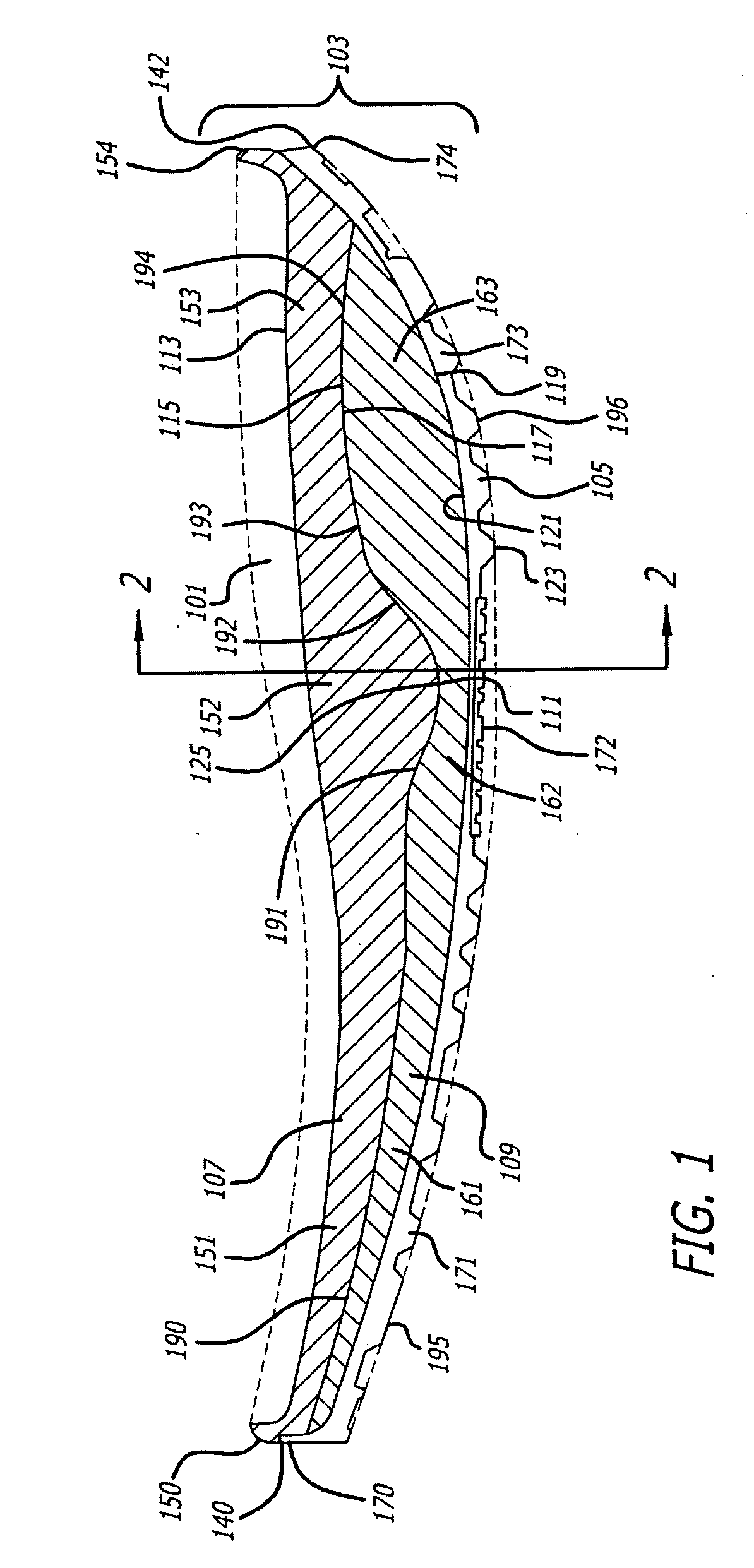

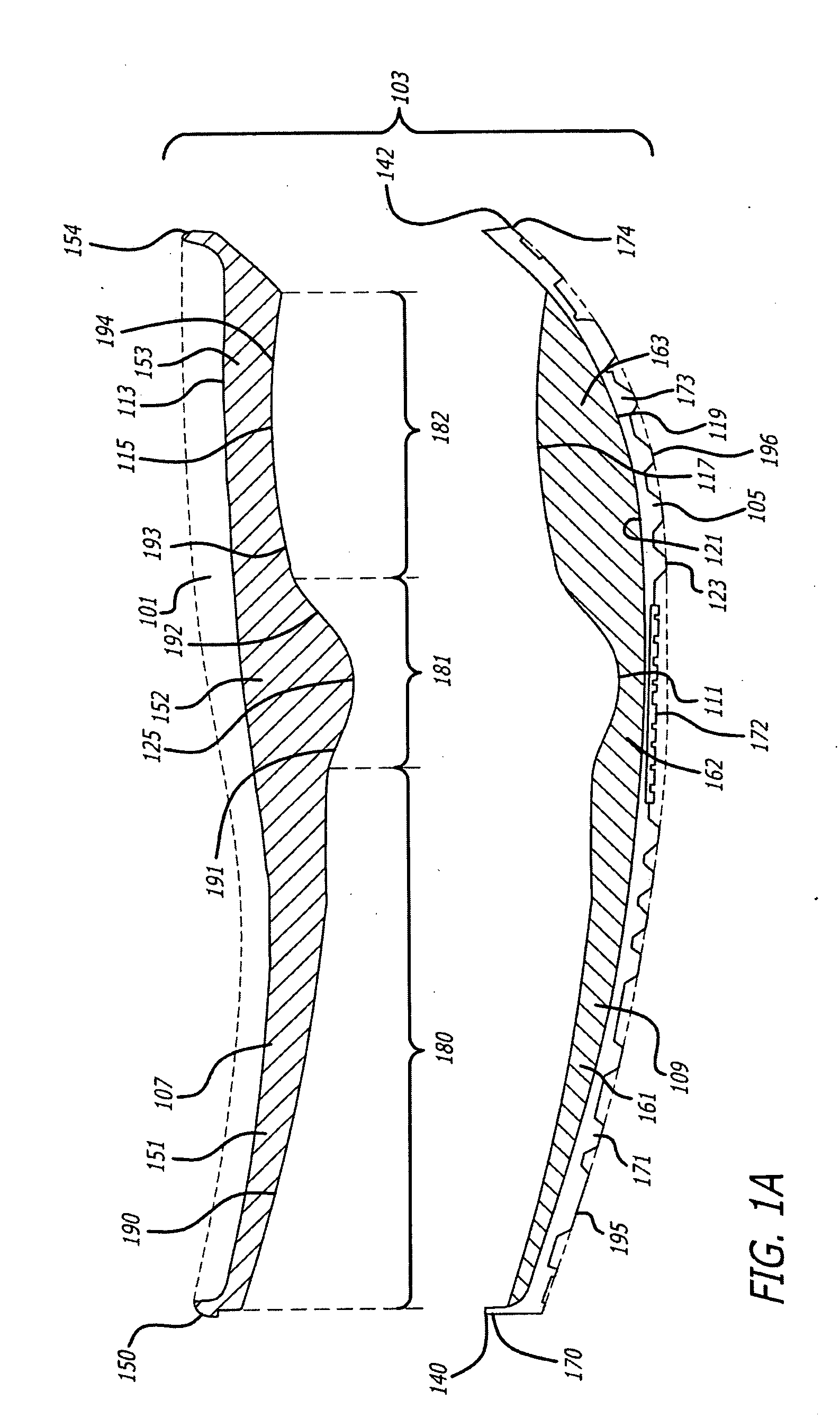

LED light fixture

InactiveUS20070247842A1Low thermal conductivityLower resistancePlanar light sourcesCeilingsInfraredElectricity

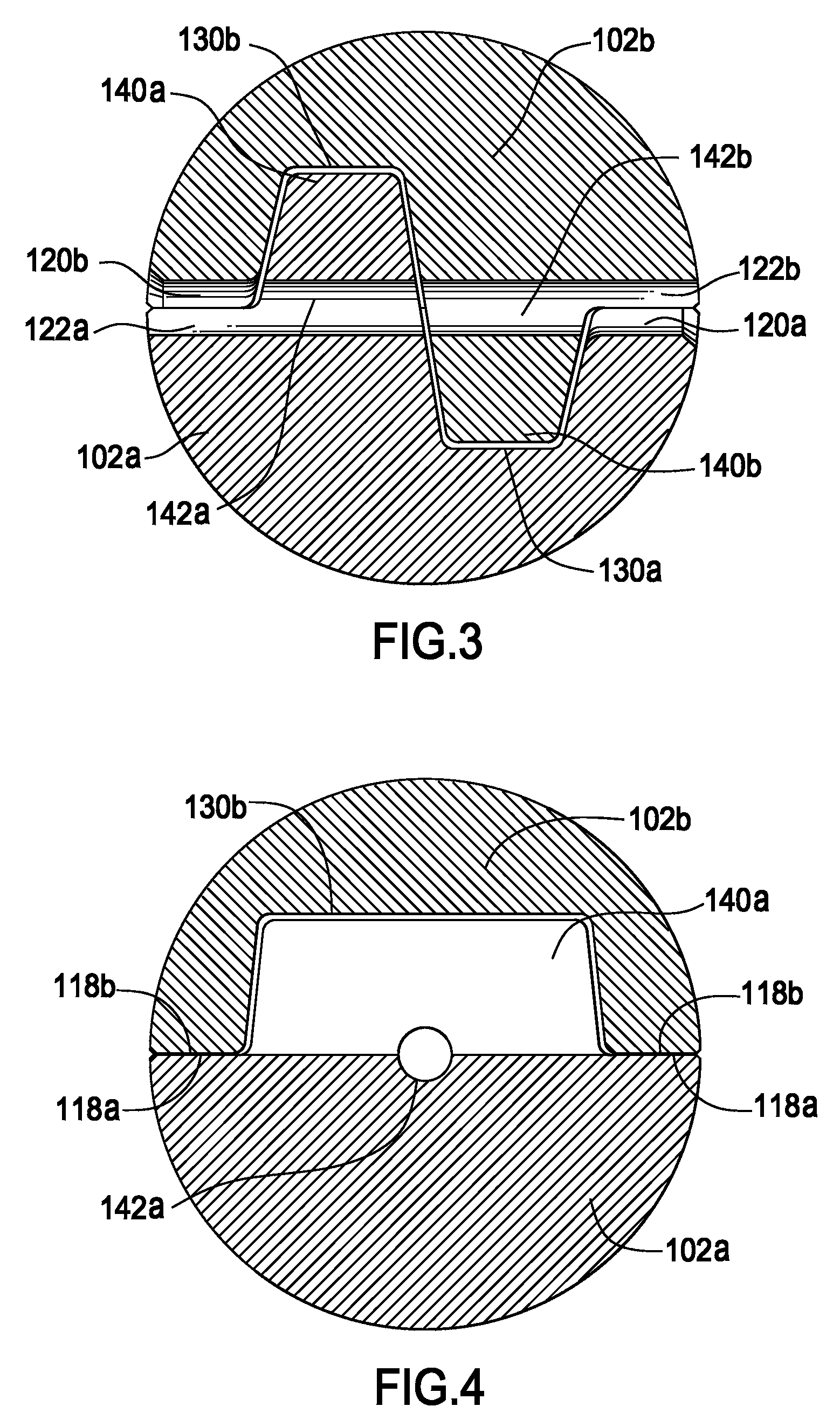

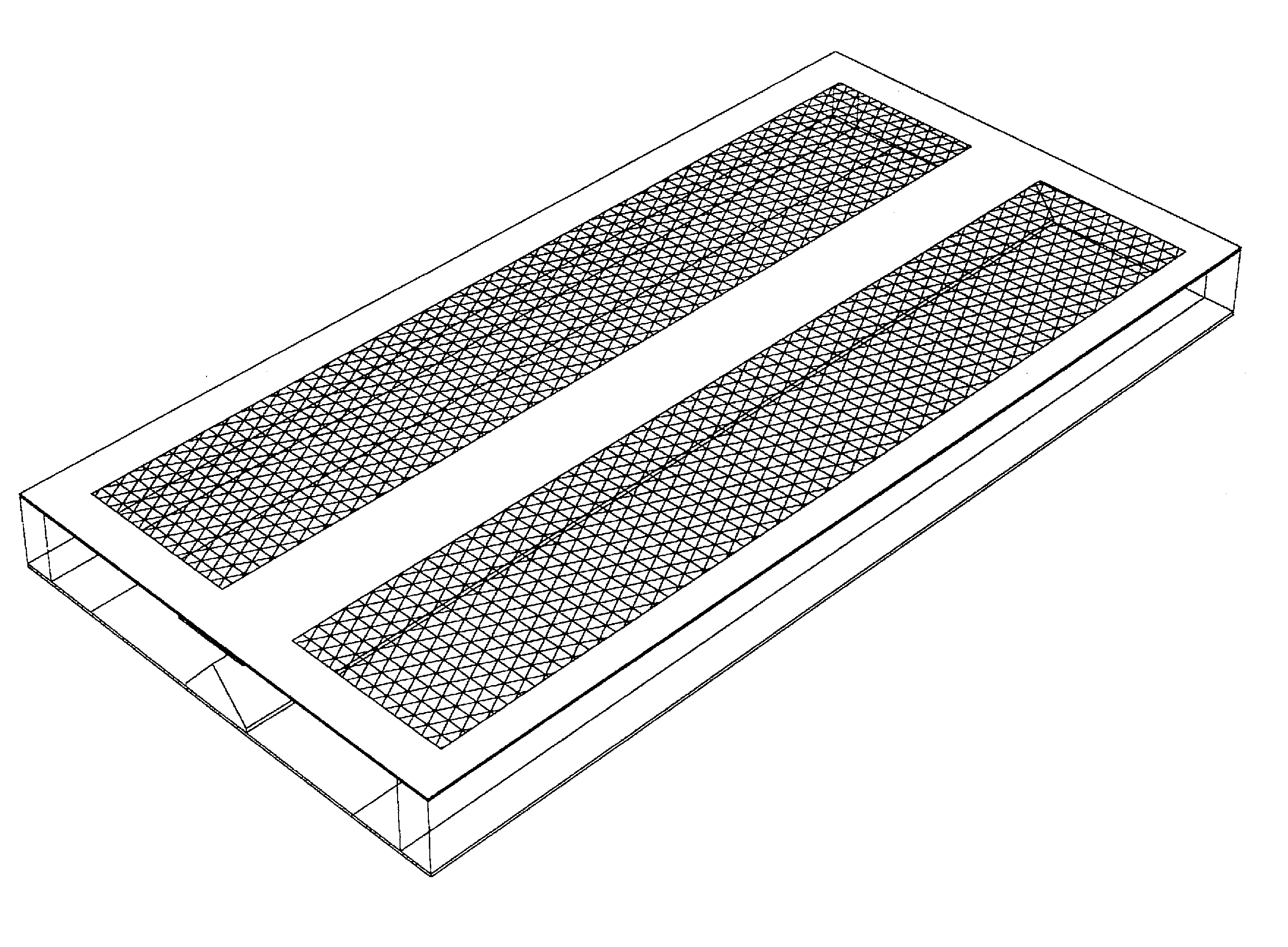

A light fixture using LEDs includes a lower skin layer possessing heat transfer properties. A circuit board is affixed to the lower skin layer, and a single LED, or a plurality of LEDs, is electrically connected to the circuit board. The single LED, or plurality of LEDs, when electrically activated, emits light through substantially around a vertical axis. The light fixture also includes a core possessing heat transfer properties that is in thermal contact with the LED and has an interior cavity for the LED. The core is affixed to the lower skin layer, and an upper skin layer, containing a window or windows over the LED or LEDs, is affixed to the core. The LEDs may be white, infrared, ultraviolet, and / or colored and may be mounted on a printed circuit board or individually.

Owner:INTEGRATED ILLUMINATION SYST

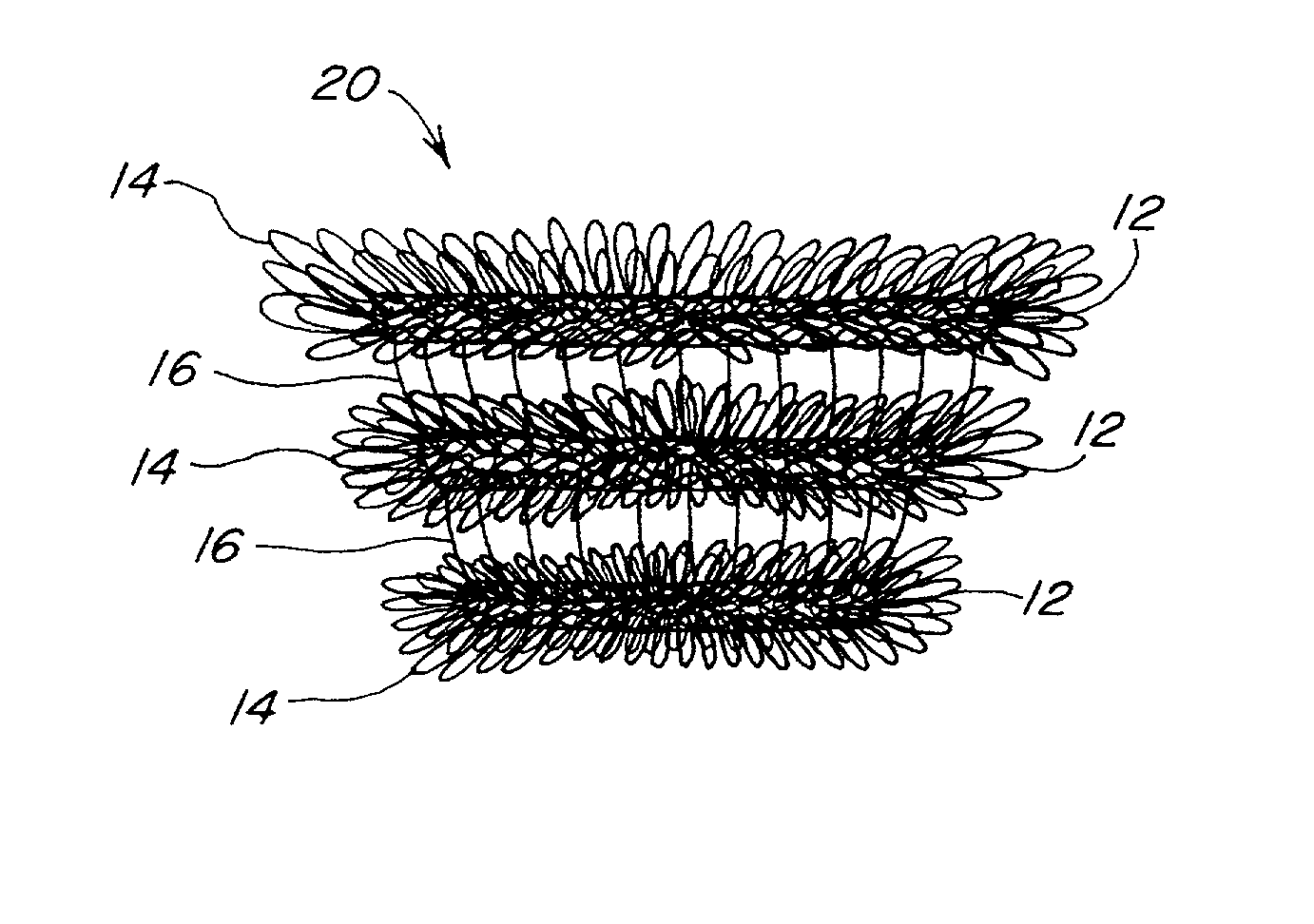

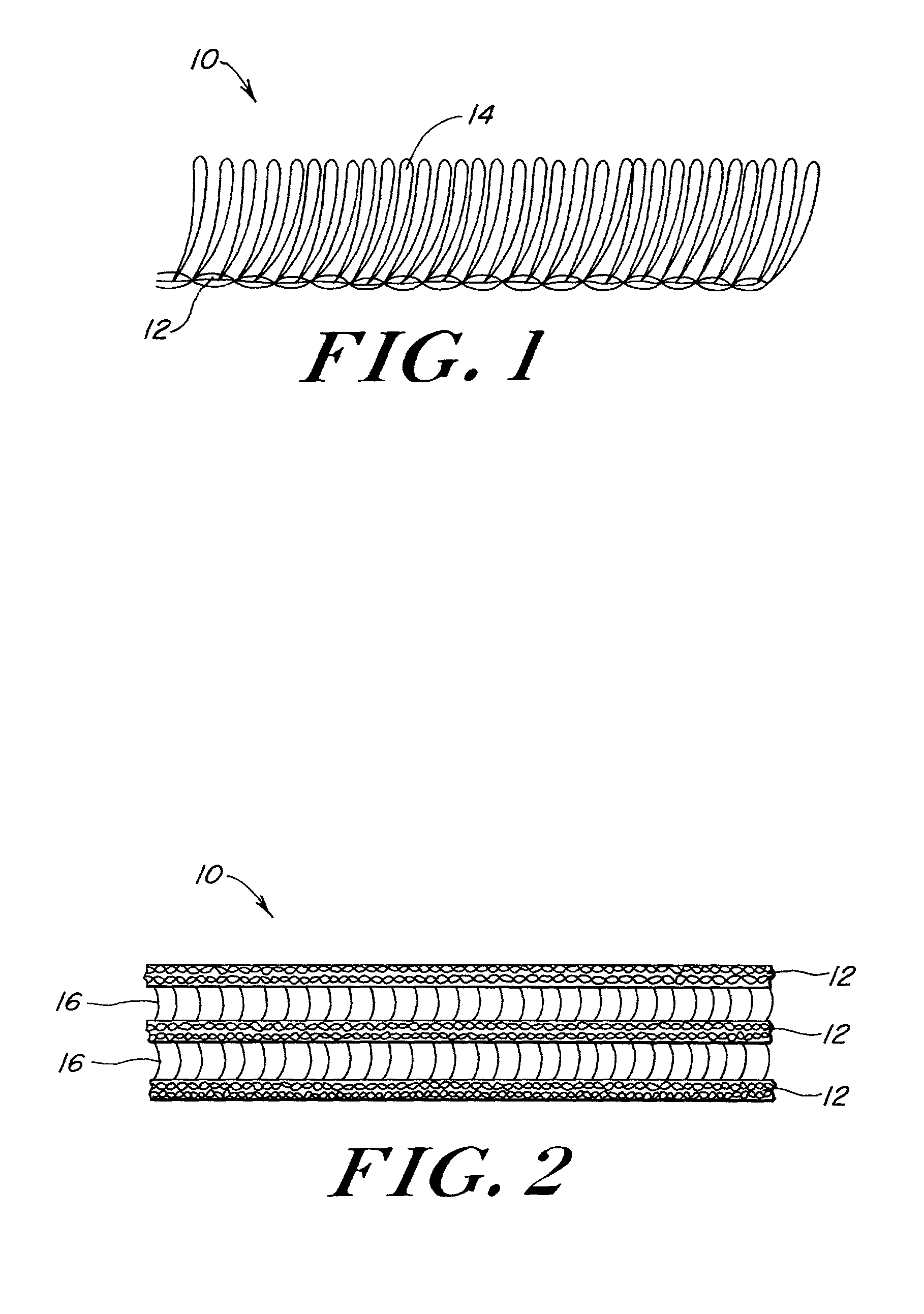

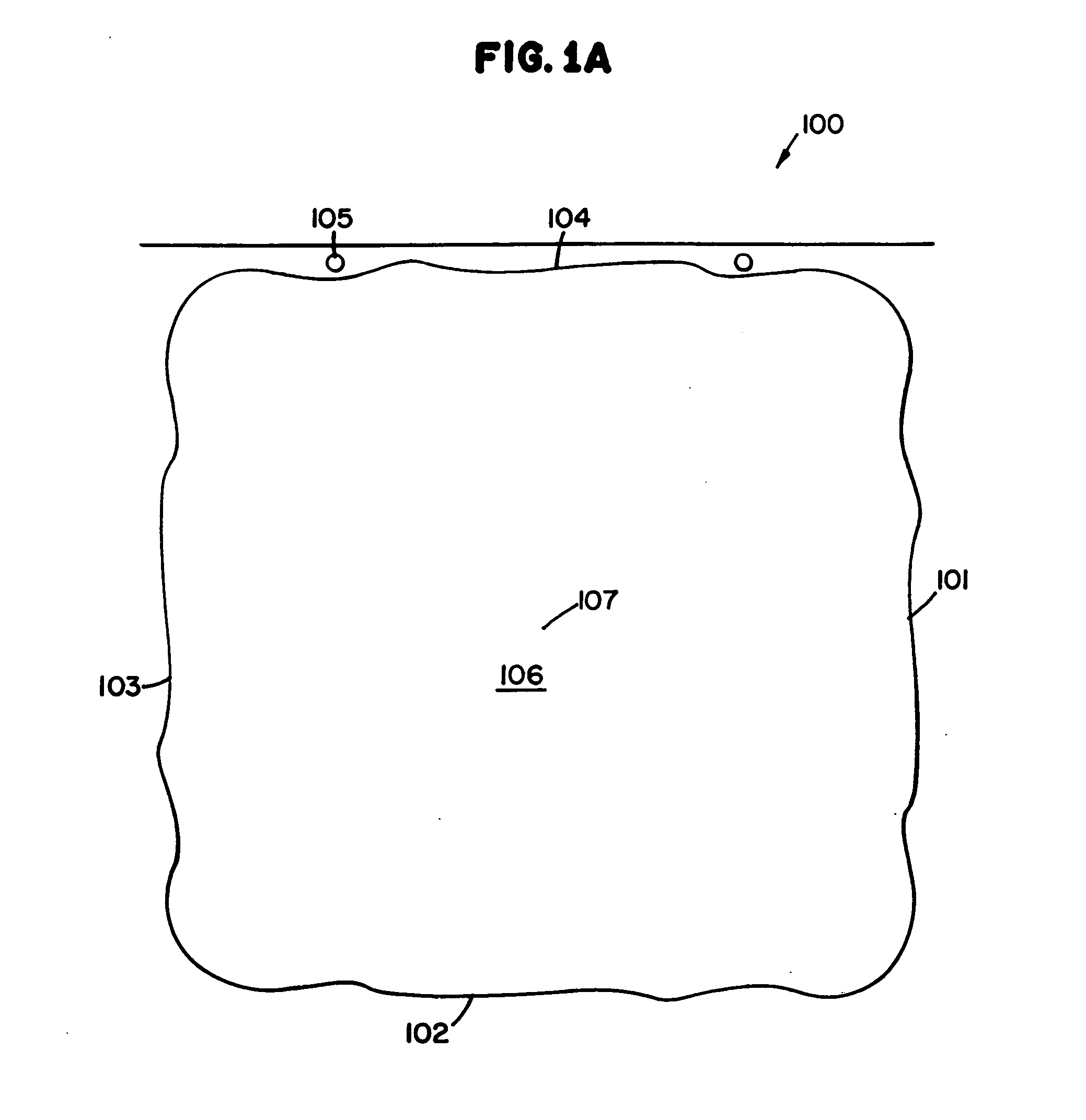

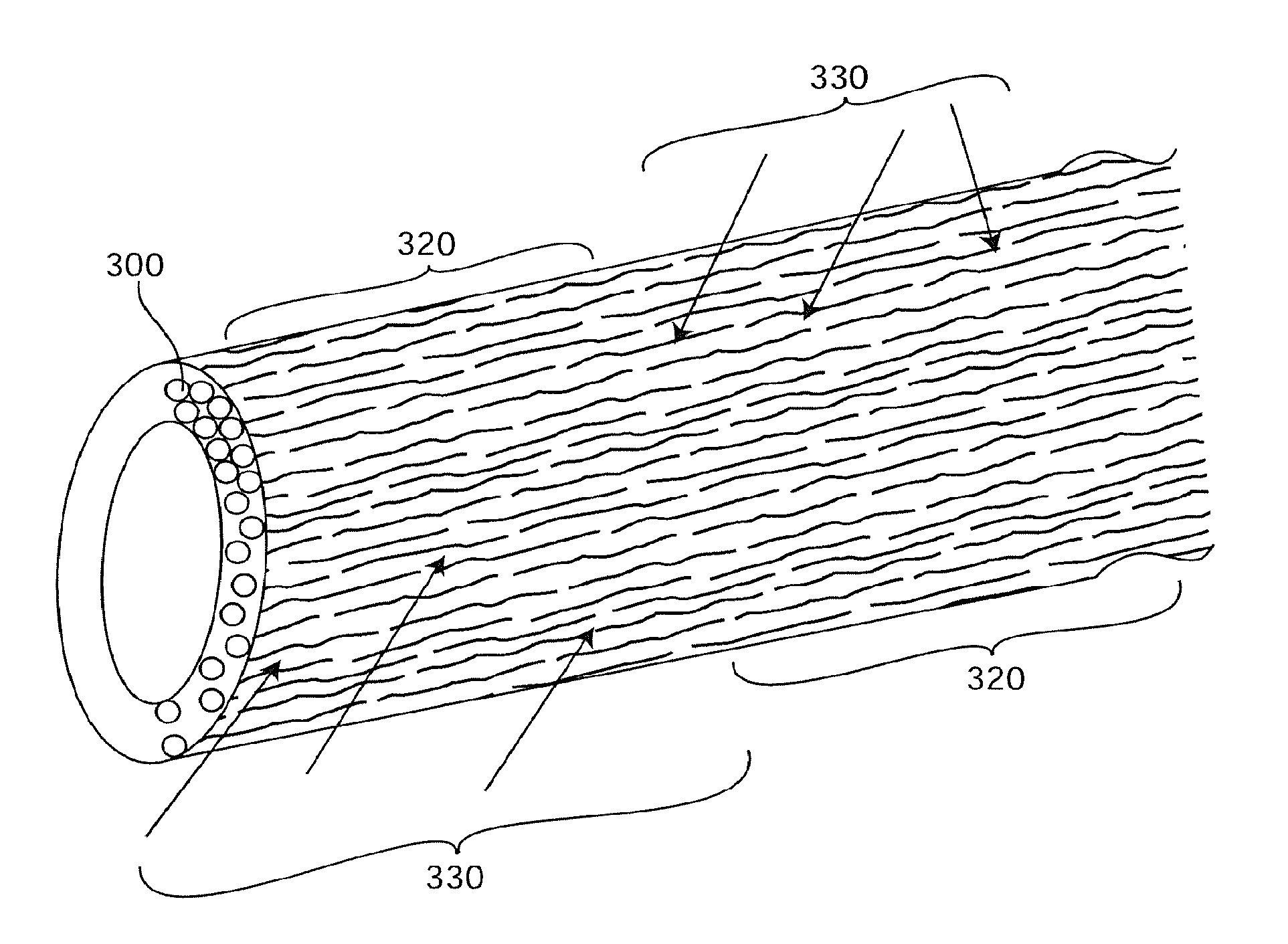

Pile mesh prosthesis

InactiveUS20020116070A1Add support structurePromoting rapid tissue in-growthWeft knittingWarp knittingRepair tissueProsthesis

A method and apparatus relating to a biocompatible soft tissue implant is disclosed. The implant, in the form of a prosthesis, is constructed of a knitted pile mesh material arranged into either a 3-dimensional structure or a planar shape or structure. The material or fabric includes a plurality of filament extensions projecting outwardly therefrom. The filament extensions can be radially projecting looping filaments from one or more rows of the knitted pile mesh material. The combination of the filament extensions with the 3-dimensional structure results in the biocompatible implant having a structural resistance to hinder anticipated crushing forces applied to the implant, and also provide a suitable 3-dimensional structure for promoting rapid tissue in-growth to anchor such implant without migration and strengthen the repaired tissue area.

