Method for manufacturing vacuum glass

A vacuum glass and manufacturing method technology, applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve the problems of affecting the service life of vacuum glass, affecting the appearance stress of vacuum glass, and difficult operation, so as to eliminate stress And the effect of hidden stress, improving appearance quality and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0027] A manufacturing method of vacuum glass, the steps are:

[0028] (1). Processing of top glass 1:

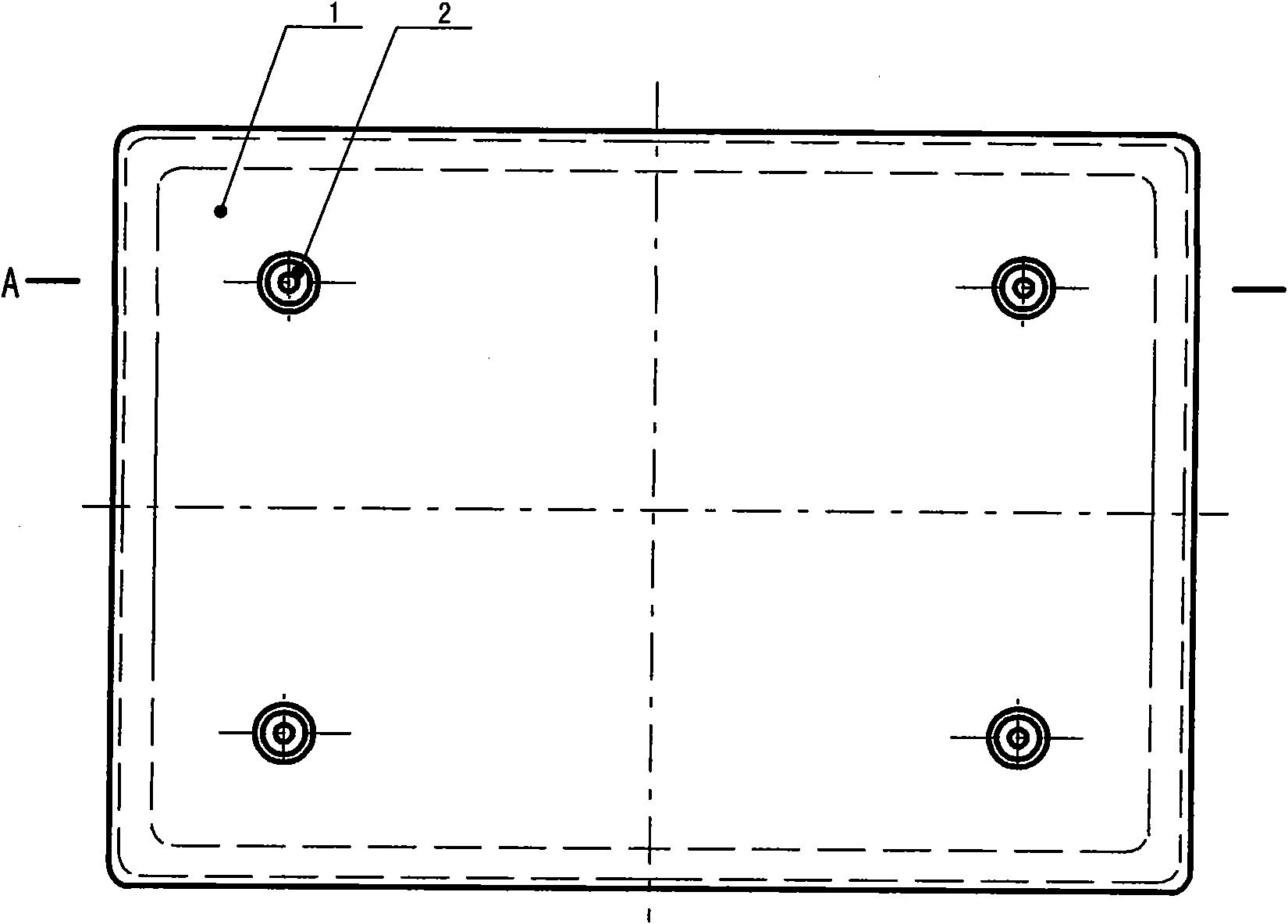

[0029] The upper part of the glass is machined with air extraction through holes whose upper part is open, and the number is 1-20. In this embodiment, there are 4 air extraction through holes, and the set positions are evenly distributed.

