Patents

Literature

39results about How to "Realize the conductive function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

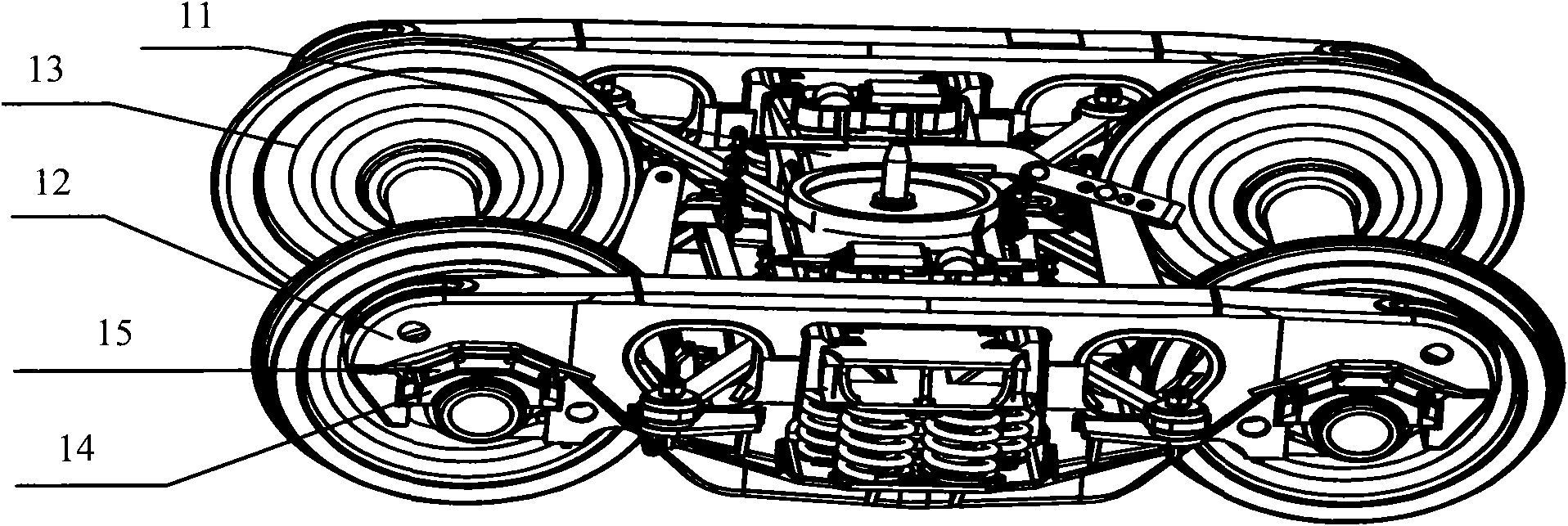

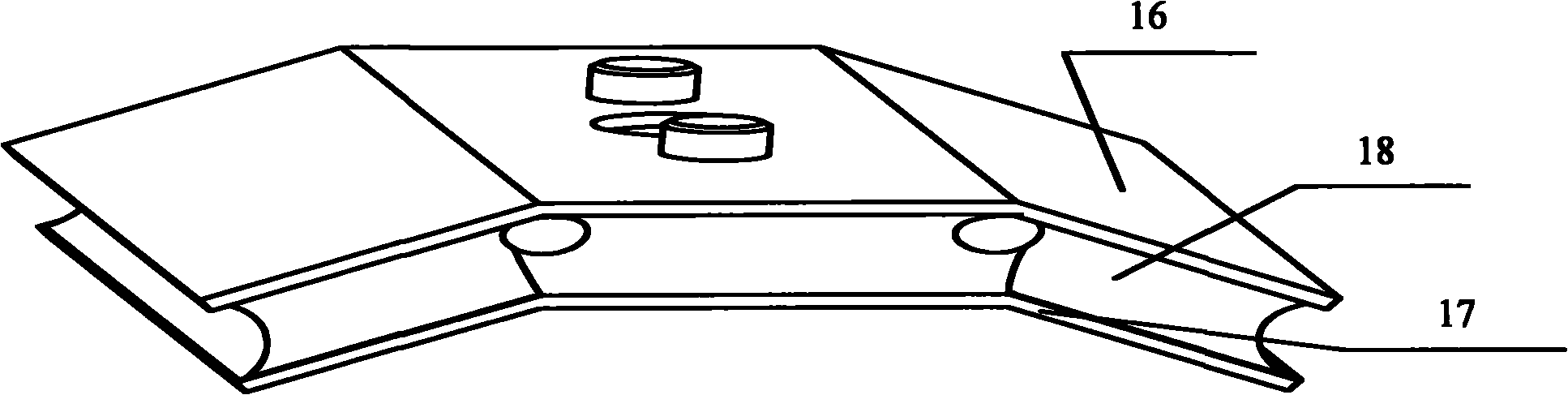

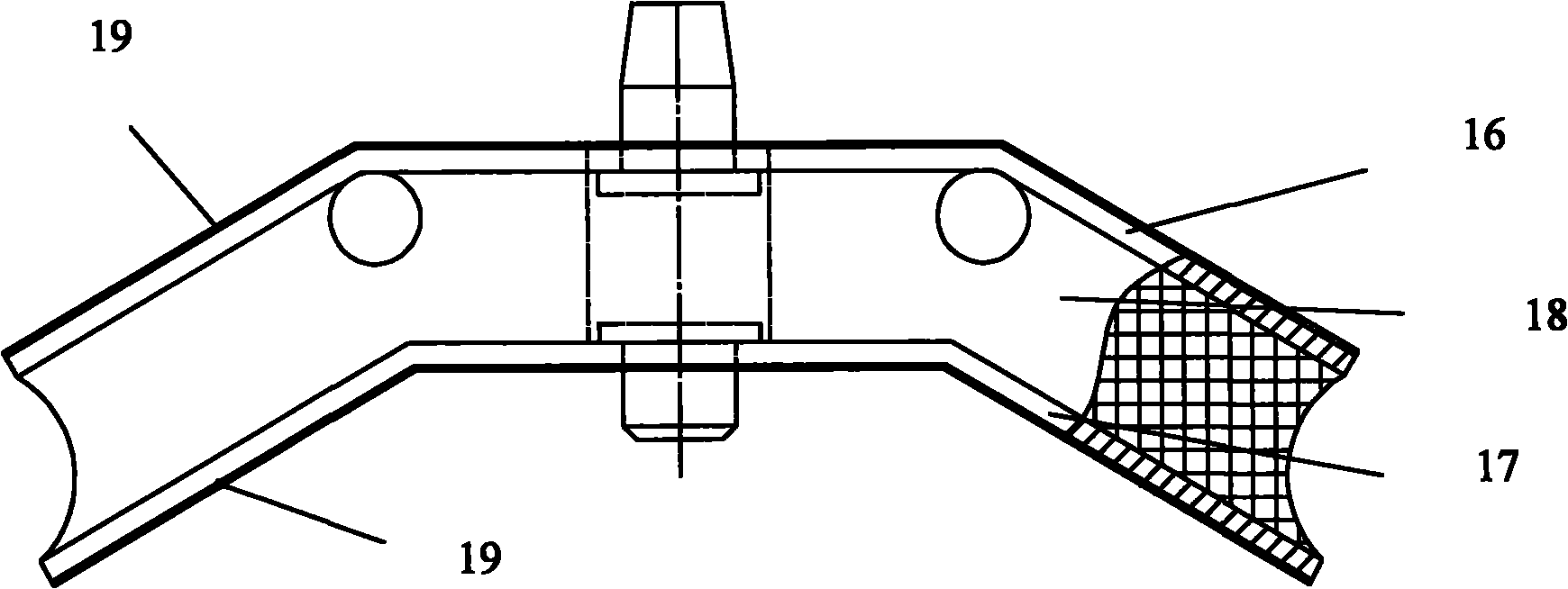

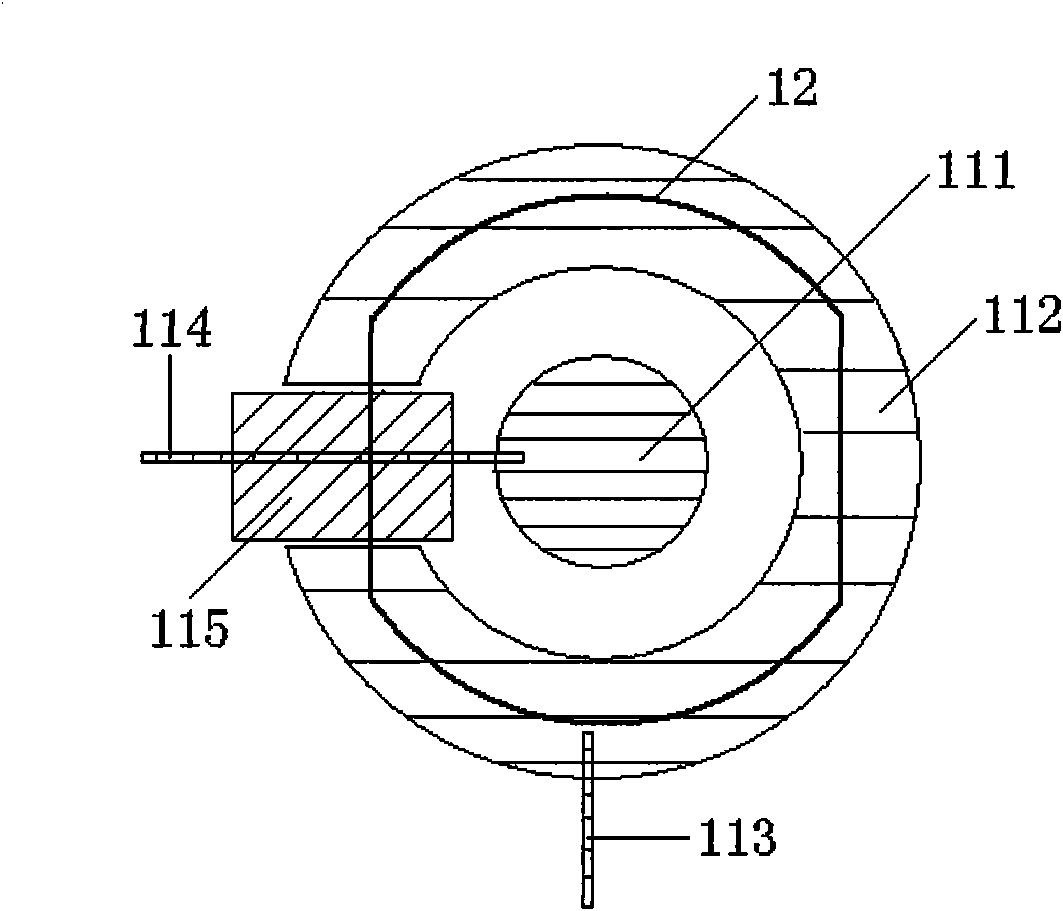

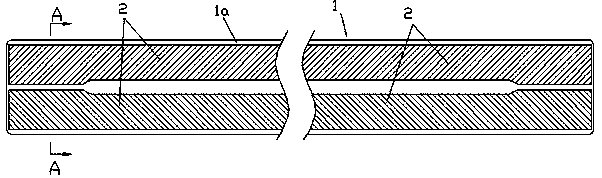

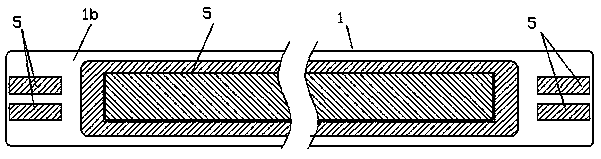

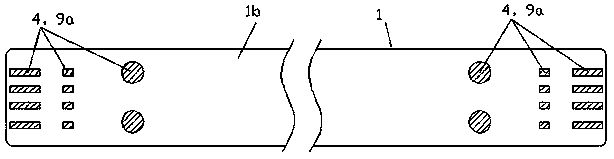

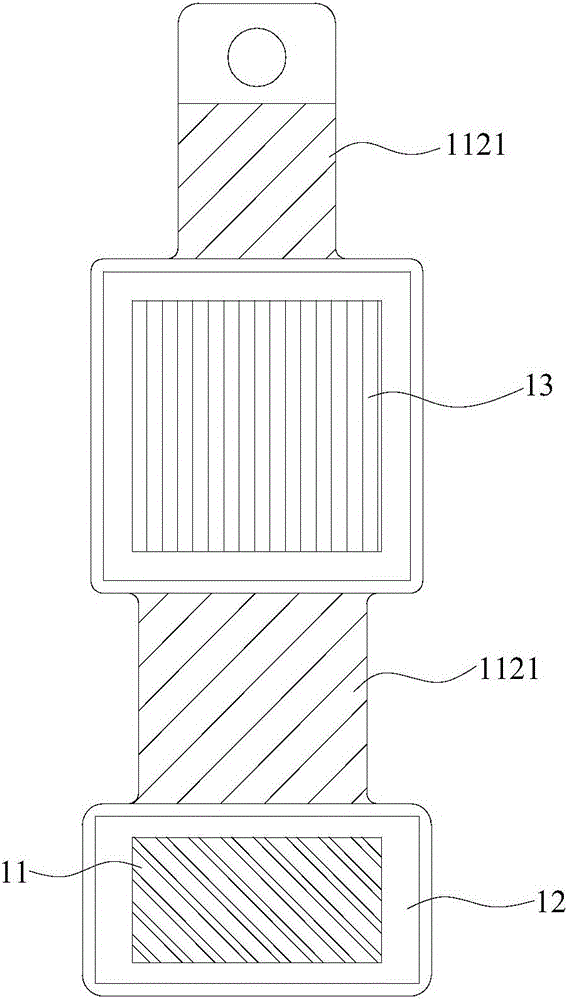

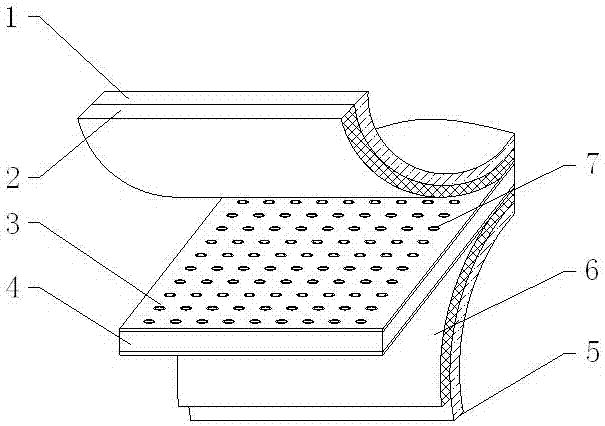

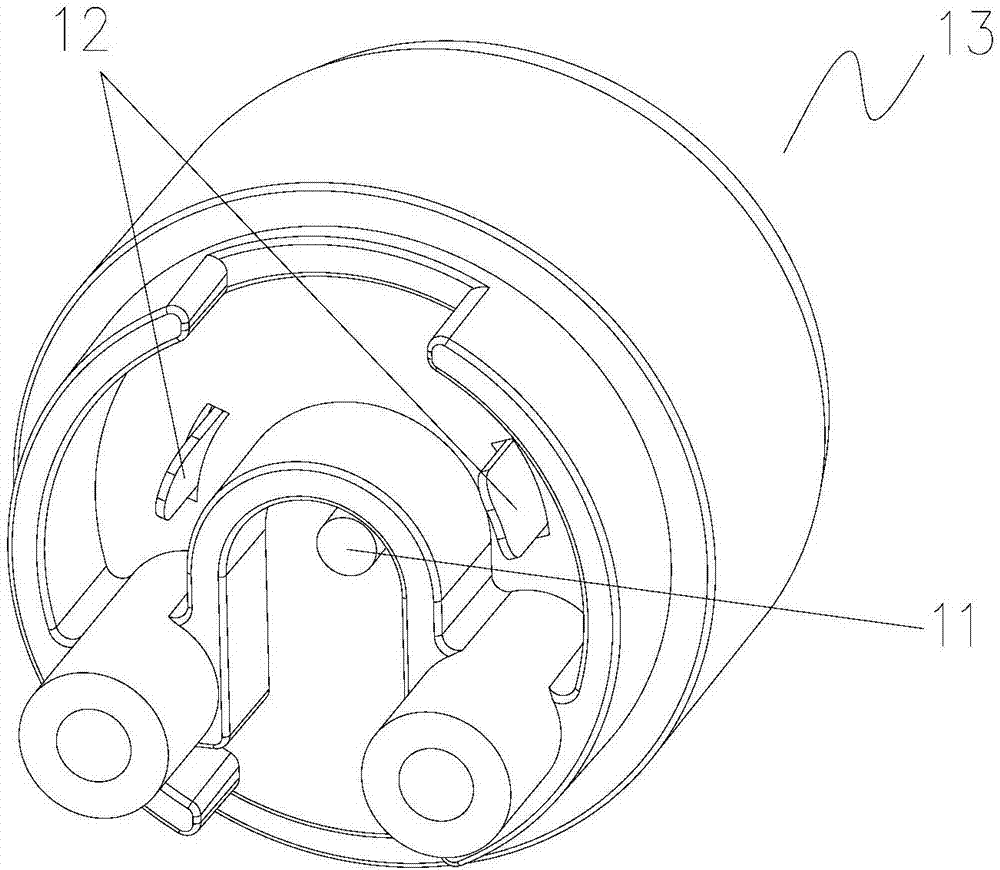

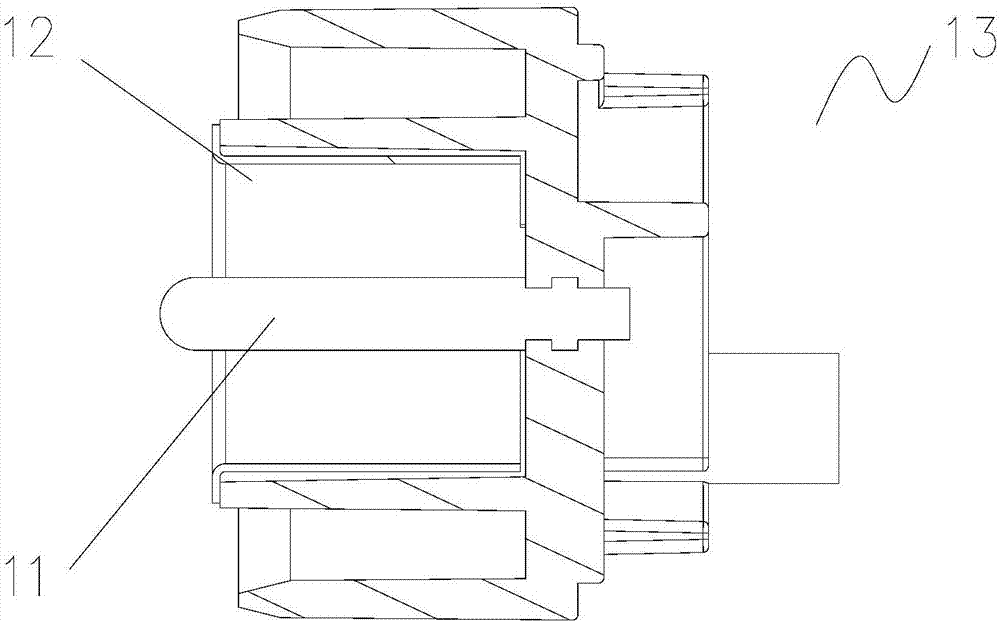

Rubber gasket of journal box and bogie

ActiveCN101791985ASolve the problem that the conductive function cannot be realized at the same timeRealize the conductive functionBogie-underframe connectionsAxle-boxes mountingBogieEngineering

The invention provides a rubber gasket of a journal box and a bogie. The rubber gasket of the journal box comprises a rubber injection hole and a conductive mechanism, wherein the rubber injection hole comprises a hollow cavity, a first hole and a second hole, the hollow cavity is formed in a rubber layer, the first hole is formed on an upper lining board, the second hole is formed on a lower lining board, and the hollow cavity, the first hole and the second hole are communicated; and the conductive mechanism is arranged in the rubber injection hole, and both ends of the conductive mechanism penetrate out from the first hole and the second hole respectively and contact with the two conducted components. By the rubber gasket of the journal box and the bogie of the embodiment of the invention, the rubber gasket of the journal box not only can overcome the defects of high requirement on the manufacturing accuracy of the upper lining board and the lower lining board, easy abrasion and easy poor contact with a side frame and an adapter, but also can realize a conductive function.