Owner:ATRIUM MEDICAL

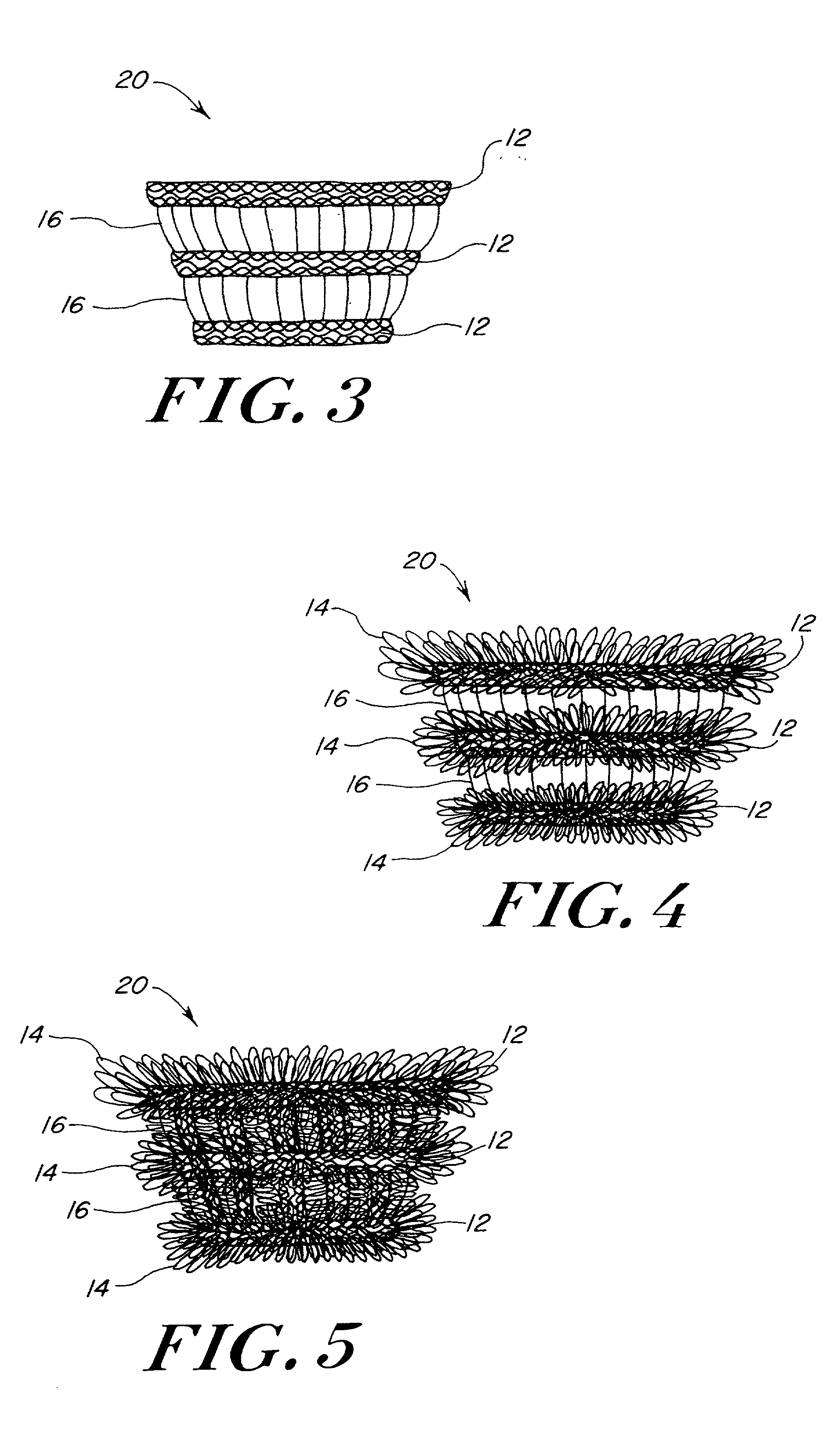

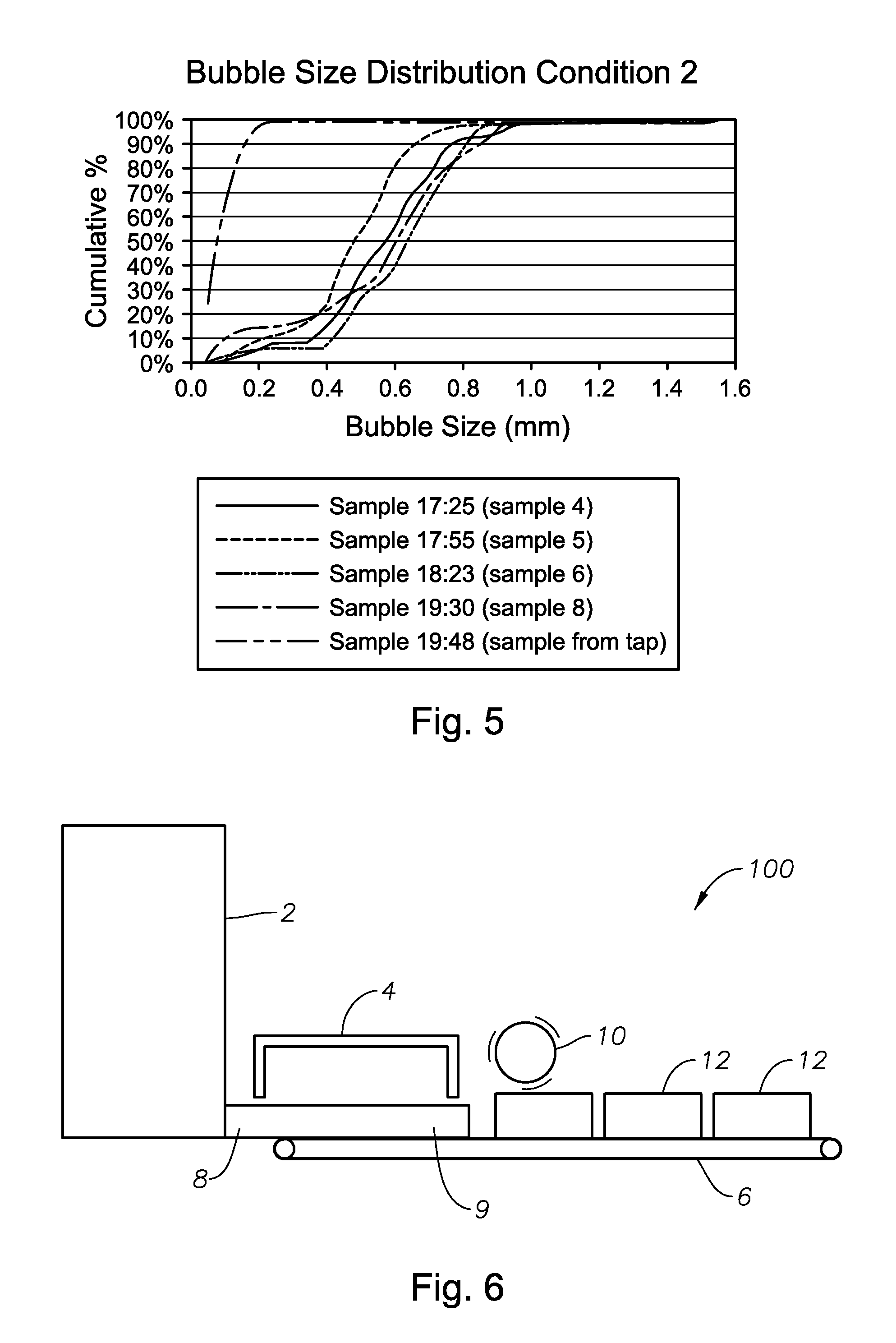

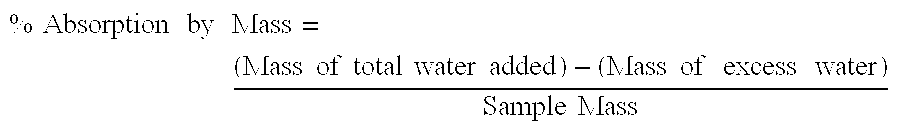

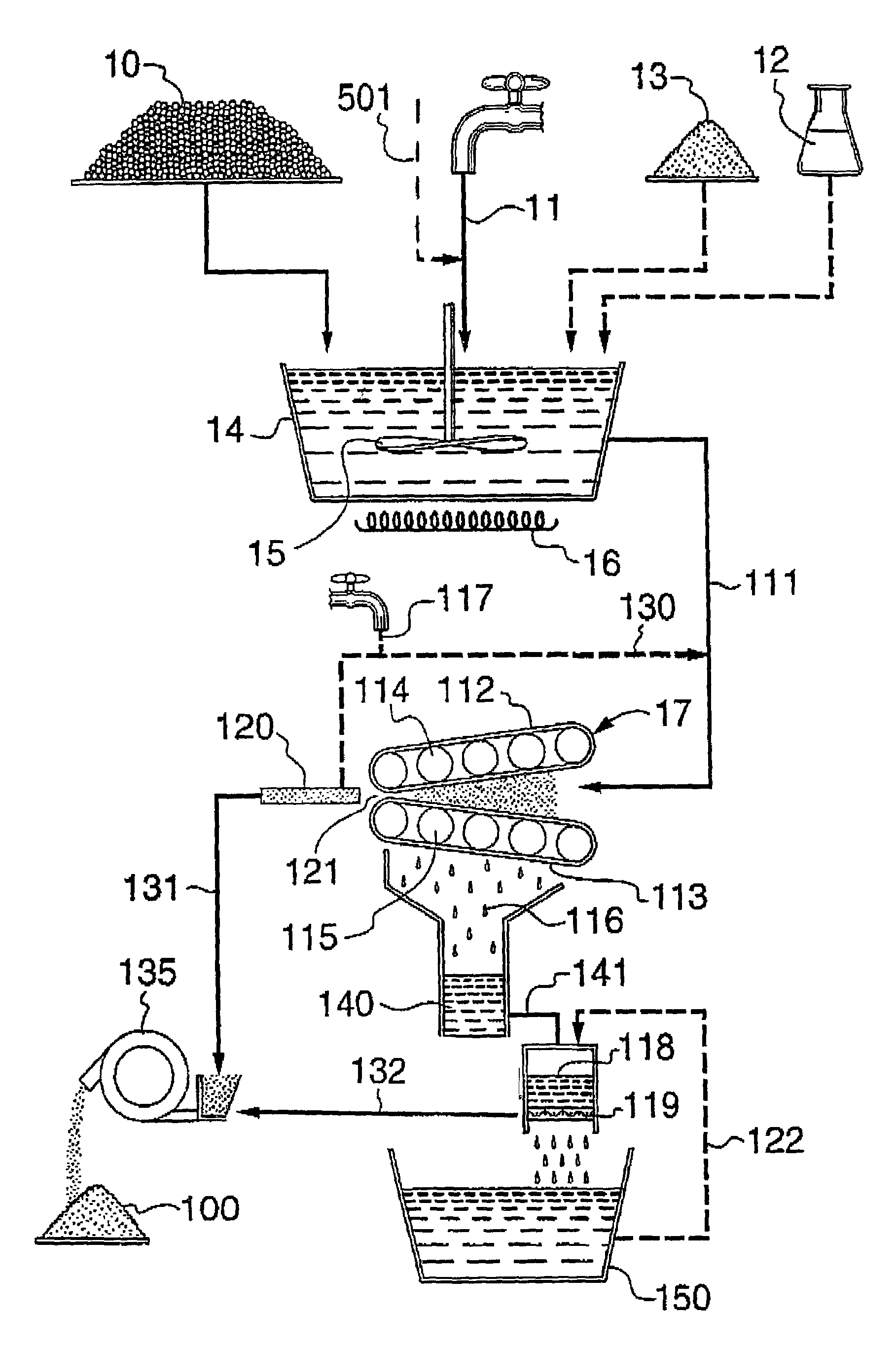

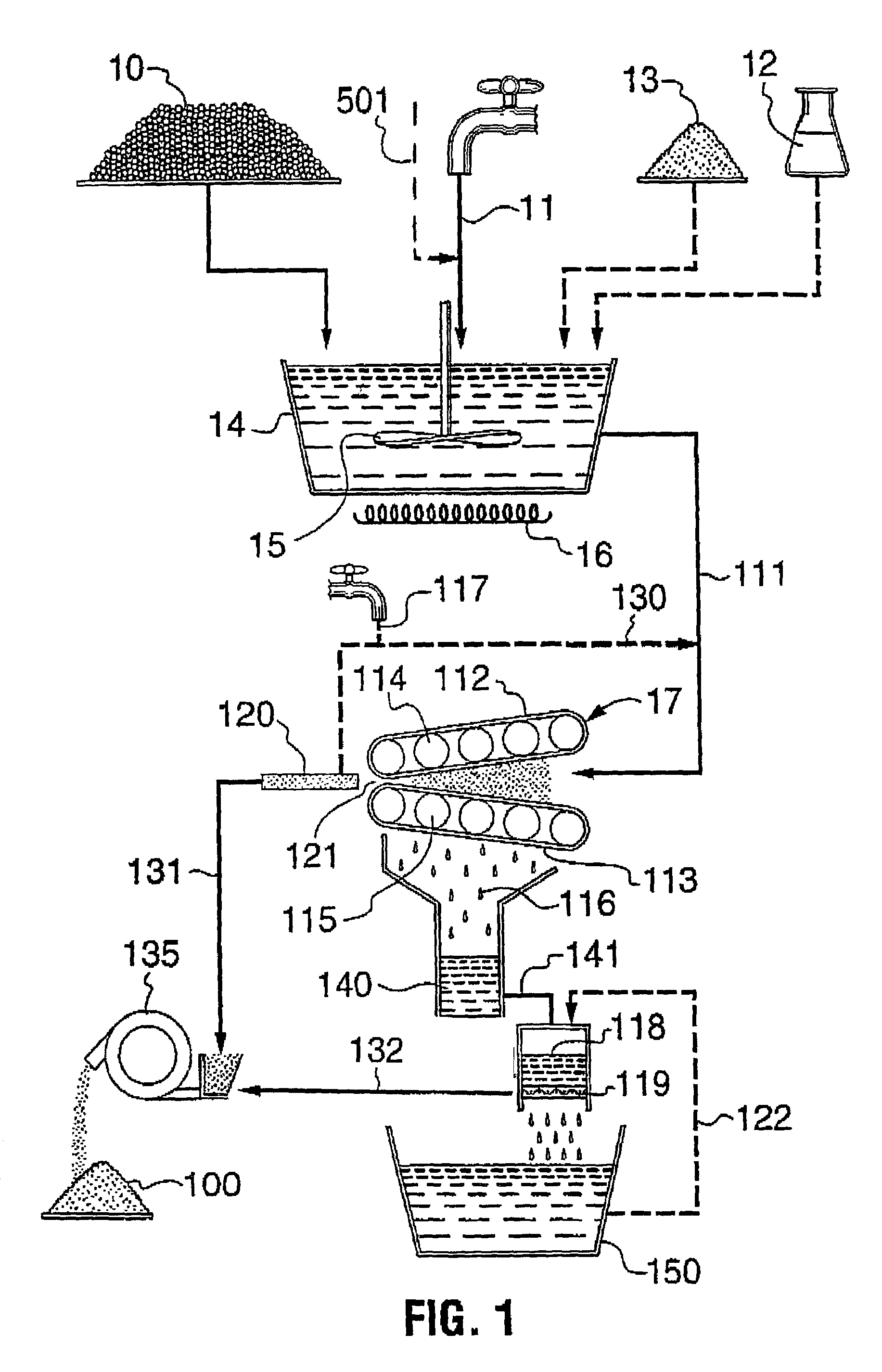

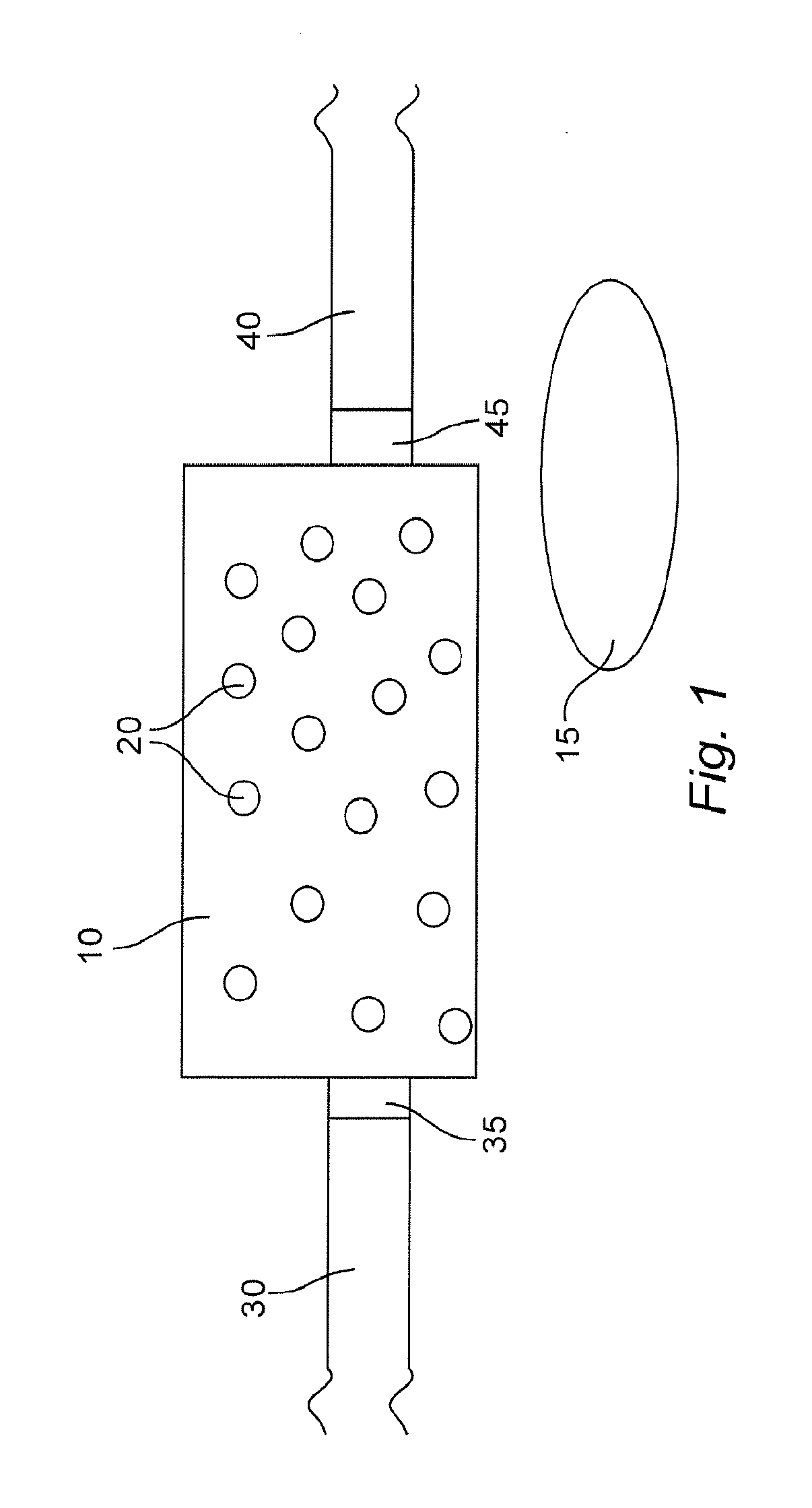

Systems and methods for making foamed glass using submerged combustion

ActiveUS20130086944A1High densityLow densityRibbon machinesGlass furnace apparatusCombustion systemDownstream processing

Submerged combustion systems and methods of use to produce foamed glass. One system includes a submerged combustion melter having an outlet, the melter configured to produce an initial foamy molten glass having a density and comprising bubbles filled primarily with combustion product gases. The initial foamy molten glass is deposited directly onto or into a transport apparatus that transports the initial foamy molten glass to a downstream processing apparatus. An intermediate stage may be included between the melter and the transport apparatus. One intermediate stage is a channel that includes gas injectors. Another intermediate stage is a channel that produces an upper flow of a less dense glass and a relatively more dense glass lower flow. The upper flow may be processed into foamed glass products, while the more dense flow may be processed into dense glass products.

Owner:JOHNS MANVILLE CORP

Extruded animal litters

ActiveUS20110185977A1Improved physical and functional and related propertyLess denseMixing operation control apparatusCement mixing apparatusAnimal scienceLitter

Owner:SOC DES PROD NESTLE SA

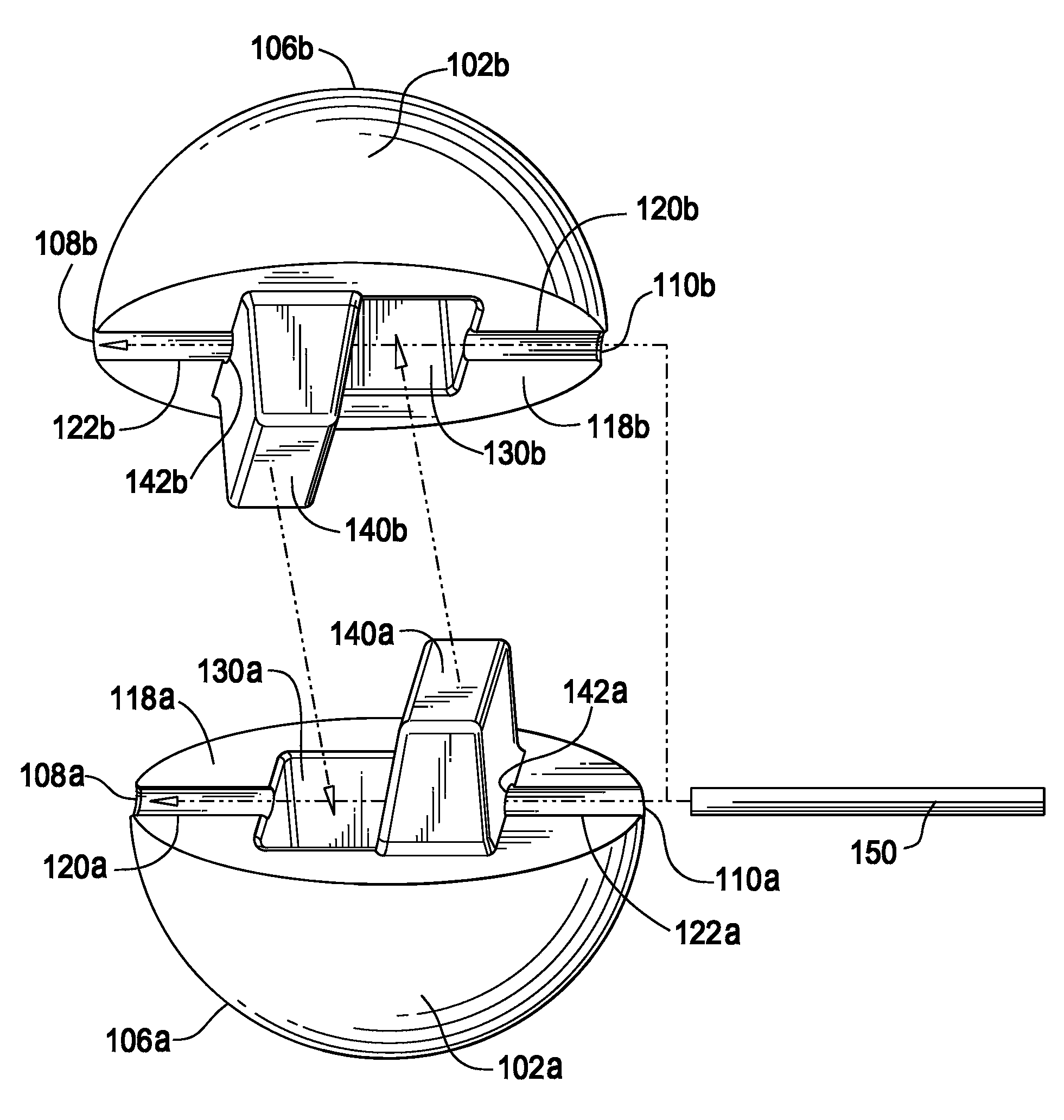

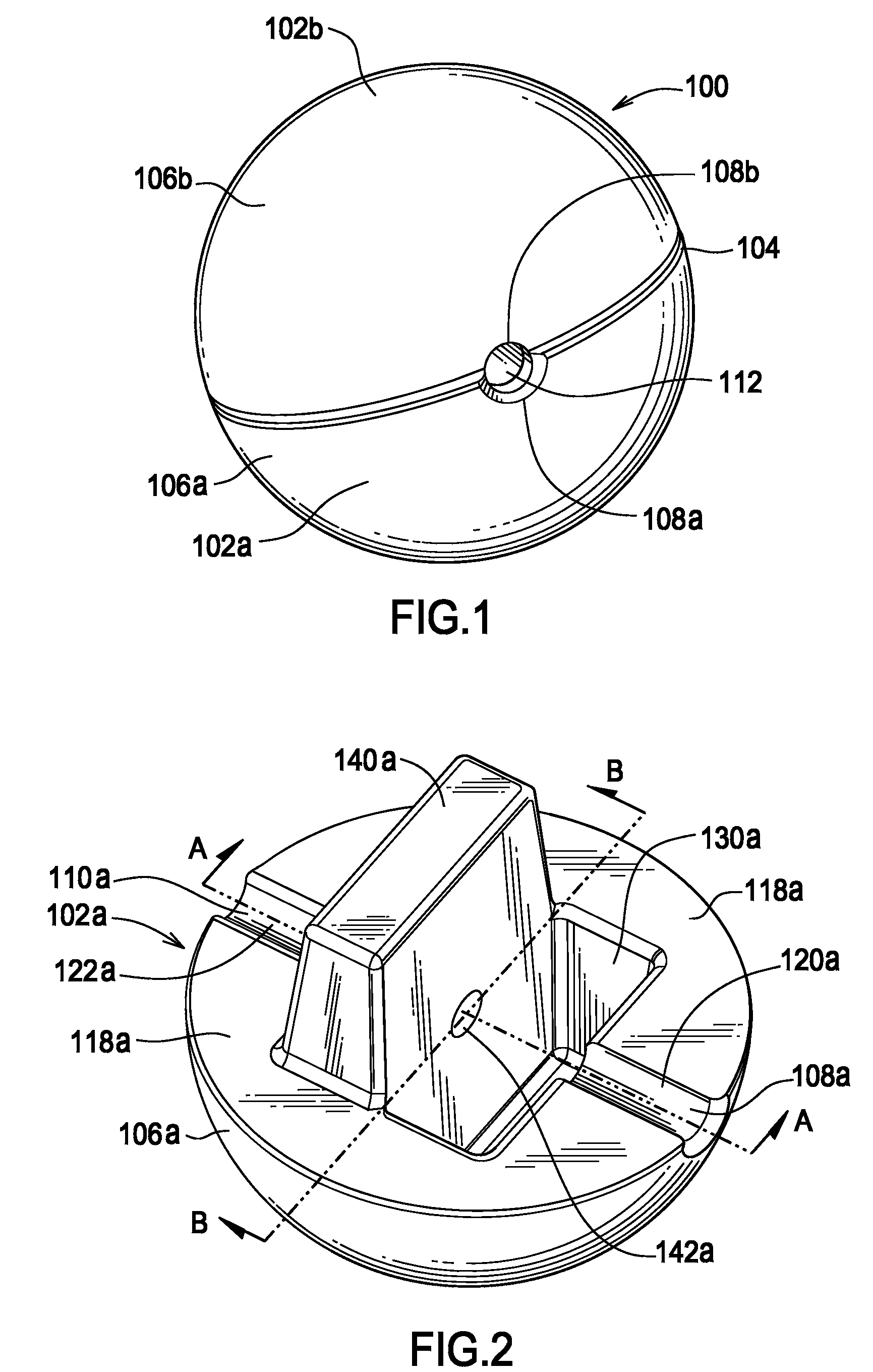

Illuminated ball and mating element for forming such ball

InactiveUS7261432B1Less denseLighting support devicesHollow inflatable ballsEngineeringMechanical engineering

