Laser marking focus rapid positioning method and device

A laser marking, fast technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of improving production, reducing loss and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

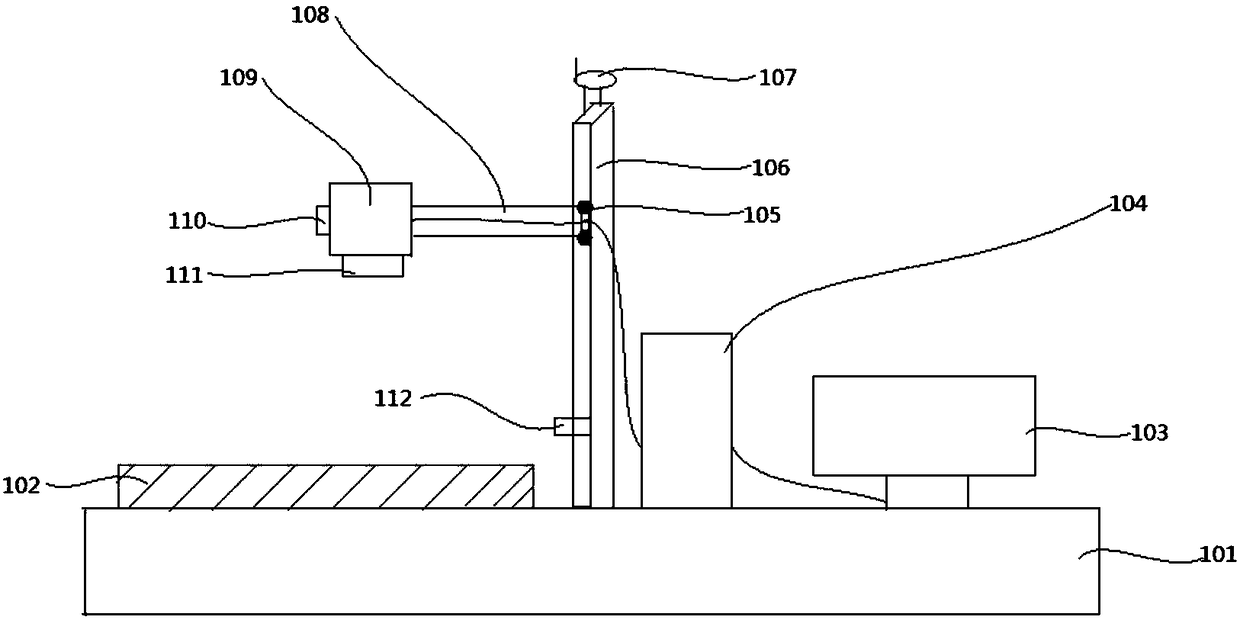

[0046] A method for quickly locating a laser marking focus, comprising: fixing a distance measuring sensor on one side of a laser lens 111 of a laser marking machine, so as to use the distance measuring sensor to focus a laser on an object to be marked.

Embodiment 2

[0048] The method for fast positioning of laser marking focus as described in Embodiment 1, the difference is that the method for fast positioning of laser marking focus further includes: establishing a laser marking focus distance database corresponding to different materials.

[0049] The establishment of the laser marking focal distance database corresponding to different materials includes: conducting experiments on objects to be laser marked of different materials, and correlating the laser marking focal distance and the material to obtain the optimal laser marking effect to form the corresponding laser marking focus distance database.

Embodiment 3

[0051] A method for fast positioning of laser marking focus as described in Example 2, the difference is that the method for fast positioning of laser marking focus further includes: establishing the laser marking focus distance database corresponding to different materials After that, coarsely adjust the focal distance of laser marking and finely adjust the focal distance of laser marking.

[0052] The coarse adjustment of the focal distance of laser marking is as follows: determining the focal distance of laser marking according to the surface material of the object to be marked, so as to realize the coarse adjustment of the focal distance of the laser lens;

[0053] Fine-tuning the focal distance of laser marking is: through the marking experiment, adjust the focal distance of the laser lens to obtain the optimal laser marking effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com