Owner:CRRC QIQIHAR ROLLING CO LTD

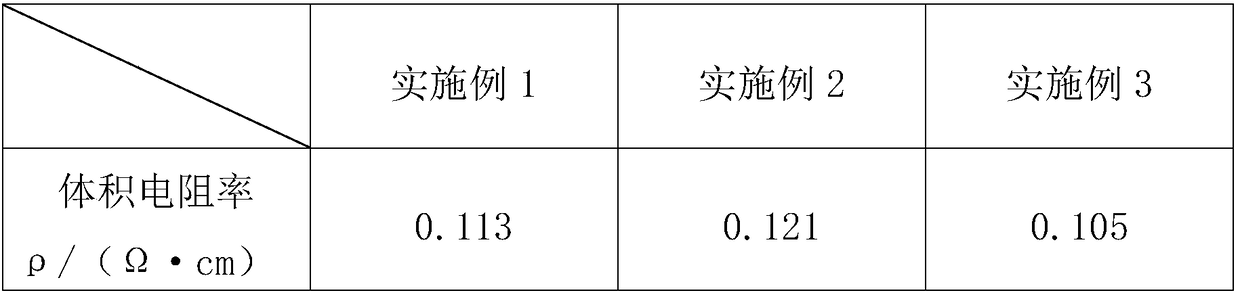

Preparation technology for graphene conductive printing ink

The invention provides a preparation technology for graphene conductive printing ink and relates to the technical field of conductive materials. The preparation technology comprises the following steps of performing pretreatment on flake graphite, performing sealing oxidization on potassium perchlorate, adding the obtained graphene oxide in deionized water, performing ultrasonic vibration stripping, and performing low-temperature evaporation after stripping to obtain a uniformly dispersed brown graphene oxide solution; slowly dropwise adding ammonium hydroxide in an ethanol solution of silvernitrate, regulating a pH value of a system to be 9 to obtain a silver ammonia solution, and preparing a graphene-loaded nanometer silver conductive material by utilizing the silver ammonia solution; and mixing and adding raw materials in a high-speed shearing dispersion machine, adding an adhesive and an additive after high-speed shearing dispersion, performing continuous high-speed shearing dispersion, removing large-particle impurities with a filter membrane with a certain aperture, and performing split charging. The graphene conductive printing ink provided by the invention has good printability; and an ink layer after printing has various excellent properties of low electrical resistivity, low curing temperature, stable conductivity, good conductivity and the like and has a very largemarket application prospect.

Owner:SICHUAN ANDGEM GRAPHENE TECH CO LTD

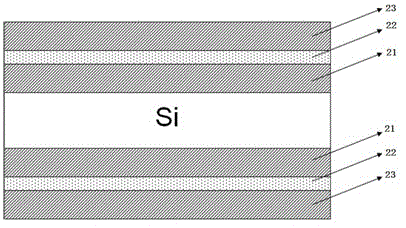

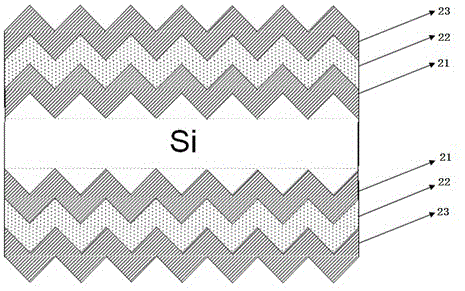

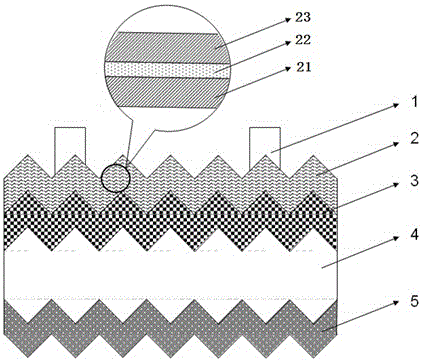

Crystalline silicon solar cell surface passivation layer having good conductive performance and passivation method

ActiveCN104992988ALow resistivityIncrease the carrier concentrationFinal product manufacturePhotovoltaic energy generationCrystallographyComposite film

The invention discloses a crystalline silicon solar cell surface passivation layer having good conductive performance. The surface passivation layer is a composite film lamination passivation layer which is disposed on the front surface and / or the back surface of a crystalline silicon solar cell and which has a dielectric-metal-dielectric structure, and the composite film lamination passivation layer comprises a first-layer medium film, a second-layer medium film and a metal film intermediate layer disposed between the first-layer medium film and the second-layer medium film. The surface passivation layer has the dielectric-metal-dielectric laminated structure and can achieve injection of current carriers into dielectrics, and the surface passivation layer has the good passivation effect and achieves a current transmission function of a surface passivation structure at the same time. The invention further discloses a method for achieving crystalline silicon solar cell surface passivation by utilizing the surface passivation layer enhancing conductivity.

Owner:江苏润阳世纪光伏科技有限公司

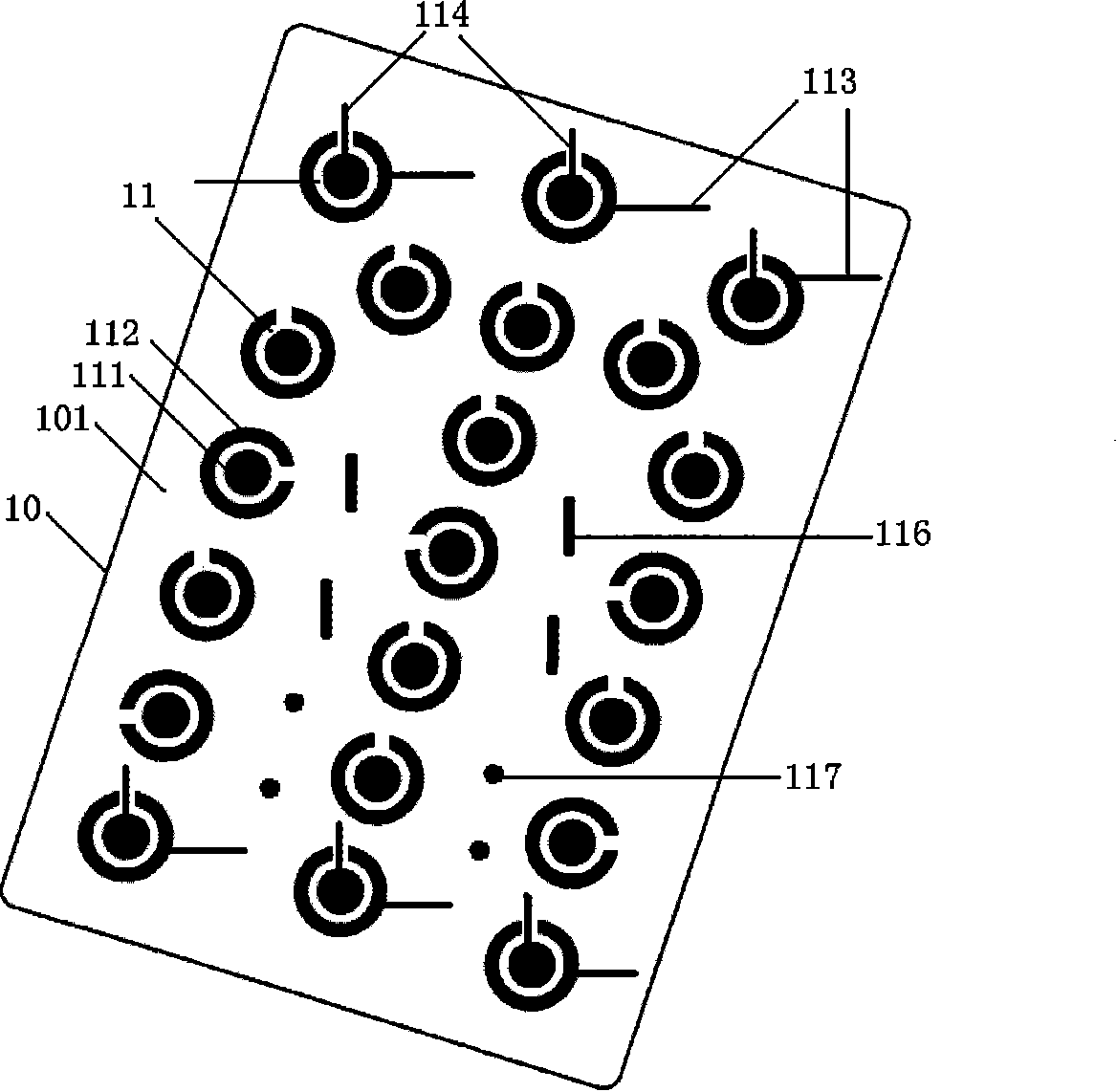

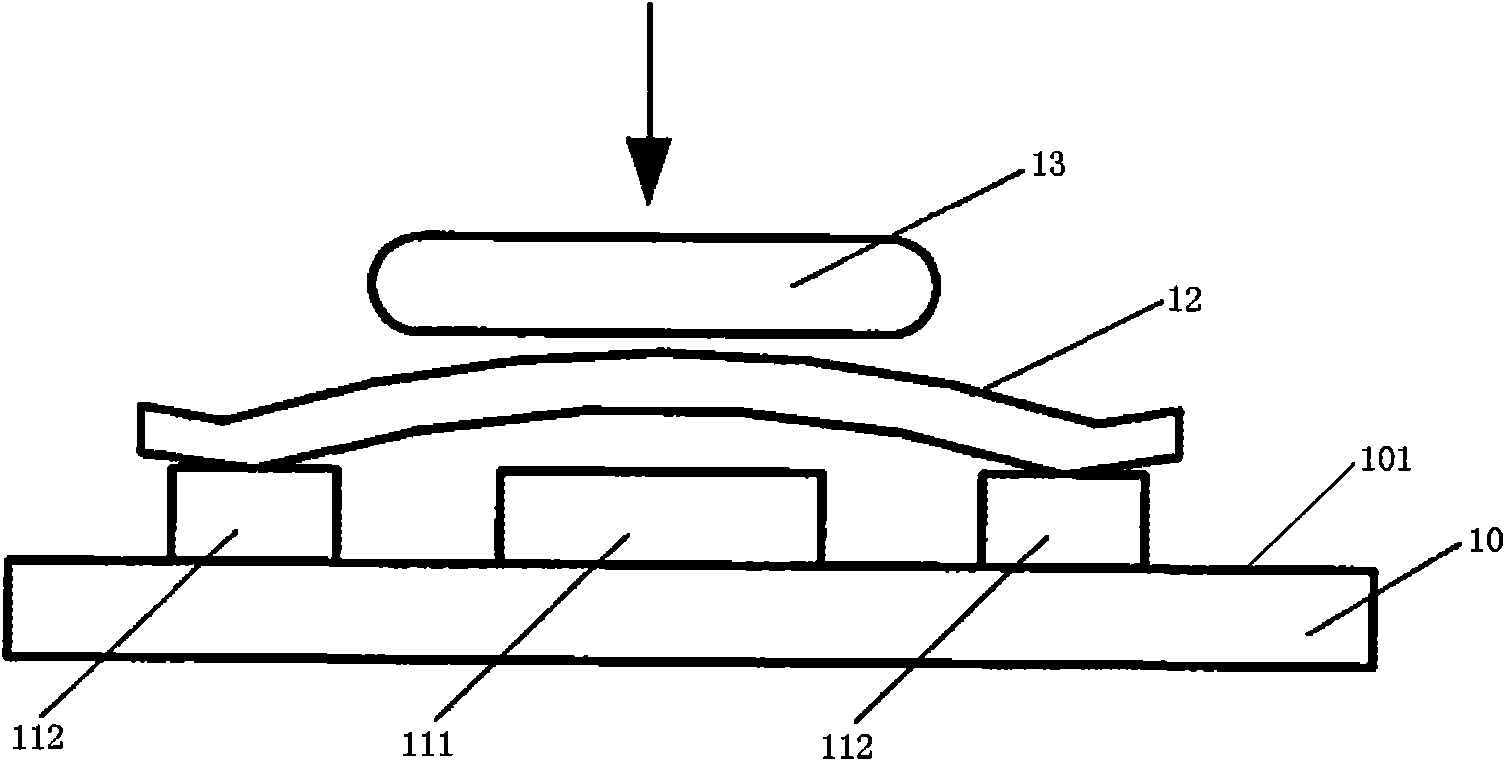

Keyboard panel

InactiveCN101673632AReduce manufacturing costHas conductive propertiesElectric switchesElectrical connection printed elementsTerminal equipmentEngineering

The embodiment of the invention discloses a keyboard panel. The keyboard panel comprises a PCB substrate and a key bonding pad which is arranged on a first surface of the PCB substrate by a carbon membrane printing graph; the key bonding pad comprises an inner ring and an outer ring, and the outer ring is connected by carbon membrane wiring on the first surface of the PCB substrate. The keyboard panel is applicable to terminal equipment.

Owner:HUAWEI DEVICE (SHENZHEN) CO LTD

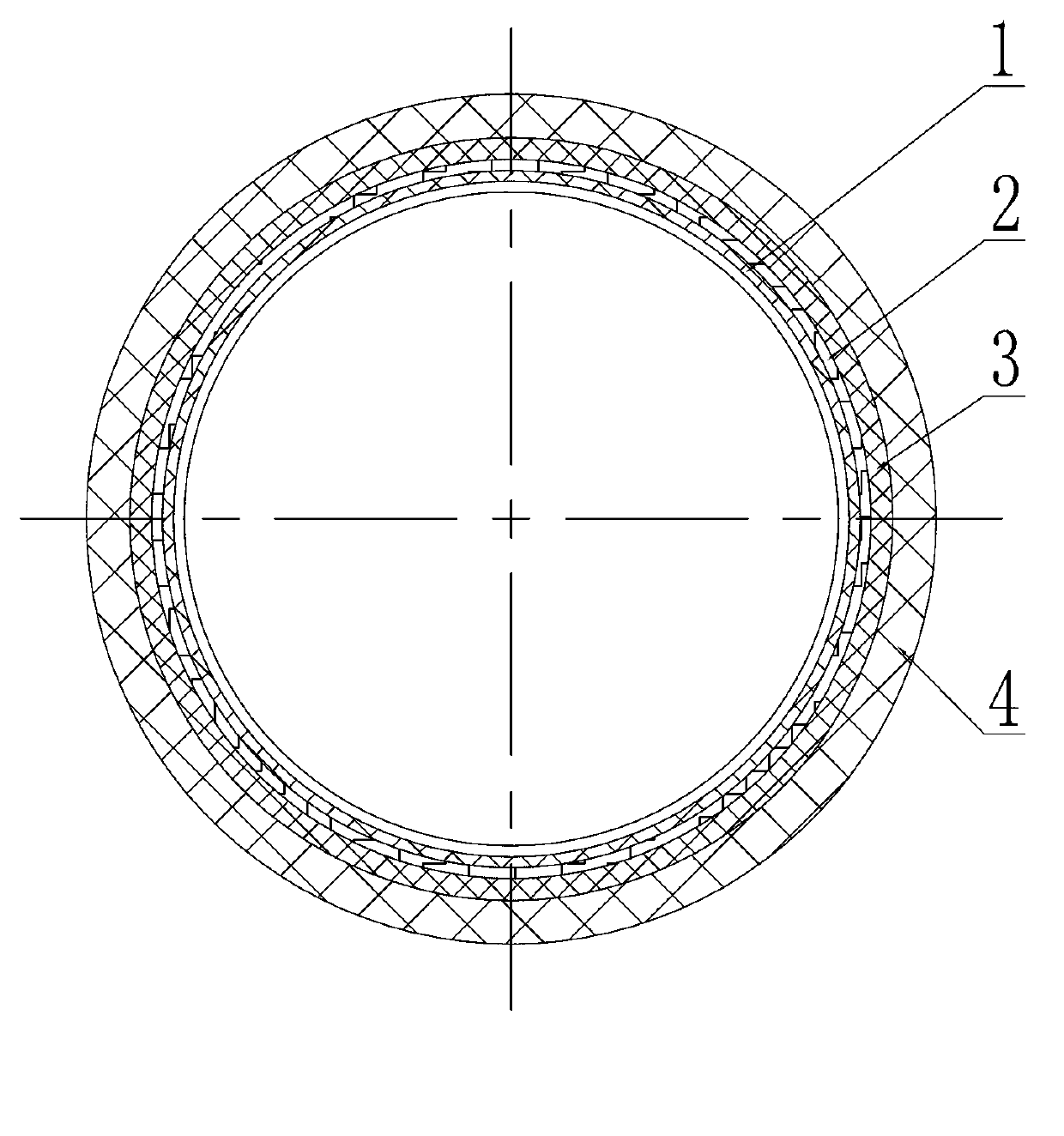

Conductive fiberglass reinforced polyester anode tube and preparation method thereof

InactiveCN102989587ARealize the conductive functionRealize anti-corrosion functionElectrode constructionsPolyesterElectric resistivity

The invention belongs to manufacture of fiberglass reinforced polyester (FRP) pipes, and particularly relates to an FRP anode tube and a preparation method thereof. The conductive FRP anode tube is composed of an inner conductive antiseptic layer, a conductive layer, a transition layer and a structure layer, wherein the inner conductive antiseptic layer, the conductive layer, the transition layer and the structure layer are sequentially composited into a whole from inside to outside, two ends of the conductive layer extend and are exposed out of two ends of the conductive FRP anode tube, and the conductive layer is made of metal mesh. The preparation method includes processing steps of cleaning a mould, manufacturing the inner conductive antiseptic layer, manufacturing the conductive layer, manufacturing the transition layer, solidifying for the first time, winding to manufacture the structure layer, solidifying for the second time, demoulding and the like. According to the FRP anode tube and the preparation method thereof, the technical problem in the prior art of being high in product electric resistivity is solved. The existing product has the advantages of being low in electrical resistivity (electric resistance of a DN 300 FRP pipe with the length of 5 meters is 20-30 ohms), reasonable in process design and the like.