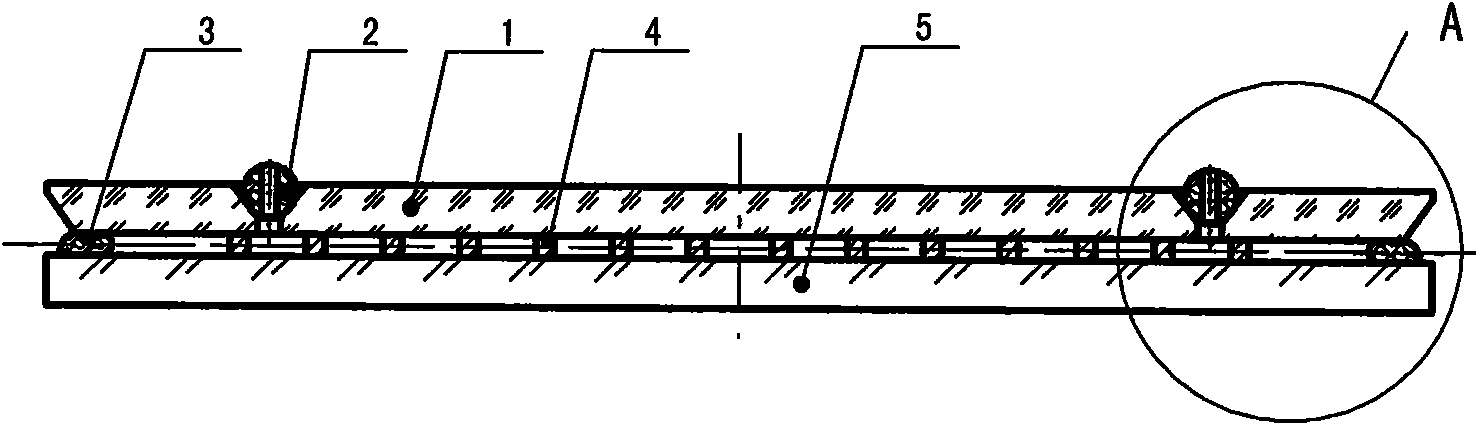

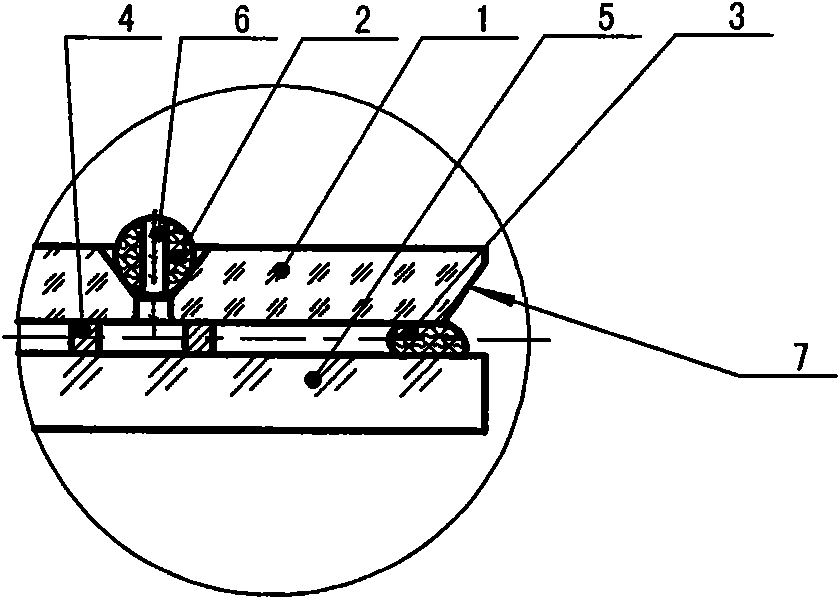

[0030] (2). Placement of vacuum glass:

[0031] Place the support 4 evenly on the upper surface of the lower glass, and then place the upper glass on the lower glass 5. The edge of the upper glass should be aligned with the edge of the lower glass, or slightly smaller than the lower glass to form a margin ; In the accompanying drawings of this embodiment, a circle of inclination angle 7 is made around the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com