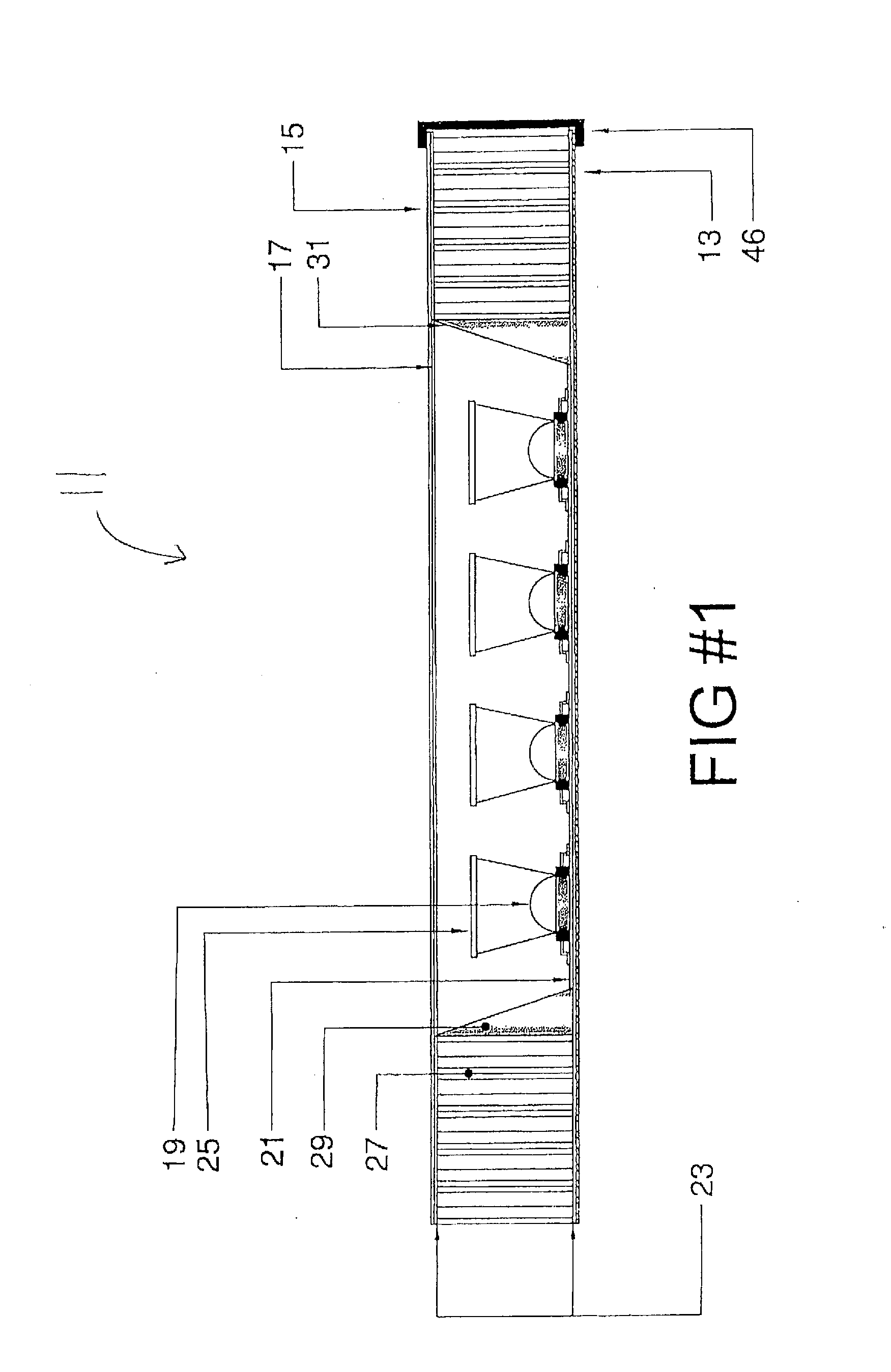

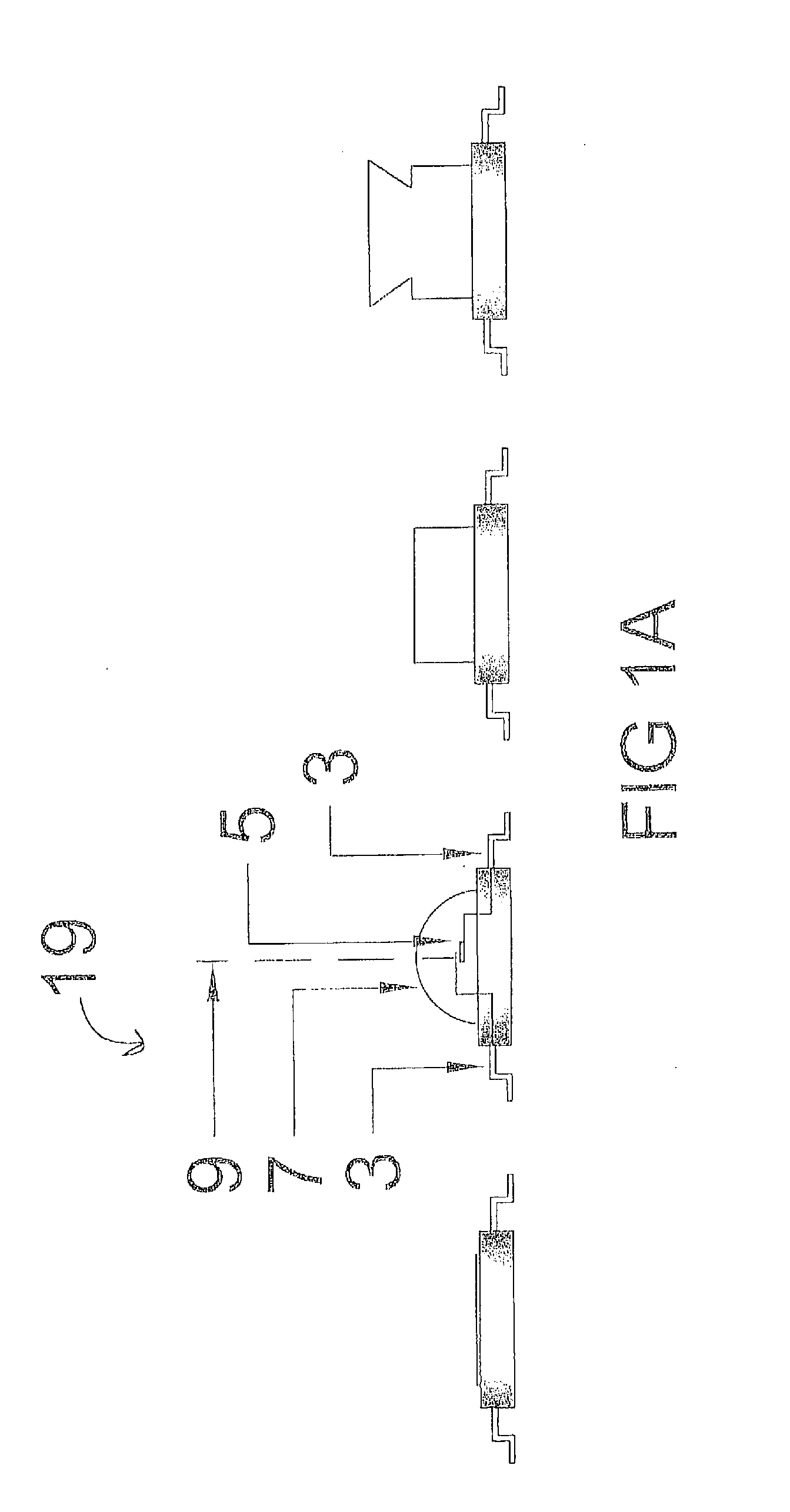

An illuminated ball formed by two substantially identical mating elements. Each mating element has an exterior surface bounded by an edge, an annular surface joined to said exterior surface at the edge, two opposed radial recesses formed in the annular surface, a well abutting a portion of the annular surface and one of the recesses, and an alignment guide abutting a portion of the annular surface and the other of the recesses. The alignment guide extends away from the exterior surface and includes a hole therethrough in alignment with the recesses. The mating element is matable with a second, substantially identical mating element by the well of each mating element receiving the alignment guide of the other element. The channel formed by the cooperation of the recesses and holes of both mating elements is sized to contain a light source.

Owner:HABITZ GERETT

LED light fixture

InactiveUS20100307075A1Low thermal conductivityLower resistancePlanar light sourcesCeilingsElectricityInfrared

A light fixture using LEDs includes a lower skin layer possessing heat transfer properties. A circuit board is affixed to the lower skin layer, and a single LED, or a plurality of LEDs, is electrically connected to the circuit board. The single LED, or plurality of LEDs, when electrically activated, emits light through substantially around a vertical axis. The light fixture also includes a core possessing heat transfer properties that is in thermal contact with the LED and has an interior cavity for the LED. The core is affixed to the lower skin layer, and an upper skin layer, containing a window or windows over the LED or LEDs, is affixed to the core. The LEDs may be white, infrared, ultraviolet, and / or colored and may be mounted on a printed circuit board or individually.

Owner:INTEGRATED ILLUMINATION SYST

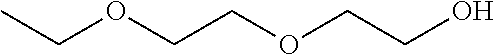

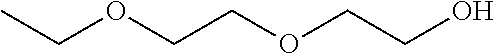

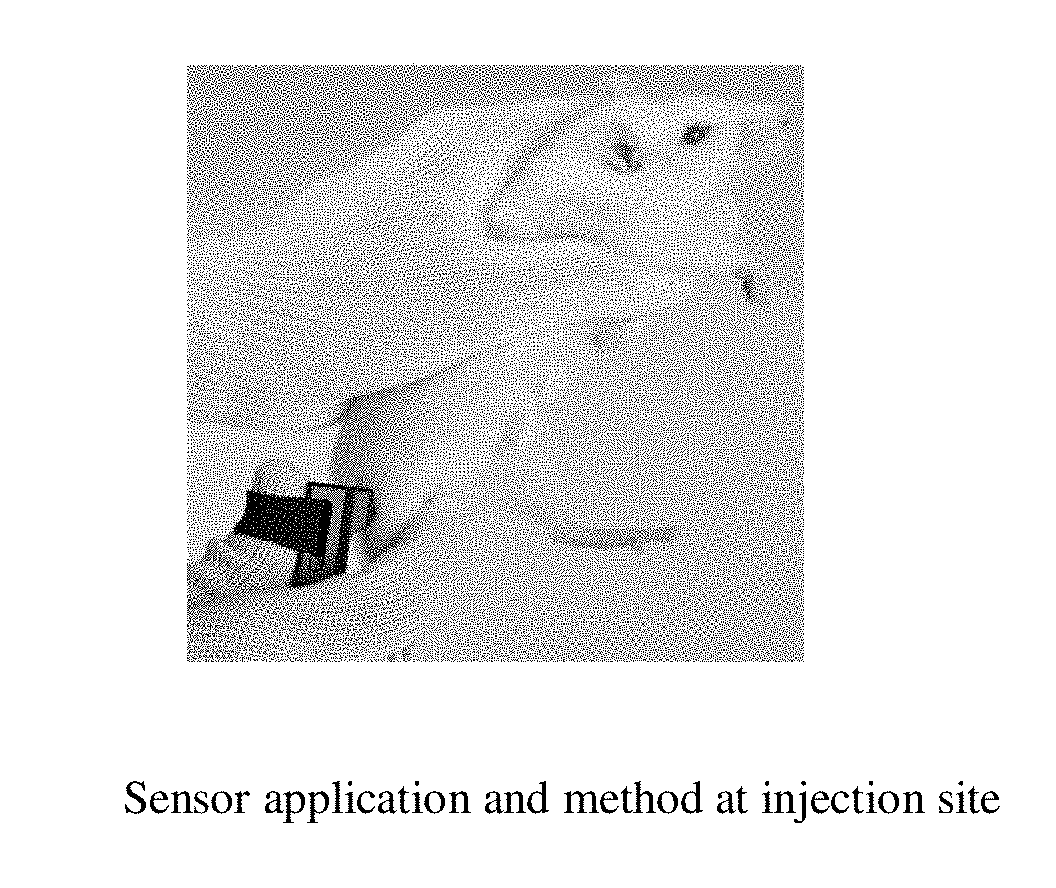

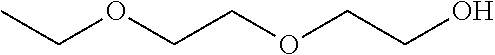

Compositions of pharmaceutical actives containing diethylene glycol monoethyl ether or other alkyl derivatives

InactiveUS20140296191A1Less viscousLess denseBiocideOrganic chemistryDiethylene glycol monoethyl etherNasal spray

The present invention relates to pharmaceutical compositions of various pharmaceutical actives, especially lyophilic and hydrophilic actives containing Diethylene glycol monoethyl ether or other alkyl derivatives thereof as a primary vehicle and / or to pharmaceutical compositions utilizing Diethylene glycol monoethyl ether or other alkyl derivatives thereof as a primary vehicle or as a solvent system in preparation of such pharmaceutical compositions. The pharmaceutical compositions of the present invention are safe, non-toxic, exhibits enhanced physical stability compared to conventional formulations containing such pharmaceutical actives and are suitable for use as injectables for intravenous and intramuscular administration, as well as for use as a preformed solution / liquid for filling in and preparation of capsules, tablets, nasal sprays, gargles, dermal applications, gels, topicals, liquid oral dosage forms and other dosage forms.