Owner:昊华中意河北新材料有限公司

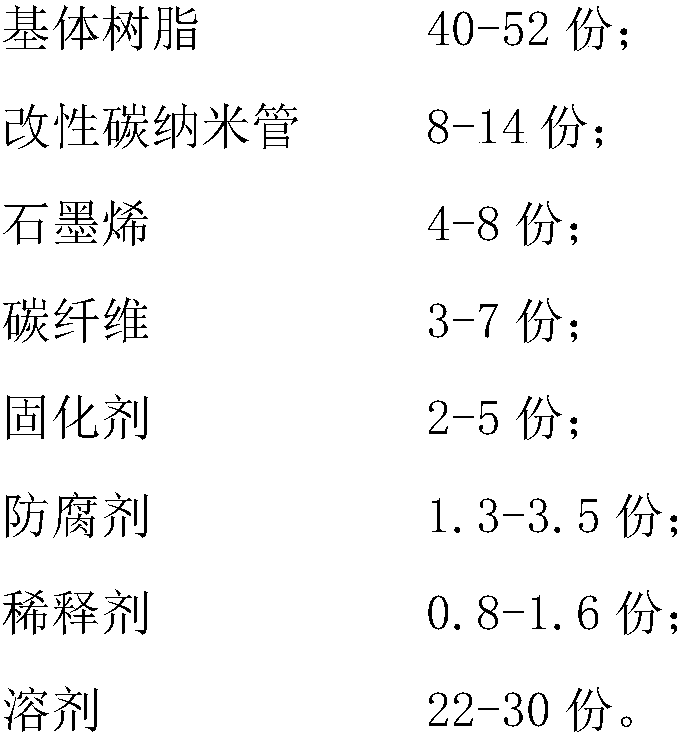

Electrically conductive anti-corrosive coating and preparation method thereof

InactiveCN108948949AGood dispersionImprove conductivityAnti-corrosive paintsEpoxy resin coatingsFiberPreservative

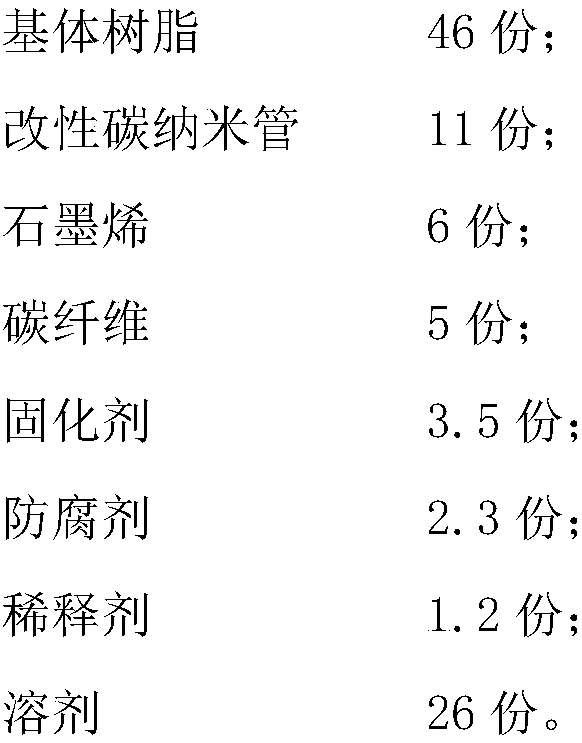

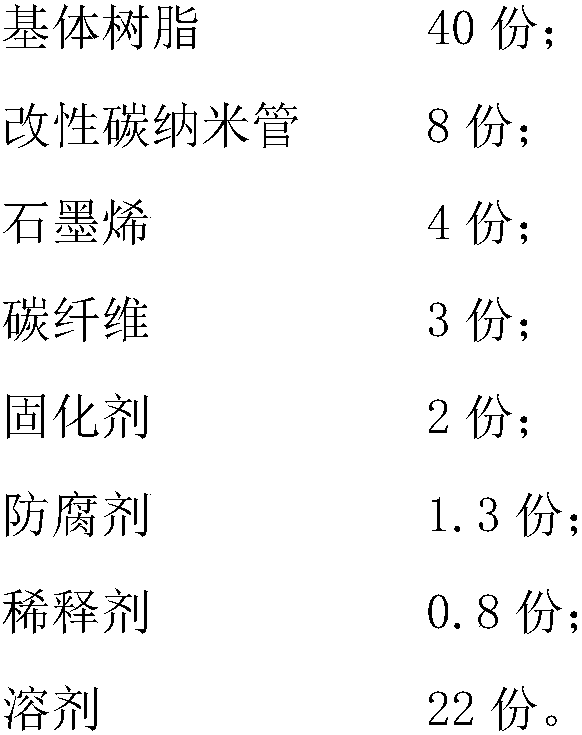

The invention discloses an electrically conductive anti-corrosive coating and a preparation method thereof. The coating comprises the following raw materials by weight: 40-52 parts of matrix resin, 8-14 parts of modified carbon nanotubes, 4-8 parts of graphene, 3-7 parts of carbon fiber, 2-5 parts of a curing agent, 1.3-3.5 parts of a preservative, 0.8-1.6 parts of a diluent, and 22-30 parts of asolvent. The coating of the invention has excellent electrical conductivity, excellent anti-corrosive performance and strong adhesion, and is not easy to be peeled off; and the preparation method is simple and suitable for large-scale production and application.

Owner:合肥奇呗数字科技有限公司

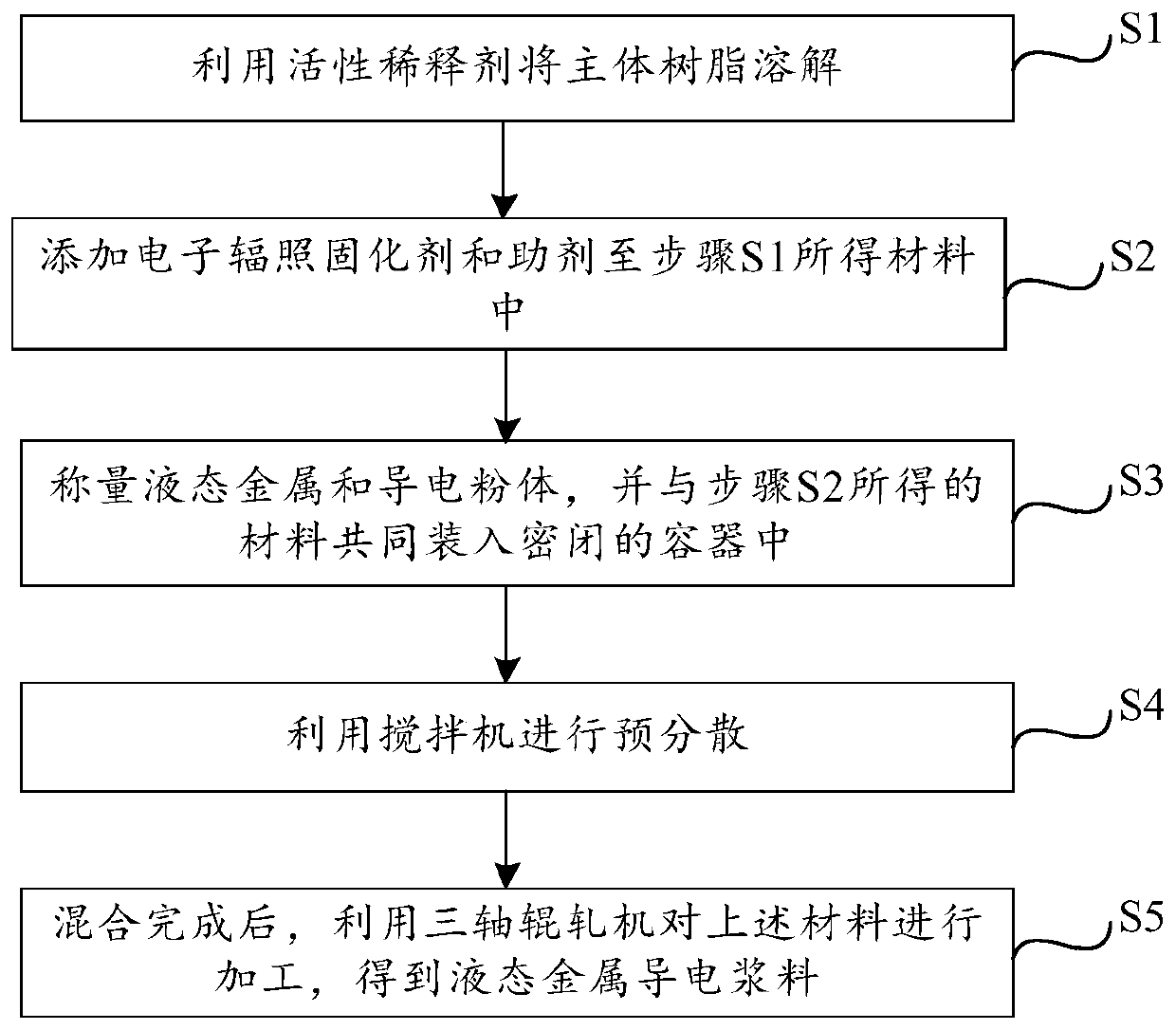

Liquid metal conductive paste and preparation method thereof, and electronic device

InactiveCN111128440AAchieve solidificationImprove liquidityNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive polymerLiquid metal

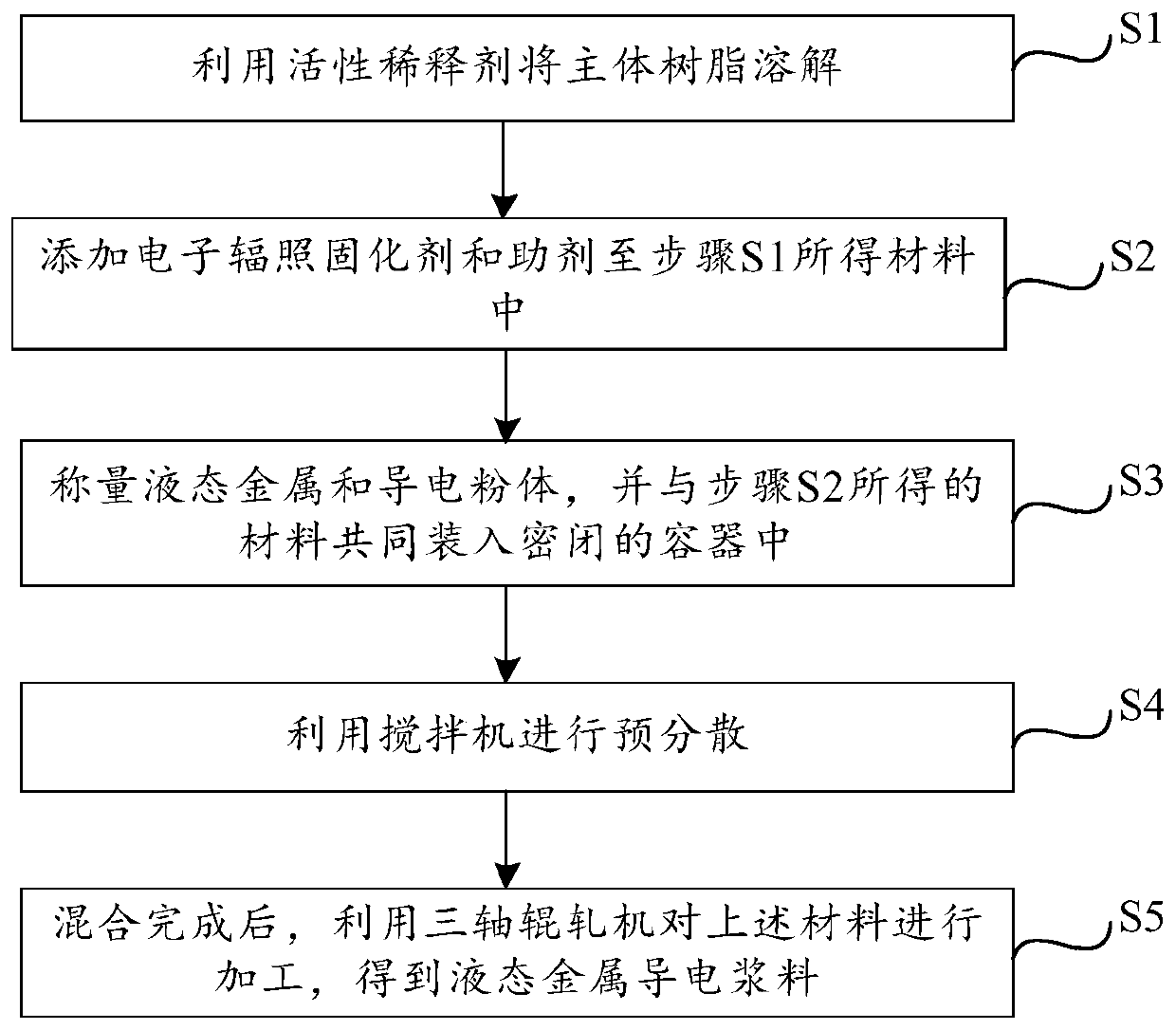

The invention provides a liquid metal conductive paste and a preparation method thereof, and an electronic device, and relates to the technical field of new materials. The liquid metal conductive paste provided by the invention comprises, by weight, 5%-30% of a matrix resin, 10%-60% of a conductive filler, 2%-30% of an electron irradiation curing agent, 1%-40% of liquid metal, 10%-30% of a reactive diluent and 0%-10% of an auxiliary agent, wherein the liquid metal is a metal simple substance or alloy with a melting point lower than a room temperature. According to the technical scheme, pollution in a forming process of a conductive circuit can be reduced, and the conductive circuit can be manufactured on a non-temperature-resistant base material.

Owner:BEIJING DREAM INK TECH CO LTD

Method of manufacturing conductive PCM plate

ActiveCN107509313AFor precise conductionRealize the conductive functionConductive material removal by irradiationCoated surfaceLacquer

The invention provides a method of manufacturing a conductive PCM plate, which comprises the following steps: (1) substrate pretreatment: degreasing a substrate through a degreasing tank I and a degreasing tank II, washing the substrate through a washing process, and passivating the substrate; (2) front paint layer applying: coating the substrate after pretreatment with a front paint layer in a coating room, drying the front paint layer in an oven, and curing the front paint layer; (3) back conductive back paint applying: coating the passivated substrate with conductive back paint in the coating room, and drying the conductive back paint in the oven; (4) rolling and cutting: rolling up a roll material, and cutting the roll material into corresponding material pieces of fixed length according to the material requirement; (5) paint layer removing: removing the finishing paint layer and priming paint layer on the front by laser; and (6) protective film applying: cleaning up powder and impurities caused by laser, and applying a corresponding protective film according to the surface property of the coating. Through the method, the problem that local conduction in any area cannot be realized through the conductive PCM plate manufacturing method in the prior art is solved.

Owner:青岛河钢复合新材料科技有限公司 +1

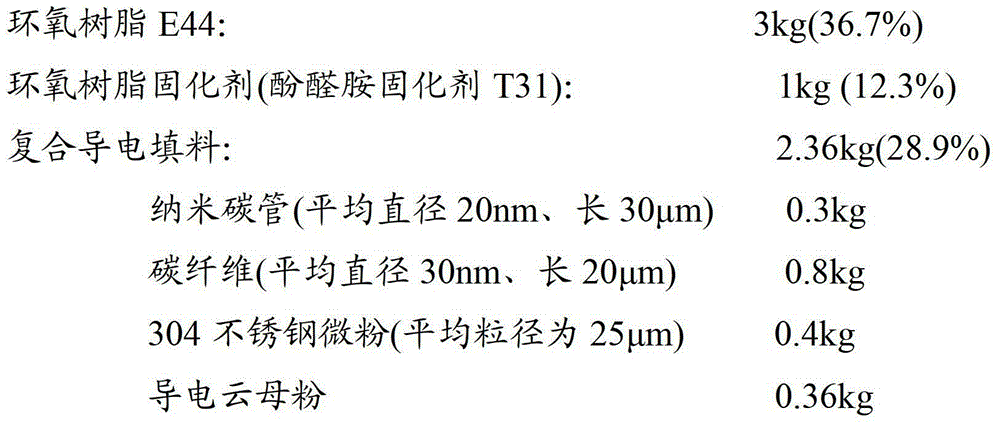

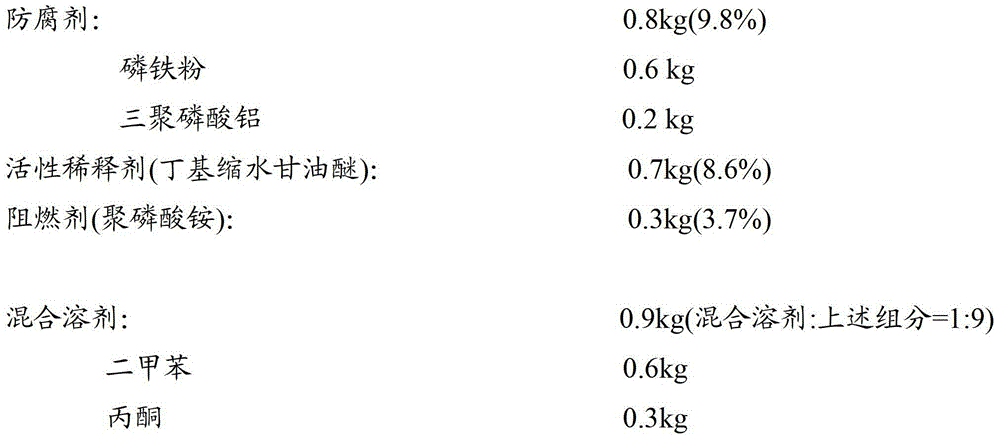

Conductive anticorrosion paint and preparation method thereof

InactiveCN108587288AGood construction technologyRealize the conductive functionFireproof paintsAnti-corrosive paintsGrounding gridSolvent

The invention discloses a conductive anticorrosion paint and a preparation method thereof. The paint is mainly composed of phenolic resin, a phenolic resin curing agent, a conductive filling material,an antiseptic, a diluent, a fire retardant, and a solvent. The conductive anticorrosion paint employs a spraying mode or a brush coating mode to prepare a conductive anticorrosion coating layer on aprocessed workpiece surface, can be widely used for metal structural members such as an electric power industry grounding grid apparatus, a petrochemical industry oil storage apparatus and the like, realizes electric conduction, static powder conduction, and anticorrosion functions, and can achieve the on-site usage requirement. The preparation technology of the paint is simple, and the industrialproduction is easily realized.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Conductive anti-corrosion paint and preparation method thereof

InactiveCN108300048AImprove construction processImprove compatibilityAnti-corrosive paintsElectrically-conductive paintsSolventSpray coating

The invention discloses conductive anti-corrosion paint and a preparation method thereof. The conductive anti-corrosion paint is mainly prepared from the following ingredients in parts by weight: 24 to 44 parts of carboxyl acrylic resin, 16 to 32 parts of carboxyl acrylic resin curing agents, 4 to 12 parts of conductive filling materials, 0.5 to 3.2 parts of diluents, 0.8 to 3.8 part of preservatives, 0.3 to 1.6 parts of coupling agents, 0.2 to 0.8 part of flatting agents and 15 to 35 parts of solvents. The paint recipe and proportion are optimized, so that the conduction and anti-corrosion functions of the paint are realized; the spray coating or brush coating mode is used for preparing the conductive anti-corrosion coating on the surface of the treated workpiece; the paint can be widelyused on metal structure elements of electric industry grounding net device, petrochemical industry oil storage devices and the like; the functions of conduction, static electricity conduction, anti-corrosion and the like can be realized; the field use requirements are met.

