Heater with an atomizer nozzle

a technology of atomizer and nozzle, which is applied in the field of atomizers, can solve problems such as and achieve the effects of avoiding chemical decomposition processes in the fuel, reliably preventing vaporization of liquid fuel, and avoiding slowing down the starting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

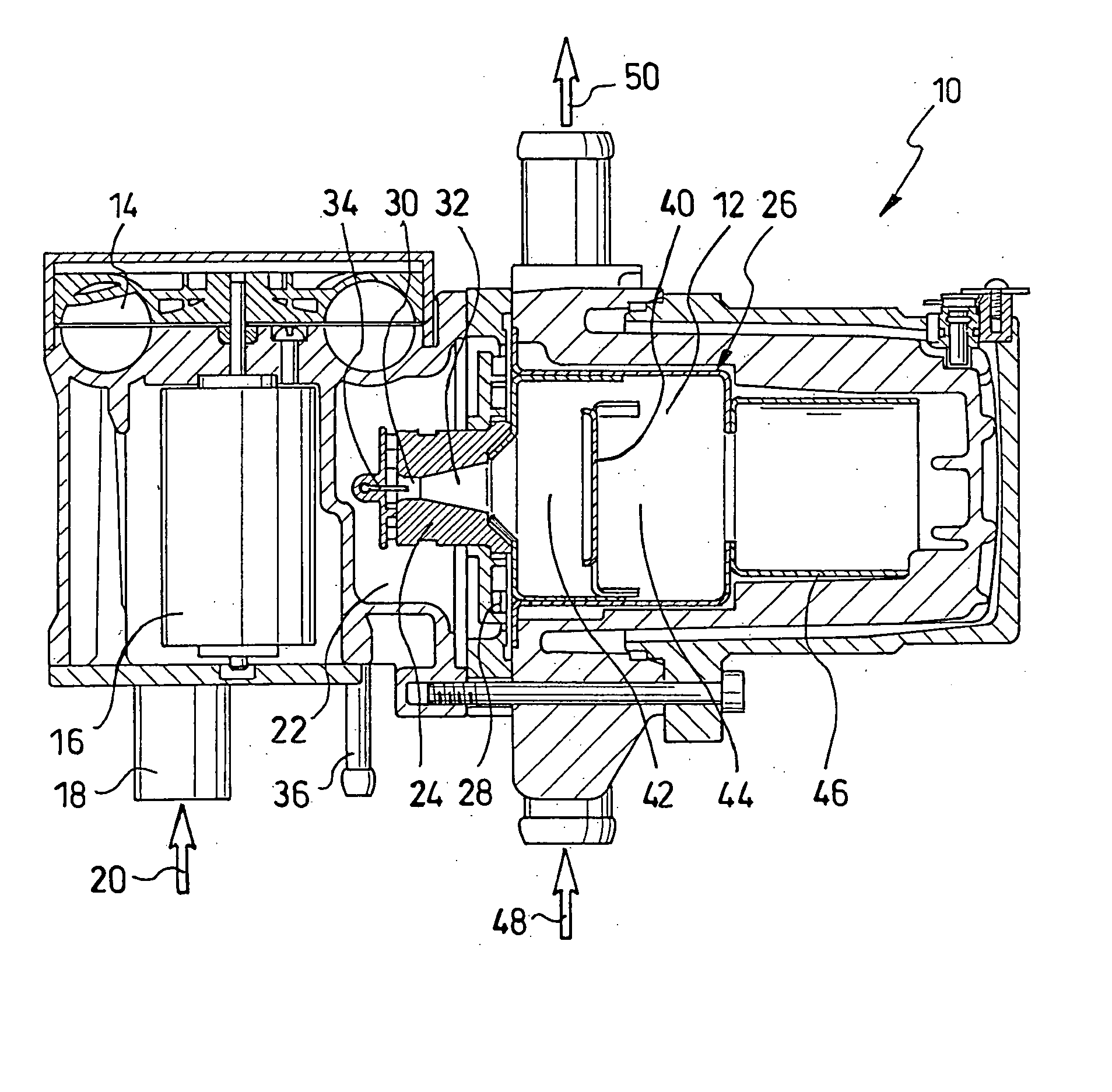

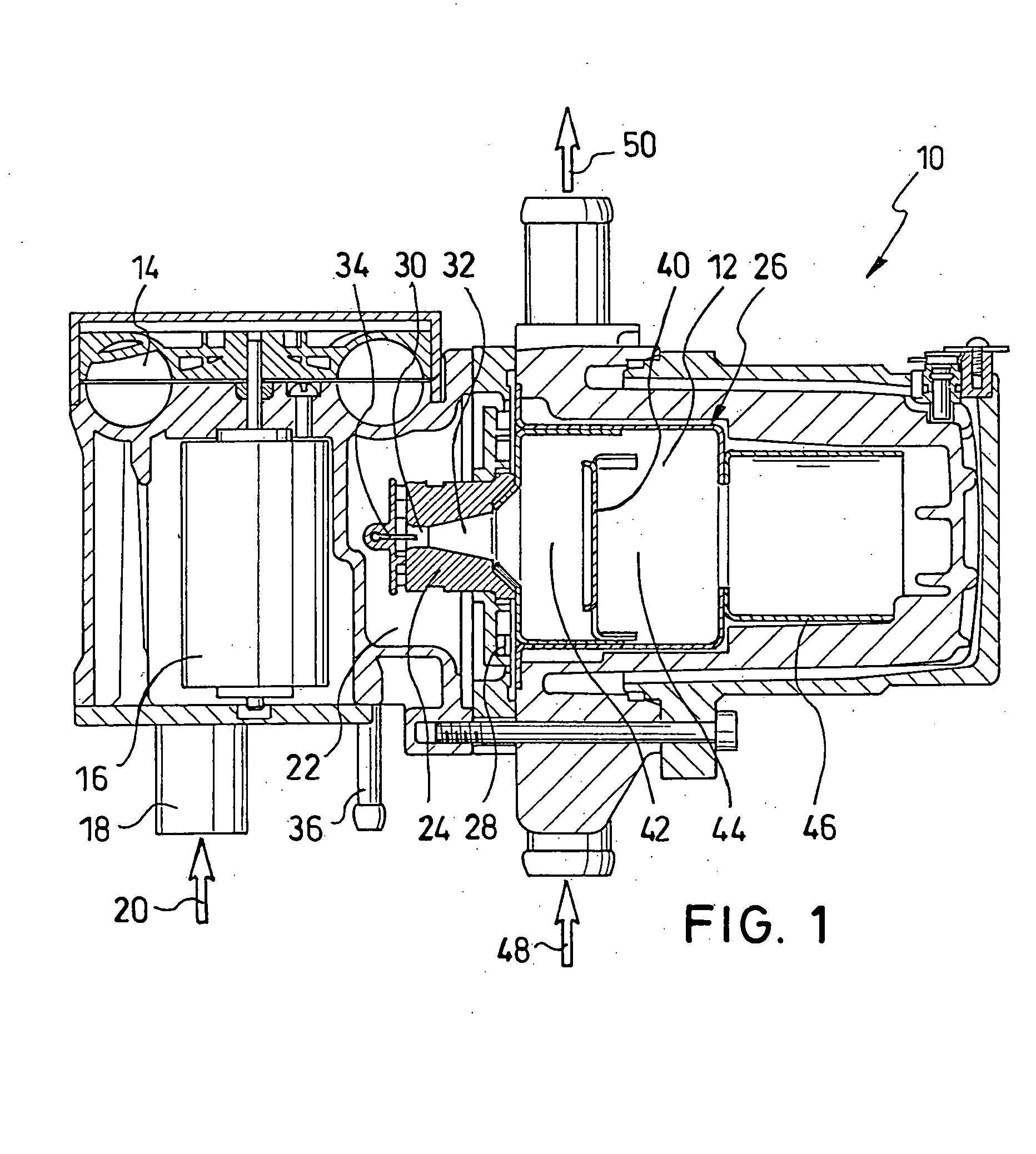

[0032]FIG. 1 shows a heater 10 which contains as the important component a burner 12 for burning a fuel / combustion air mixture. The heater 10 furthermore comprises an annular channel fan 14 with a fan motor 16 with which combustion air 20 is taken in via an air inlet connection 18 and is blown on the pressure side into the combustion air collecting space 22. Part of the combustion air which is made available in the combustion air collecting space 22 is delivered as primary air by an atomizer nozzle 24, which in this case is made as a Venturi nozzle, into the combustion chamber 26. The remaining part of the combustion air in the combustion air collecting space 22 is delivered as secondary air by secondary air holes 28 into the combustion chamber 26. Division of the combustion air into primary air and secondary air is useful in order to make available an ignitable mixture at the discharge of the atomizer nozzle 24 which is detailed below.