Owner:THEMIS MEDICARE LTD

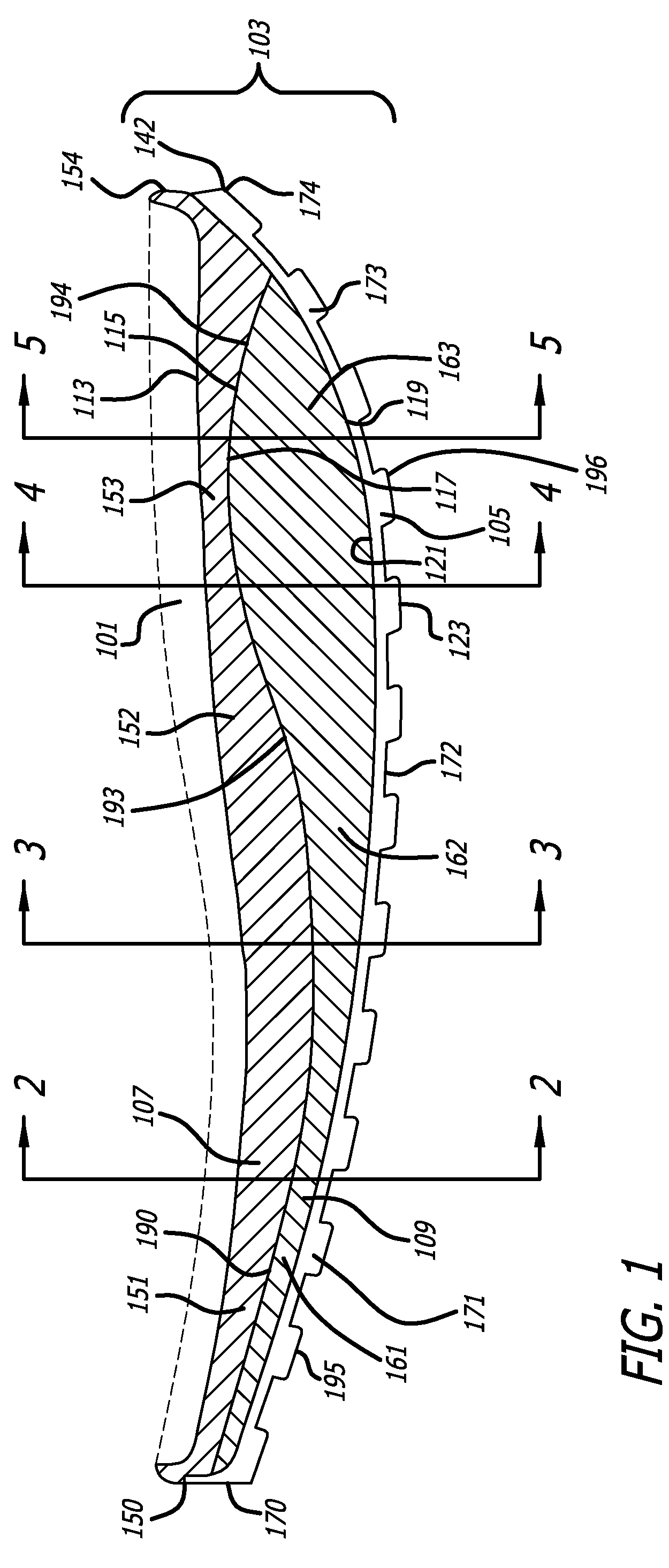

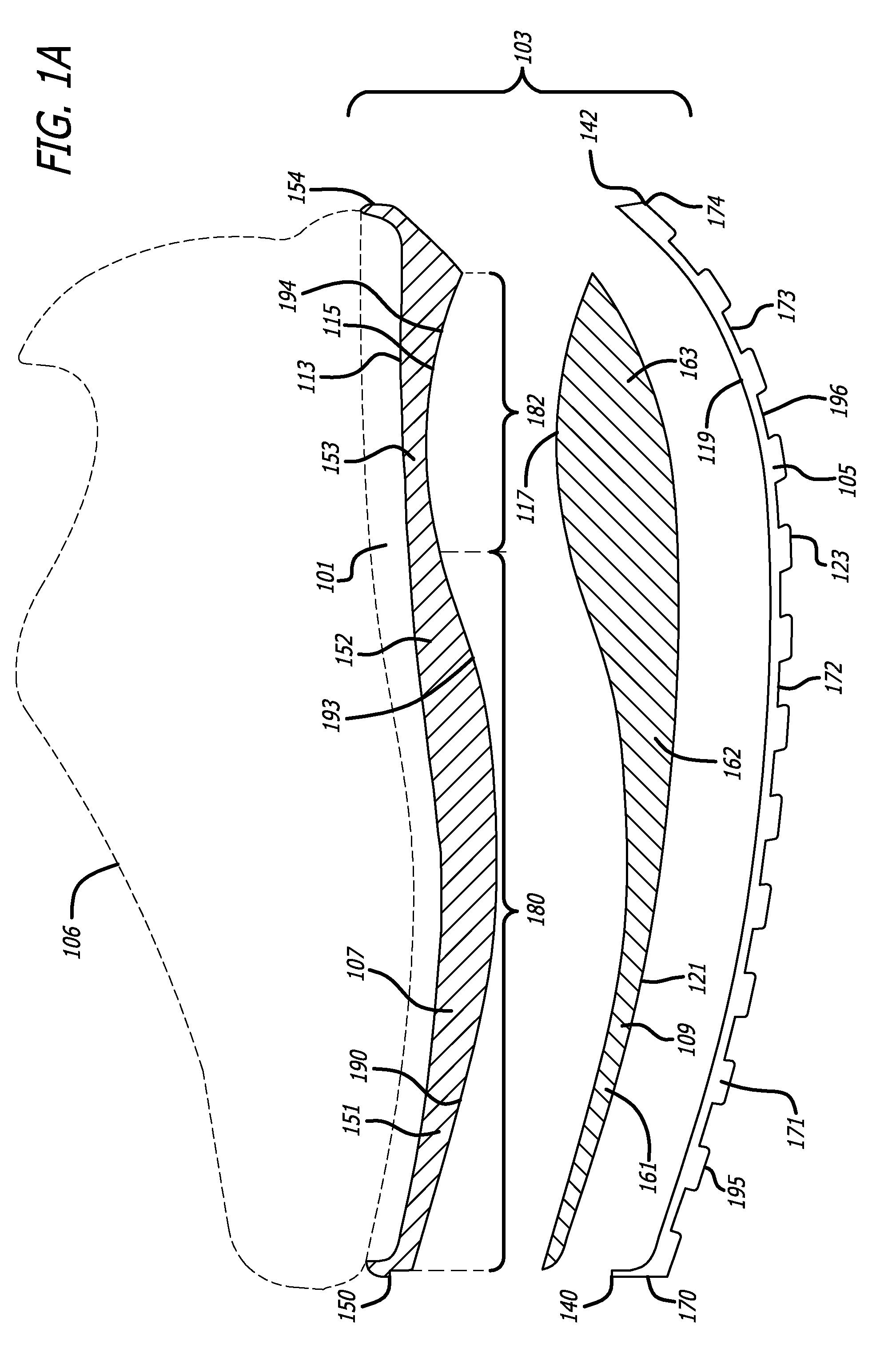

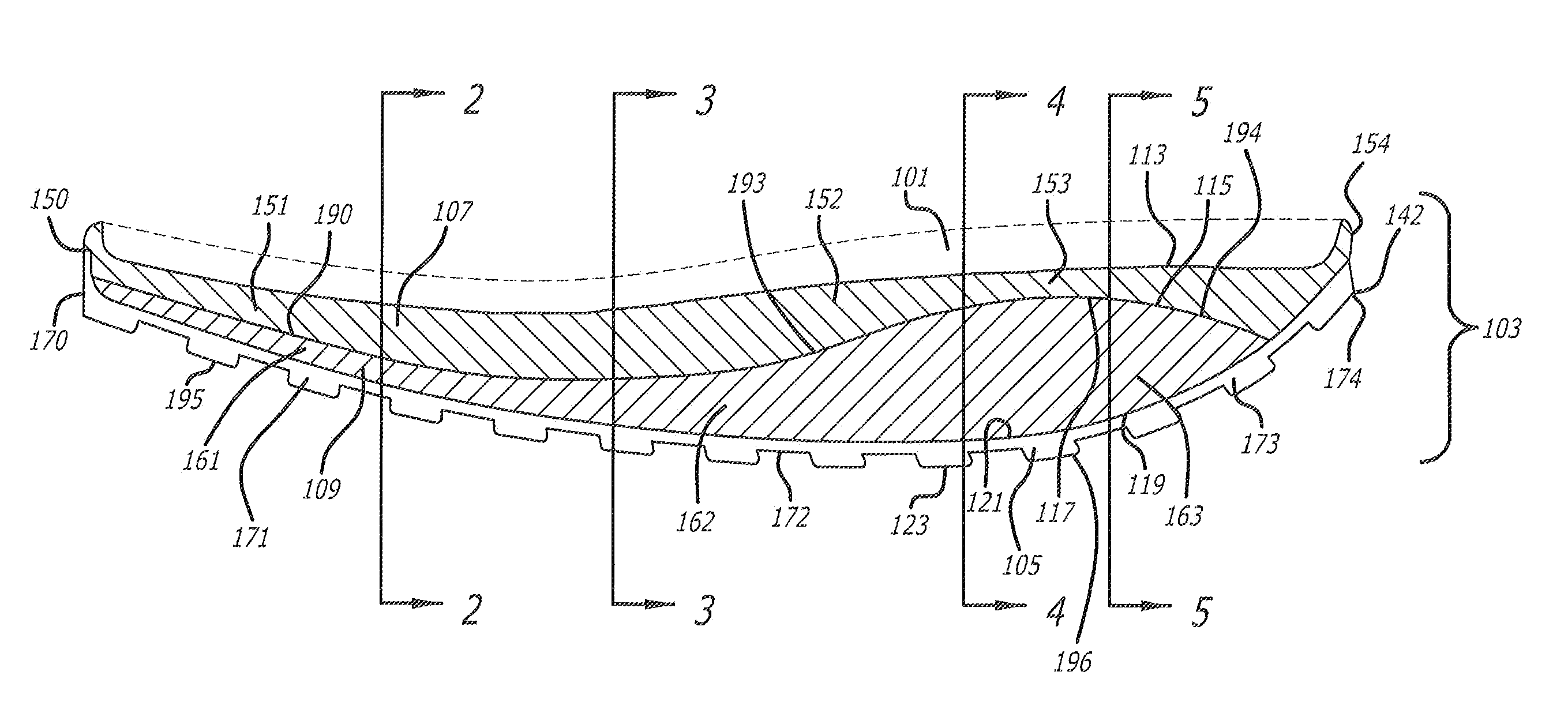

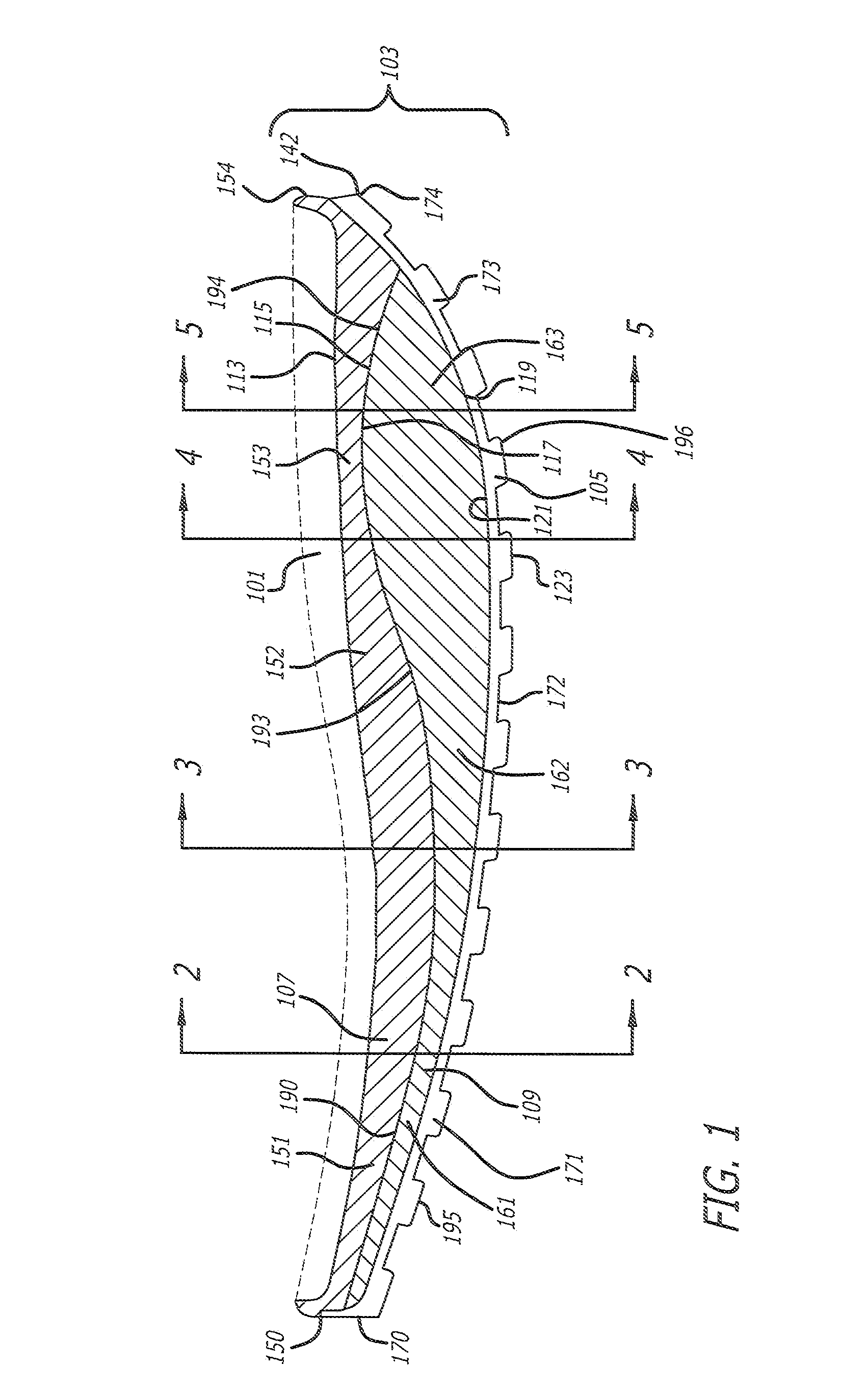

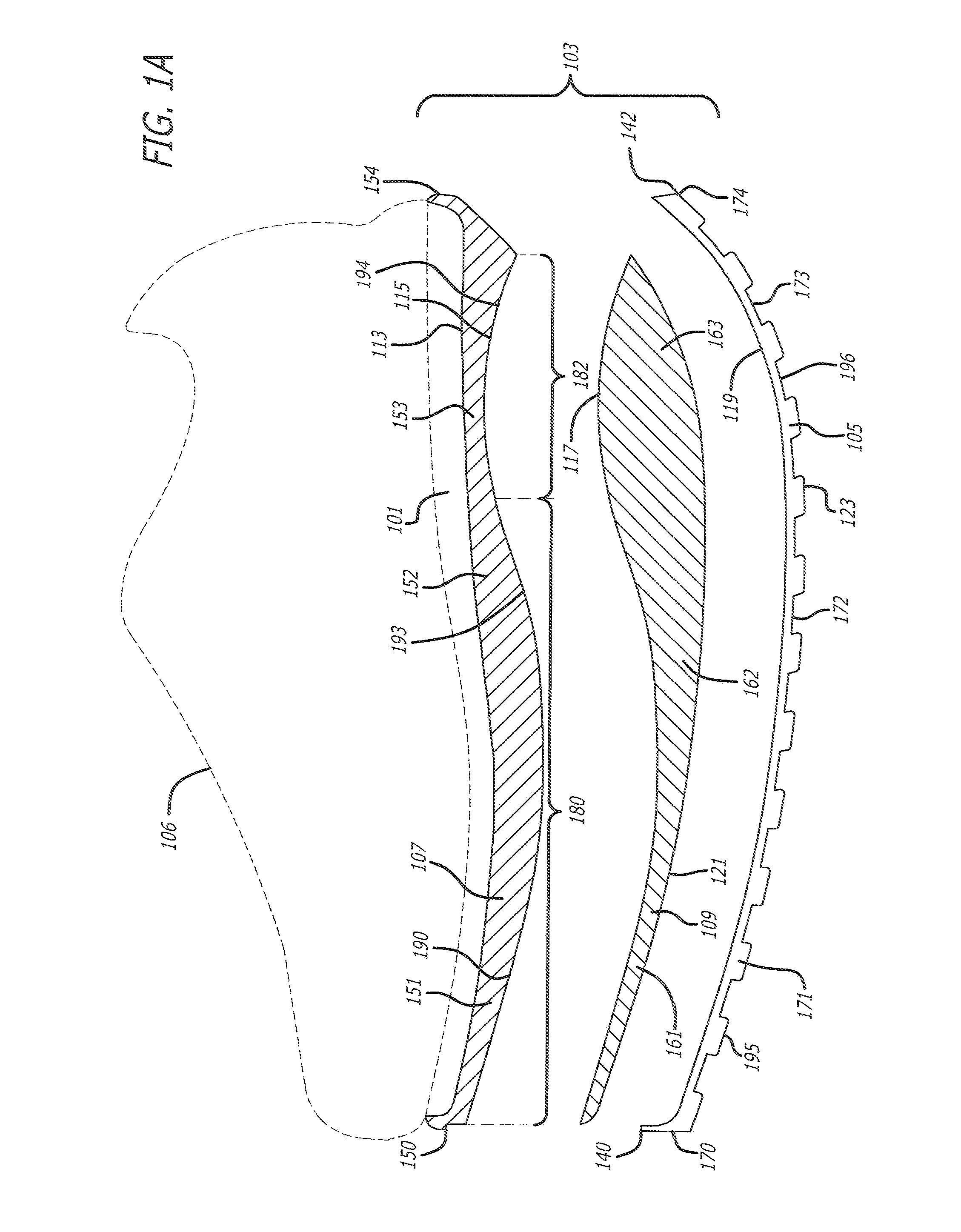

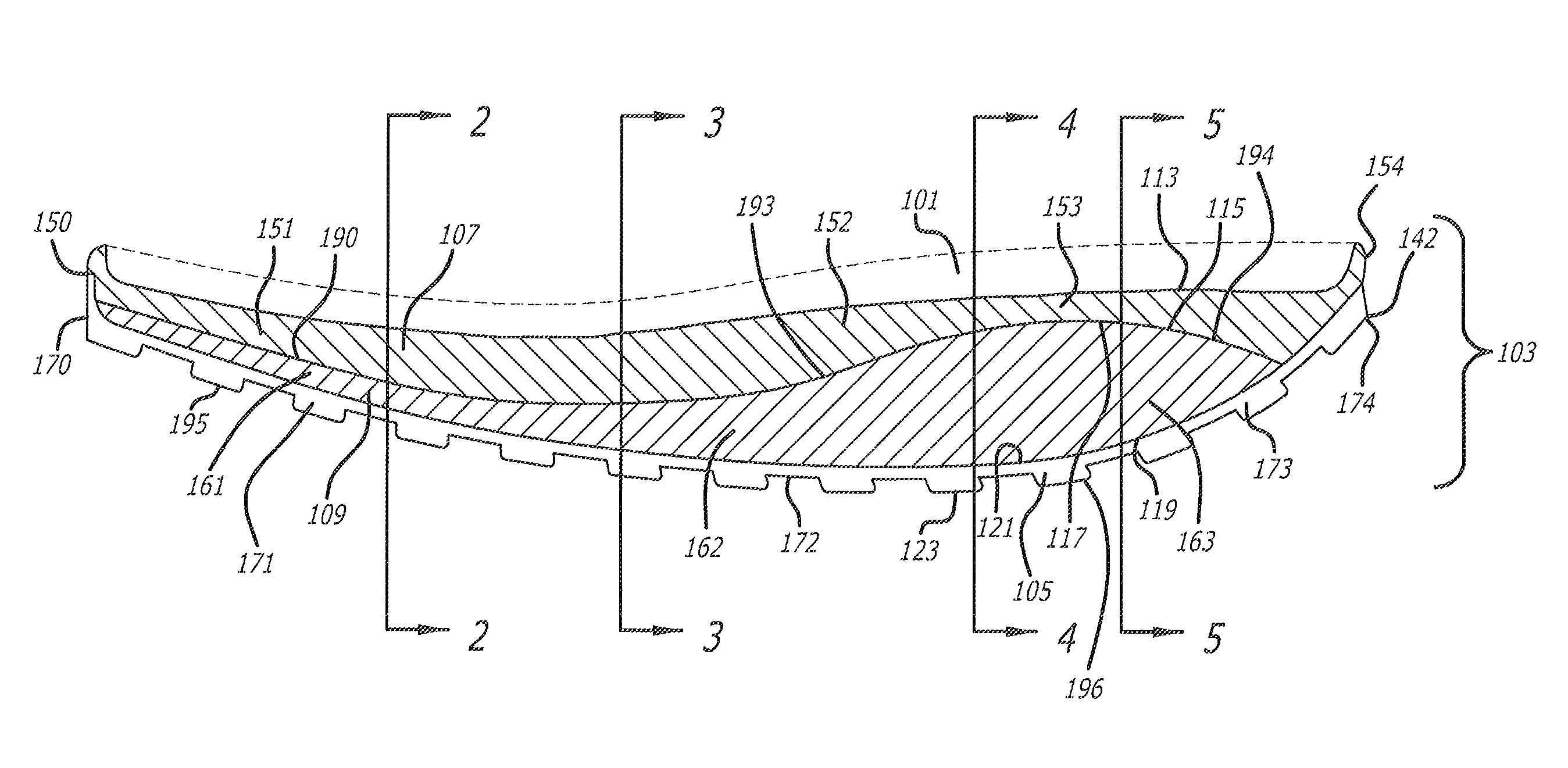

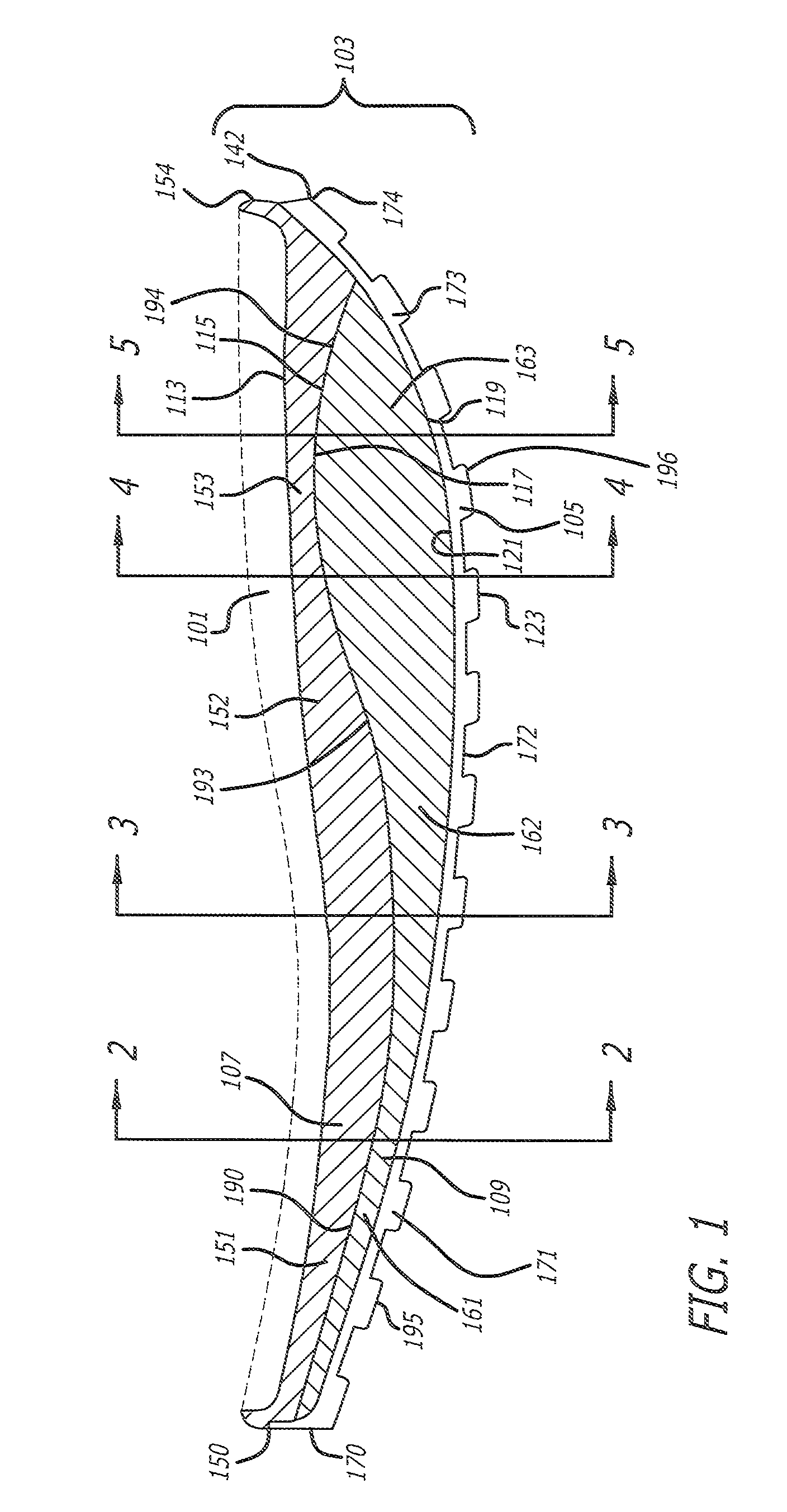

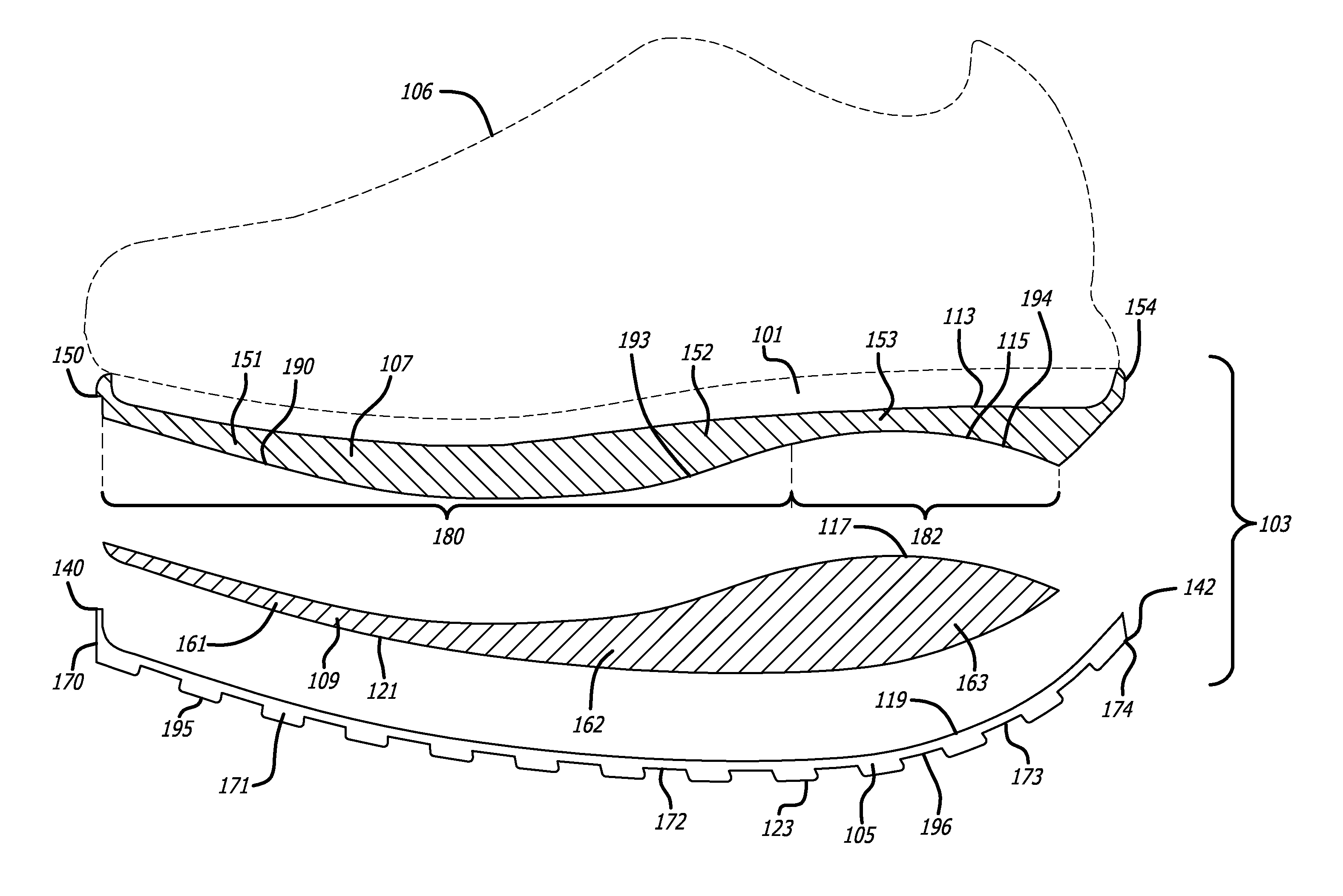

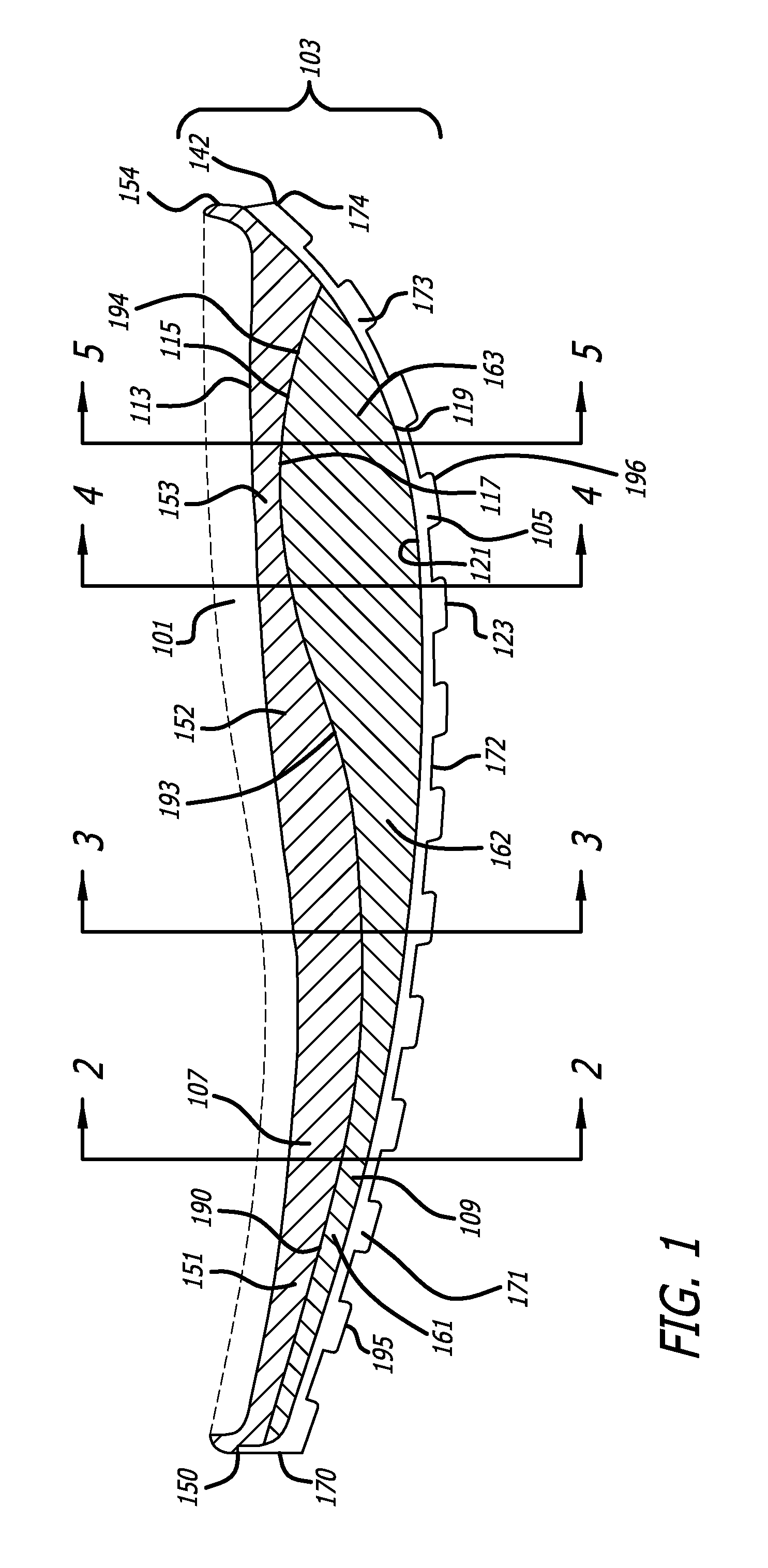

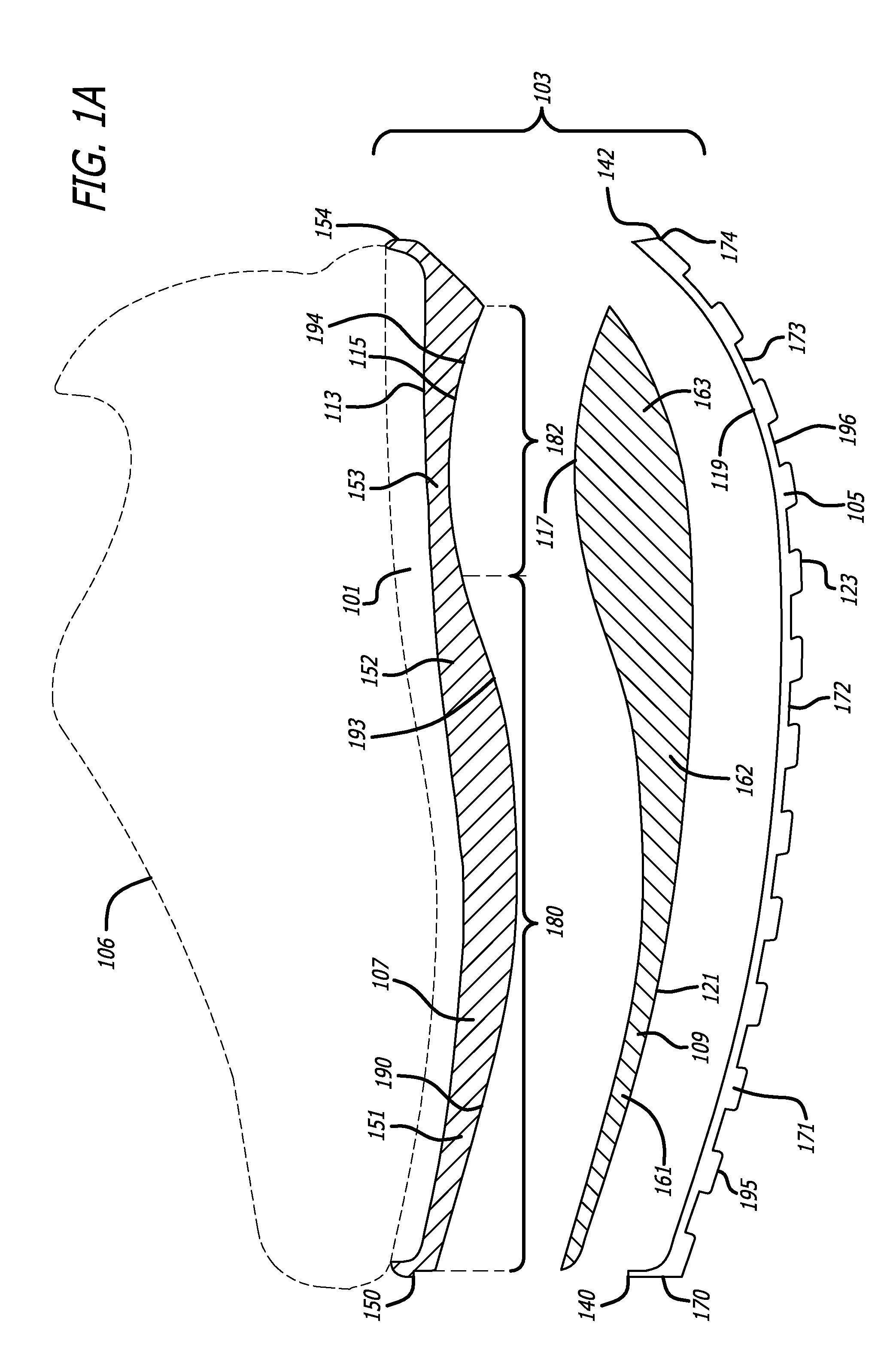

Shoe

A shoe having a toe region, a middle region, a heel region, and a multi-layer, multi-density midsole wherein an upper layer of the midsole has a bottom surface that has a longitudinal convexity and a longitudinal concavity, the longitudinal convexity typically occupying a substantial portion of the toe region or a substantial portion of the toe region and middle region, and the longitudinal concavity typically occupying a substantial portion of the heel region, the longitudinal convexity and the longitudinal concavity collectively contributing to simulating the effect, and imparting the fitness benefits, of walking on a sandy beach or on a giving or uneven surface regardless of the actual hardness of the surface.

Owner:SKECHERS US II

LED light fixture

InactiveUS7766511B2Low thermal conductivityLower resistancePlanar light sourcesCeilingsInfraredElectricity

A light fixture using LEDs includes a lower skin layer possessing heat transfer properties. A circuit board is affixed to the lower skin layer, and a single LED, or a plurality of LEDs, is electrically connected to the circuit board. The single LED, or plurality of LEDs, when electrically activated, emits light through substantially around a vertical axis. The light fixture also includes a core possessing heat transfer properties that is in thermal contact with the LED and has an interior cavity for the LED. The core is affixed to the lower skin layer, and an upper skin layer, containing a window or windows over the LED or LEDs, is affixed to the core. The LEDs may be white, infrared, ultraviolet, and / or colored and may be mounted on a printed circuit board or individually.

Owner:INTEGRATED ILLUMINATION SYST

Shoe

A shoe having a toe region, a middle region, a heel region, and a multi-layer, multi-density midsole wherein an upper layer of the midsole has a bottom surface that has a longitudinal convexity and a longitudinal concavity, the longitudinal convexity typically occupying a substantial portion of the toe region or a substantial portion of the toe region and middle region, and the longitudinal concavity typically occupying a substantial portion of the heel region, the longitudinal convexity and the longitudinal concavity collectively contributing to simulating the effect, and imparting the fitness benefits, of walking on a sandy beach or on a giving or uneven surface regardless of the actual hardness of the surface.