Owner:合肥卓创新材料有限公司

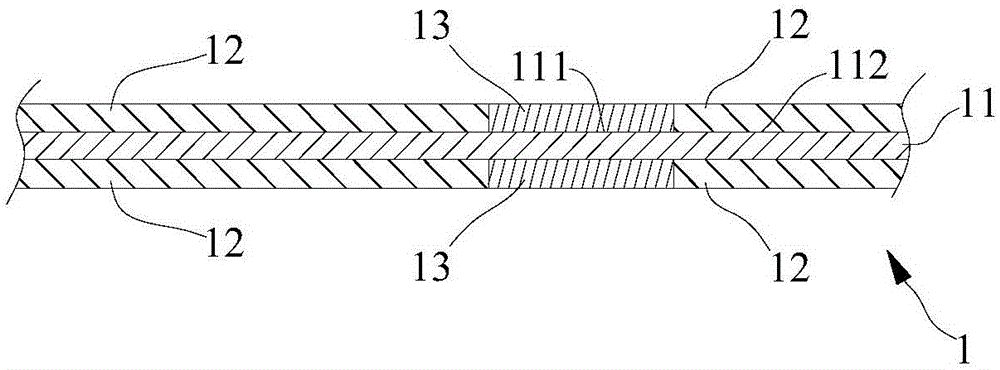

Carbon fiber overhead conductor with optical fiber communication function

PendingCN111768906AFrom erosionImprove bending resistancePower cables for overhead applicationInsulated cablesFiberFiber-optic communication

The invention discloses a carbon fiber overhead conductor with an optical fiber communication function. The carbon fiber overhead conductor comprises a carbon fiber composite material core, an opticalfiber structure, an inner aluminum layer, a middle aluminum layer wrapping the inner aluminum layer and the optical fiber structure, and an outer aluminum layer. The optical fiber structure comprisesan aluminum alloy pipe, heat insulation cotton and an optical fiber. According to the invention, the optical fiber structure and the inner aluminum layer are twisted together to coat the carbon fibercomposite material core. Meanwhile, the functions of electric conduction and communication are achieved, the time and cost required by line erecting are saved, the inner aluminum layer and the optical fiber structure are wrapped by the aluminum layer in use, the composite carbon fiber material core is protected against corrosion caused by weather such as external acid rain and saline-alkaline fog, the bending resistance of the wire is improved, and optical fibers can be protected advantageously. The carbon fiber composite overhead conductor has the advantages of a carbon fiber conductor, optical fiber communication and transmission of data such as conductor voltage, current, operating temperature and tension can be achieved, and real-time monitoring of the operating state of the overheadconductor is facilitated.

Owner:JIANGSU NARI YINLONG CABLE

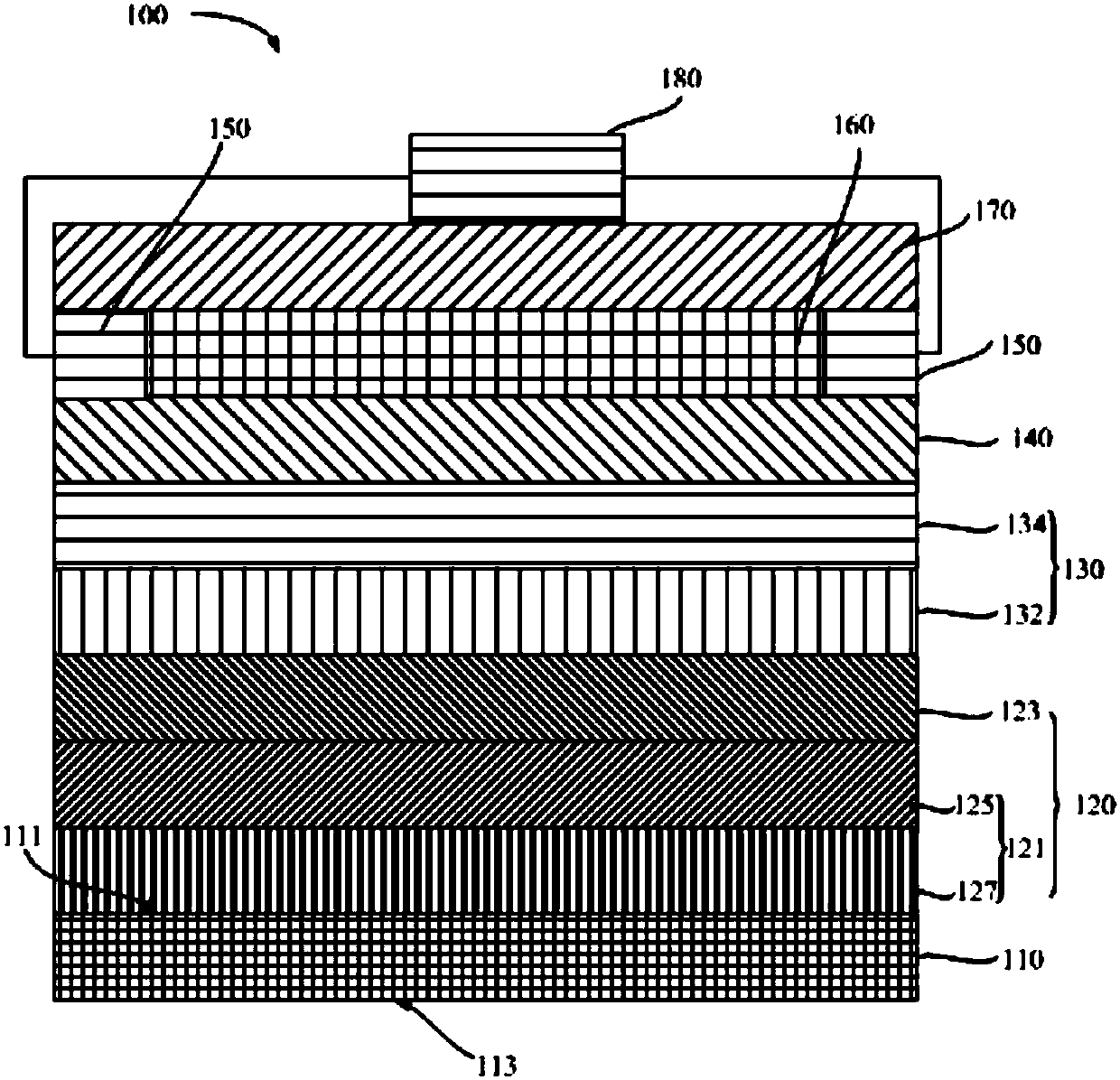

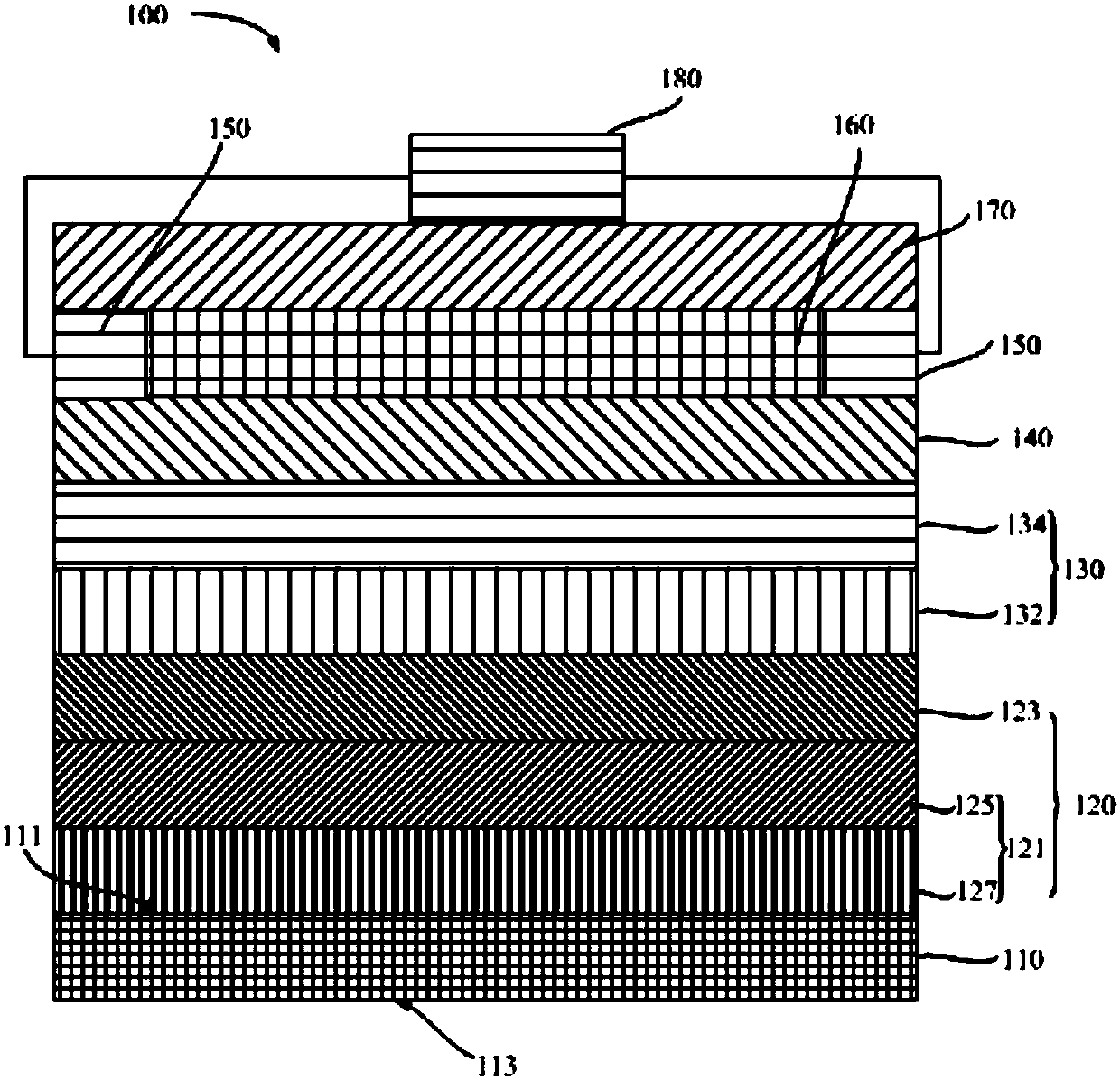

Color photovoltaic module, and preparation method and application thereof

InactiveCN109920866AGood weather resistanceAchieve colorFinal product manufacturePhotovoltaic energy generationMetal flowJunction box

The invention relates to a color photovoltaic module, and a preparation method and an application thereof. The color photovoltaic module comprises a color transparent conductive substrate, a photovoltaic function layer, a back electrode layer, a metal flow guide tape, a glue layer, a packaging layer and a junction box which are stacked in sequence, wherein the color transparent conductive substrate comprises a transparent substrate, and a color transparent conductive thin film stacked on the transparent substrate; and the color transparent conductive thin film comprises a functional layer stacked on the surface of the transparent substrate and a conductive layer stacked on the surface of the functional layer. The color photovoltaic module realizes color impression through sunlight reflection control outdoors, and is very suitable for outdoor application; and the embarrassing situation of no color rendering in the daytime is avoided.

Owner:CSG HOLDING +1

Conductive anticorrosion coating and preparation method thereof

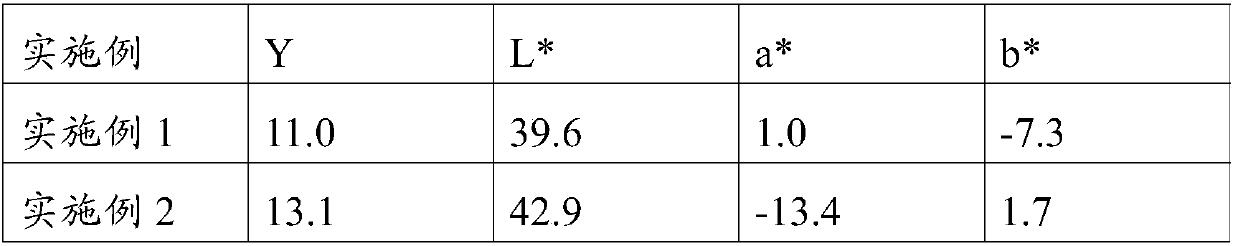

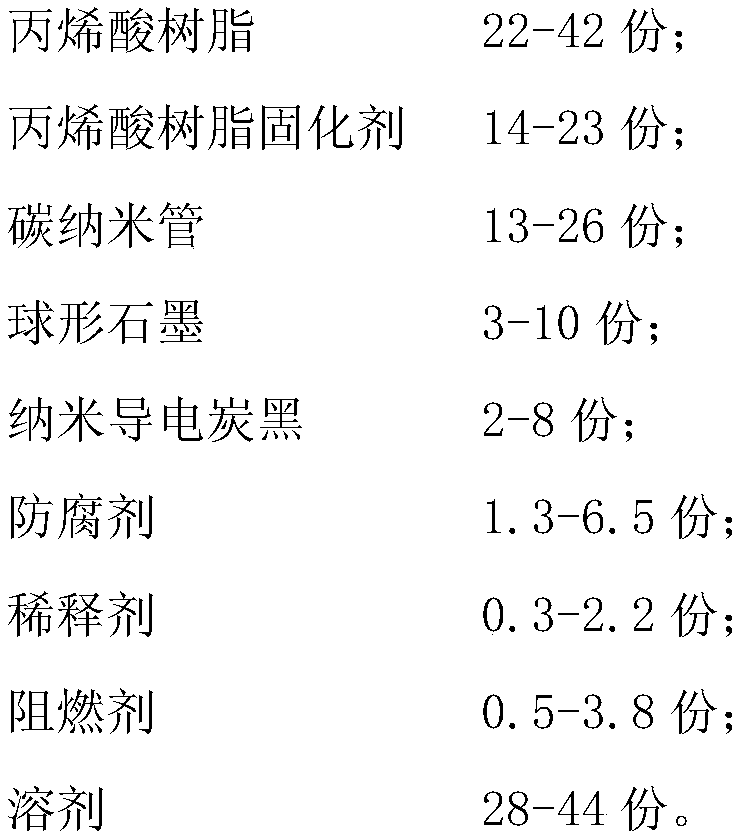

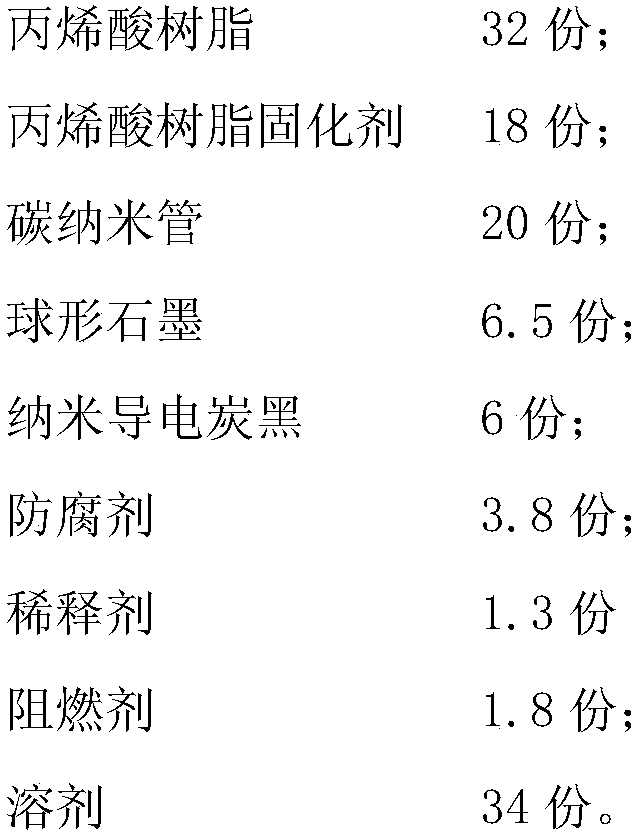

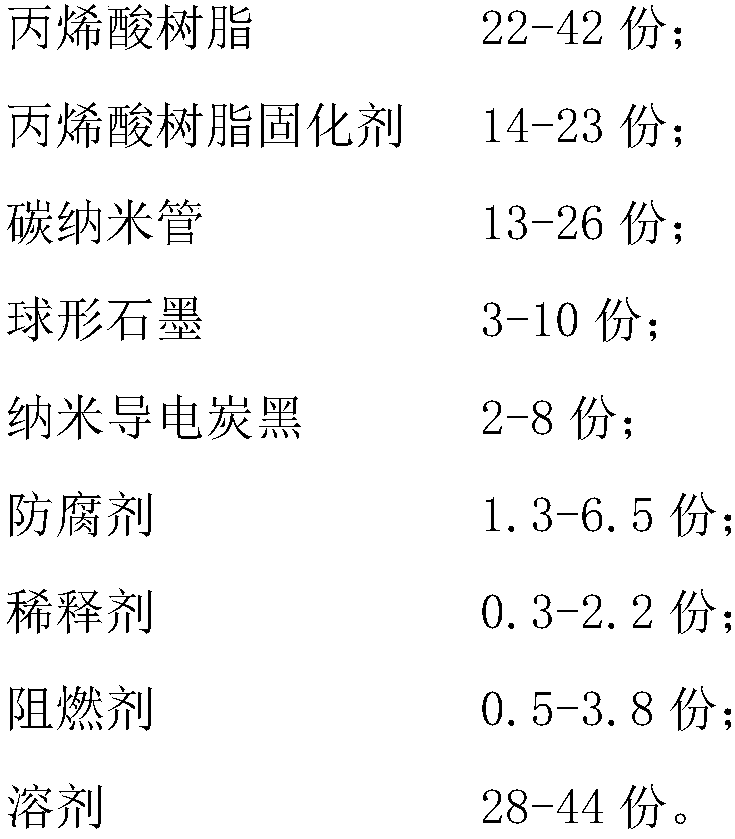

InactiveCN108250870AImprove corrosion resistanceGood construction technologyFireproof paintsAnti-corrosive paintsAcrylic resinCarbon nanotube

The invention discloses a conductive anticorrosion coating and a preparation method thereof. The coating is mainly prepared from acrylic resin, an acrylic resin curing agent, a carbon nanotube, spherical graphite, nanometer conductive carbon black, an anticorrosion agent, a diluent, a flame retardant and a solvent. The conductive anticorrosion coating adopts a spraying or brushing mode to preparea conductive and anticorrosion coating layer on the surface of a well-treated workpiece, and can be widely applied to metal structural pieces such as grounding grid devices in the power industry and oil storage devices in the petrochemical industry, achieves the functions of electricity conduction, static electricity conduction and corrosion resistance, and meets the field service requirement. Thepreparation technology of the coating is simple, and industrialized production can be achieved easily.

