Method for marking on glass by YAG laser

A technology on YAG laser and glass, which is applied in the field of YAG laser marking on glass. It can solve the problems of not being able to meet the requirements of marking, the high price of the whole machine equipment, and the deterioration of marking effect, so as to achieve beautiful marking effect and filling effect. Smooth, fast marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

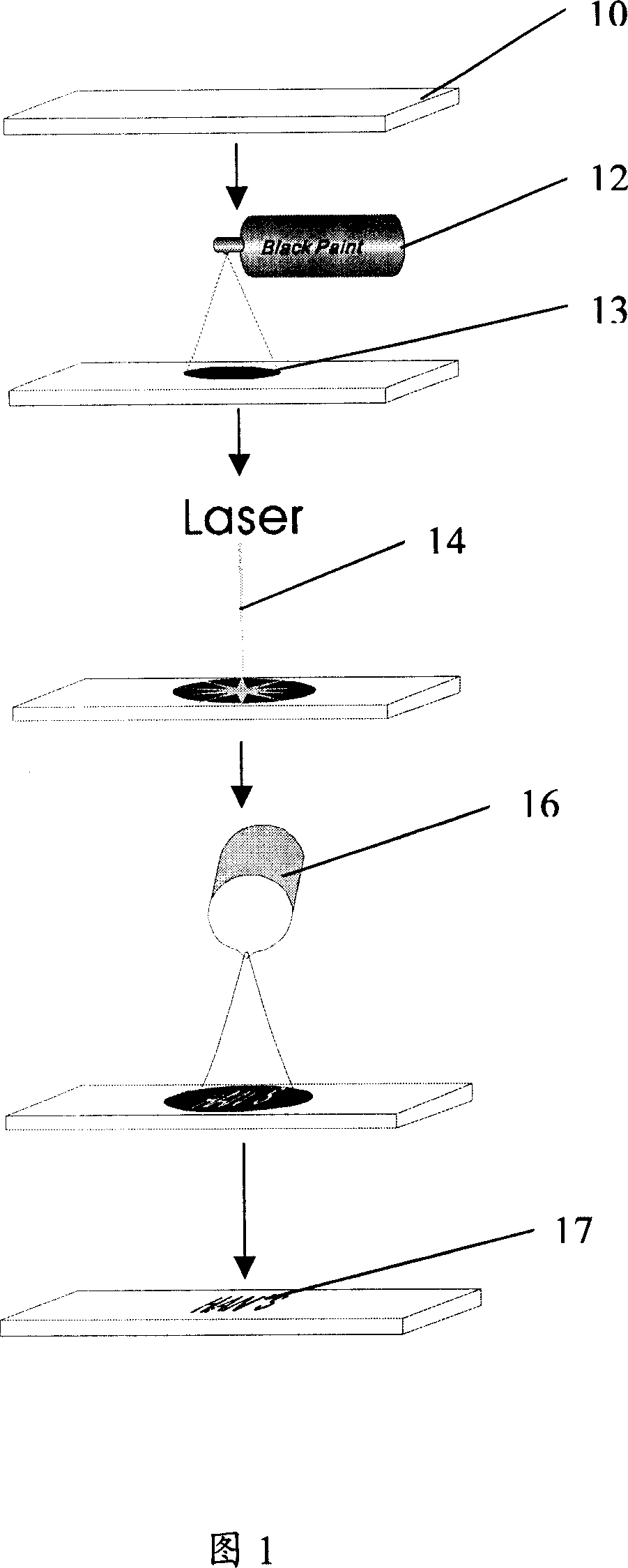

[0023] With the current state of the art, the bottleneck in the application of YAG laser marking on glass is how to improve the absorption rate of the glass surface. On the one hand, it is necessary to increase the single-point pulse energy of the laser. Lamp-pumped laser marking machines (such as YAG-T50 or YAG-T80 from Han’s Laser) use lenses with smaller multiples (such as f=80mm, f=100mm focusing lens); on the other hand, The glass surface needs to be treated to increase the absorption rate.

[0024] We first experiment with YAG-T50,

[0025] Method 1: Use a black water-based marker to paint on the glass surface

[0026] Since the adhesion of the water-based ink is not very strong, after the laser is irradiated, the coating is knocked off, and the glass will not absorb the laser when the second time is applied, but after cleaning the glass, it can be found that there is a faint mark of the laser left. The glass surface, although not clear, has achieved the function of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com