Manufacturing method of bent vacuum glass

A technology of vacuum glass and manufacturing method, which is applied in the field of vacuum glass, can solve problems such as undiscovered bending vacuum glass technology reports, and achieve the effects of avoiding random sliding, good quality, and scientific and reasonable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for manufacturing curved vacuum glass, the steps are:

[0025] ⑴Cut and clean the flat glass;

[0026] ⑵Put the flat glass sheet into the heating furnace for hot bending, and the hot bending is made on a mold with deflection. The time and temperature are the same as the existing single glass hot bending process. The curvature of the two sheets of vacuum glass remains basically the same;

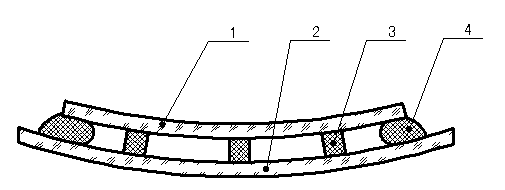

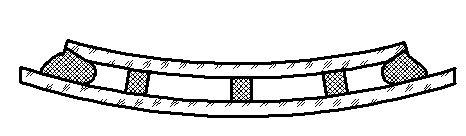

[0027] (3) Print the adhesive on the inner surface of the hot-bent glass, and then place the support 3;

[0028] (4) Combine the glass with the support placed, and add packing sealing material 4 to the edge between the two pieces of glass for edge sealing;

[0029] ⑸Put the combined glass into the heating furnace for heating, and then vacuumize;

[0030] ⑹ After the filler sealing material on the edge of the glass is melted and sealed and the vacuum meets the requirements, seal the suction port and cool to obtain a curved vacuum glass.

[0031] Because the sealing edge of ...

Embodiment 2

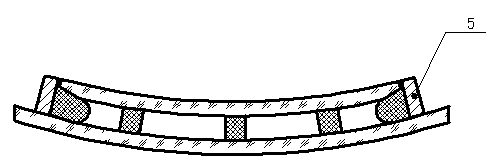

[0039] Its difference with embodiment 1 is:

[0040] Two pieces of curved glass purchased with substantially the same degree of curvature are used to manufacture curved vacuum glass instead of the curved glass produced in steps (1) and (2) of the embodiment, and the others are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com