Owner:尚福平

Conductive plate, track lamp and production method of conductive plate

PendingCN111043548AImprove conductivityRealize the conductive functionLighting support devicesNon-metallic protective coating applicationLight equipmentConductive membrane

The invention discloses the technical field of illuminating equipment, and discloses a conductive plate. The conductive plate comprises a conductive surface; conductive strips are arranged on the conductive surface; the conductive strips extend along the length direction of the conductive plate; the conductive strips are covered with conductive films without metallic luster; the problems that dueto the fact that when a metal is directly adopted for conducting electricity, people visually feel unsafe, the exposed metal is prone to oxidation, and the conductivity is affected are solved. According to the utility model, worries of people in the aspect of safety are eliminated, the conductive films isolate the conductive strips from the outside to protect the conductive strips, and the conductive films have good conductivity and can better realize a conductive function.

Owner:深圳市卓越华予电路有限公司

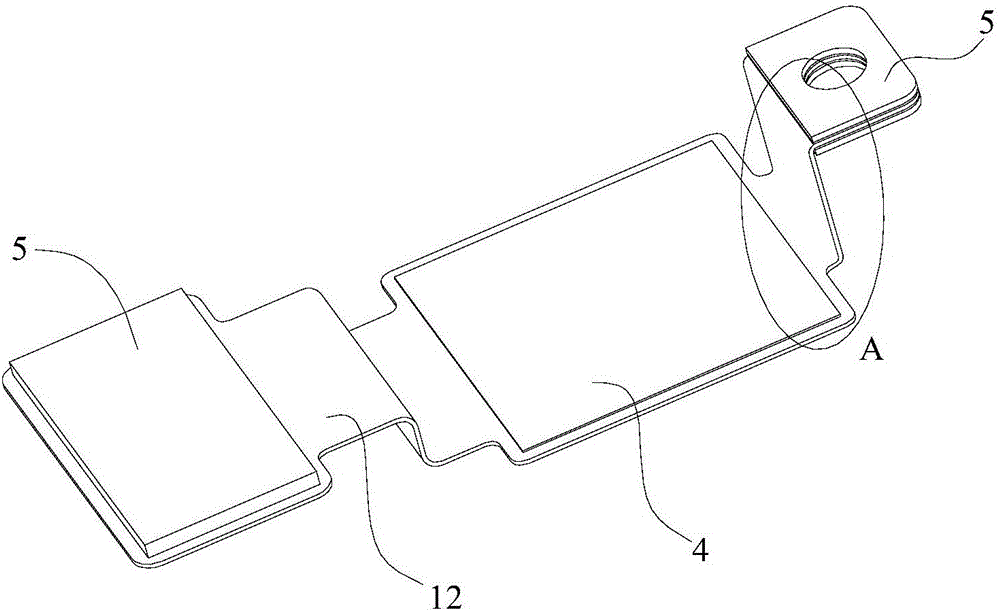

Flexible circuit board, circuit connection structure and mobile equipment

ActiveCN106332439AHighly integratedSmall footprintCircuit thermal arrangementsElectricityFlexible circuits

The invention discloses a flexible circuit board with functions of heat dissipation and electric conduction, a circuit connection structure applying the flexible circuit board and mobile equipment. The flexible circuit board comprises a conducting layer and an insulating layer, and is characterized in that the surface of the conducting layer is divided into a heat dissipation area and a non heat dissipation area, the non heat dissipation area is covered by the insulating layer, a heat dissipation metal layer is laid in the heat dissipation area, the heat dissipation metal layer is electrically connected with the conducting layer of the heat dissipation area, and both ends of the flexible circuit board are conductive ends. According to the invention, both ends of the flexible circuit board serve as conductive ends, thereby being capable of connecting components requiring electric connection, and realizing the electric conducting function. The heat dissipation metal layer laid in the heat dissipation area not only can realize the heat dissipating function, but also can realize the electric conducting function. Electronic devices located on the heat dissipation metal layer are electrically connected to a circuit of the flexible circuit board, the integration level of the electronic devices is improved, and the space occupied by the electronic device is reduced.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

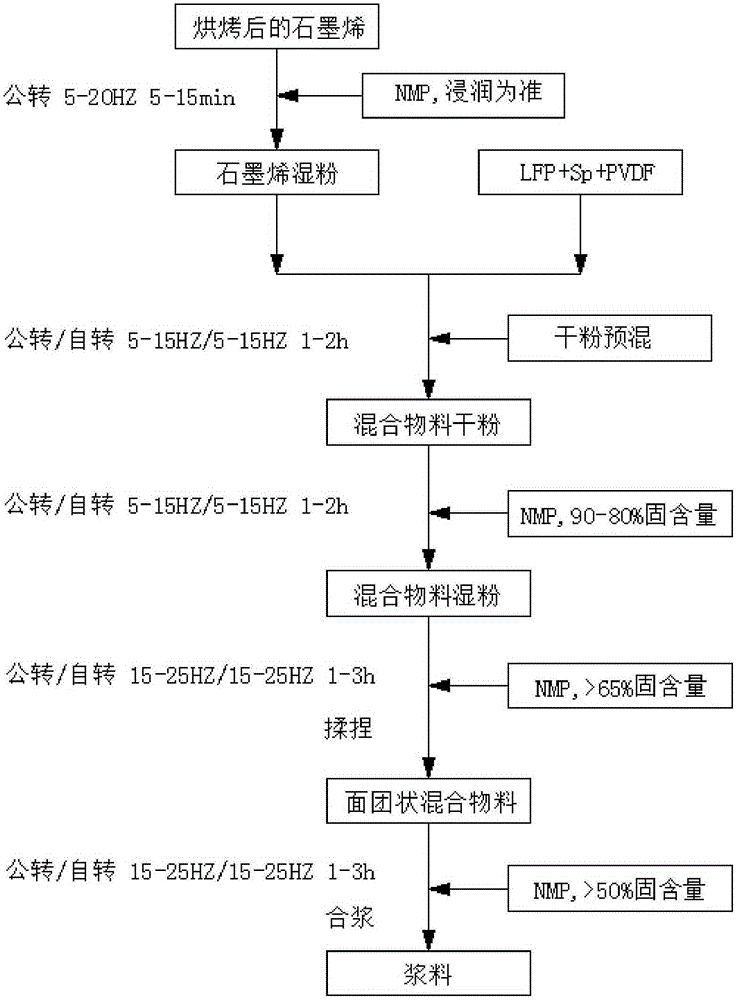

A kind of preparation method of positive electrode slurry

ActiveCN103811764BRealize the conductive functionEvenly dispersedCell electrodesLithium iron phosphateNanotechnology

The invention discloses a preparation method of graphene dry powder for LFP (lithium ferric phosphate) anode paste. The preparation method of graphene dry powder for LFP anode paste comprises the following steps: (1) putting a baked graphene layer into a stirrer, diluting by using NMP (N-methyl pyrrolidinone), and stirring at a low speed till the material is at a wet powder state; (2) adding the baked anode active substances of LFP, SP and PVDF (polyvinylidene fluoride) into the graphene wet powder, and stirring continuously at a low speed for 1-2 hours, thereby preparing anode premix; (3) diluting by using NMP, and stirring the anode premix at a low speed till the anode premix is at a wet powder state and the solid content of the premix is 80%-90%; (4) diluting the premix at the wet powder state by using NMP until the solid content is around 65%, and stirring the premix at a high speed until each component is uniform and dispersive, thereby preparing a mixed material; and (5) beginning to dilute the mixed material when the mixed material generates a pole climbing phenomenon, controlling the solid content of the mixed material to be around 49%, and stirring at a high speed so as to prepare the required paste. The preparation method provided by the invention can effectively disperse graphene and each component of other anode materials without adopting any additive for helping the graphene to disperse, and reduces the influence on the battery performance of substances of the type of additives.

Owner:唐山国轩电池有限公司

Conductive coating for computers and preparation method thereof

InactiveCN108410341ARealize the conductive functionConductive function hasAnti-corrosive paintsPolyurea/polyurethane coatingsConductive coatingPolyester resin

The invention discloses a conductive coating for computers and a preparation method thereof. The coating is mainly prepared from polyester resin, polyester resin curing agent, conductive filler, nano-silver powder, ethyl cellulose, anticorrosive agent, thinner and solvent. The conductive coating for computers which is disclosed by the invention has excellent conductivity; with high adhesion, the conductive coating cannot be easily stripped; moreover, the conductive coating has relatively good corrosion resistance; the preparation method is simple; and the conductive coating is suitable for large-scale production and application.

Owner:合肥酷睿网络科技有限公司

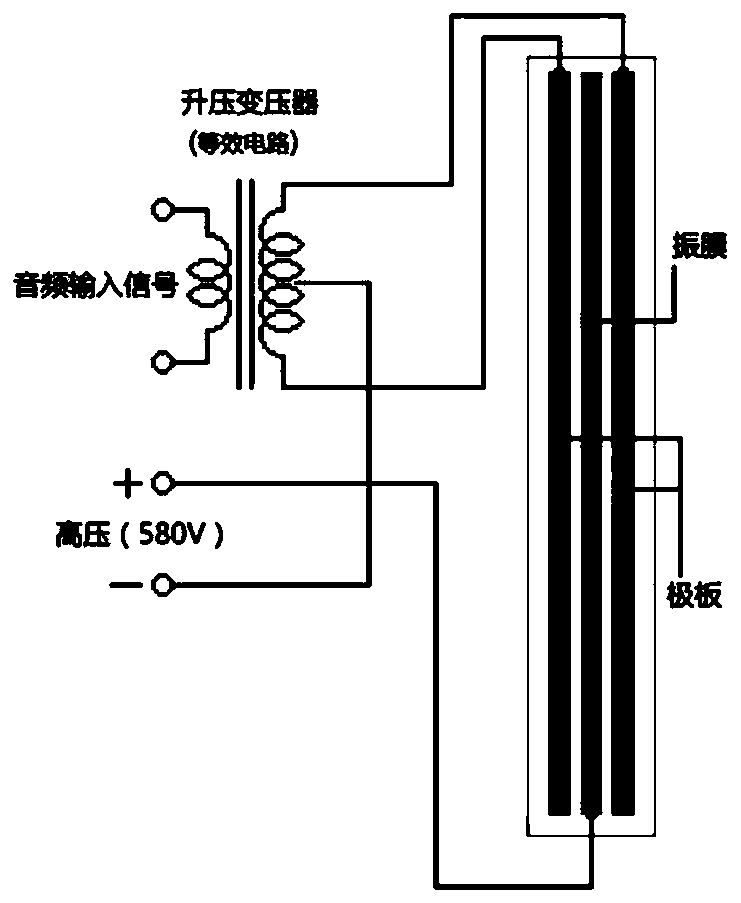

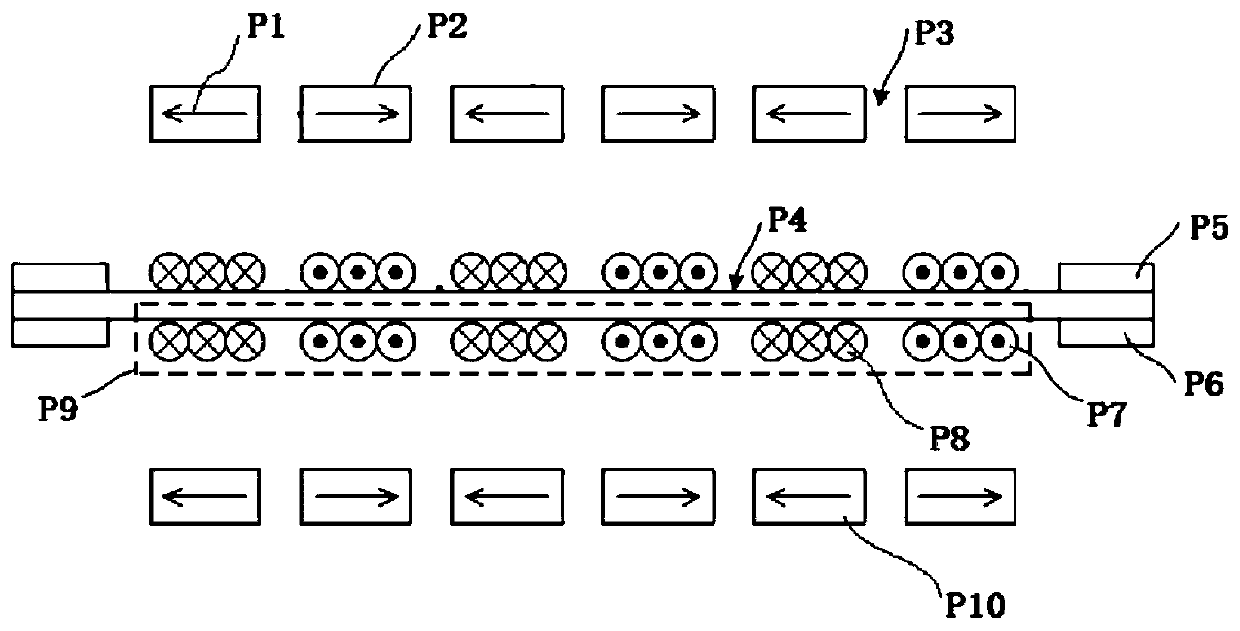

Planar coil diaphragm loudspeaker and application thereof

The invention discloses a planar coil diaphragm loudspeaker, which comprises an outer shell, wherein a membrane assembly, a magnet assembly and a supporting assembly are packaged in the outer shell; the membrane assembly at least comprises a coil, the two ends of the coil are each provided with an end point, one end point is located in the coil, and the other end point is located outside the coil;the number of the supporting assemblies is at least one; the supporting assemblies are used for supporting the membrane assembly; the surfaces, making contact with the membrane assembly, of the supporting assemblies are provided with bonding pads connected with end points located outside the coil; and the supporting assemblies are further provided with bonding pads for audio current input and bonding pads for audio current output. Compared with the prior art, the planar coil diaphragm loudspeaker has the advantages that the problem of how to effectively connect the internal end point of the closed coil with the outside is solved, the integrity of the membrane is not damaged, the area of the membrane is utilized to the maximum extent, damage to the film caused by spot welding or conductiveadhesive bonding after perforation is avoided, and damage to the integrity of the film is further avoided.

