Preparation method for laser-markable halogen-free fire retardation polyester having variable ground color

A laser marking, flame retardant polyester technology, applied in the field of polymer processing, can solve the problems of low absorption rate of halogen-free flame retardants, difficulty, little contrast between font color and background color, etc. Mechanical properties, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the laser-markable halogen-free flame-retardant polyester with a variable background color proposed by the present invention comprises the following steps:

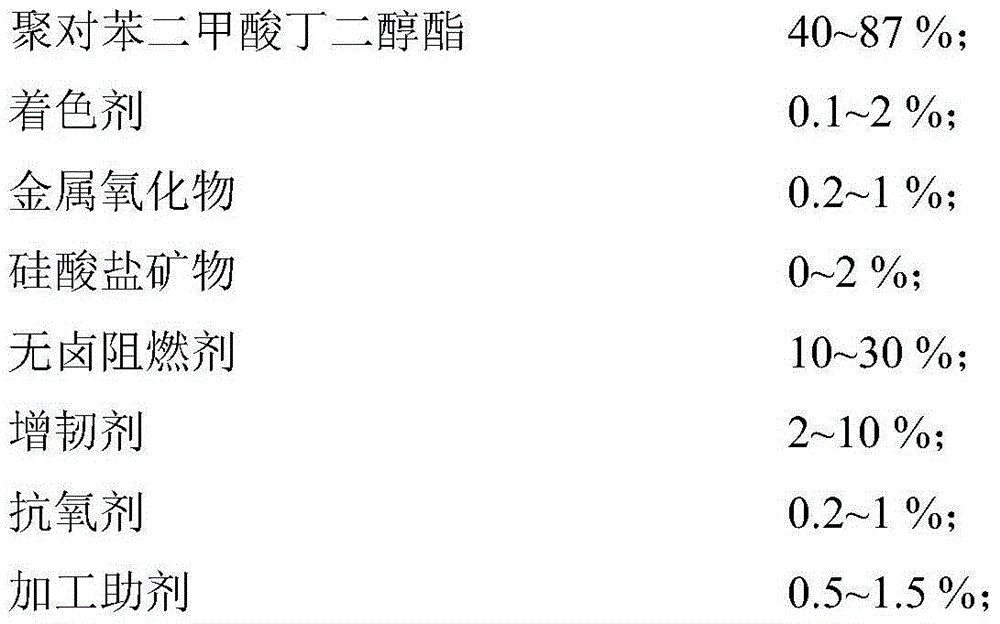

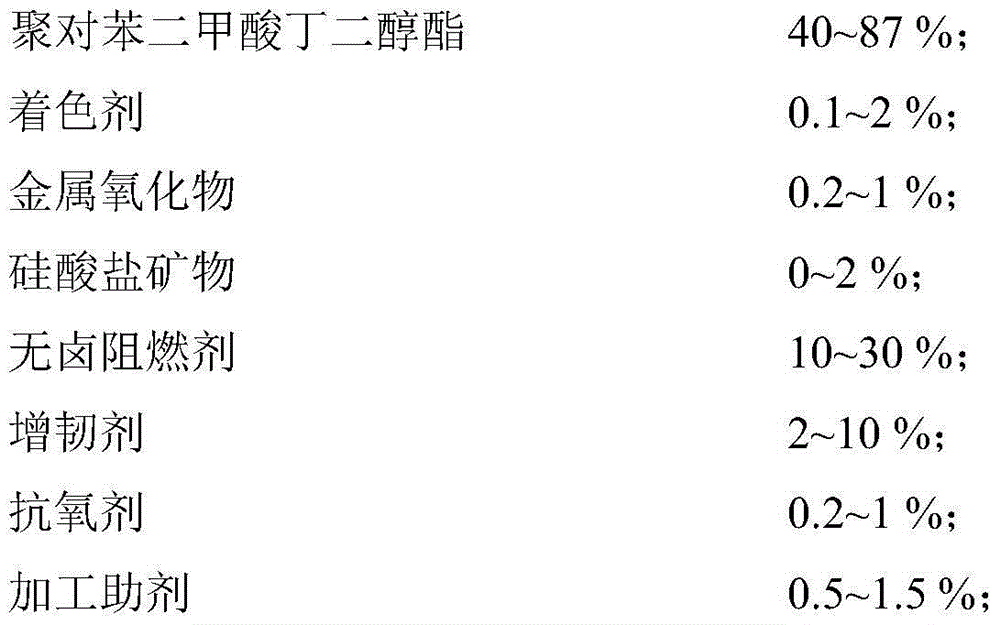

[0022] (1) Weigh the raw materials according to the following weight percentages:

