Rubber gasket of journal box and bogie

An axle box rubber pad and rubber layer technology is applied in the installation of the axle box, the device for lateral relative movement between the underframe and the bogie, etc., which can solve problems such as the potential difference between the vehicle and the ground and the track, and potential safety hazards for vehicle operators. , to achieve the effect of realizing the conductive function and overcoming the high requirements of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

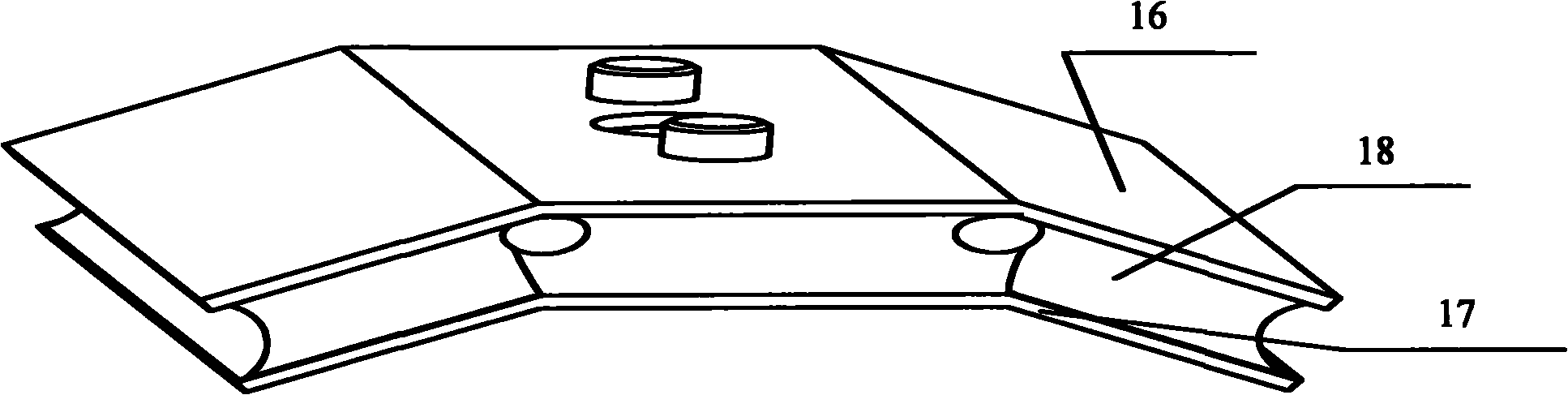

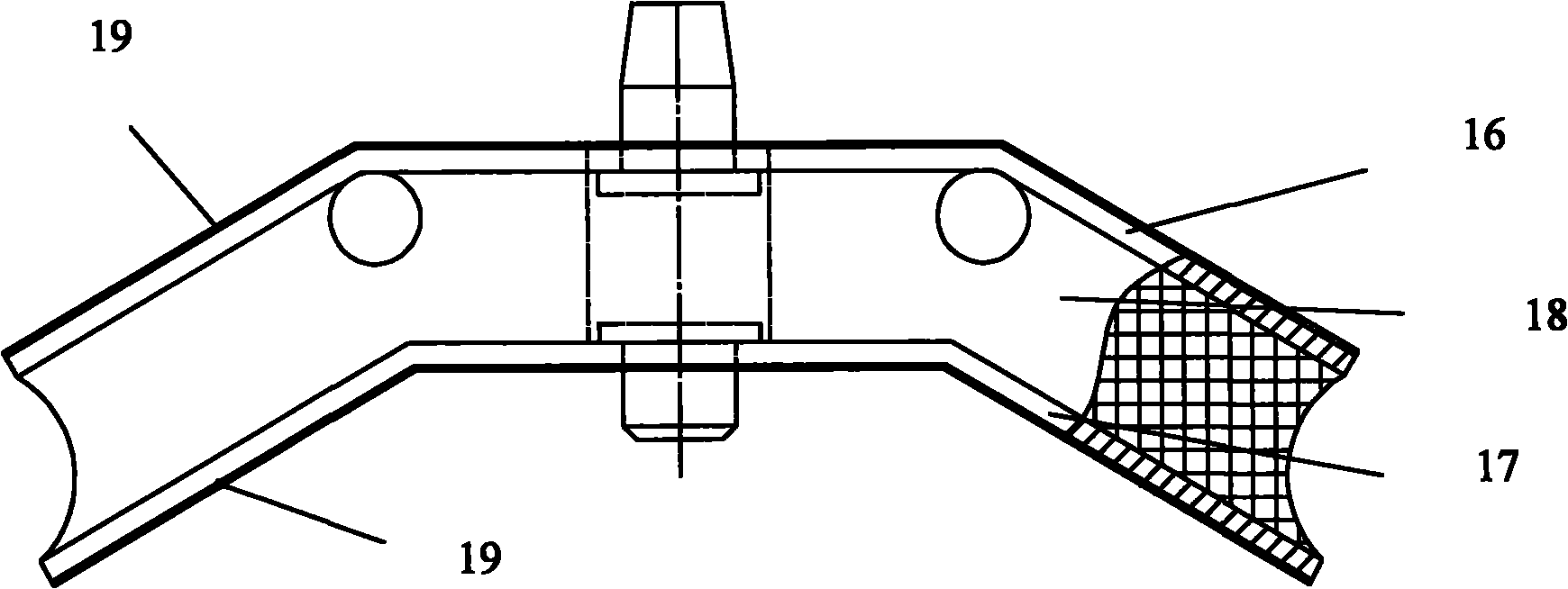

[0028] Figure 4 It is a structural schematic diagram of an embodiment of the axle box rubber pad of the present invention, Figure 5 for Figure 4 A partial enlarged view of the A region in the combined Figure 4 and Figure 5 As shown, the axle box rubber pad of this embodiment can be used for the bogie of a railway freight car, which can include an upper liner 16, a lower liner 17, and a rubber layer 18 formed between the upper and lower liners by vulcanization, respectively formed on the upper and lower liners. A thin layer of rubber 19 on the outer surface of the liner, a glue injection hole 20 , and a conductive mechanism built in the glue injection hole 20 .