Owner:颜君玲

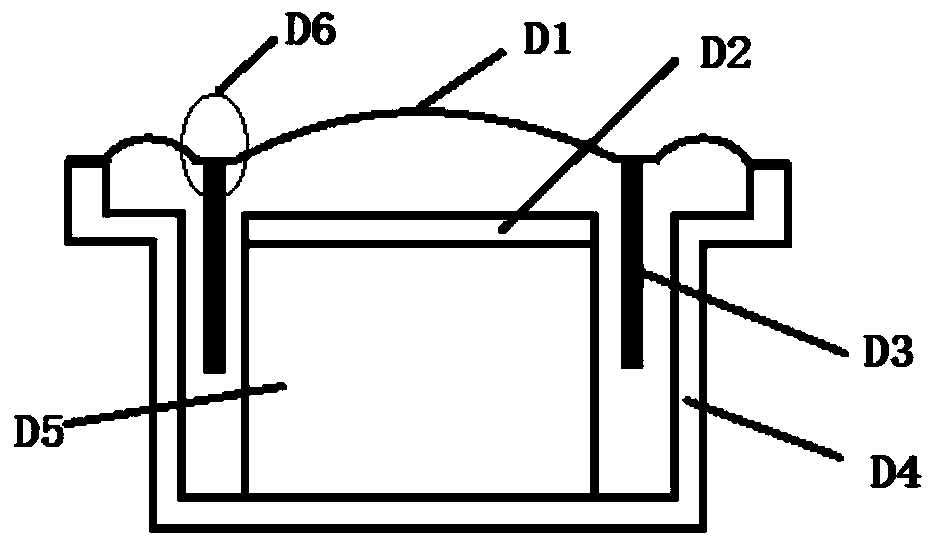

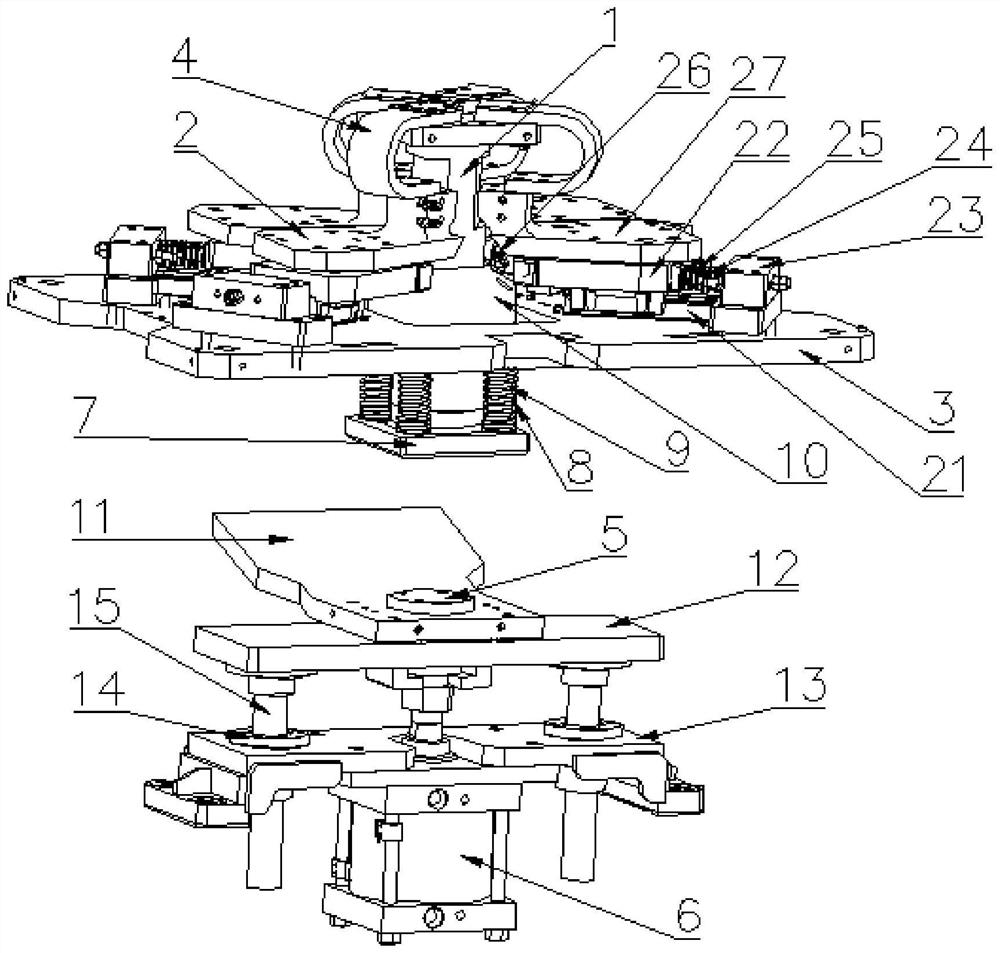

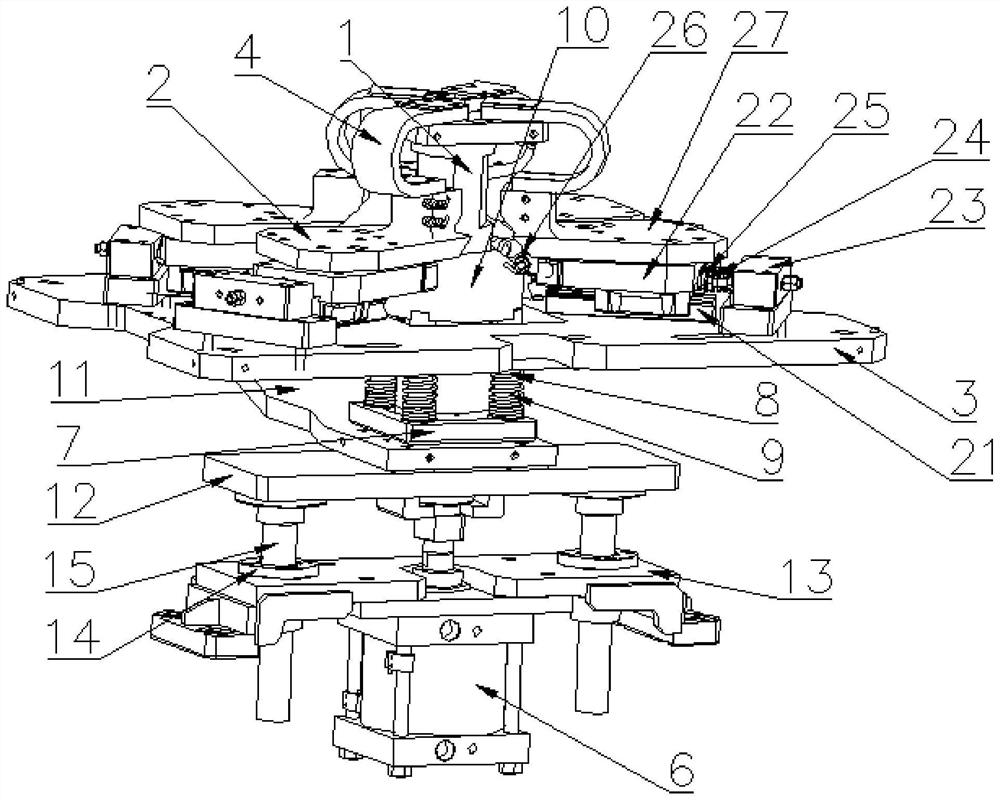

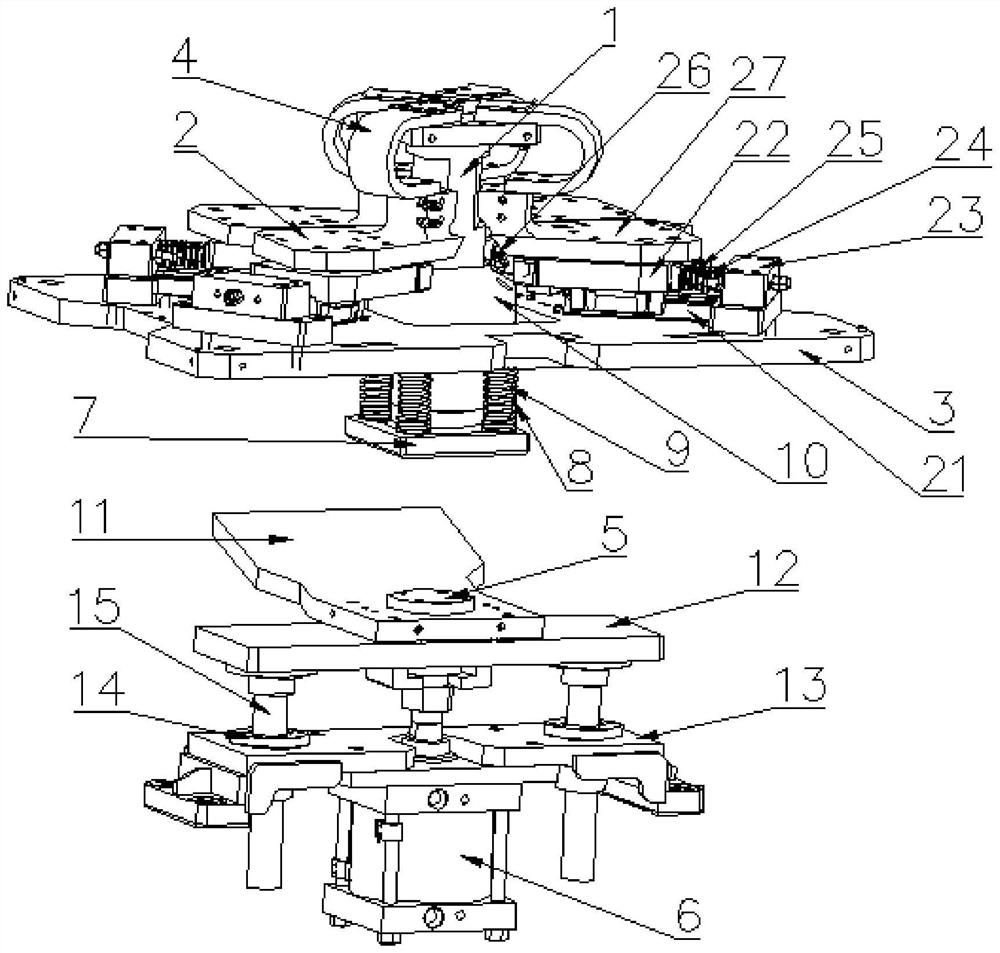

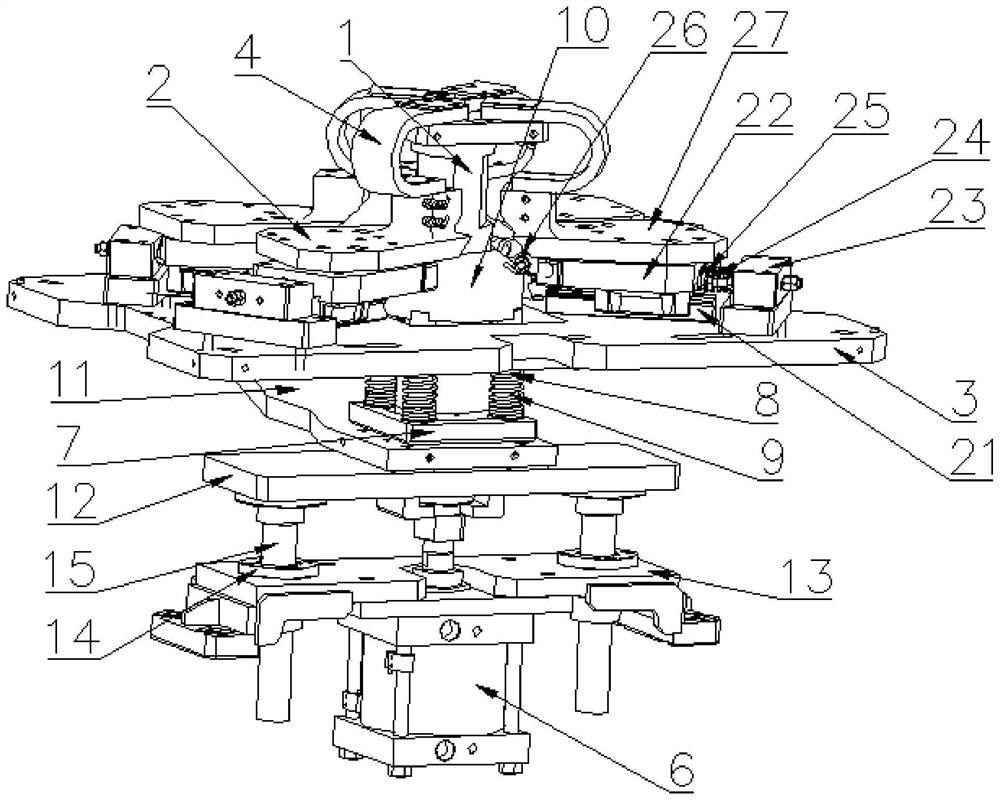

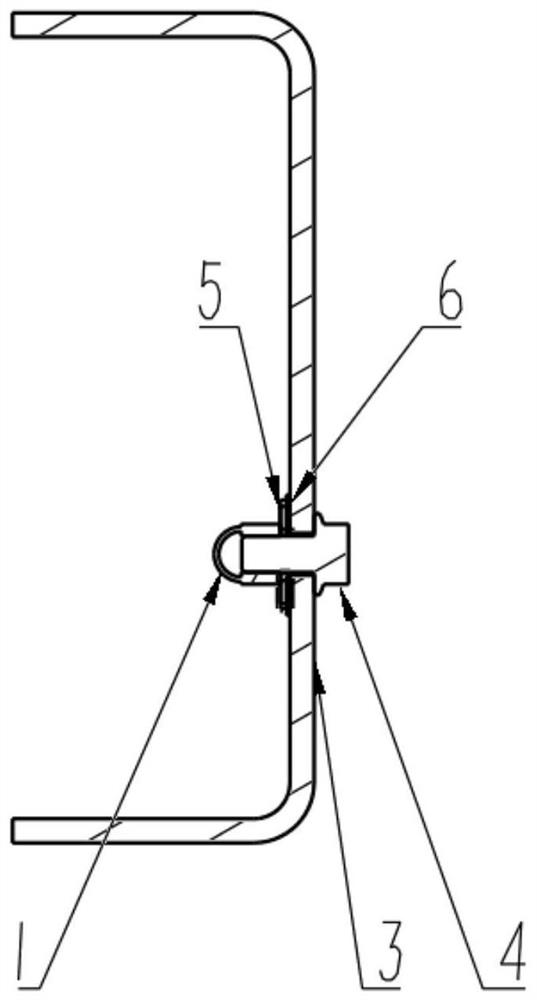

Positioning device with conductive function

ActiveCN113182756AAchieve electrificationRealize the conductive functionWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention provides a positioning device with a conductive function. The positioning device comprises a mounting plate, wherein an opening is formed in the mounting plate, a positioning mechanism is mounted above the mounting plate, a guide shaft is arranged below the mounting plate, a first spring penetrates through the guide shaft, and a pressing plate is mounted below the guide shaft; a round hole is formed in the position, corresponding to the guide shaft, of the pressing plate, a conductive copper sleeve is arranged above the pressing plate, the upper end of the conductive copper sleeve is connected with a first conductive soft belt, and the other end of the first conductive soft belt is connected with a positioning mechanism; a wedge block is arranged outside the conductive copper sleeve, the wedge block is fixed on the pressing plate, and the upper part of the wedge block is in contact with the positioning mechanism; a pressing head is arranged below the pressing plate, the connecting end of a second conductive soft belt is fixed below the pressing head, and the pressing head and the second conductive soft belt are fixed to an air cylinder. The positioning function and the conductive function can be achieved only through one power source, so that the structure is simple, the control program is saved, the cost is reduced, and the production efficiency is improved.

Owner:GUANGZHOU SONGXING ELECTRIC

Fabric having functions of mugwort floss

InactiveCN107009695AFeel goodQuick assemblySynthetic resin layered productsGlass/slag layered productsYarnMugwort

The invention provides a fabric having the functions of mugwort floss. The fabric having the functions of mugwort floss comprises a cotton fiber layer, an anti-ultraviolet alkali glass grey yarn layer, an adhesive layer, a mugwort floss layer, a silk layer, a silver ion antibacterial layer and ventilating holes; the bottom of the cotton fabric layer is provided with the anti-ultraviolet alkali glass grey yarn layer in order to realize an anti-ultraviolet function and improve the hand feeling of the fabric is improved; the top of the silk layer is provided with the silver ion antibacterial layer to realize an antibacterial function; two or more ventilating holes are arranged in the adhesive layer to enhance the ventilating effect; and the anti-ultraviolet alkali glass grey yarn layer and the silver ion antibacterial layer are connected with the mugwort floss layer through the adhesive layer in order to realize rapid assembling. The fabric has the advantages of improved anti-ultraviolet effect, achieving of healthcare and sterilization functions, improved wearing comfort degree and high reliability.

Owner:相里海霞

A positioning device with conductive function

ActiveCN113182756BAchieve electrificationRealize the conductive functionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Owner:GUANGZHOU SONGXING ELECTRIC

Protective device and protective method for vehicle frame grounding

ActiveCN109624889BFacilitate the realization of conductive functionRealize the conductive functionElectric/fluid circuitElectrophoresesVehicle frame

Owner:CHERY COMML VEHICLE ANHUI

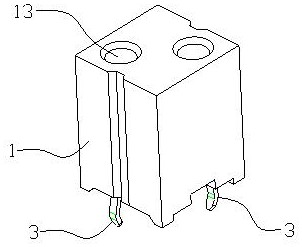

Small plug-in connector with wire locking function

PendingCN113054451ARealize the locking functionRealize the conductive functionCoupling contact membersClamped/spring connectionsMiniaturizationElectric wire

The invention discloses a small plug-in connector with a wire locking function. The connector comprises a plastic shell and a locking mechanism arranged in the plastic shell. The locking mechanism comprises an elastic sheet terminal and a contact conductive terminal which are oppositely arranged; and the elastic sheet terminal and the contact conductive terminal are used for clamping an electric wire inserted between the elastic sheet terminal and the contact conductive terminal through elastic deformation. According to the small plug-in connector provided by the invention, the wire locking function is realized through the cooperation of the two metal parts, namely the elastic sheet terminal and the contact conductive terminal, and through the two metal parts, the clamping force can be improved, and meanwhile, the conductive function is also realized; and according to the small plug-in connector provided by the invention, the clamping force is enough so that the size of the elastic sheet terminal is reduced, the size of the plastic shell is further decreased, product miniaturization is realized, the use space is saved, and the production cost is reduced.

