Electrically conductive anti-corrosive coating and preparation method thereof

A conductive anti-corrosion and coating technology, applied in anti-corrosion coatings, conductive coatings, polyester coatings, etc., can solve problems such as poor corrosion resistance, high cost, and serious metal pollution, and achieve stable electrical conductivity, improved bonding strength, and flexibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

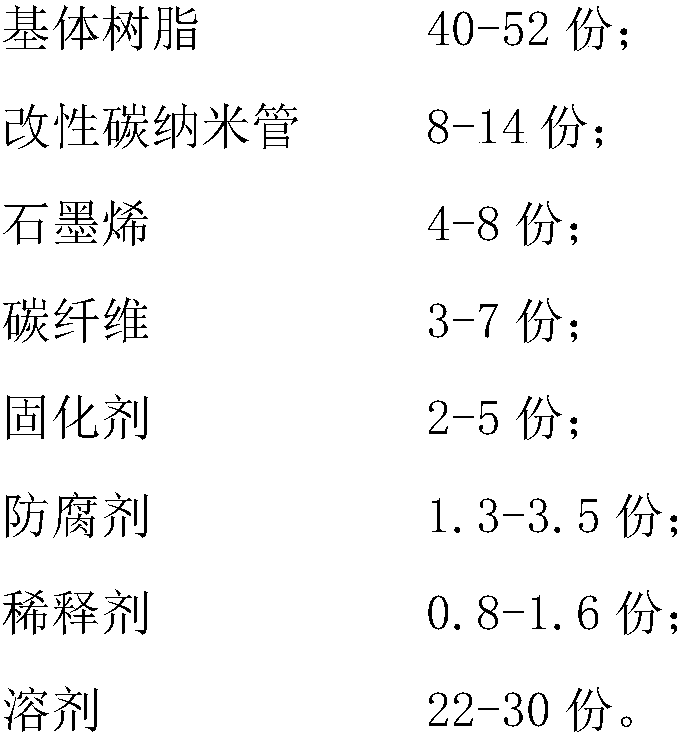

[0037] The conductive anticorrosion coating of the present embodiment, in parts by weight, the coating mainly includes the following components:

[0038]

[0039] Wherein, the matrix resin is selected from one of epoxy resin, fluorocarbon resin, amino resin, acrylic resin and polyester resin.

[0040] Wherein, the preparation method of the modified carbon nanotubes is:

[0041] (1) Weighing concentrated sulfuric acid, concentrated nitric acid and carbon nanotubes with a weight ratio of 50:15:5, and mixing them at 55° C. for 5 hours to obtain acidified carbon nanotubes;

[0042] (2) adding the acidified carbon nanotubes into absolute ethanol, and adding stearyl alcohol at 40° C., stirring and reacting for 10 hours, and obtaining dry carbon nanotubes by filtering, washing and drying after the reaction;

[0043] (3) Sodium bicarbonate, oleic acid and the dried carbon nanotubes are treated with ultrasonic vibration, and after the reaction is completed, the modified carbon nano...

