Color-changing water-permeable brick with gradient pore structure and preparation method of color-changing water-permeable brick

A gradient structure, permeable brick technology, applied in the field of building materials, to achieve the effect of rich decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

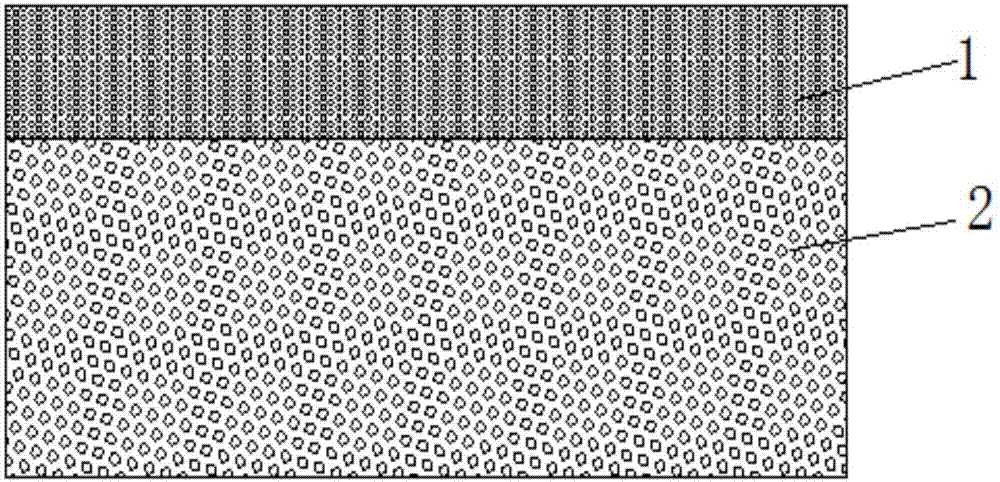

[0029] 1-2.5mm ceramic waste particles, photochromic glass particles as color-changing components (3-5mm), kaolin, albite, and water glass solution with a mass concentration of 30%, the ratios are 65:15:5:5:10 respectively The weight ratio is evenly mixed to make a color-changing surface layer mixture.

[0030] 3-5mm ceramic waste particles, kaolin, albite, and water glass solution with a mass concentration of 30% are mixed uniformly in a weight ratio of 80:5:5:10 to make a matrix layer mixture.

[0031] When the above-mentioned mixture is pressed into adobe, two times of cloth are used, and one time is pressed to form, that is, firstly fill the metal mold with the color-changing surface layer mixture 5mm; then fill the base layer mixture on it, and then press once. 20MPa. The pressed brick adobe is dried at 110°C for 8 hours, then fired at 950°C for 2 hours, and cooled naturally to obtain a permeable brick with a pore gradient structure and a color-changing effect. The perf...

Embodiment 2

[0033] 1-2.5mm ceramic waste particles, thermochromic glass particles as color-changing components (3-5mm), kaolin, albite, and water glass solution with a mass concentration of 30%, the ratios are 65:15:5:5:10 respectively The weight ratio is evenly mixed to make a color-changing surface layer mixture.

[0034] 3-5mm ceramic waste particles, kaolin, albite, and water glass solution with a mass concentration of 30% are mixed uniformly in a weight ratio of 80:5:5:10 to make a matrix layer mixture.

[0035] When the above-mentioned mixture is pressed into adobe, two times of cloth are used, and one time is pressed to form, that is, the color-changing surface layer mixture is first filled in the metal mold 8mm; 25MPa. The pressed brick adobe is dried at 150°C for 12 hours, then fired at 1050°C for 1 hour, and cooled naturally to obtain a permeable brick with a pore gradient structure and a color-changing effect. The performance indicators of permeable bricks are shown in Table ...

Embodiment 3

[0037] 1-2.5mm ceramic waste particles, photochromic glass particles as color-changing components (3-5mm), kaolin, albite, and water glass solution with a mass concentration of 30%, the ratios are 70:12:4:4:10 respectively The weight ratio is evenly mixed to make a color-changing surface layer mixture.

[0038] 3-5mm ceramic waste particles, kaolin, albite, and water glass solution with a mass concentration of 30% are mixed uniformly according to the weight ratio of 82:4:4:10 to make a matrix layer mixture.

[0039] When the above-mentioned mixture is pressed into adobe, two cloths are used, and one press is formed, that is, the color-changing surface layer mixture is first filled in the metal mold 6mm; 23 MPa. The pressed brick adobe is dried at 120°C for 10 hours, then fired at 1000°C for 1.5 hours, and cooled naturally to obtain a permeable brick with a pore gradient structure and a color-changing effect. The performance indicators of permeable bricks are shown in Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com