Owner:SKECHERS US II

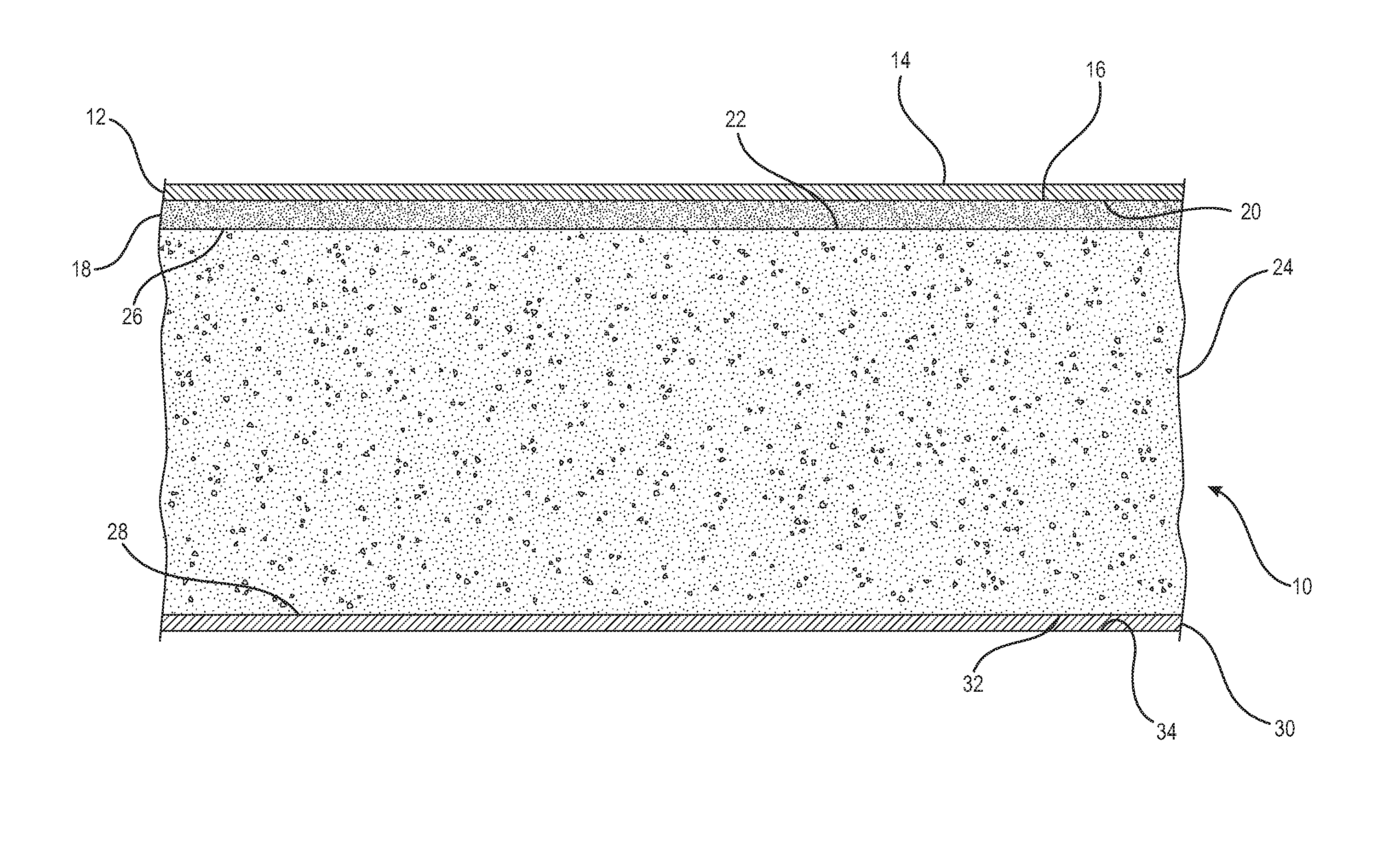

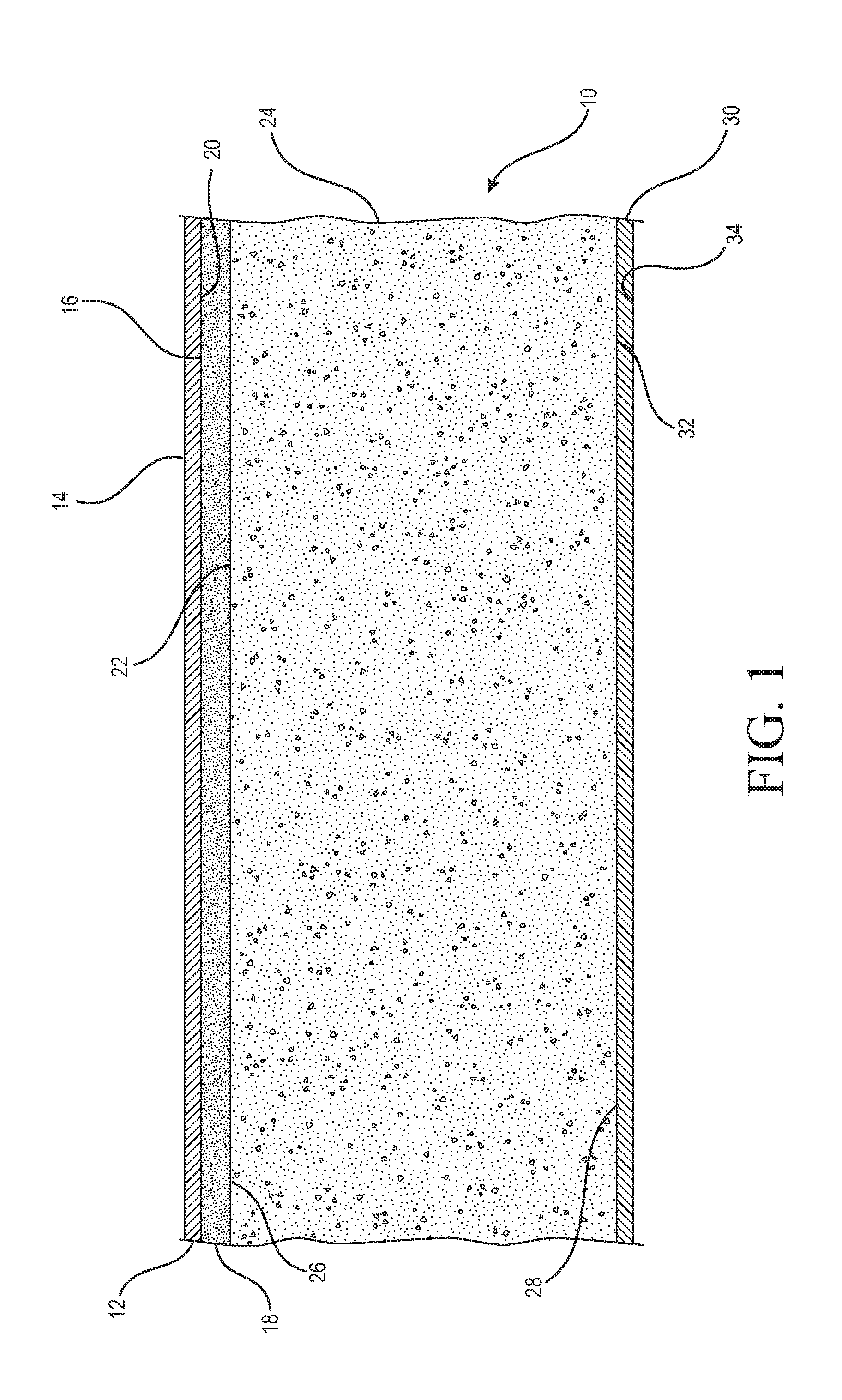

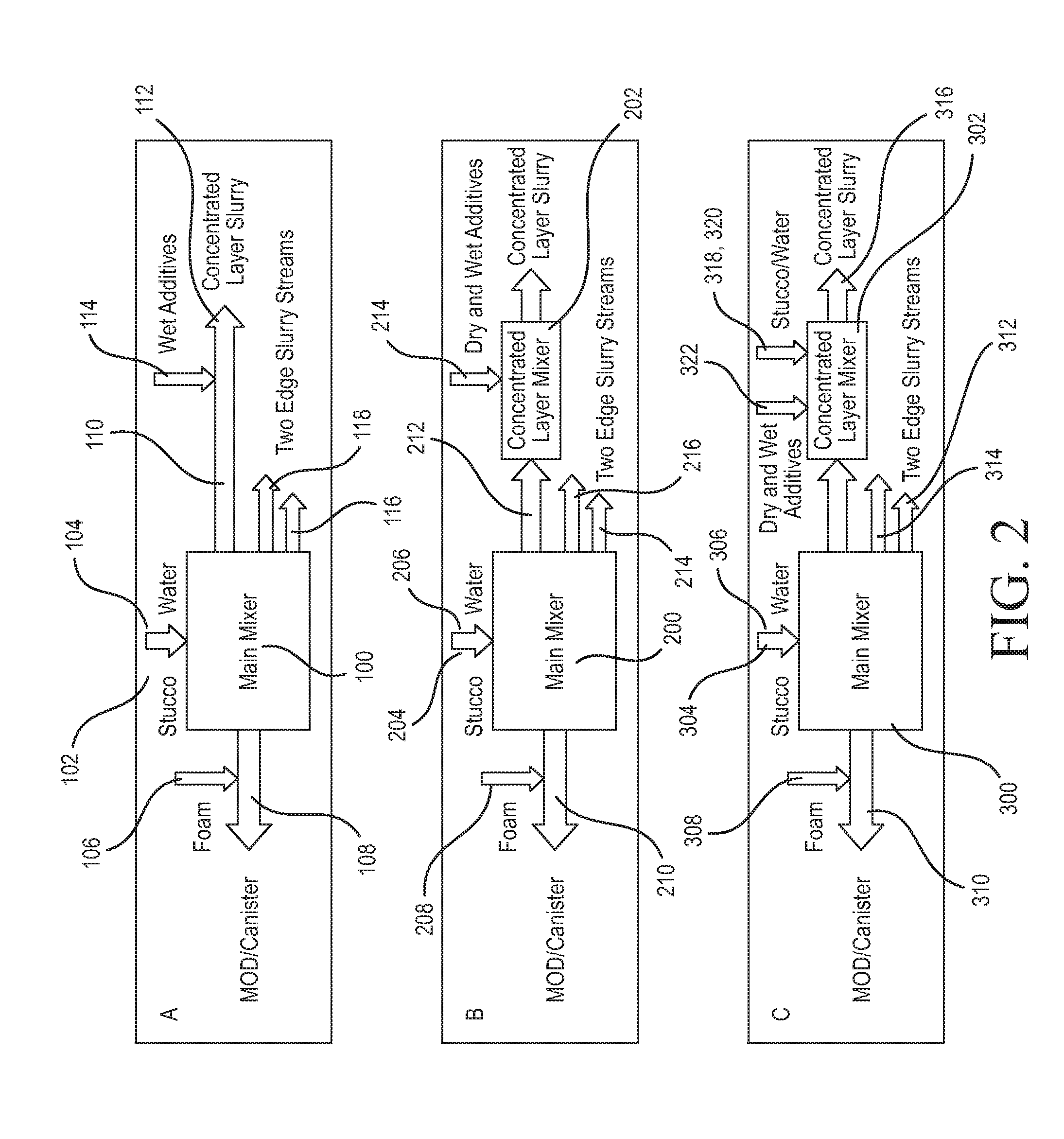

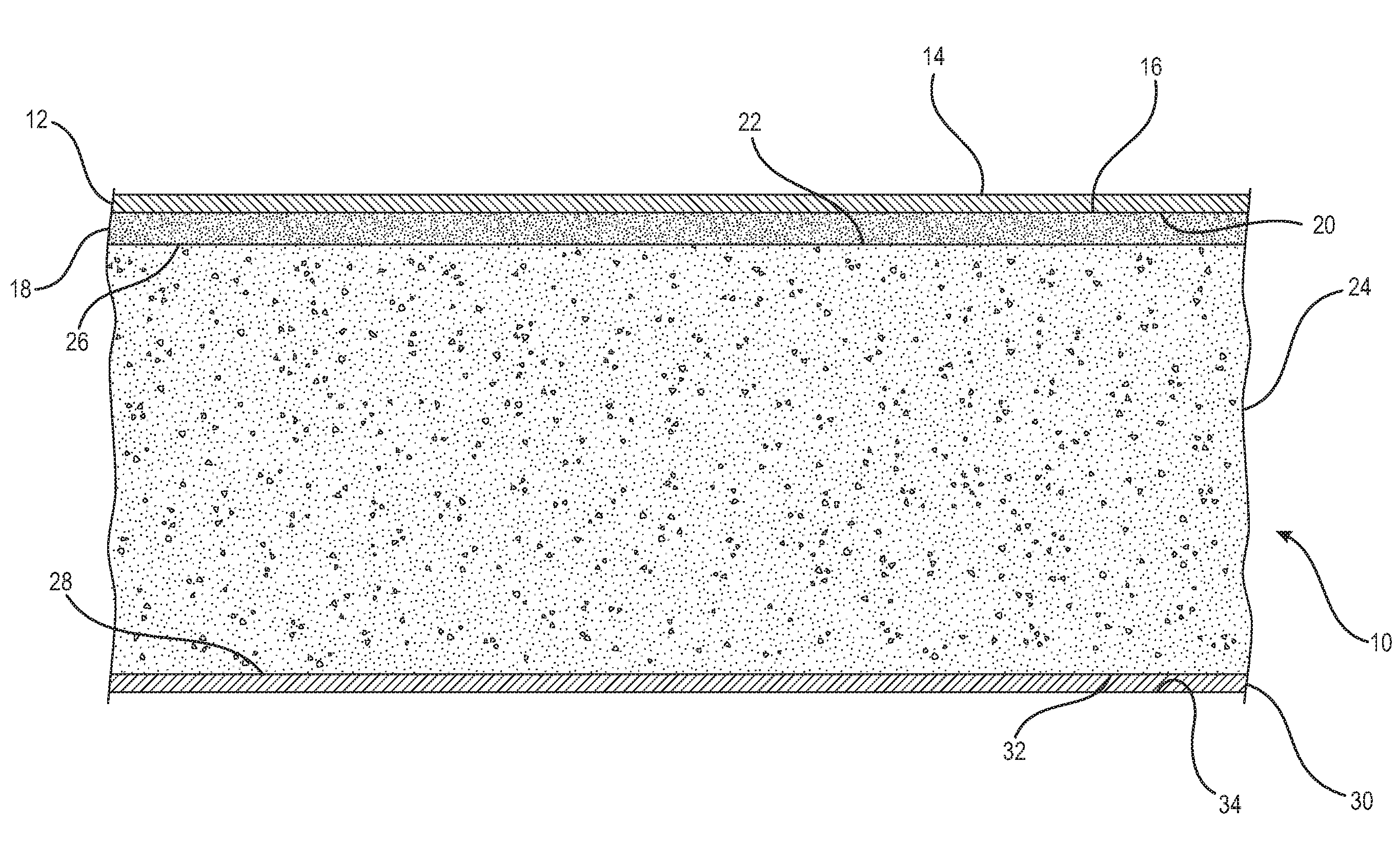

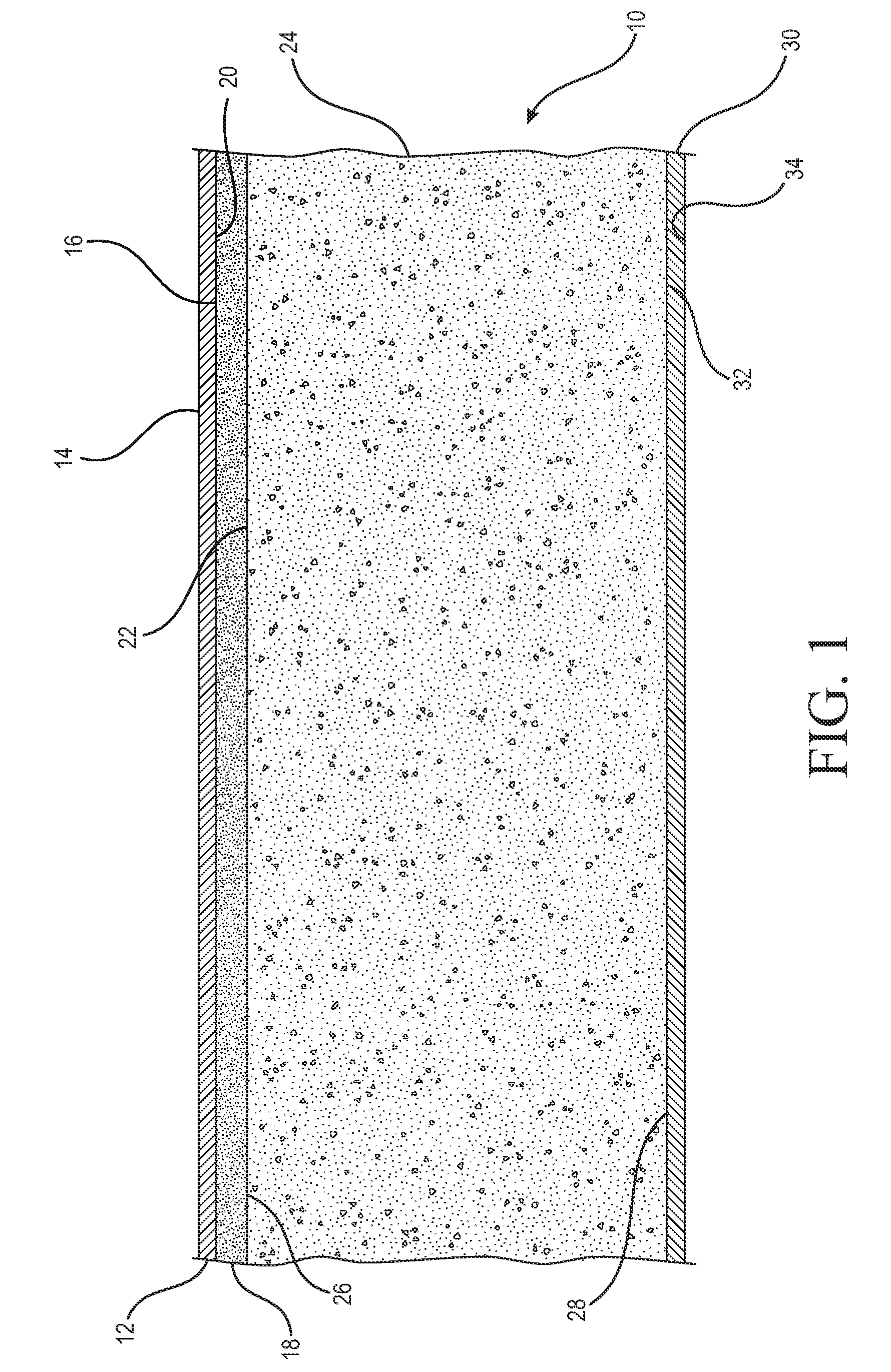

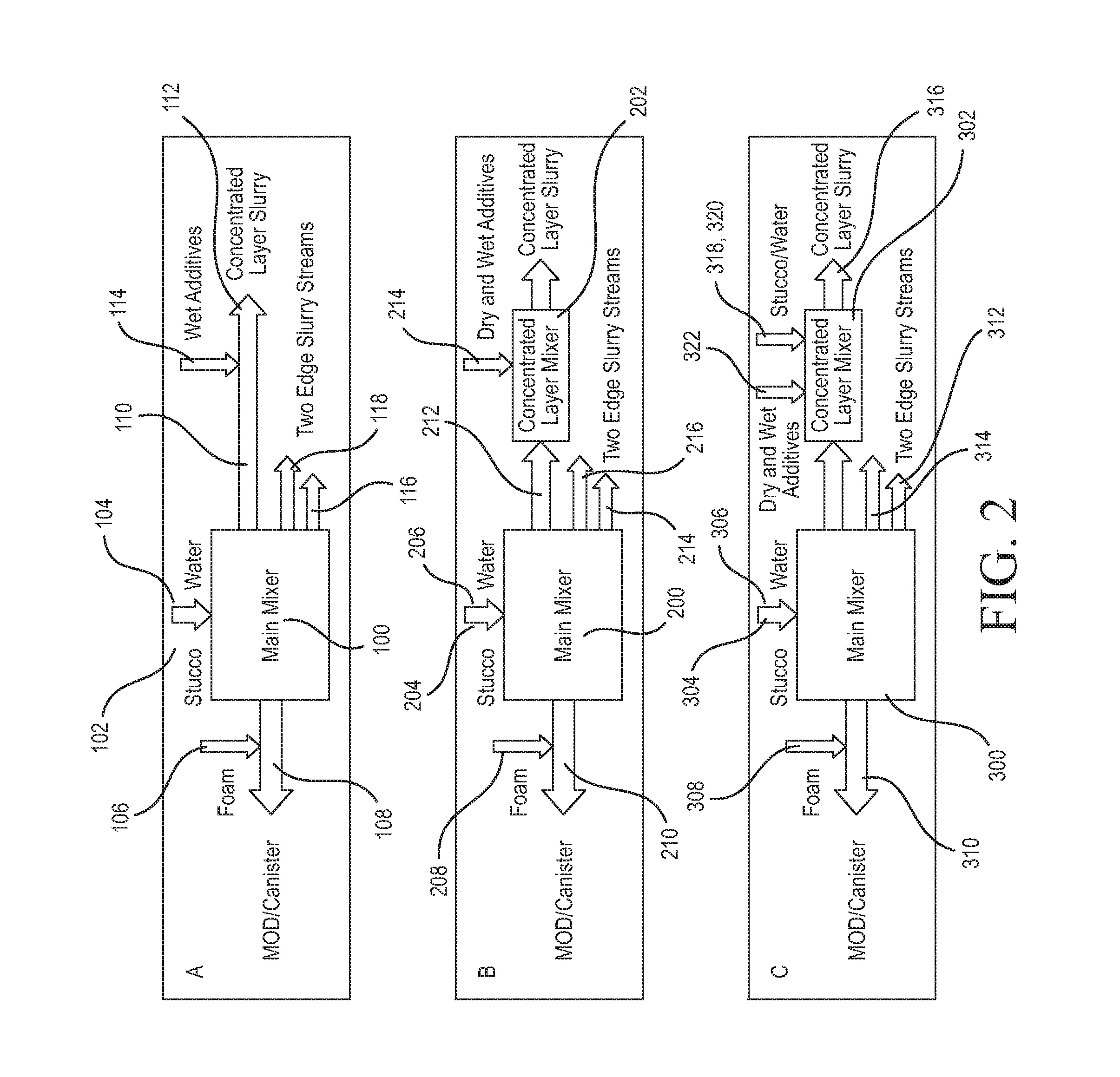

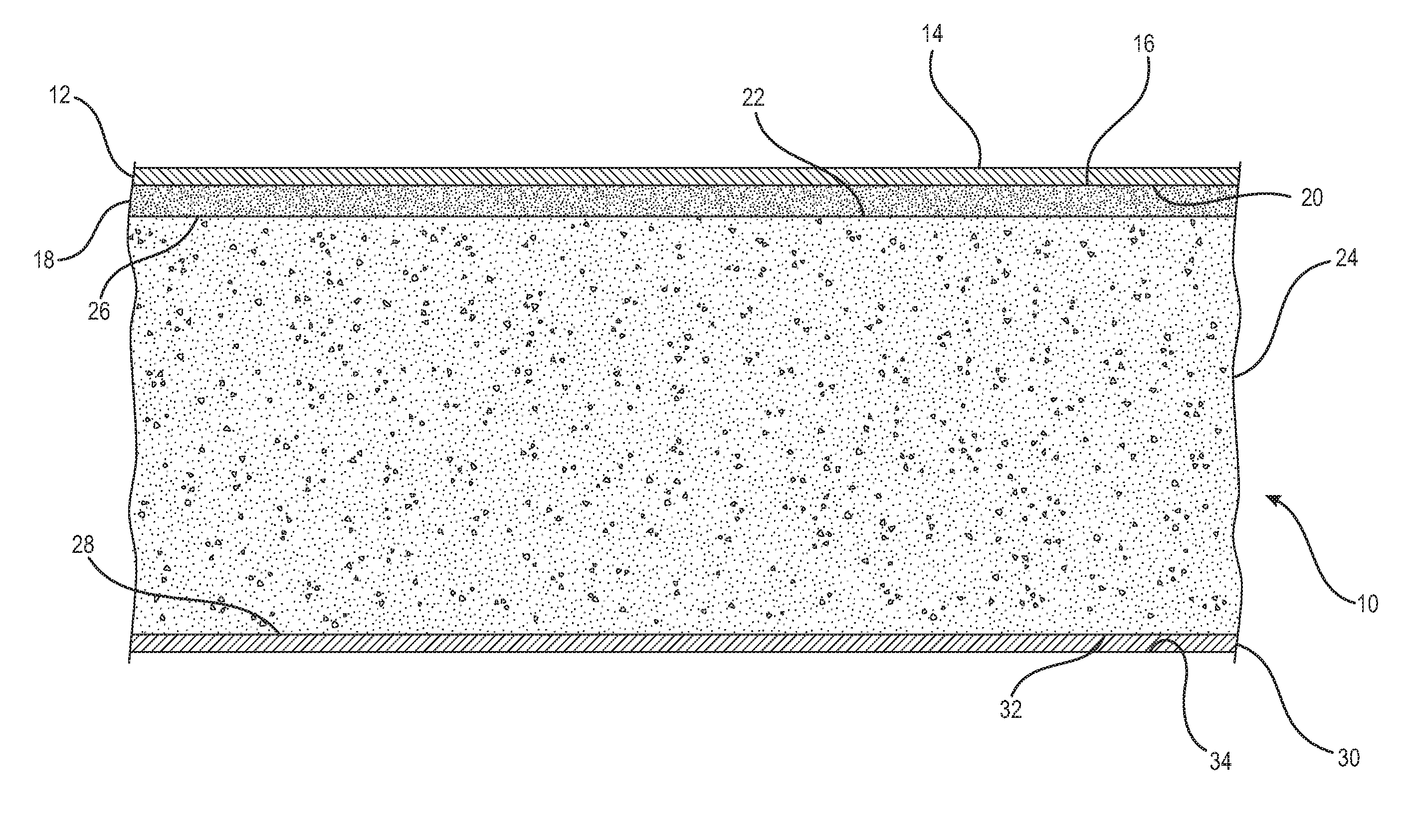

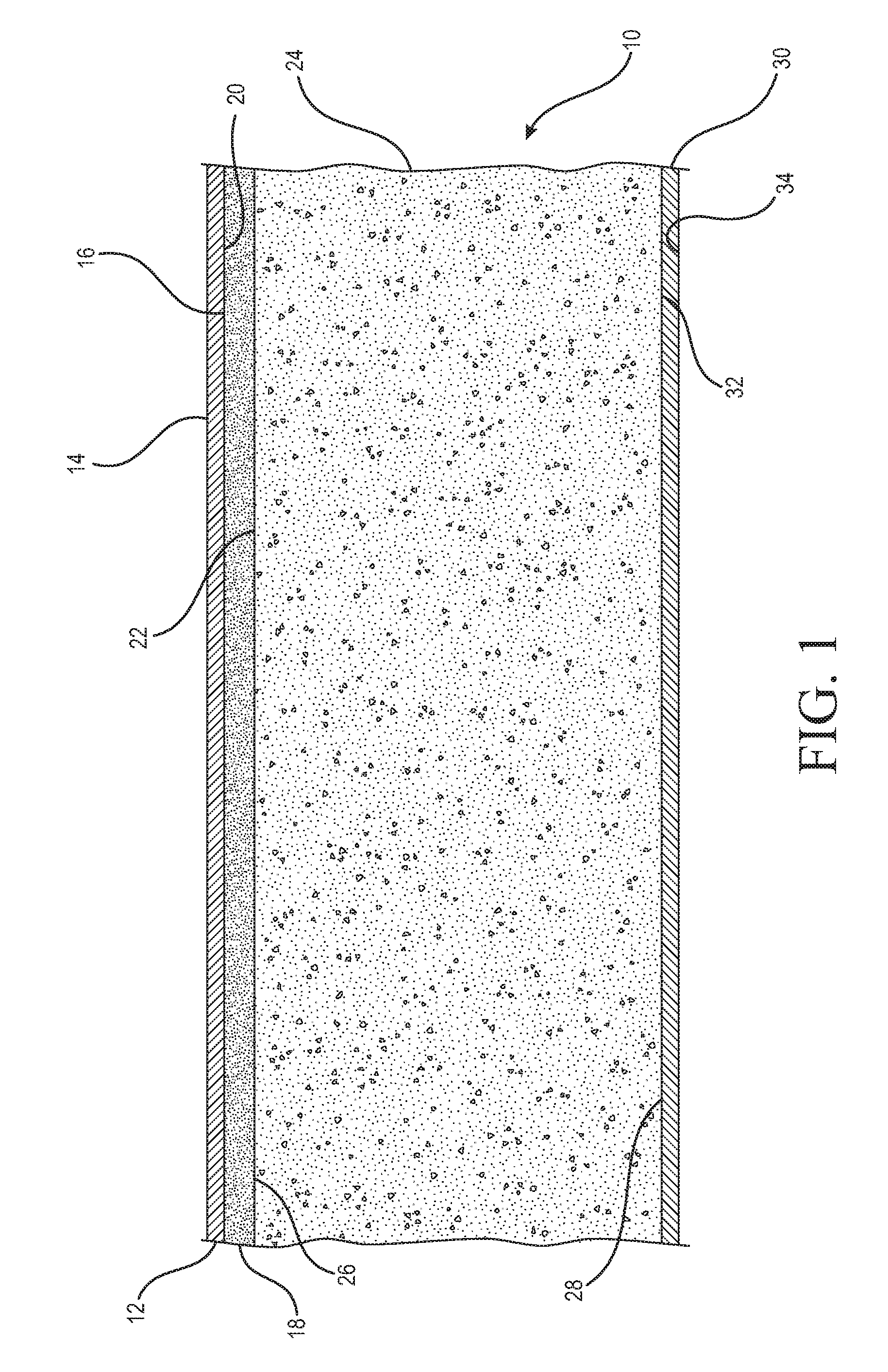

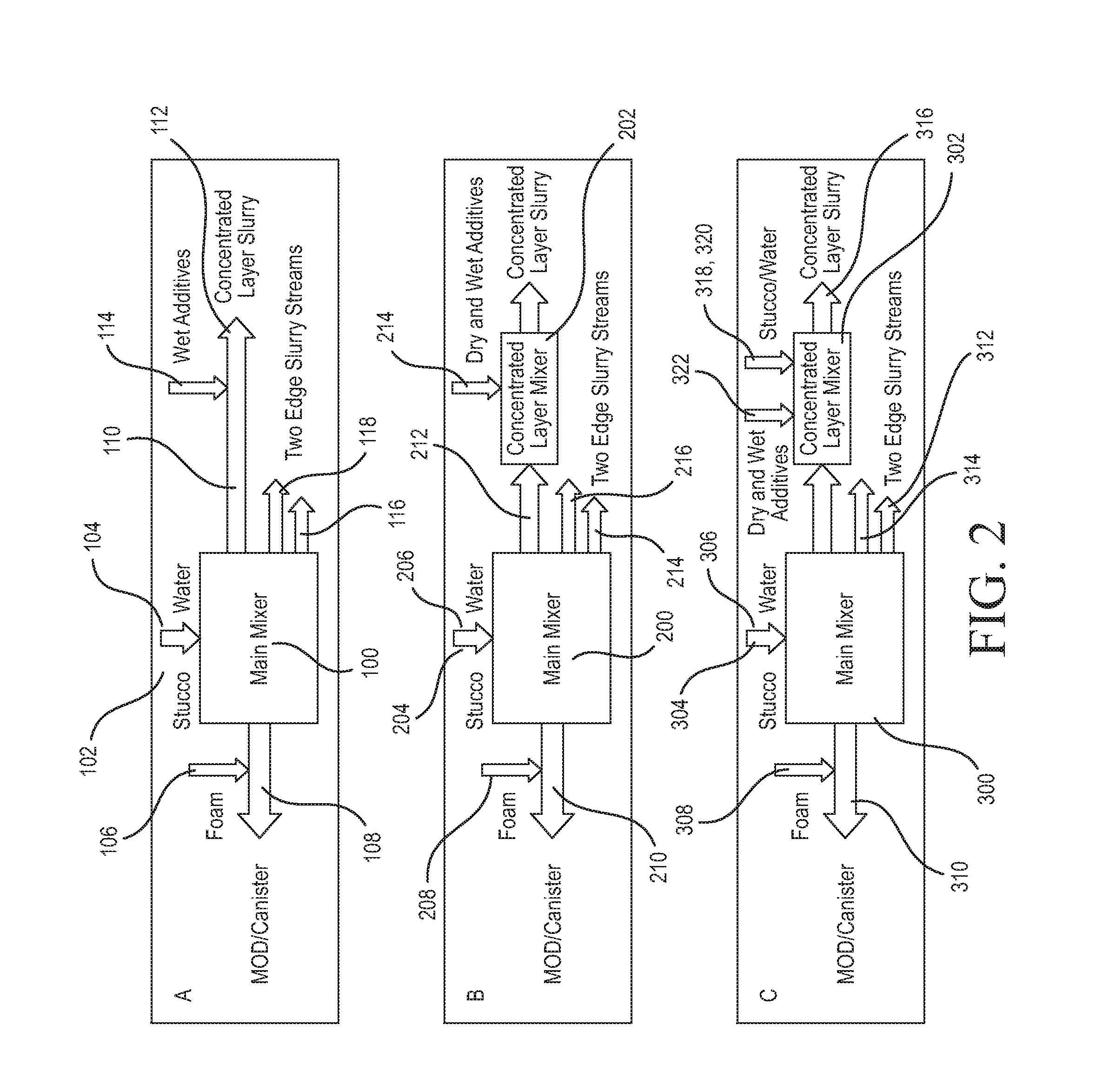

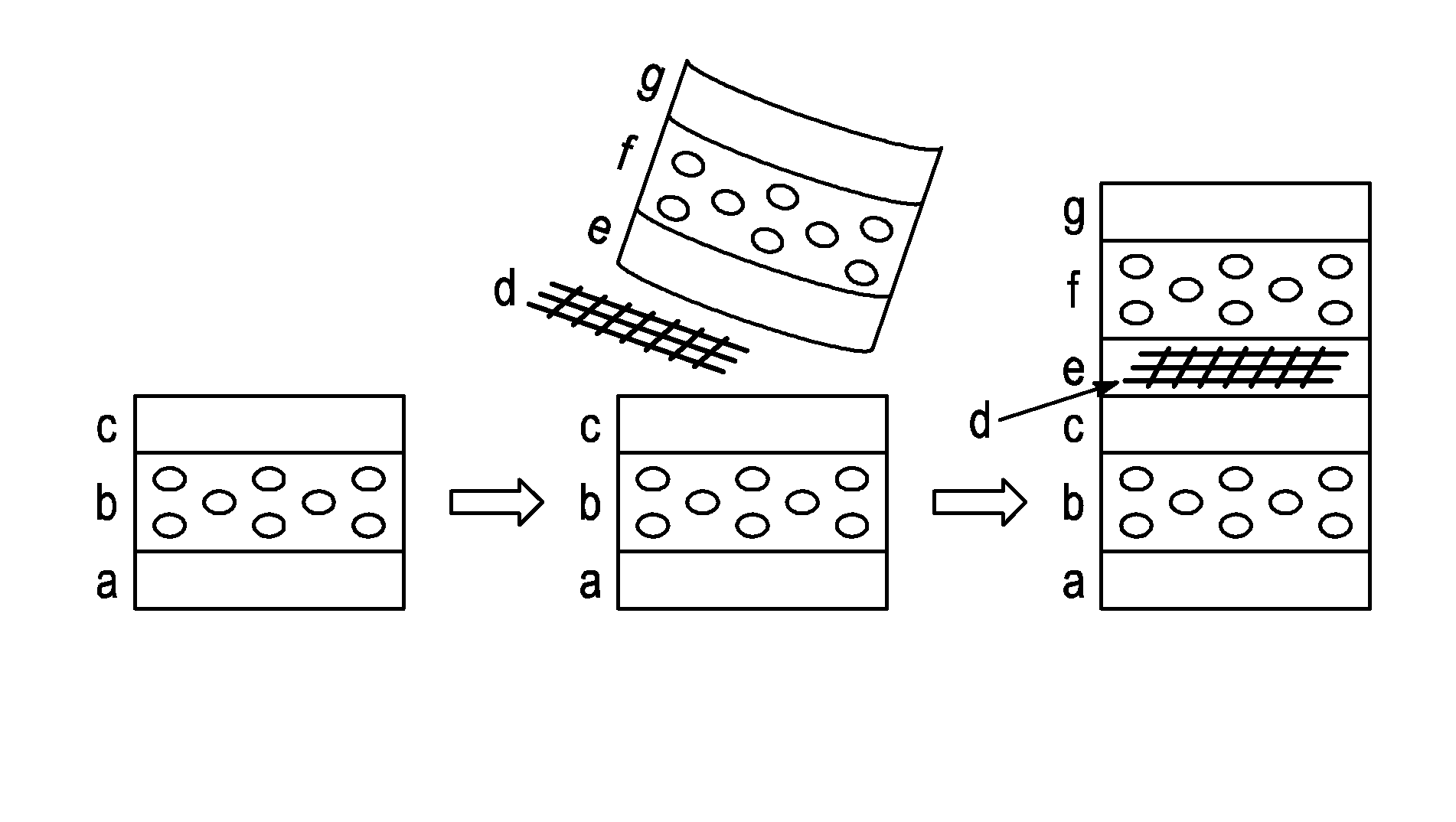

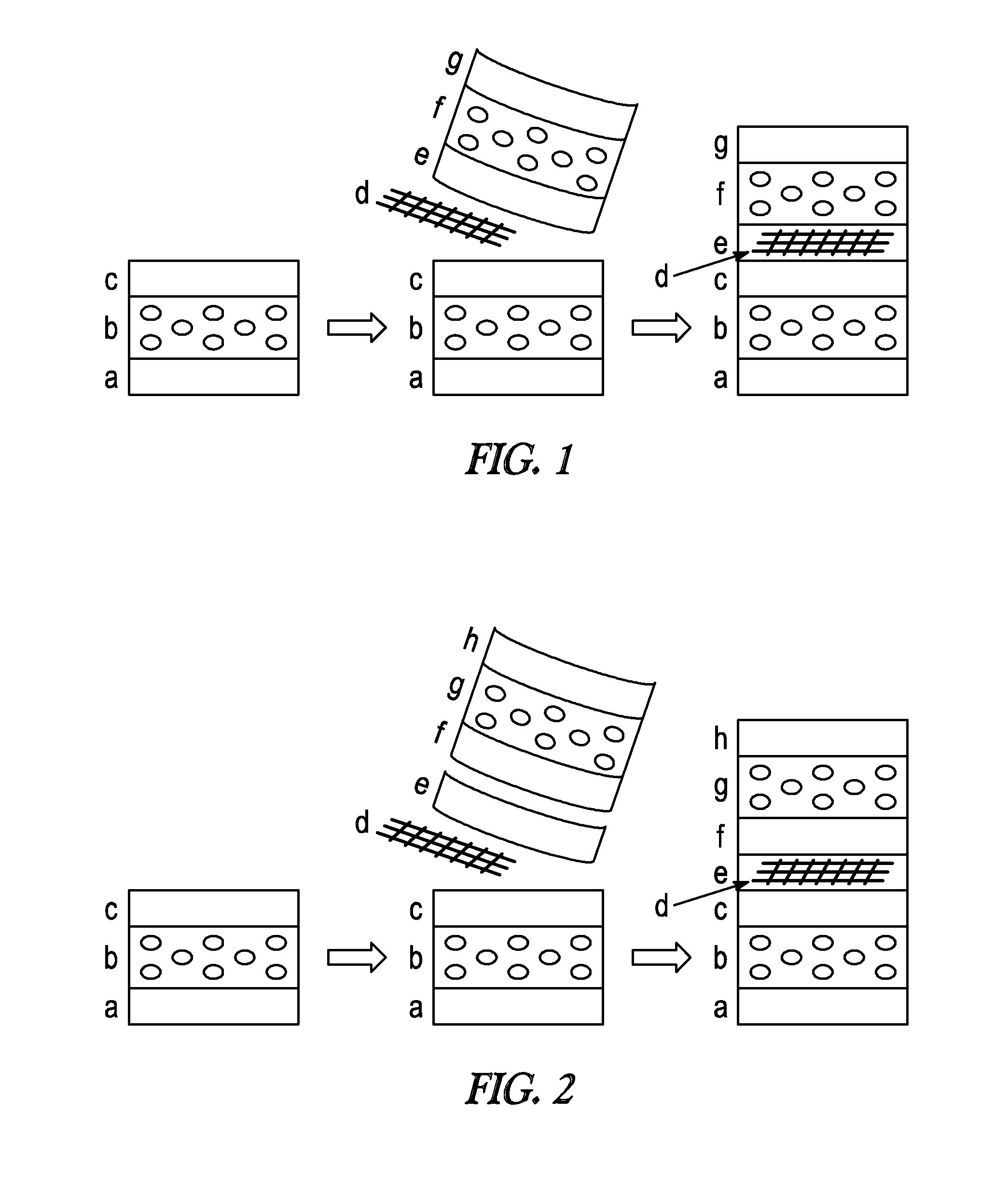

Composite gypsum board and methods related thereto

ActiveUS20160375655A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a board core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the board core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

Shoe

A shoe having a toe region, a middle region, a heel region, and a multi-layer, multi-density midsole wherein an upper layer of the midsole has a bottom surface that has a longitudinal convexity and a longitudinal concavity, the longitudinal convexity typically occupying a substantial portion of the toe region or a substantial portion of the toe region and middle region, and the longitudinal concavity typically occupying a substantial portion of the heel region, the longitudinal convexity and the longitudinal concavity collectively contributing to simulating the effect, and imparting the fitness benefits, of walking on a sandy beach or on a giving or uneven surface regardless of the actual hardness of the surface.