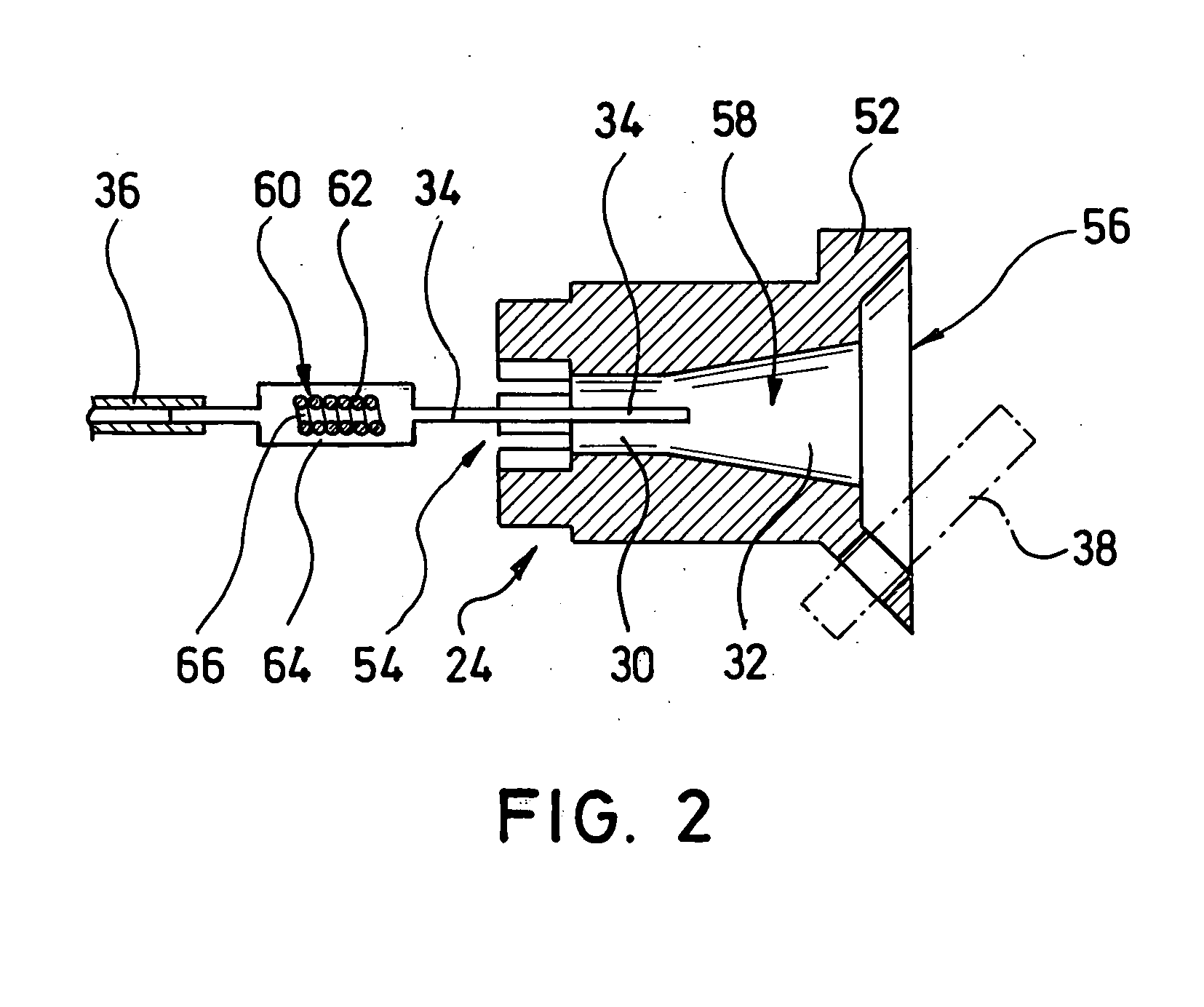

[0033] The atomizer nozzle 24 comprises an inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com