Embodiment 2

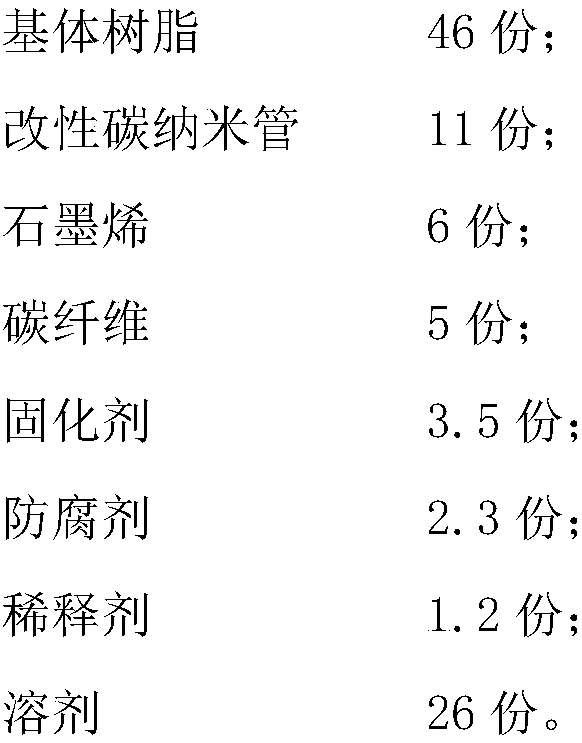

[0053] The conductive anticorrosion coating of the present embodiment, in parts by weight, the coating mainly includes the following components:

[0054]

[0055] Wherein, the matrix resin is selected from one of epoxy resin, fluorocarbon resin, amino resin, acrylic resin and polyester resin.

[0056] Wherein, the preparation method of the modified carbon nanotubes is:

[0057] (1) Weighing concentrated sulfuric acid, concentrated nitric acid and carbon nanotubes with a weight ratio of 50:15:5, and mixing them at 55° C. for 5 hours to obtain acidified carbon nanotubes;

[0058](2) adding the acidified carbon nanotubes into absolute ethanol, and adding stearyl alcohol at 40° C., stirring and reacting for 10 hours, and obtaining dry carbon nanotubes by filtering, washing and drying after the reaction;

[0059] (3) Sodium bicarbonate, oleic acid and the dried carbon nanotubes are treated with ultrasonic vibration, and after the reaction is completed, the modified carbon nanot...

Embodiment 3

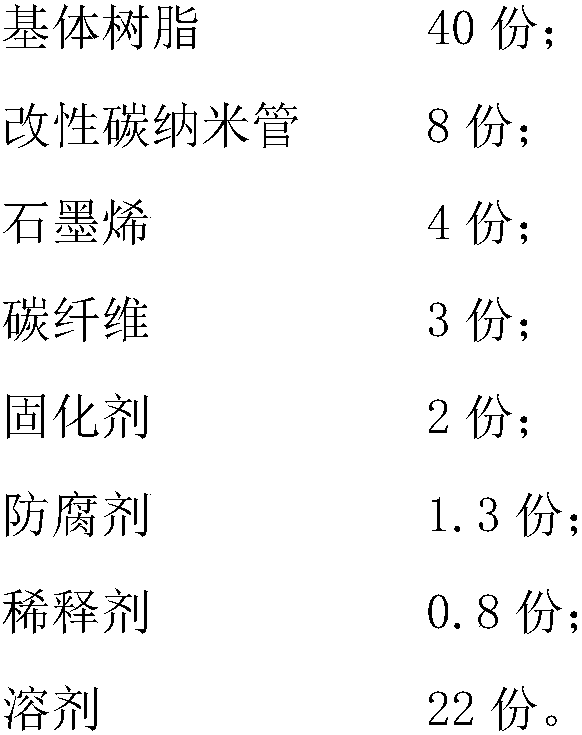

[0069] The conductive anticorrosion coating of the present embodiment, in parts by weight, the coating mainly includes the following components:

[0070]

[0071] Wherein, the matrix resin is selected from one of epoxy resin, fluorocarbon resin, amino resin, acrylic resin and polyester resin.

[0072] Wherein, the preparation method of the modified carbon nanotubes is:

[0073] (1) Weighing concentrated sulfuric acid, concentrated nitric acid and carbon nanotubes with a weight ratio of 50:15:5, and mixing them at 55° C. for 5 hours to obtain acidified carbon nanotubes;

[0074] (2) adding the acidified carbon nanotubes into absolute ethanol, and adding stearyl alcohol at 40° C., stirring and reacting for 10 hours, and obtaining dry carbon nanotubes by filtering, washing and drying after the reaction;

[0075] (3) Sodium bicarbonate, oleic acid and the dried carbon nanotubes are treated with ultrasonic vibration, and after the reaction is completed, the modified carbon nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com