[0029] Specifically, the glue injection hole 20 can be arranged at the middle position of the axle box rubber pad, and the glue injection hole 20 can include a cavity formed in the rubber layer 18, a first hole on the upper liner and a first hole on the lower liner respectively. The second hole on the top, the...

Embodiment 2

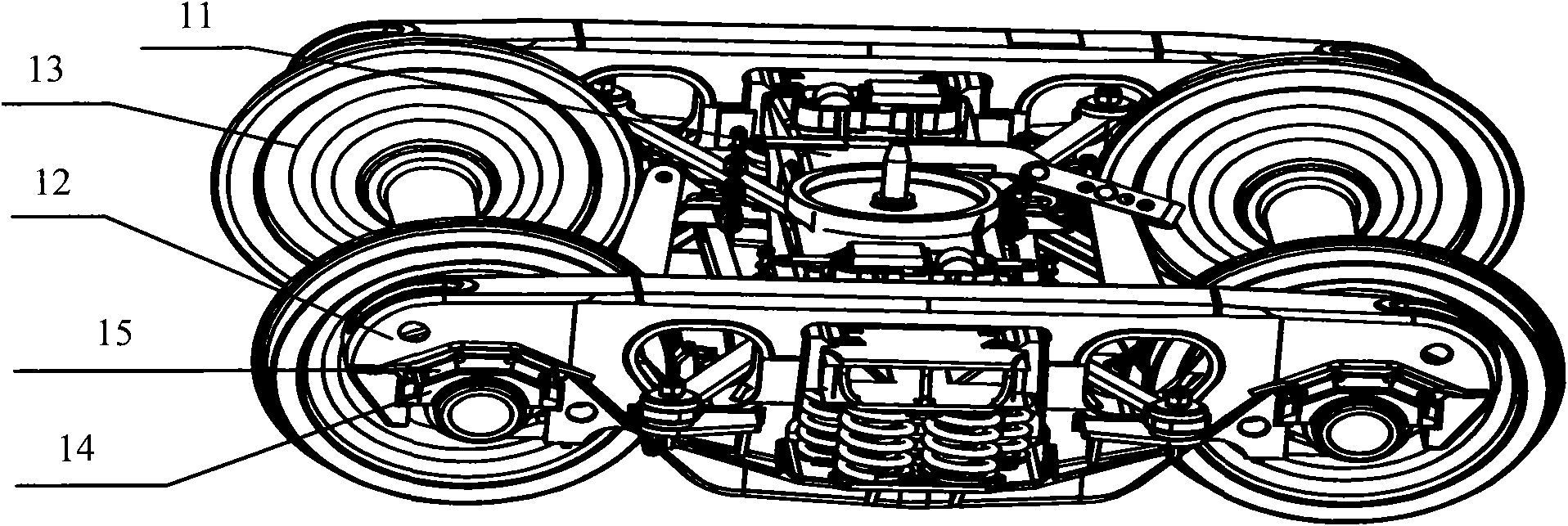

[0047] This embodiment provides a bogie, the bogie includes a bolster, a side frame and a wheel set, the side frame is connected to the wheel set through a bearing saddle provided at the end of the wheel set; the side frame is connected to the wheel set Axle box rubber pads for elastic buffering are arranged between the bearing saddles.

[0048] The main difference between the bogie in this embodiment and the bogie in the prior art is that the axlebox rubber pad can be the axlebox rubber pad described in the first embodiment. By adopting the axle box rubber pad, the electrical conduction between the side frame and the bearing saddle can be realized while the surface of the liner is provided with a thin layer of rubber, which not only overcomes the high manufacturing precision requirements of the upper and lower liners and the tendency to wear, It is not easy to have poor contact with the side frame and the bearing saddle, but it can also realize the conductive function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com