Owner:SKECHERS US II

Compositions of pharmaceutical actives containing diethylene glycol monoethyl ether or other alkyl derivatives

ActiveUS20180071390A1Less viscousLess denseOrganic active ingredientsAerosol deliveryUse medicationDiethylene glycol monoethyl ether

The present invention relates to pharmaceutical compositions of various pharmaceutical actives, especially lyophilic and hydrophilic actives containing Diethylene glycol monoethyl ether or other alkyl derivatives thereof as a primary vehicle and / or to pharmaceutical compositions utilizing Diethylene glycol monoethyl ether or other alkyl derivatives thereof as a primary vehicle or as a solvent system in preparation of such pharmaceutical compositions. The pharmaceutical compositions of the present invention are safe, non-toxic, exhibits enhanced physical stability compared to conventional formulations containing such pharmaceutical actives and are suitable for use as injectables for intravenous and intramuscular administration, as well as for use as a preformed solution / liquid for filling in and preparation of capsules, tablets, nasal sprays, gargles, dermal applications, gels, topicals, liquid oral dosage forms and other dosage forms.

Owner:THEMIS MEDICARE LTD

Shoe

InactiveUS20100146819A1Increase in sizeImprove compression performanceSolesUpperEngineeringHeel region

A shoe having a toe region, a middle region, a heel region, and a multi-layer, multi-density midsole wherein an upper layer of the midsole has a bottom surface that has a longitudinal convexity and a longitudinal concavity, the longitudinal convexity typically occupying a substantial portion of the toe region or a substantial portion of the toe region and middle region, and the longitudinal concavity typically occupying a substantial portion of the heel region, the longitudinal convexity and the longitudinal concavity collectively contributing to simulating the effect, and imparting the fitness benefits, of walking on a sandy beach or on a giving or uneven surface regardless of the actual hardness of the surface.

Owner:SKECHERS US II

Composite gypsum board and methods related thereto

PendingUS20160376191A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a board core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the hoard core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

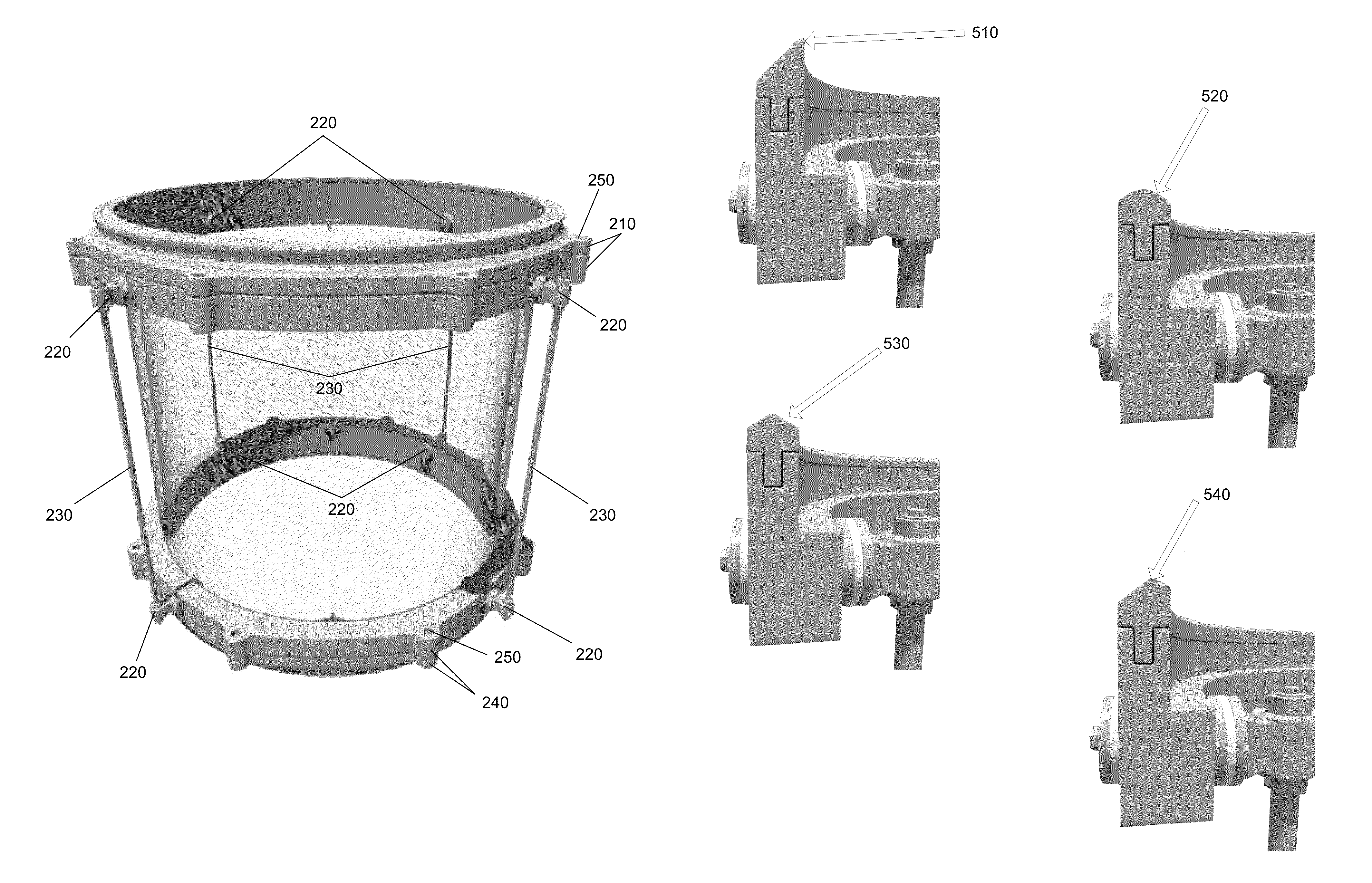

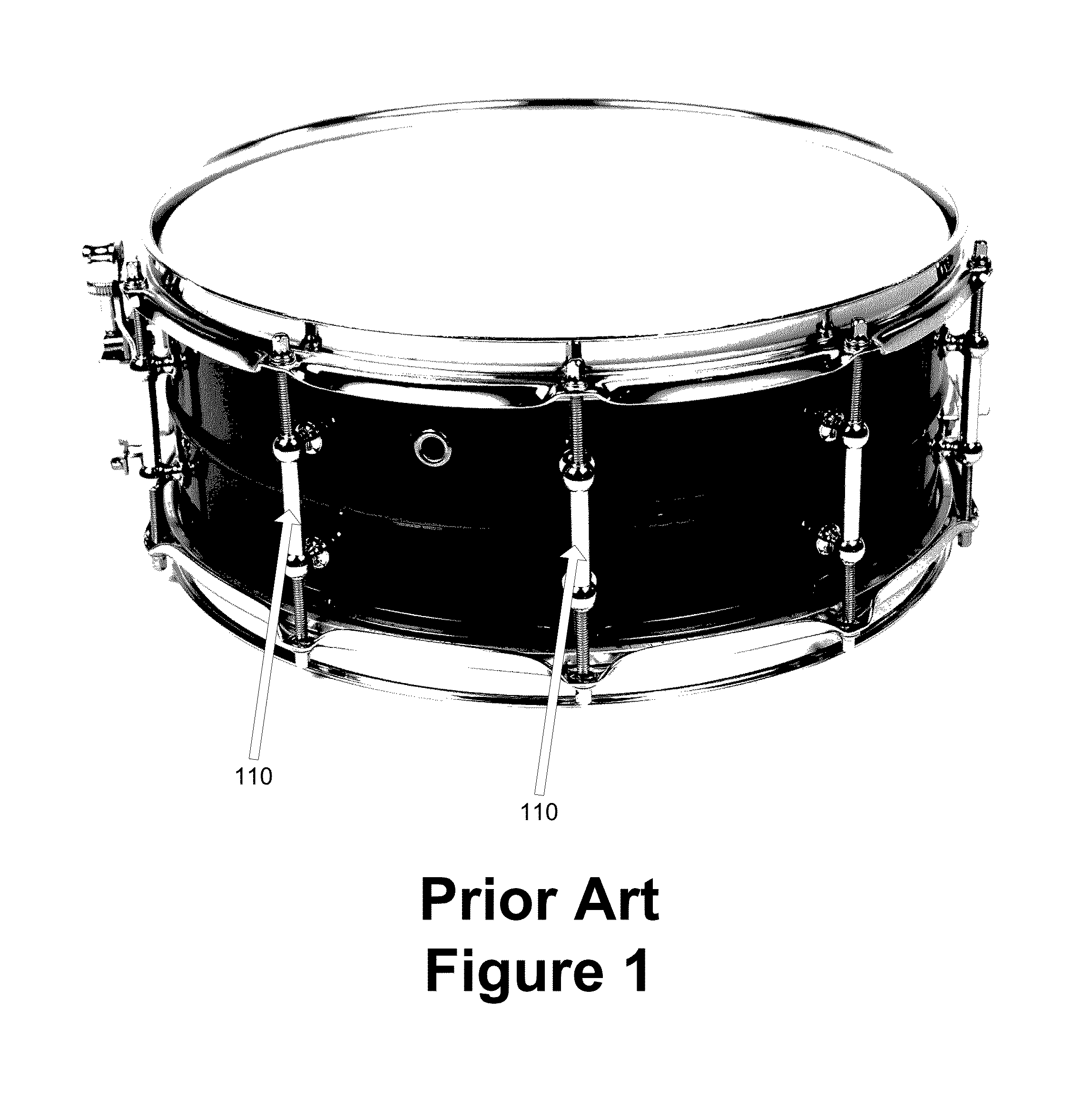

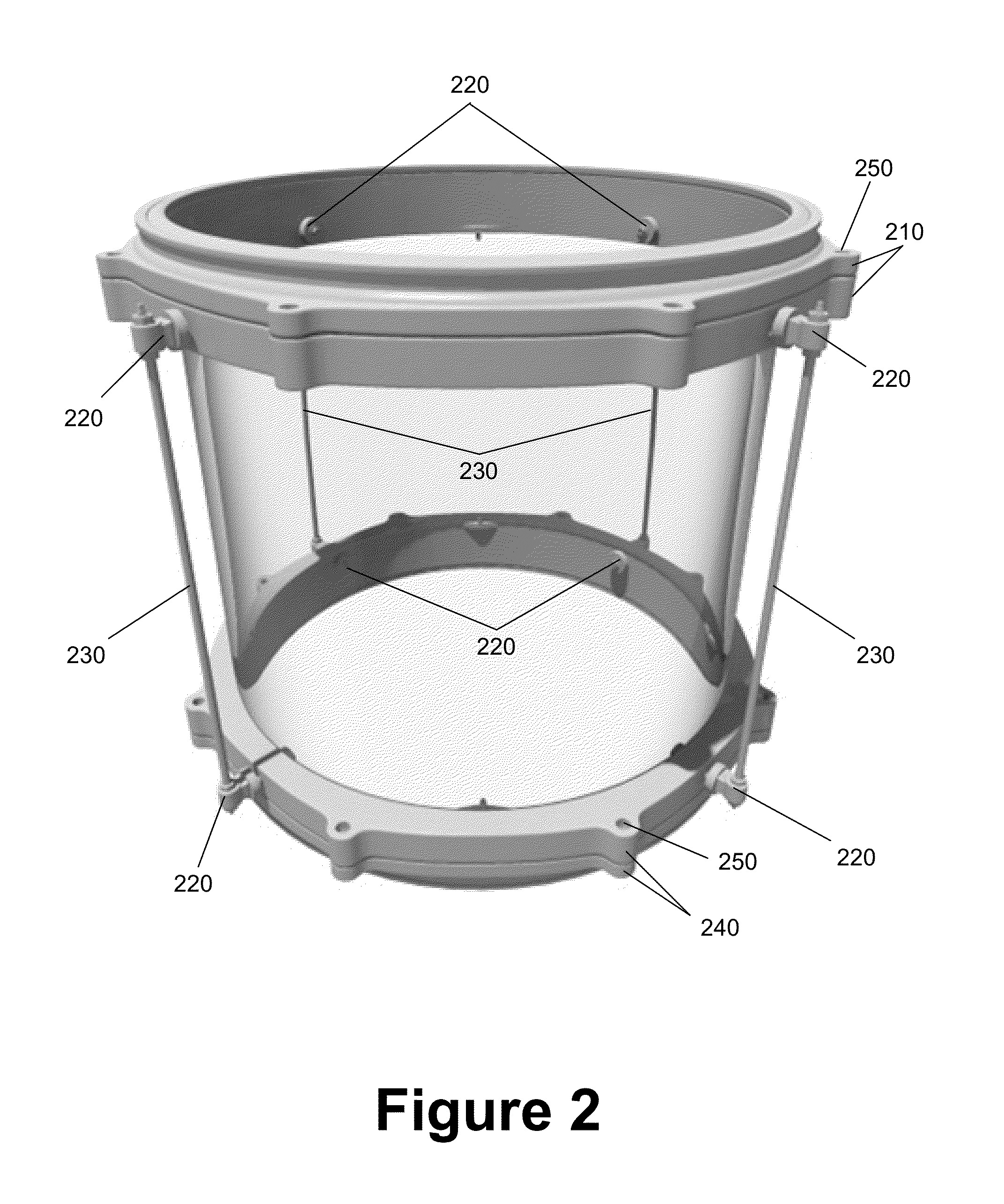

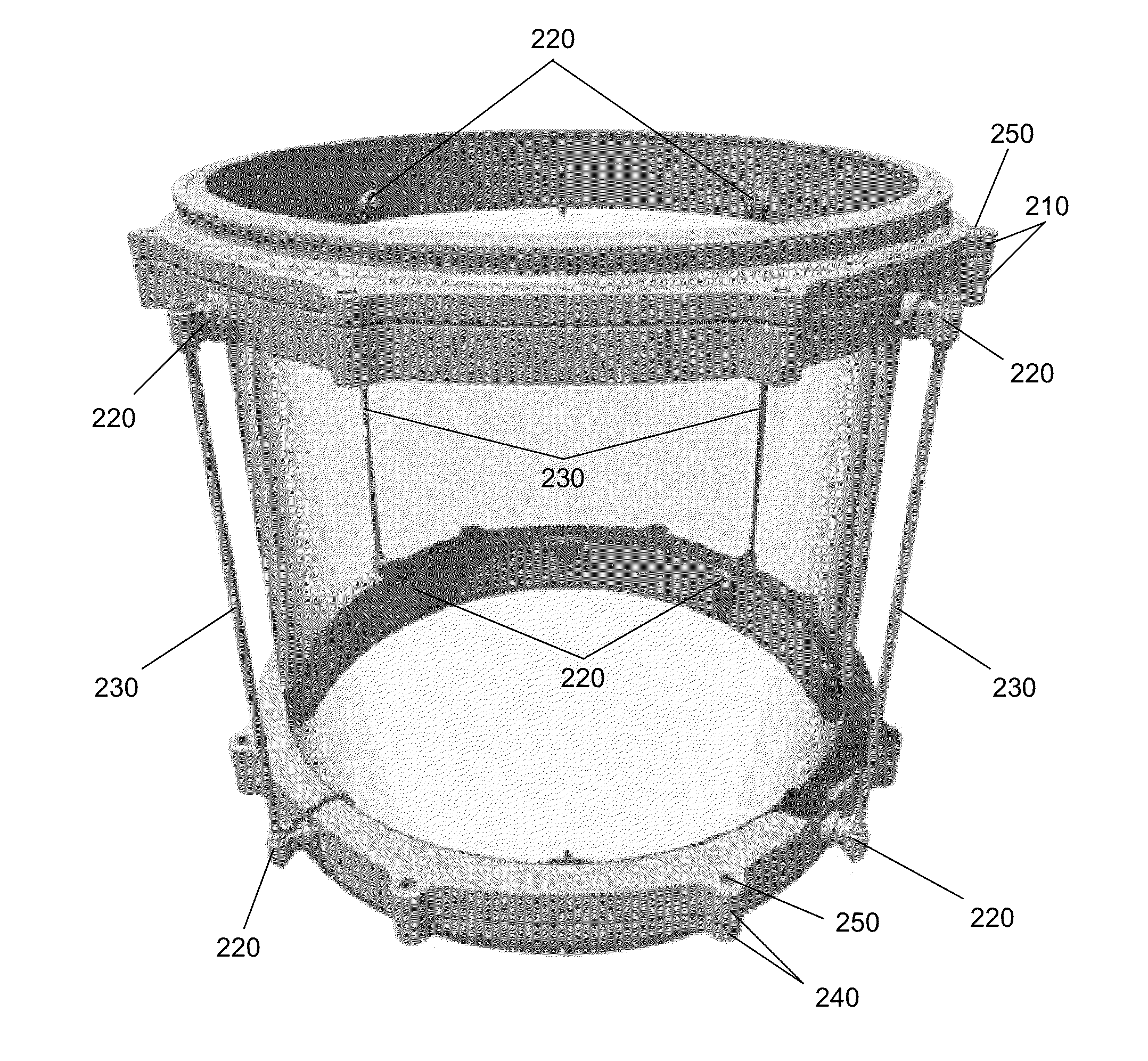

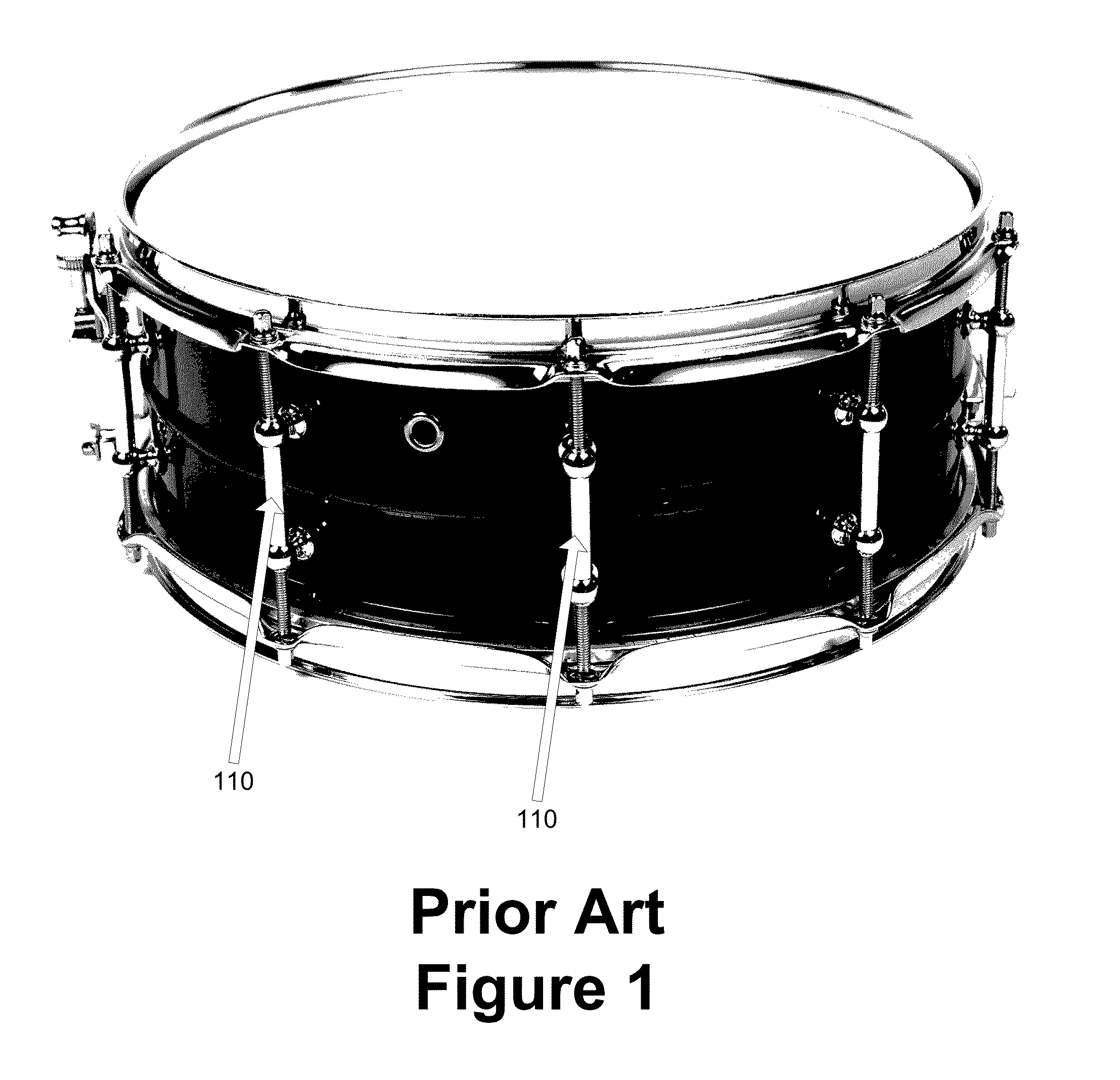

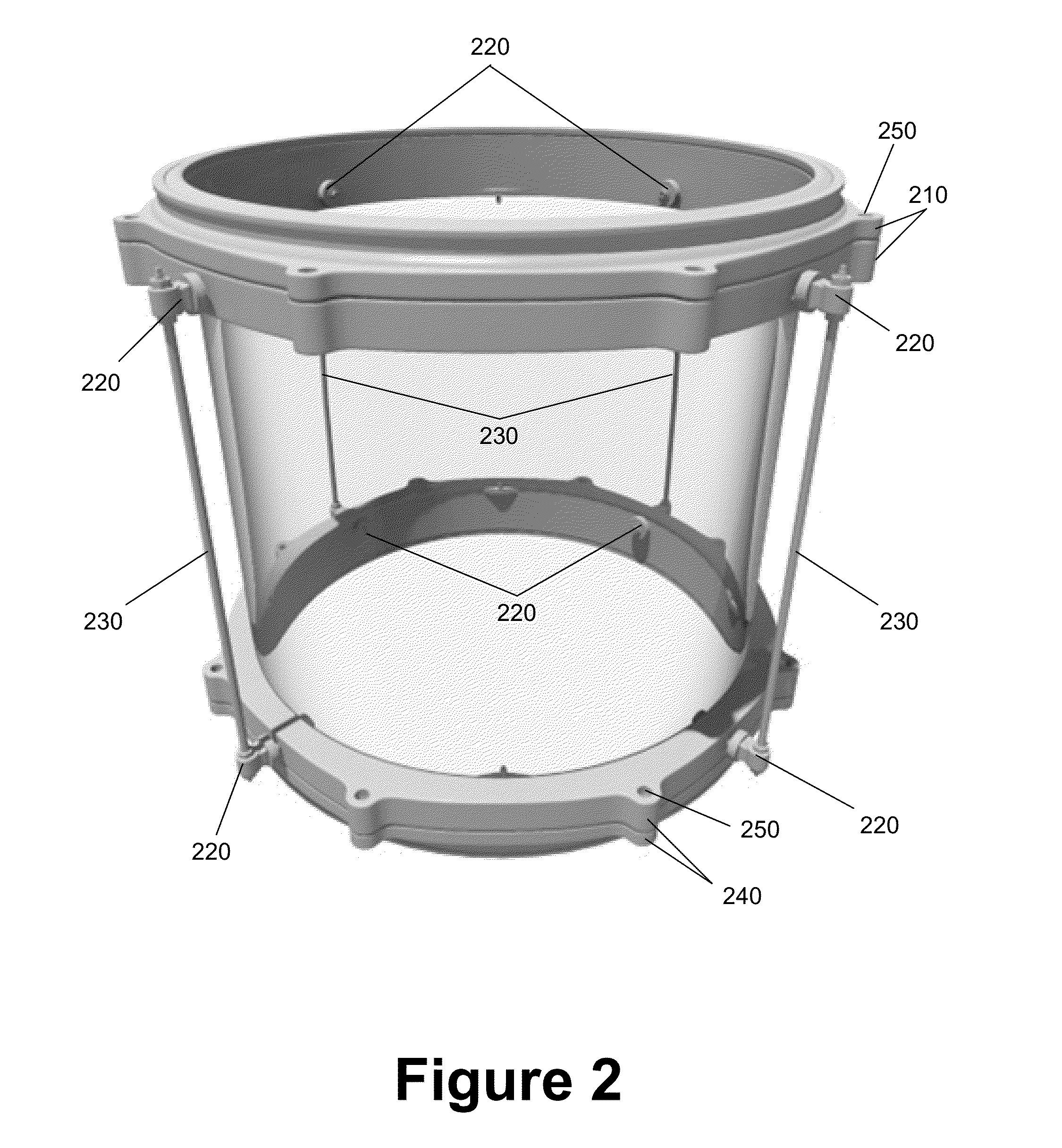

Drum mounting and tuning system providing unhindered and isolated resonance

InactiveUS8629340B1Reducing and completely isolating same energyUndesired distortionPercussion musical instrumentsResonanceEngineering

Some embodiments provide a drum structural framework comprising a top shell mount, bottom shell mount, rod holders, and tension rods. The top shell mount and bottom shell mount are mounted to either ending edge of a drum shell disposed between the two mounts. A first set of the rod holders are coupled to the top shell mount and an aligned second set of the rod holders are coupled to the bottom shell mount. The tension rods link the two sets of rod holders without hindering resonance of the drum shell. Tuning assemblies on the rod holders adjust the distance separating the top shell mount from the bottom shell mount, thereby controlling the force imposed on the drum shell. Each rod holder includes one or more dampeners that isolate energy passing from the drumhead to the shell from also reverberating throughout the structural framework of the tension rods and rod holders.