Owner:苏州新亚电通股份有限公司

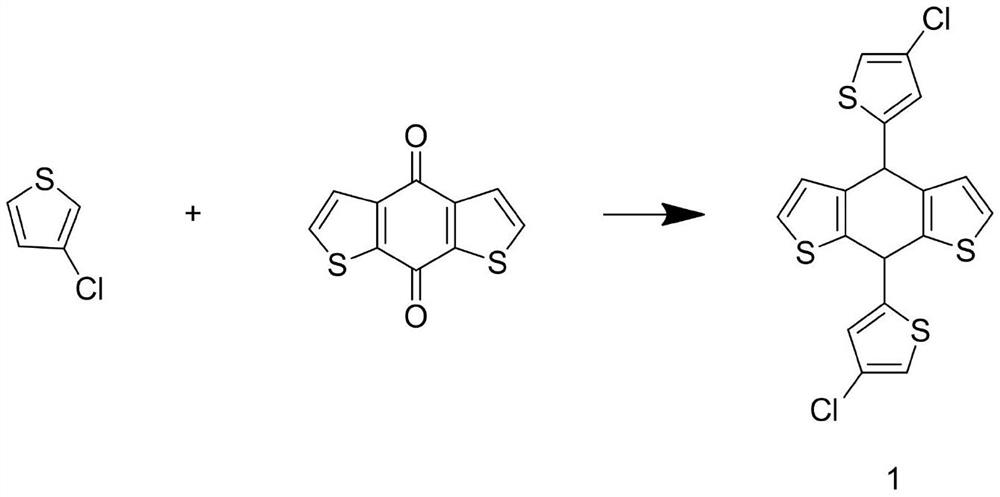

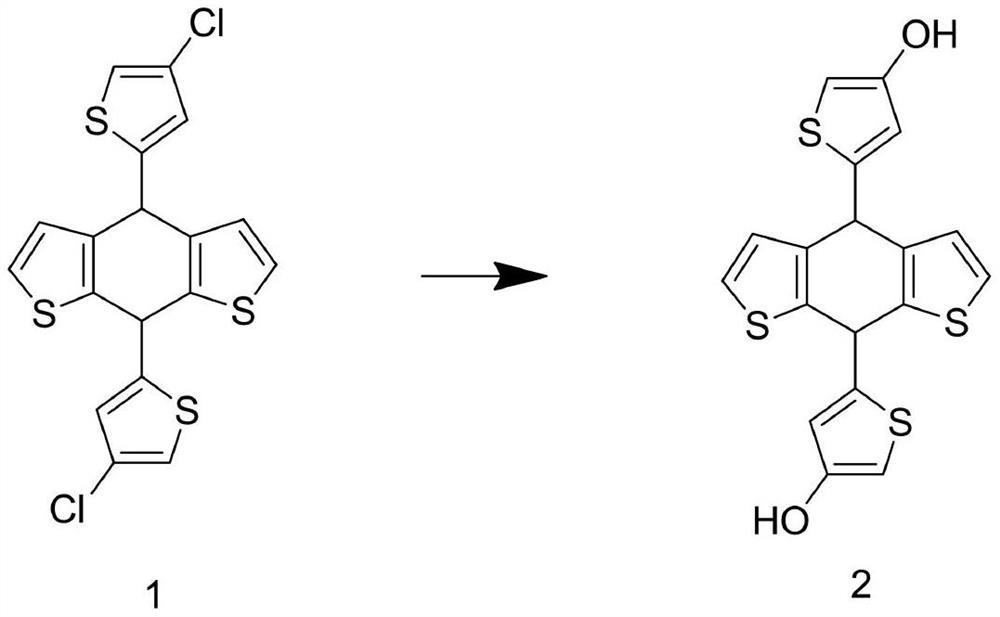

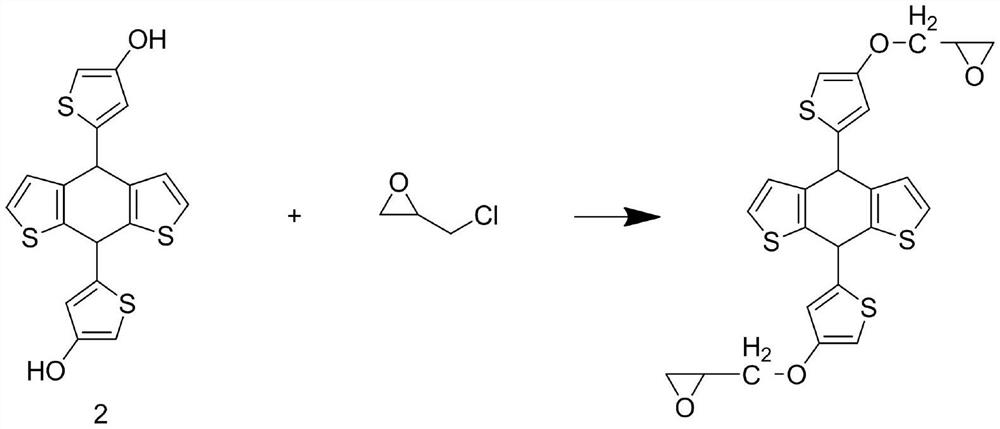

A method for preparing epoxy resin composite material from recycled circuit board materials

ActiveCN113214605BIncreased elastic propertiesHave the ability to conduct electricityPlastic recyclingMolten stateFirming agent

The invention discloses a method for preparing epoxy resin composite materials from recycled circuit board materials, comprising raw materials, 20-30 parts of circuit board recycled materials, 30-40 parts of epoxy resin prepolymer, and 10-20 parts of curing agent; The method, step A1, breaks the recovered material of the circuit board into small pieces, boils it in a sodium hydroxide solution, washes and dries it with water, then soaks it in an acidic solution, and then carries out a hydrometallurgical method to obtain a metal compound precipitation from the soaking solution ; Step A2, put the metal compound precipitation and sulfur powder into the flask, add DMF, stir until dissolved, add the mixed solution of triethylenetetramine and ethylenediamine and polyvinylpyrrolidone, in a nitrogen atmosphere at 150‑160 °C Reflux reaction for 5-6 hours to prepare modified nanocrystals; step A3, heating the epoxy resin prepolymer to a molten state, adding modified nanocrystals and curing agent for 3-4 hours to prepare epoxy resin composite material .

Owner:安徽绿洲危险废物综合利用有限公司

A kind of manufacturing method of conductive PCM board

ActiveCN107509313BFor precise conductionRealize the conductive functionConductive material removal by irradiationCoated surfaceElectrically conductive

The invention provides a method of manufacturing a conductive PCM plate, which comprises the following steps: (1) substrate pretreatment: degreasing a substrate through a degreasing tank I and a degreasing tank II, washing the substrate through a washing process, and passivating the substrate; (2) front paint layer applying: coating the substrate after pretreatment with a front paint layer in a coating room, drying the front paint layer in an oven, and curing the front paint layer; (3) back conductive back paint applying: coating the passivated substrate with conductive back paint in the coating room, and drying the conductive back paint in the oven; (4) rolling and cutting: rolling up a roll material, and cutting the roll material into corresponding material pieces of fixed length according to the material requirement; (5) paint layer removing: removing the finishing paint layer and priming paint layer on the front by laser; and (6) protective film applying: cleaning up powder and impurities caused by laser, and applying a corresponding protective film according to the surface property of the coating. Through the method, the problem that local conduction in any area cannot be realized through the conductive PCM plate manufacturing method in the prior art is solved.

Owner:青岛河钢复合新材料科技有限公司 +1

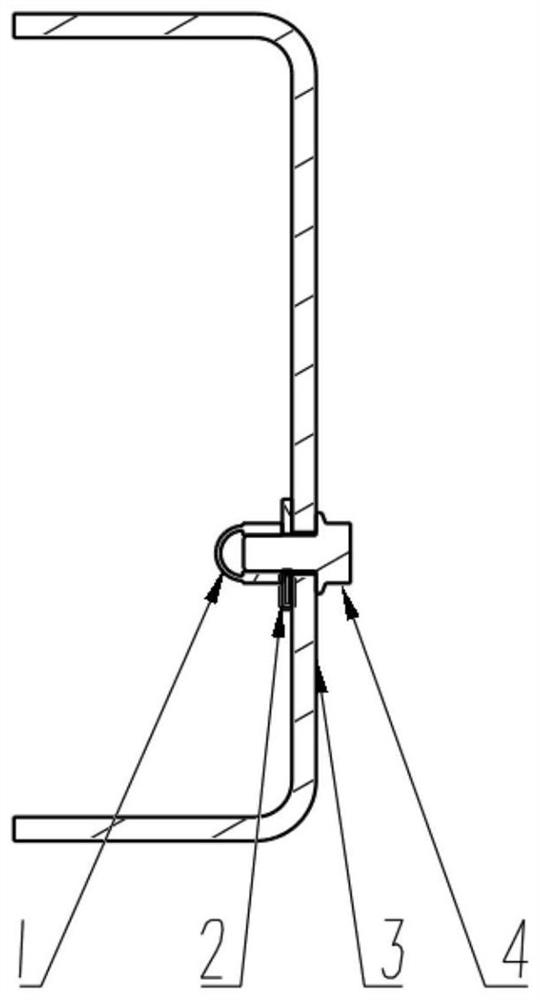

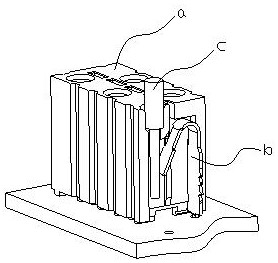

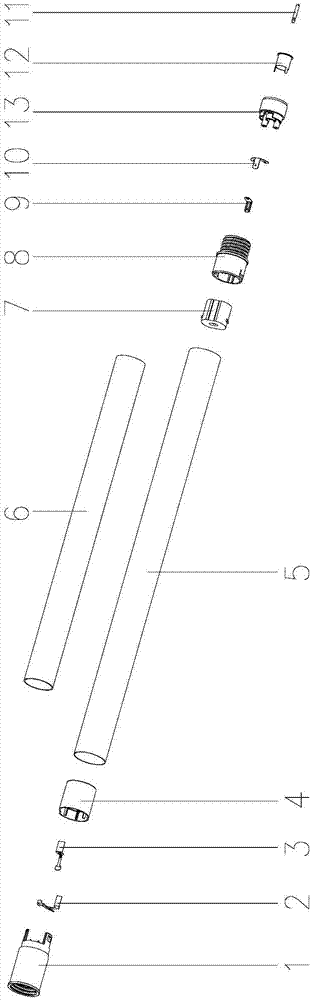

Supporting rod assembly and garment steamer provided with same

PendingCN107059368AAvoid scratchesRealize the conductive functionIroning apparatusTextiles and paperElectrically conductiveStructural engineering

The invention provides a supporting rod assembly and a garment steamer provided with the supporting rod assembly. The supporting rod assembly comprises at least one supporting rod body, wherein a conducting male end is arranged at the first end of the supporting rod body, and a conducting female end is arranged at the second end of the supporting rod body; the conducting male end is matched with the conducting female end, so that a plurality of supporting rod bodies can be assembled together; and each supporting rod body is internally provided with a conductor for connecting the corresponding conducting male end and the corresponding conducting female end. Through the technical scheme of the invention, the problems that the supporting rods and a power line are separated, users are easily stumbled and the safety is low in the prior art are effectively solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Conductive anticorrosive coating and preparation method thereof

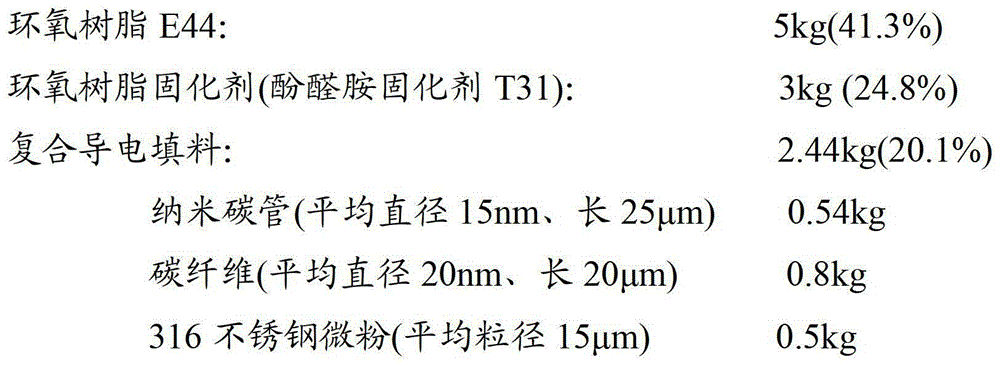

ActiveCN103409033BGood construction technologyImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsGrounding gridPreservative

The invention discloses a conductive anticorrosive coating and a preparation method thereof. The conductive anticorrosive coating mainly consists of epoxy resin, an epoxy resin curing agent, a composite conductive filler, a preservative, a reactive diluent, a flame retardant and a mixed solvent. The conductive anticorrosive coating provided by the invention is used for preparing a conductive anticorrosive coating layer on the surface of a workpiece well treated in a spray-coating or brush-coating way, and can be widely applied to metal structural elements such as a grounding grid device in the power industry and an oil storing device in the petrochemical industry to realize the functions of electric conducting, electrostatic conducting, anti-corrosion and the like, and therefore, the metal structural elements are capable of meeting the requirements of use on spot. The preparation process of the coating provided by the invention is simple and easy for realization of industrial production.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

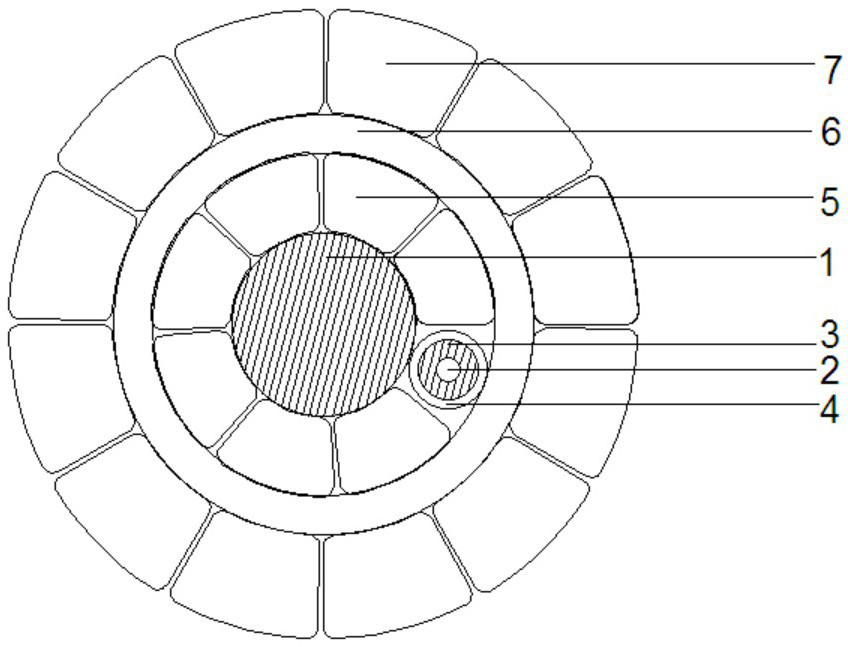

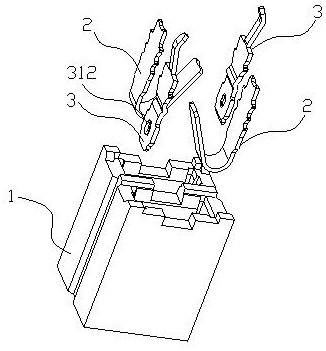

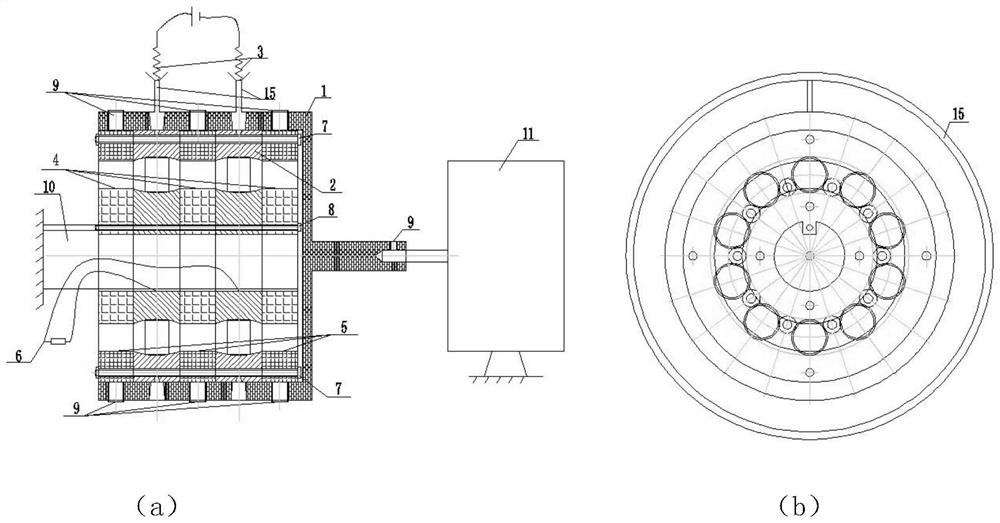

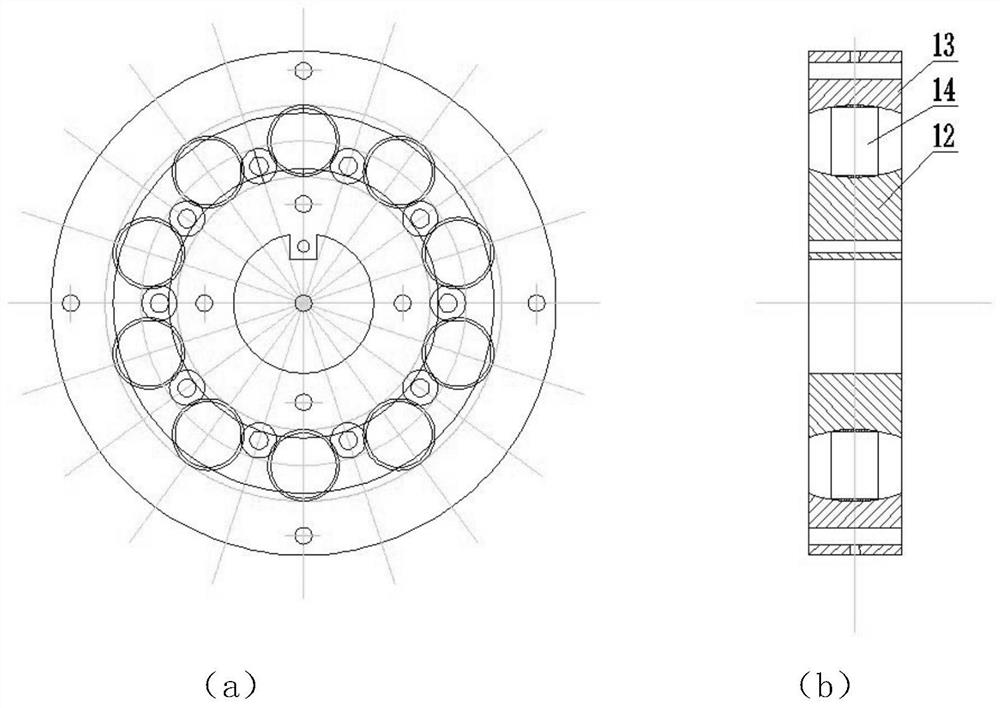

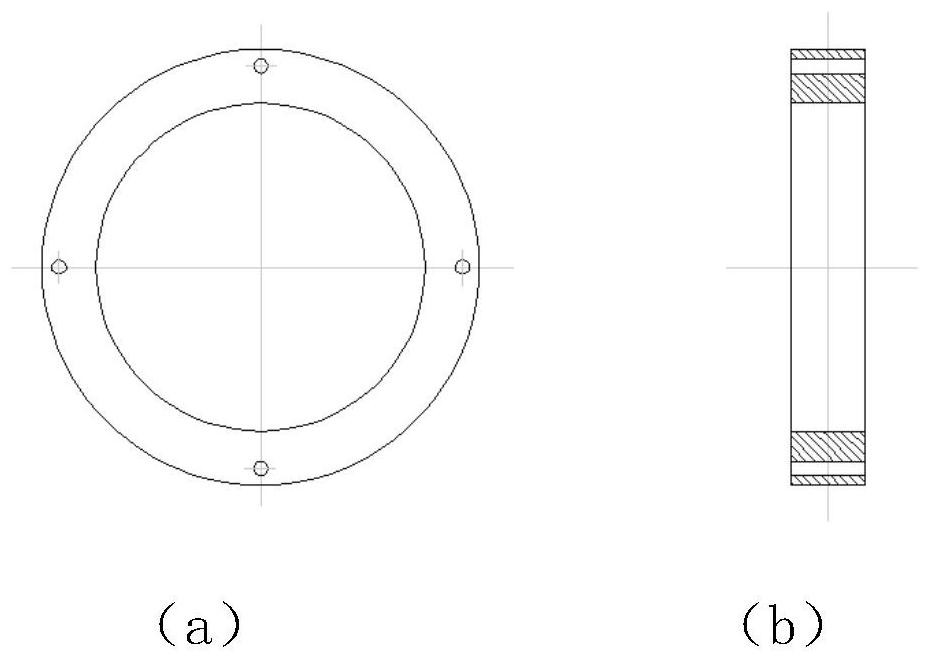

Device for simulating modular rolling type conductive rotary motion in vacuum environment