[0023]

[0024] (2) Pre-dry the polybutylene terephthalate weighed according to the above proportion at 120-140°C for 4-6 hours, so that the moisture content in it is less than 0.05%. After drying, the polybutylene terephthalate Butylene glycol formate and other raw materials weighed in proportion are mixed uniformly in a twin-screw mixer;

[0025] (3) Send the mixture of the above step (2) into the twin-screw extruder, the feeding speed of the twin-screw extruder is 200rpm, and the temperature of each section of the twin-screw extruder is from the feed port to the machine head. The temperature is 230-235℃ in the first zone, 235-240℃ in the second zone, 240-250℃ in the third zone, 240-245℃ in the fourth...

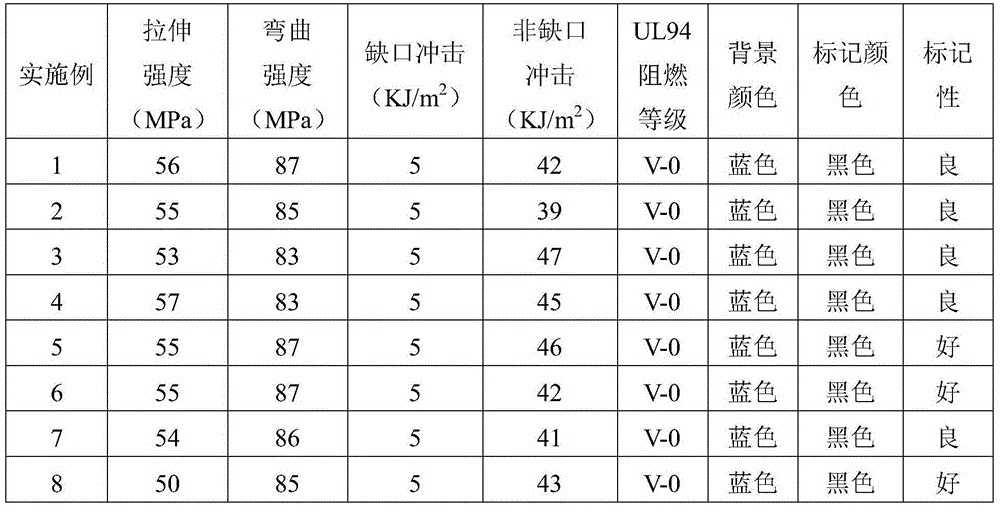

Embodiment 1

[0036] (1) Weigh the raw materials according to the following percentages: polybutylene terephthalate: 74.9%; phthalocyanine blue: 1%; copper oxide: 0.5%; mica: 1%; organic phosphate and melamine cyanuric acid Salt Flame Retardant Blend: 18%; Hindered Phenolic and Phosphite Antioxidants: 0.6%; Ethylene-Butyl Methacrylate-Glycidyl Methacrylate Terpolymer: 3.5%; Stearin Calcium acid: 0.5%.

[0037] (2) Pre-dry the polybutylene terephthalate weighed according to the above ratio at 130°C for 5 hours, so that the water mass percentage in it is less than 0.05%, and the dried polyester resin is mixed with other The weighed raw materials are mixed evenly in a double screw mixer.

[0038] (3) Send the above-mentioned mixture into the twin-screw extruder, the feeding speed of the twin-screw extruder is 200rpm, and the temperature of each section of the twin-screw extruder from the feeding port to the head of the machine is respectively a zone The temperature is 230°C, the temperature ...

Embodiment 2

[0040] (1) Weigh the raw materials according to the following percentages: polybutylene terephthalate: 74.9%; phthalocyanine blue: 1%; iron oxide: 0.5%; mica: 1%; organic phosphate and melamine cyanuric acid Salt Flame Retardant Blend: 18%; Hindered Phenolic and Phosphite Antioxidants: 0.6%; Ethylene-Butyl Methacrylate-Glycidyl Methacrylate Terpolymer: 3.5%; Stearin Calcium acid: 0.5%.

[0041] (2) Pre-dry the polybutylene terephthalate weighed according to the above ratio at 130°C for 5 hours, so that the water mass percentage in it is less than 0.05%, and the dried polyester resin is mixed with other The weighed raw materials are mixed evenly in a double screw mixer.

[0042] (3) Send the above mixture into the twin-screw extruder. The feeding speed of the twin-screw extruder is 200rpm. The temperature is 230°C, the temperature in the second zone is 235°C, the temperature in the third zone is 240°C, the temperature in the fourth zone is 240°C, the temperature in the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com