Owner:MARTIN AUGUST D

Composite gypsum board and methods related thereto

ActiveUS20160375651A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a hoard core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the board core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

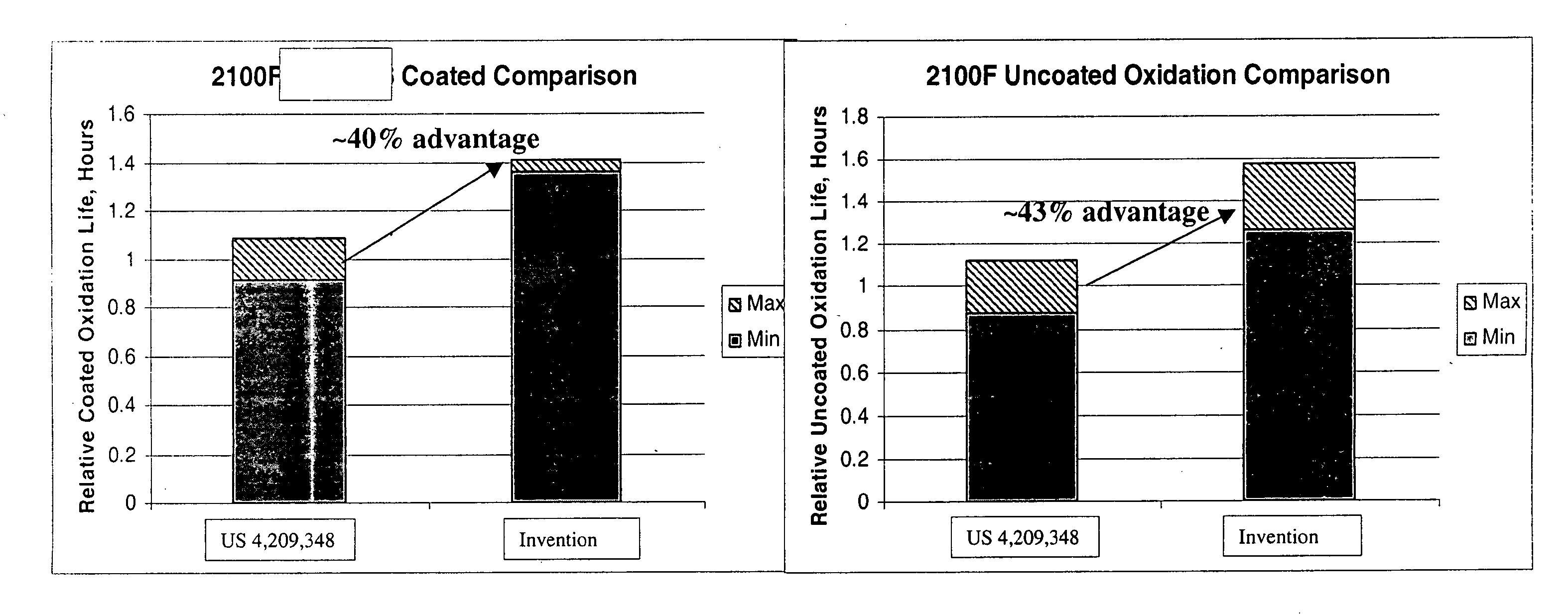

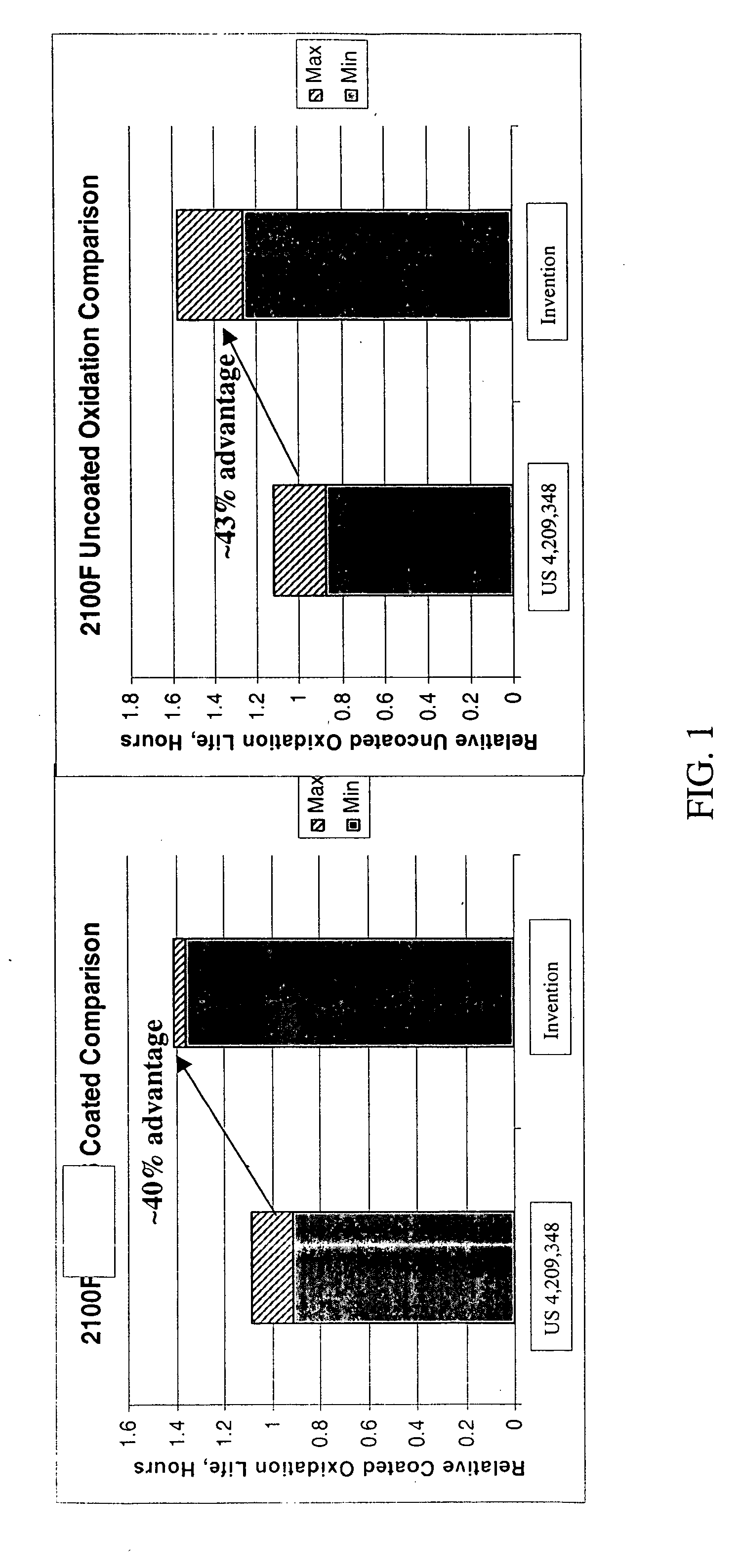

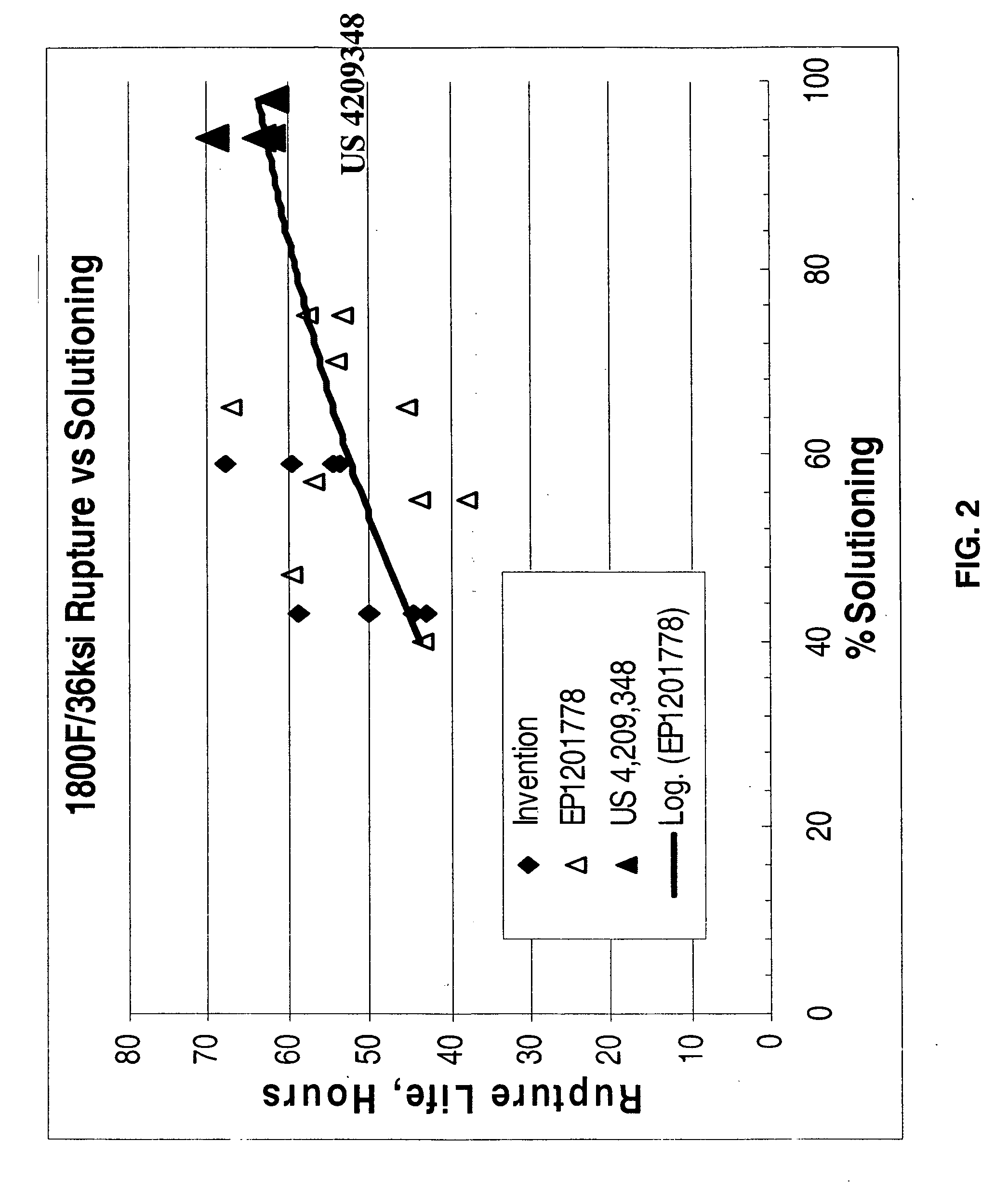

Oxidation resistant superalloy and article

InactiveUS20050271886A1Increased uncoatedIncreased coated oxidation resistanceBlade accessoriesSolid state diffusion coatingOxidation resistantTurbine

An oxidation resistant, nickel base superalloy is described. The combination of alloy and a thermal barrier coating can be used to fabricate turbine components with good high temperature strength and good oxidation resistance, while maintaining other relevant properties.

Owner:UNITED TECH CORP

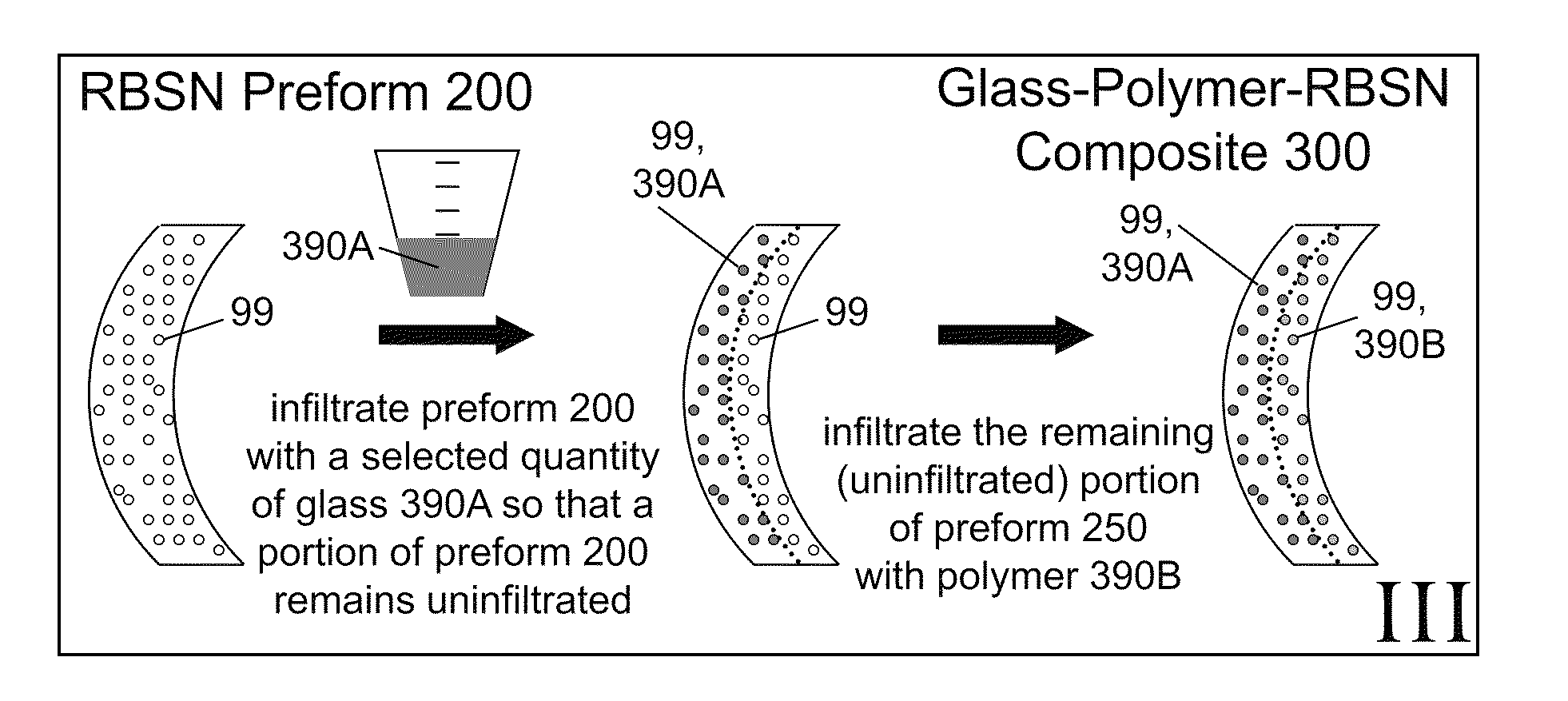

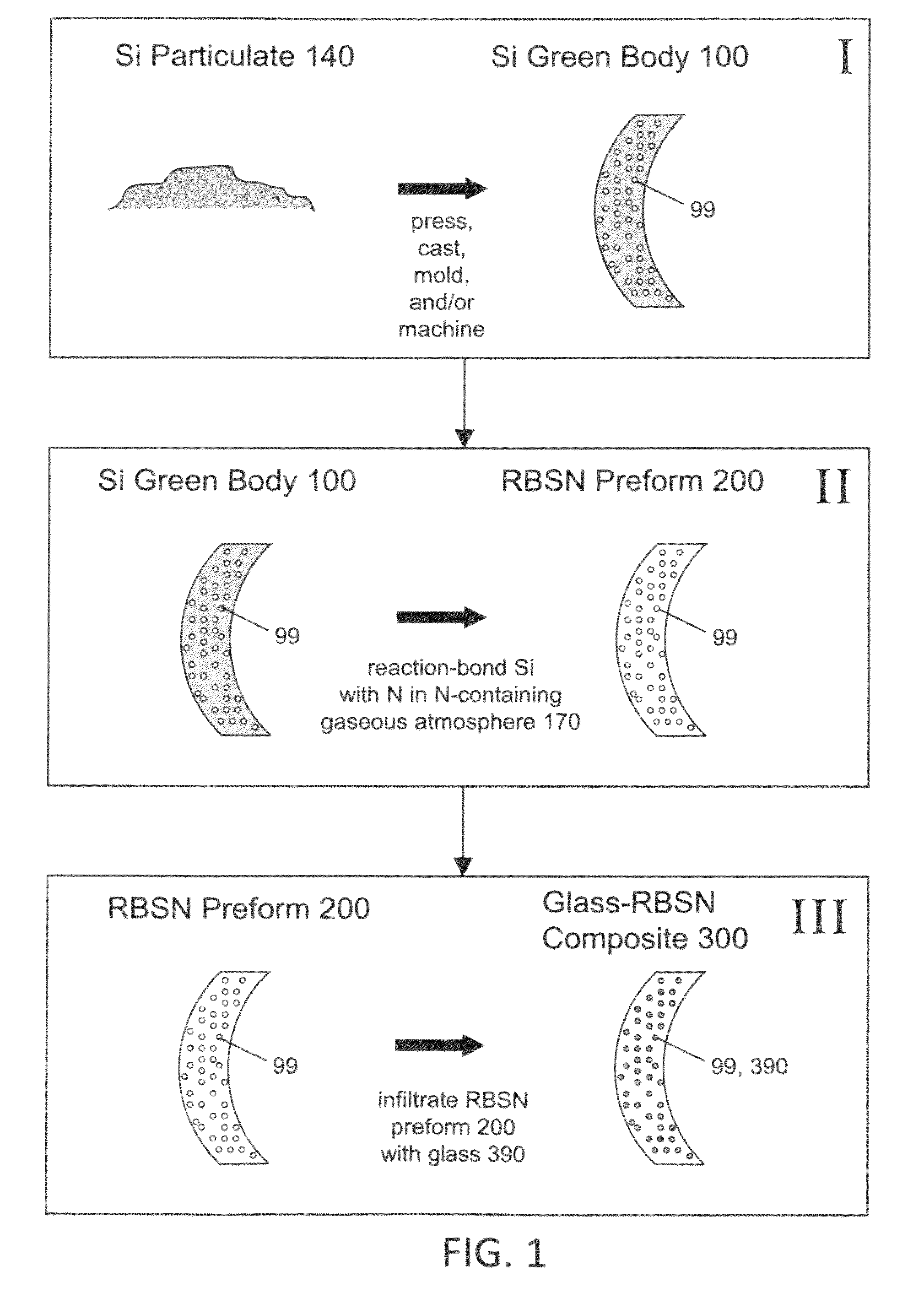

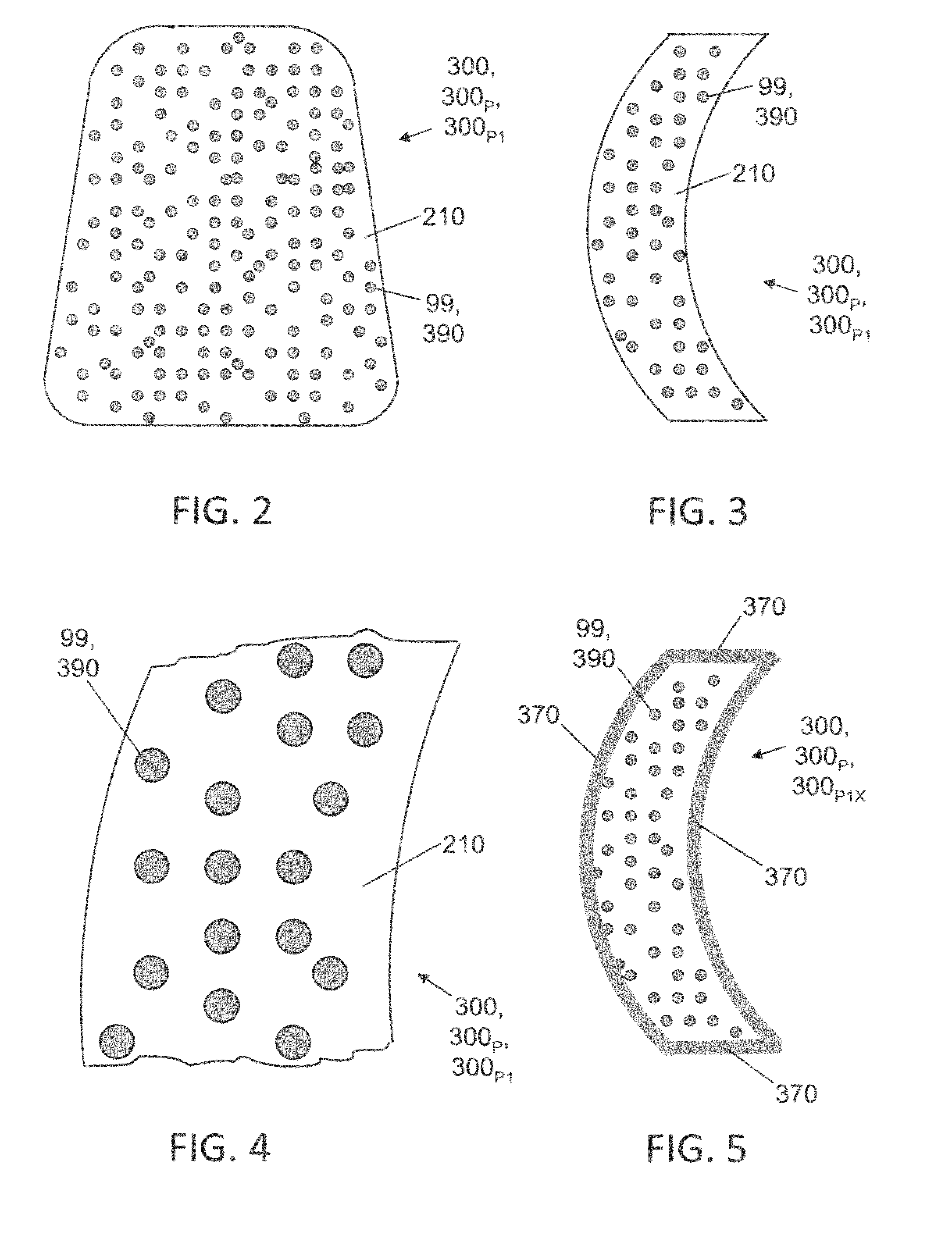

Lightweight ballistic armor including non-ceramic-infiltrated reaction-bonded-ceramic composite material

ActiveUS8105967B1Improve performanceLight weightArmourProtective equipmentParticulatesCeramic composite

According to typical inventive practice, precursor particulate is pressed and / or caste and / or molded and / or machined, thereby producing a porous green body of a desired shape. A gas is brought into contact with the porous green body so that, via reaction bonding between the gas and the porous green body, the porous green body becomes a porous reaction-bonded ceramic preform, geometrically corresponding to the porous green body. One or more infiltrant materials, at least one of which is glass or polymer, is / are caused to infiltrate the pores of the RB ceramic perform. The infiltrants are selected from glass, polymer, and metal. The infiltrated preform is permitted to cool and solidify, resulting in an embodiment of an inventive non-ceramic-infiltrated reaction-bonded-ceramic structure. Because of their potential material attributes such as strength, energy dissipation, and low density, the present invention's non-ceramic-infiltrated reaction-bonded-ceramic structures are especially favorable for inclusion in personal / personnel ballistic armor systems.

Owner:NAVY UNITED STATES OF AMERICA SEC OF THE

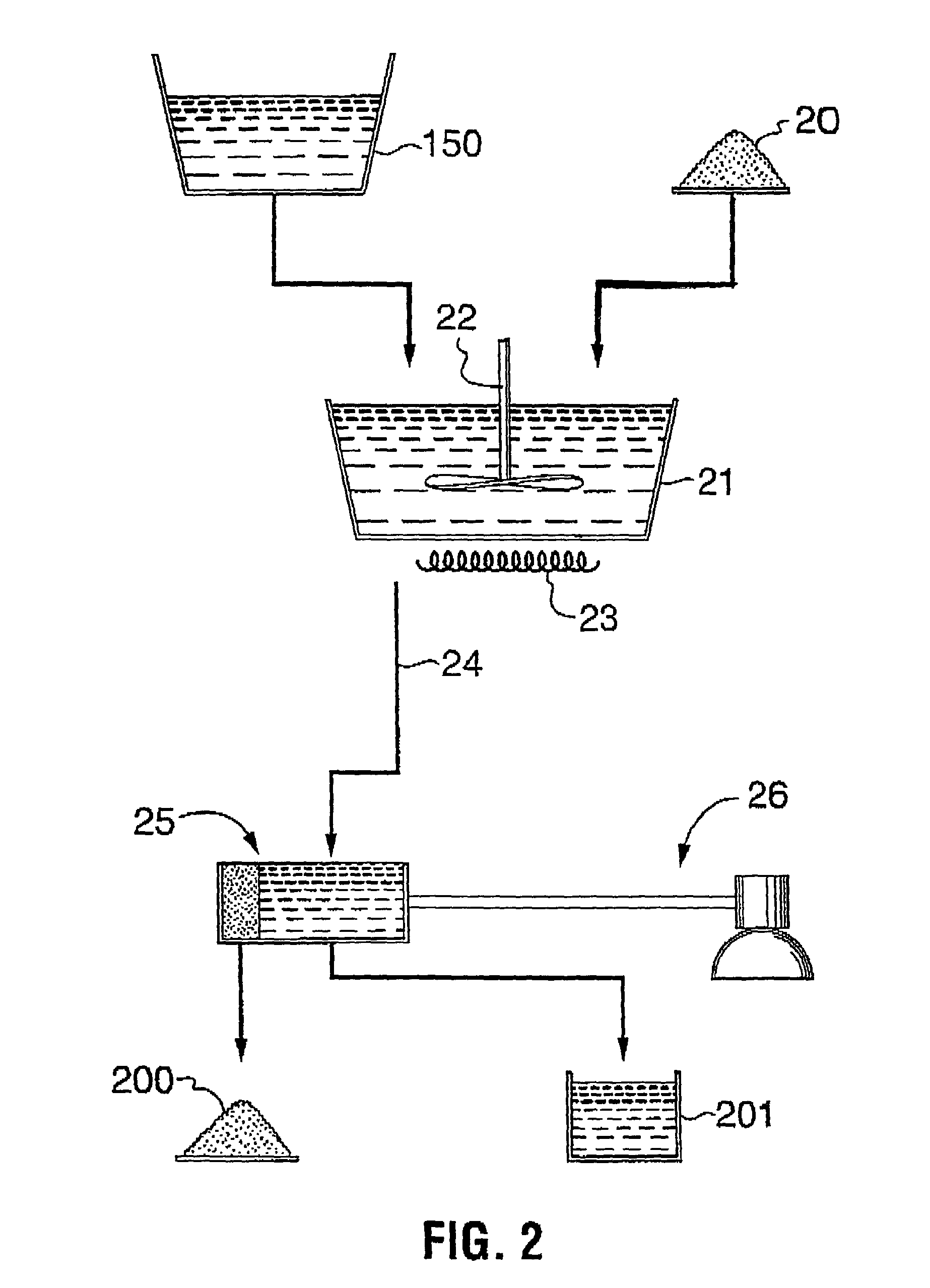

Oilseed processing

InactiveUS7090887B2Improve solubilityEasy to separateOrganic active ingredientsHydrolasesBiotechnologyAnimal food

Crushed and de-fatted oilseed is extracted with water at neutral, mildly basic or mildly acidic pH; and is filtered. The filter media allows passage of small fragments of solid cell meat into the filtrate. The filtrate is treated with a base to increase pH to over pH 9, and solids are separated out. Protein is separated from other constituents of the liquid and concentrated, for example by heat-induced or isoelectric precipitation and / or ultrafiltration. The remaining liquid is rich in sugars. The process results in one or more protein products suited for human or animal food ingredients or for production of cosmetics, a sugar rich product suitable for fermentation or use as a feed ingredient, and a fiber-protein animal feed ingredient.

Owner:BUNGE GLOBAL INNOVATION LLC

Pizza and crust having an irregular edge

InactiveUS20040175477A1Enhanced premium crustIncrease moisture contentBaking mixturesPre-baking dough treatmentBrickEngineering

Premium quality parbaked frozen pizza can be made by adding premium rough cut toppings to a premium generally square crust having a rough edge mimicking a hand formed crust. The pizza provides the appearance of being hand made and baked in a brick wood fired oven providing a crispy exterior, a soft interior crust having characteristic toasted color indicia. In use, the pizza is packaged in conventional corrugated forms, outer wrapped and packaged for delivery in retail environments. The product can be removed from its packaging and baked at home, mimicking a product from a restaurant grade preparation.

Owner:SCHWANS GLOBAL SUPPLY CHAIN +1

Compositions of pharmaceutical actives containing diethylene glycol monoethyl ether or other alkyl derivatives

InactiveUS9827315B2Less viscousLess denseOrganic active ingredientsBiocideUse medicationDiethylene glycol monoethyl ether

The present invention relates to pharmaceutical compositions of various pharmaceutical actives, especially lyophilic and hydrophilic actives containing Diethylene glycol monoethyl ether or other alkyl derivatives thereof as a primary vehicle and / or to pharmaceutical compositions utilizing Diethylene glycol monoethyl ether or other alkyl derivatives thereof as a primary vehicle or as a solvent system in preparation of such pharmaceutical compositions. The pharmaceutical compositions of the present invention are safe, non-toxic, exhibits enhanced physical stability compared to conventional formulations containing such pharmaceutical actives and are suitable for use as injectables for intravenous and intramuscular administration, as well as for use as a preformed solution / liquid for filling in and preparation of capsules, tablets, nasal sprays, gargles, dermal applications, gels, topicals, liquid oral dosage forms and other dosage forms.

Owner:THEMIS MEDICARE LTD

Shoe

The present invention provides a shoe having a multi-layer, multi-density midsole where the surfaces between midsole layers have one or more convexities and one or more concavities which collectively contribute to simulating the effect, and imparting the fitness benefits, of walking on a sandy beach or on a giving or uneven surface regardless of the actual hardness of the surface.