ActiveCN111769416AAchieve rotational movementIncrease elasticityRotary current collectorElectric power transmissionJackscrew

The invention relates to a device for simulating modular rolling type conductive rotary motion in a vacuum environment. The device comprises an insulating shell, a rolling conductive module, a high-voltage electric brush, an inner ring insulating layer, an outer ring insulating layer, a load resistor, an insulating jackscrew, an insulating mandrel, a vacuum motor and an annular conductive groove.The device provided by the invention is used for simulating the relative rotation of a power transmission key part, namely a conductive rotary joint, of a space super-power and power-expandable spacecraft such as a platform type space solar power station in the electrifying process. By simulating the motion, a basis is provided for detecting the rolling friction / conductive contact performance of the conductive rotary joint, a mechanical friction / electric contact composite damage mechanism and an insulating medium charging and discharging mechanism.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

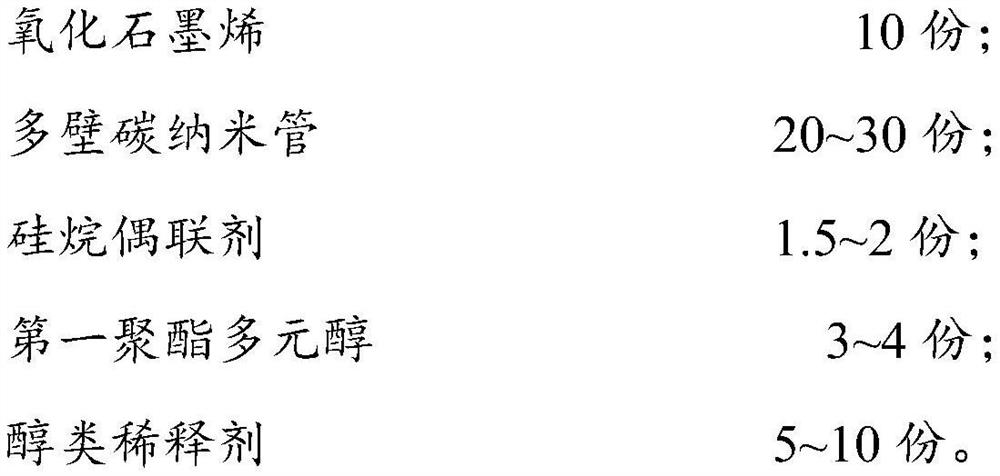

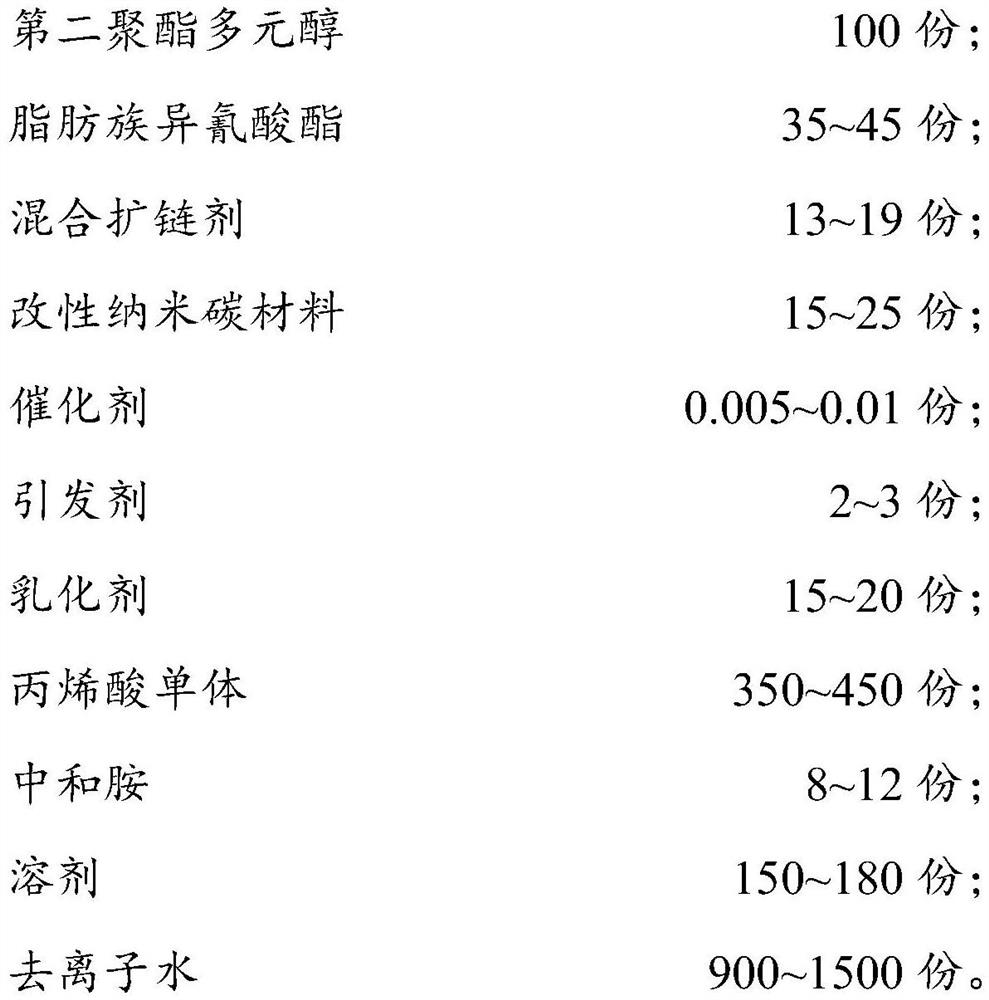

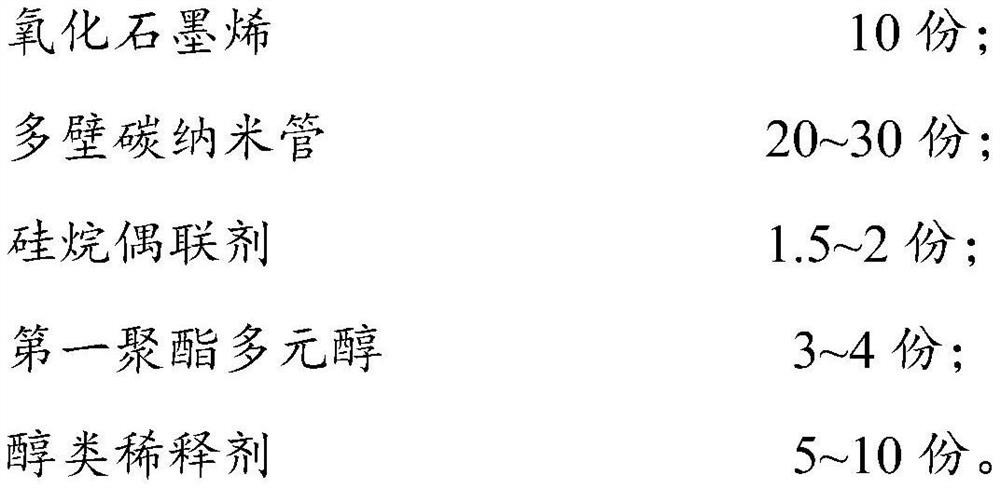

Conductive PUA composite emulsion and preparation method thereof

The invention discloses a conductive PUA composite emulsion and a preparation method thereof, raw materials of the conductive PUA composite emulsion comprise a modified nano carbon material, and preparation raw materials of the modified nano carbon material comprise, by weight, 10 parts of graphene oxide, 20-30 parts of multi-walled carbon nanotubes, 1.5-2 parts of a silane coupling agent, 3-4 parts of first polyester polyol, and 5-10 parts of an alcohol diluent. The conductive PUA composite emulsion is good in stability and high in conductivity, and can be well applied to the fields of conductive coatings, electric heating coatings, electromagnetic shielding coatings and the like.

Owner:GUANGDONG BANGGU CHEM TECH +1

A kind of anticorrosion conductive coating for grounding grid and preparation method thereof

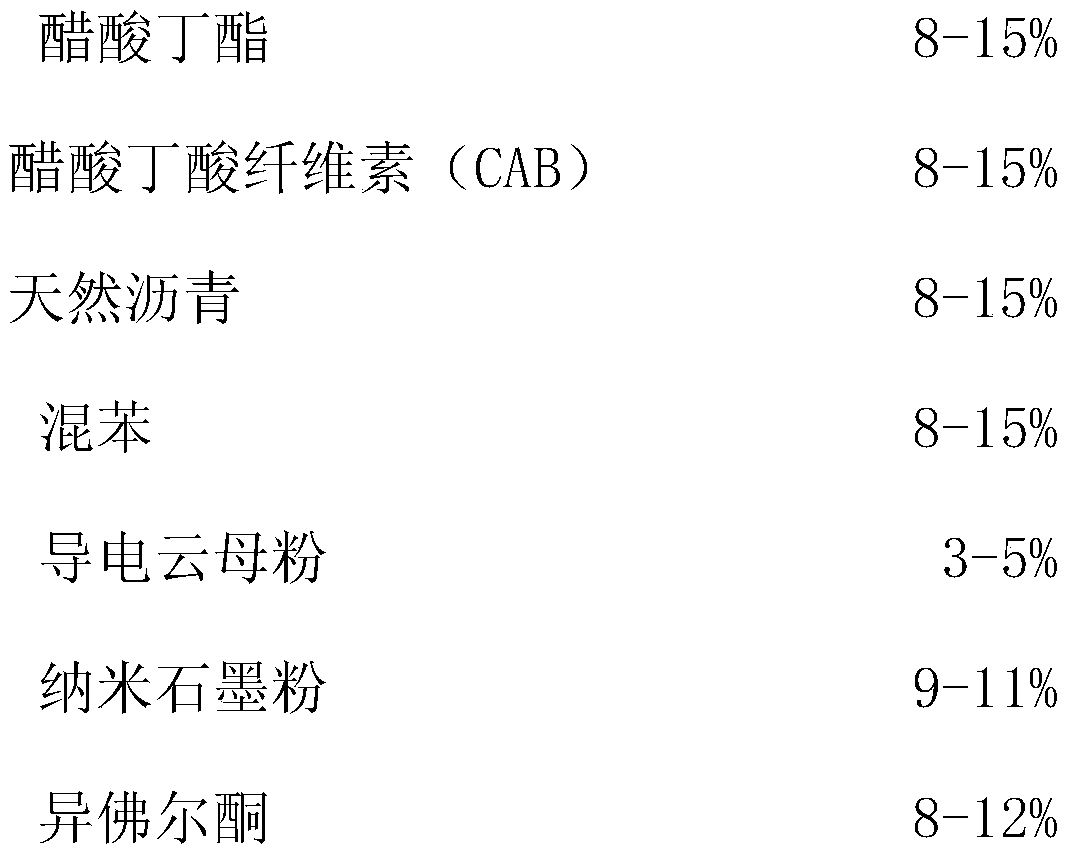

ActiveCN104263119BEfficient anti-corrosion effectImprove anti-corrosion performanceAnti-corrosive paintsElectrically-conductive paintsN-Butyl acetateChemistry

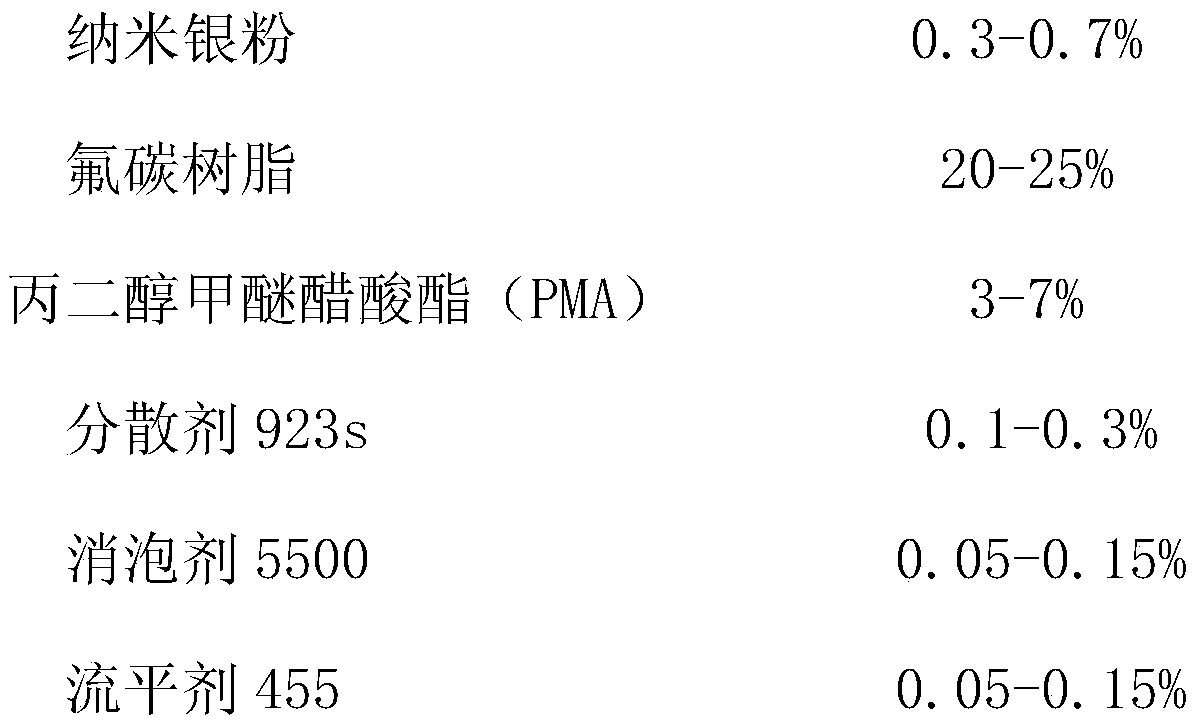

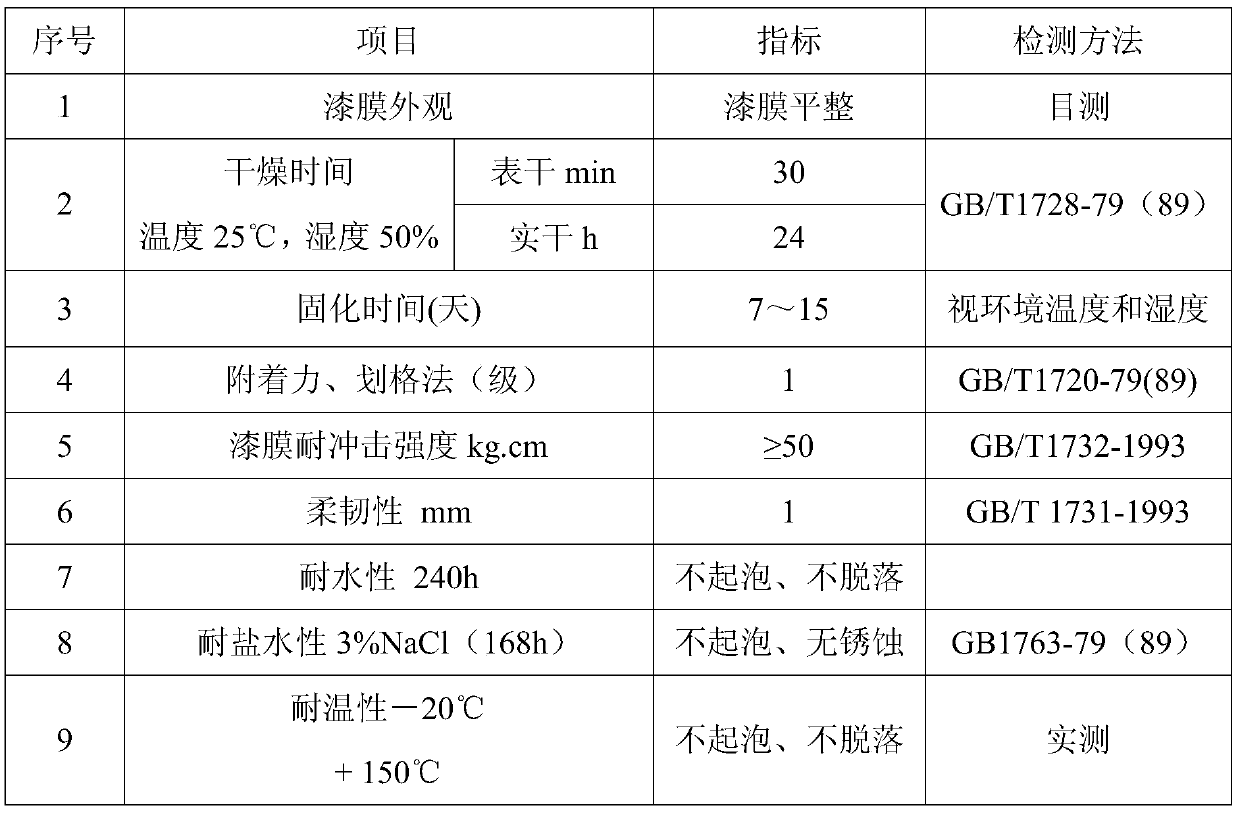

The invention provides an anticorrosion conductive coating for a grounding grid and a preparation method thereof. The anticorrosion conductive coating for the grounding grid is prepared by mixing two components A and B in site according to a mass ratio of 100:2 to 100:8, wherein the component A is prepared by mixing the following substances in percentage by mass and filtering the mixture by a filter screen with a specification of 60 to 100 meshes: 8 to 15 percent of n-butyl acetate, 8 to 15 percent of cellulose acetate butyrate, 8 to 15 percent of natural asphalt, 8 to 15 percent of benzene mixture, 3 to 5 percent of conductive mica powder, 9 to 11 percent of nano graphite powder, 8 to 12 percent of isophorone, 0.3 to 0.7 percent of nano silver powder, 20 to 25 percent of fluorocarbon resin, 3 to 7 percent of propylene glycol methyl ether acetate, 0.1 to 0.3 percent of dispersing agent 923s, 0.05 to 0.15 percent of antifoaming agent 5500 and 0.05 to 0.15 percent of leveling agent 455; the component B is prepared by mixing 20 to 30 percent of a curing agent 3390, 20 to 30 percent of a curing agent TPA-90SB and 40 to 60 percent of n-butyl acetate.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com