Owner:SKECHERS US II

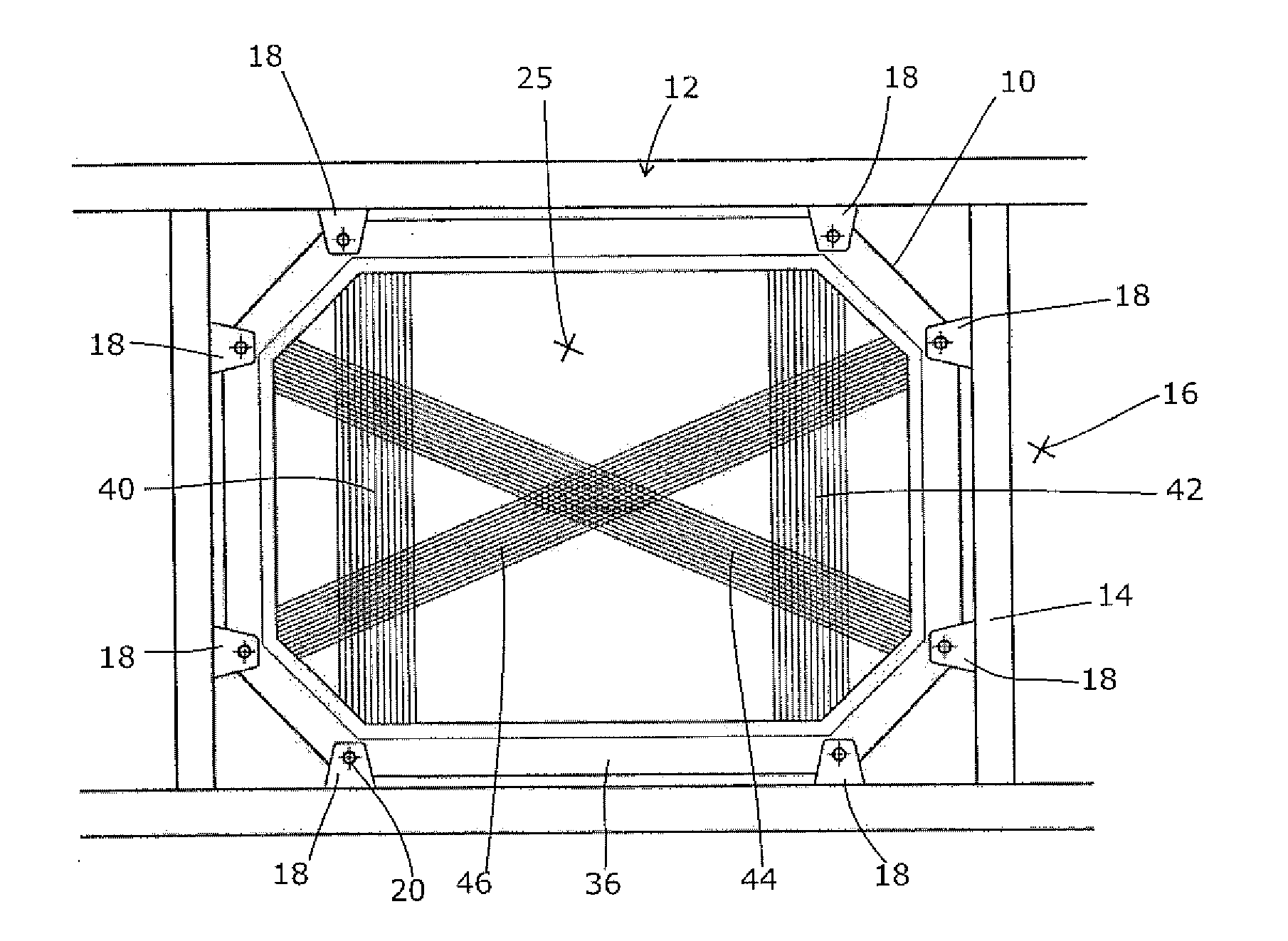

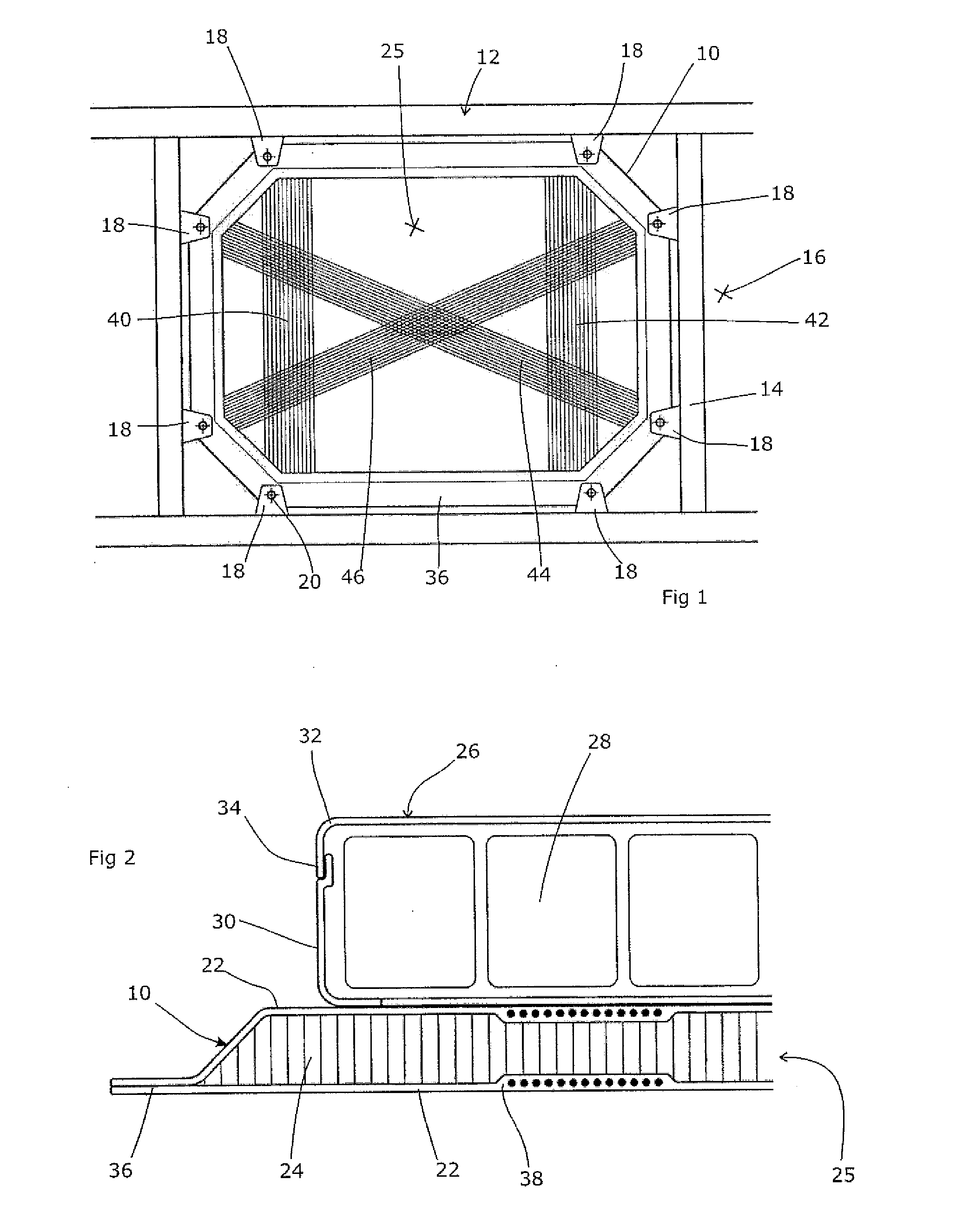

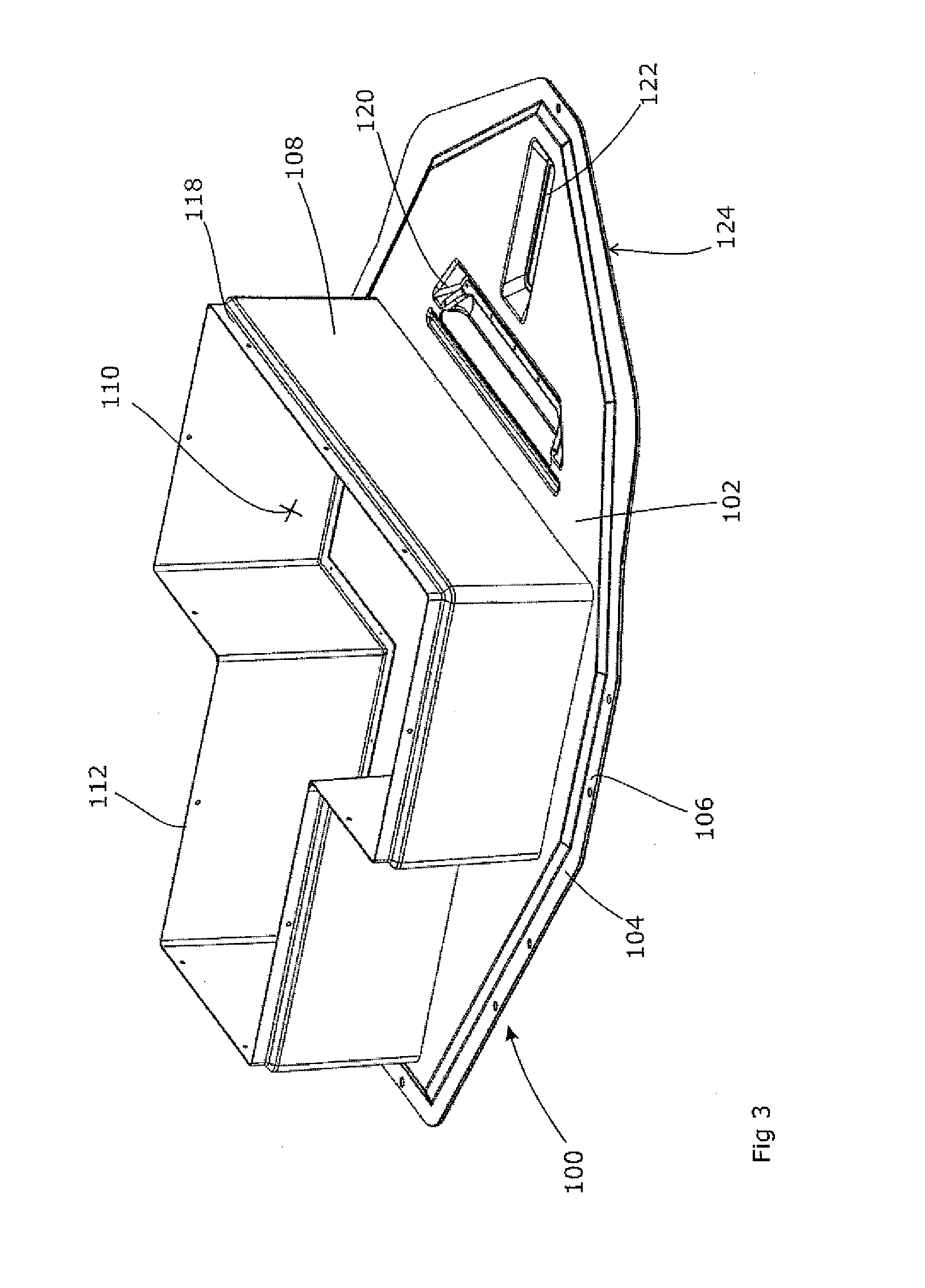

Electric vehicles

ActiveUS20130175104A1Light weightImprove rigidityCharging stationsElectric propulsion mountingFiberElectricity

Electric vehicles usually inherit a chassis of a pressed steel construction from a conventional vehicle design. This imposes a substantial weight penalty on the vehicle. We disclose a chassis element for a vehicle, formed of an outer skin material, an inner core material enveloped by the outer skin material, and at least one array of aligned fibres, and comprising a restraint for an electrical battery adapted to locate the battery over the at least one array. There can be multiple arrays of aligned fibres, preferably disposed at a transverse angle relative to each other of less than 90°. We particularly prefer three arrays of aligned fibres, which can be disposed relative to each other at an angle of 60°. The fibres can be disposed within the skin material. The restraint ideally comprises an upstanding wall which will serve to confine the batteries in the event of a collision or other sudden movement, but will allow them to be replaced easily for maintenance purposes or to replace an exhausted set of batteries with a charged set. Alternatively, the restraint can comprise an attachment point for the battery. The core material is preferably less dense than the skin material, thereby allowing the composite element to have a light weight and a high rigidity. The application also relates to a vehicle comprising a chassis, an electric motor, a chassis element as set out above, and electrical connections from the battery to the motor, wherein the chassis element is attached to the chassis via removable fixings extending through the fixing points of the chassis element into corresponding fixing points on the chassis

Owner:GORDON MURRAY TECH LTD

Polyethylene foam and multilayered structure including the same

InactiveUS20140272229A1Superior physical and mechanical propertyGreat tear strengthWarp knittingKnotting netsGeomembraneMaterials science

The present invention relates to polyethylene foam and materials including the same. In various embodiments, the present invention provides a foam including a solid composition including polyethylene, and a gaseous composition including a blowing agent. Various embodiments provide a multilayered structure including the foam, and methods of making and using the foam and multilayered structure. In various embodiments, the multilayered structure can be a geomembrane.

Owner:RAVEN ENGINEERED FILMS INC

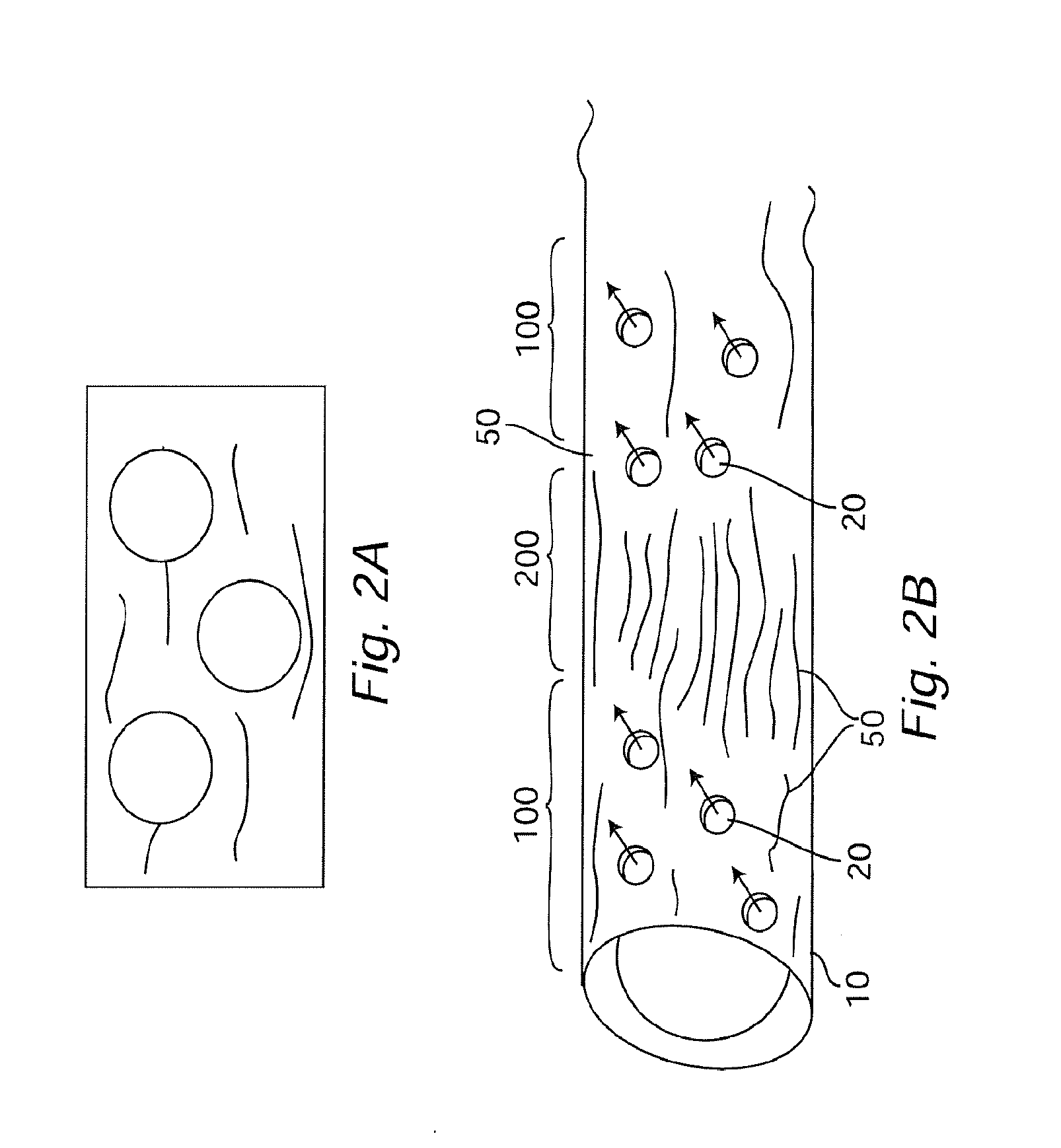

Air impedance electrospinning for controlled porosity

InactiveUS20130178949A1Less to cell infiltrationHigh porosityFilament/thread formingAuxillary shaping apparatusPorosityFlow impedance

Electrospun materials are fabricated using air-flow impedance technology, which results in the production of scaffolds in which some regions are dense with low porosity and others regions are less dense and more porous. The dense regions provide structural support for the scaffold while the porous regions permit entry of cells and other materials into the scaffold, e.g. when used for tissue engineering.

Owner:VIRGINIA COMMONWEALTH UNIV

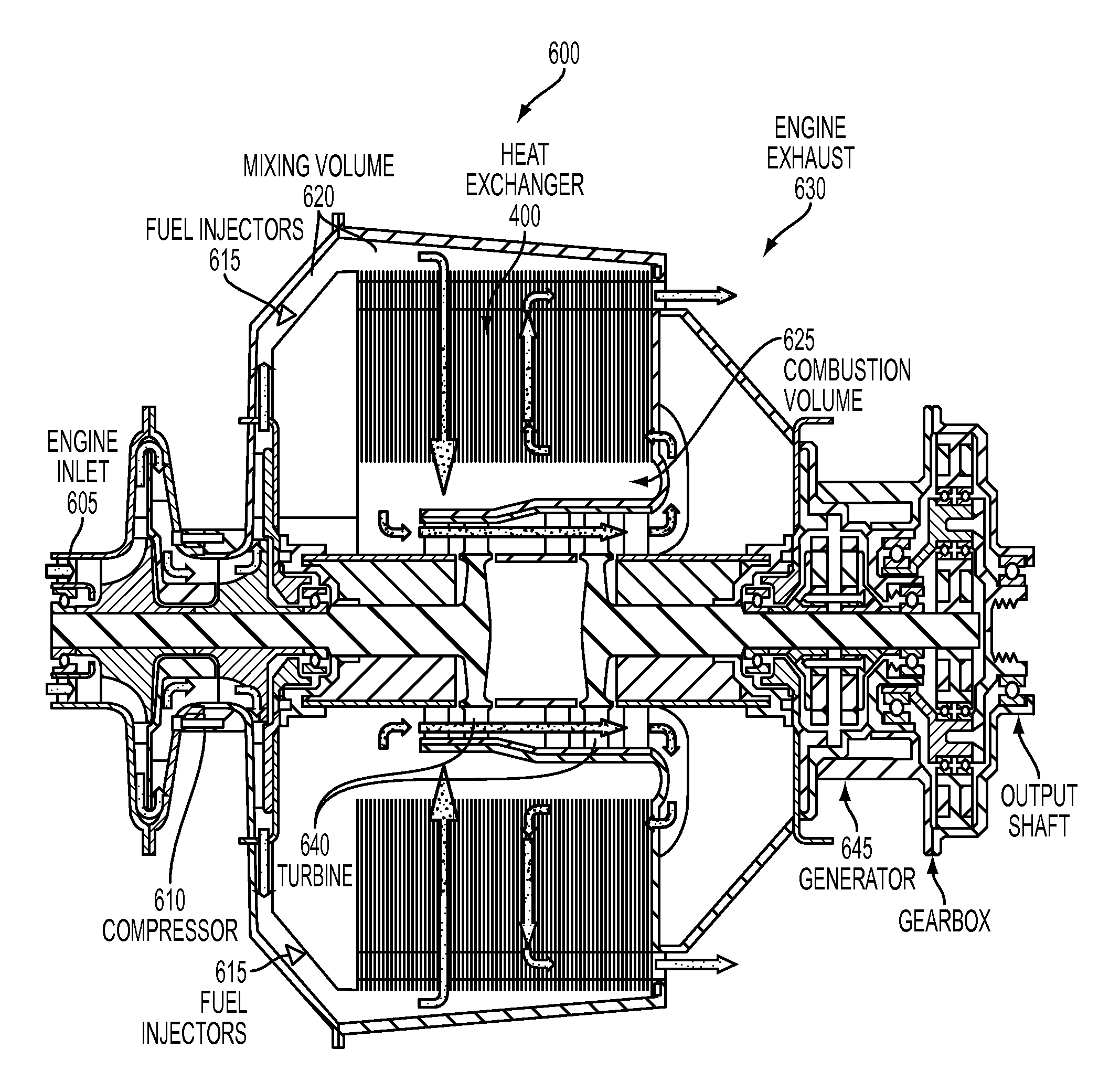

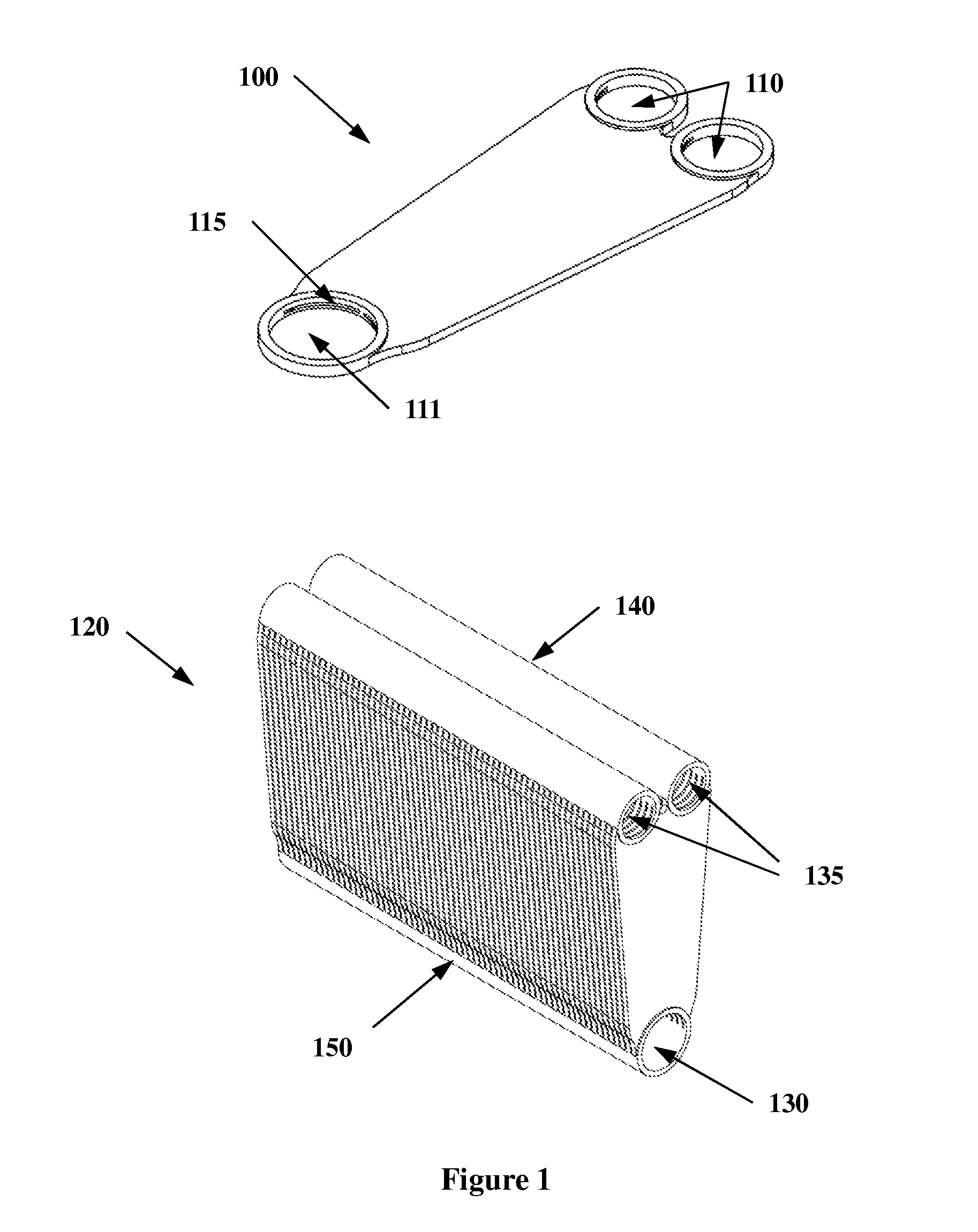

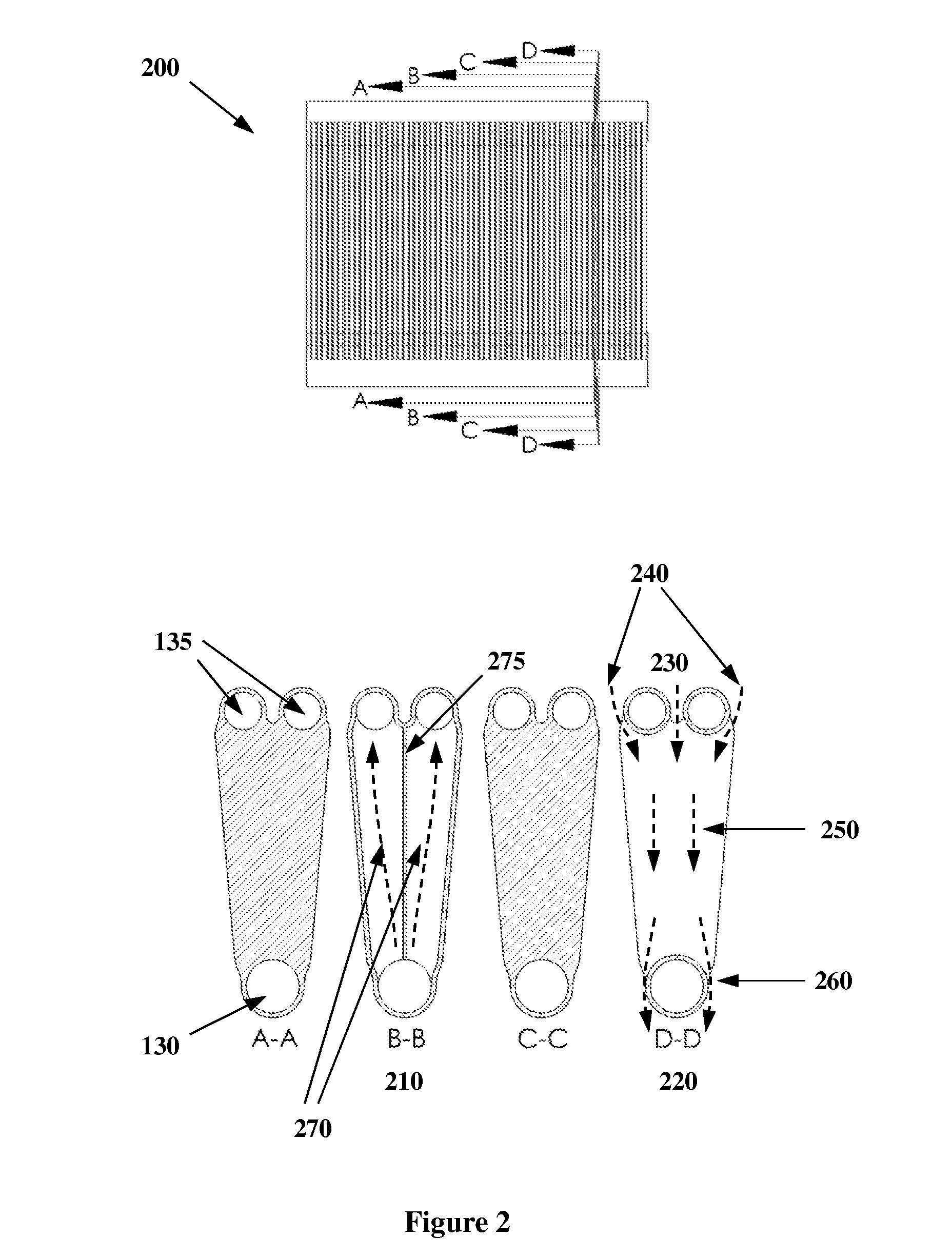

Compact radial counterflow recuperator

ActiveUS8573291B2Reduce manufacturing costLess denseRecuperative heat exchangersEfficient propulsion technologiesCombustorEngineering

An annular design heat exchanger is formed from an arrangement of wedge-shaped stacks of wafers. Each wafer includes sheets of material separated by peripheral and supporting walls that define interior flow channels through which a first fluid can flow. Holes in the sheets provide inlets and outlets to the channels, and walls surrounding the holes mate with neighboring wafers in the stack, forming integral inlet and outlet manifolds, while ensuring uniform spacing between the wafers. A second fluid can flow around the manifolds and through the spaces between the wafers in a counterflow pattern. In the annular assembly, the manifolds are oriented substantially axially, and the flow channels are oriented substantially radially. The heat exchanger can be formed from a ceramic material, and can be incorporated into an engine assembly or a heat-recirculating combustor.

Owner:UNITED STATES OF AMERICA

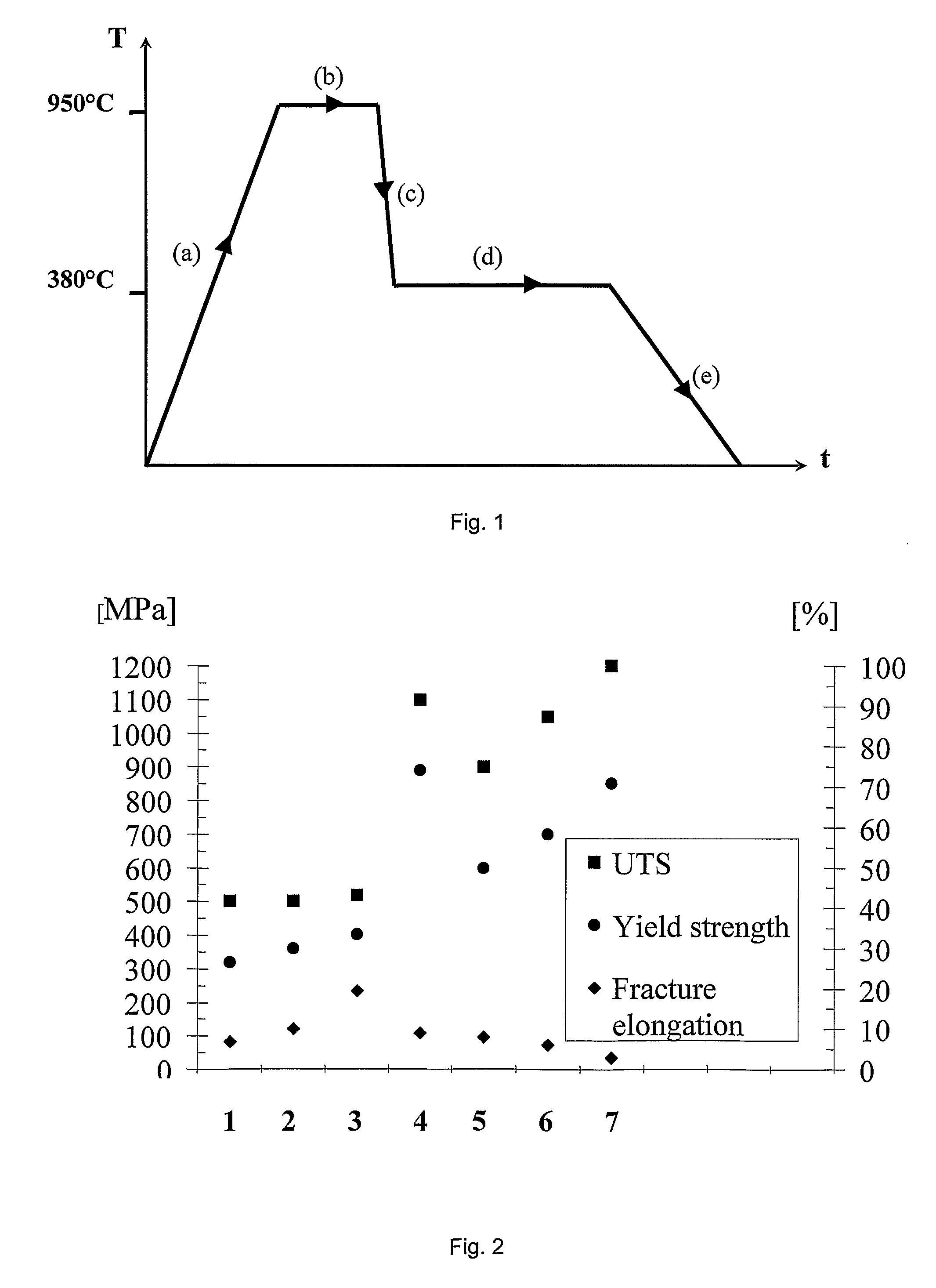

Austempered ductile iron, method for producing this and component compri

ActiveUS20100006189A1Easy to combineImprove ductilitySoil-shifting machines/dredgersFurnace typesAustemperingHigh intensity

Austempered ductile iron (ADI) for components requiring high strength and / or ductility, which has a silicon content of 3.35 weight-% to 4.60 weight-%, and which is obtainable by performing an ADI-heat treatment using an austenitization temperature of at least 910° C.

Owner:INDEXATOR GROUP

Drum Mounting and Tuning System Providing Unhindered and Isolated Resonance

ActiveUS20150059553A1Reducing and completely isolating same energyUndesired distortionPercussion musical instrumentsResonanceEngineering

Some embodiments provide a drum structural framework comprising a top shell mount, bottom shell mount, rod holders, and tension rods. The top shell mount and bottom shell mount are mounted to either ending edge of a drum shell disposed between the two mounts. A first set of the rod holders are coupled to the top shell mount and an aligned second set of the rod holders are coupled to the bottom shell mount. The tension rods link the two sets of rod holders without hindering resonance of the drum shell. Tuning assemblies on the rod holders adjust the distance separating the top shell mount from the bottom shell mount, thereby controlling the force imposed on the drum shell. Each rod holder includes one or more dampeners that isolate energy passing from the drumhead to the shell from also reverberating throughout the structural framework of the tension rods and rod holders.

Owner:MARTIN AUGUST D

Method for preparing copper alloy additive material based on electron beam powder laying forming

ActiveCN109202081AAdditive Manufacturing PremiumAdditive manufacturing is efficientAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyMolding machine

The invention discloses a method for preparing a copper alloy additive material based on electron beam powder laying forming. The method comprises steps that an obtained STL format file is inputted into rapid forming software of a molding machine; a layer of copper alloy powder is spread on a forming platform in advance, and an electron beam preheats a substrate and a powder bed; the outline is melt, and the electron beam scans the boundary in a spotted mode; the cross section is melt, and an electron beam linear scanning cross-section beam current value is increased from 5.5 mA to 7 mA over time; the process is repeated till manufacturing of copper alloy parts is completed. The method is advantaged in that the method is the additive material manufacturing technology utilizing powder laying electron beam selective zone melting, due to substrate and powder bed preheating and beam incremental scanning modes of the electron beam before melting, warping and non-dense organization caused bythe residual stress in the forming process are effectively reduced, the phenomenon of overheating or spheroidization of formed parts is avoided, and thereby high quality and efficient additive material manufacturing of the copper alloy is achieved.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com