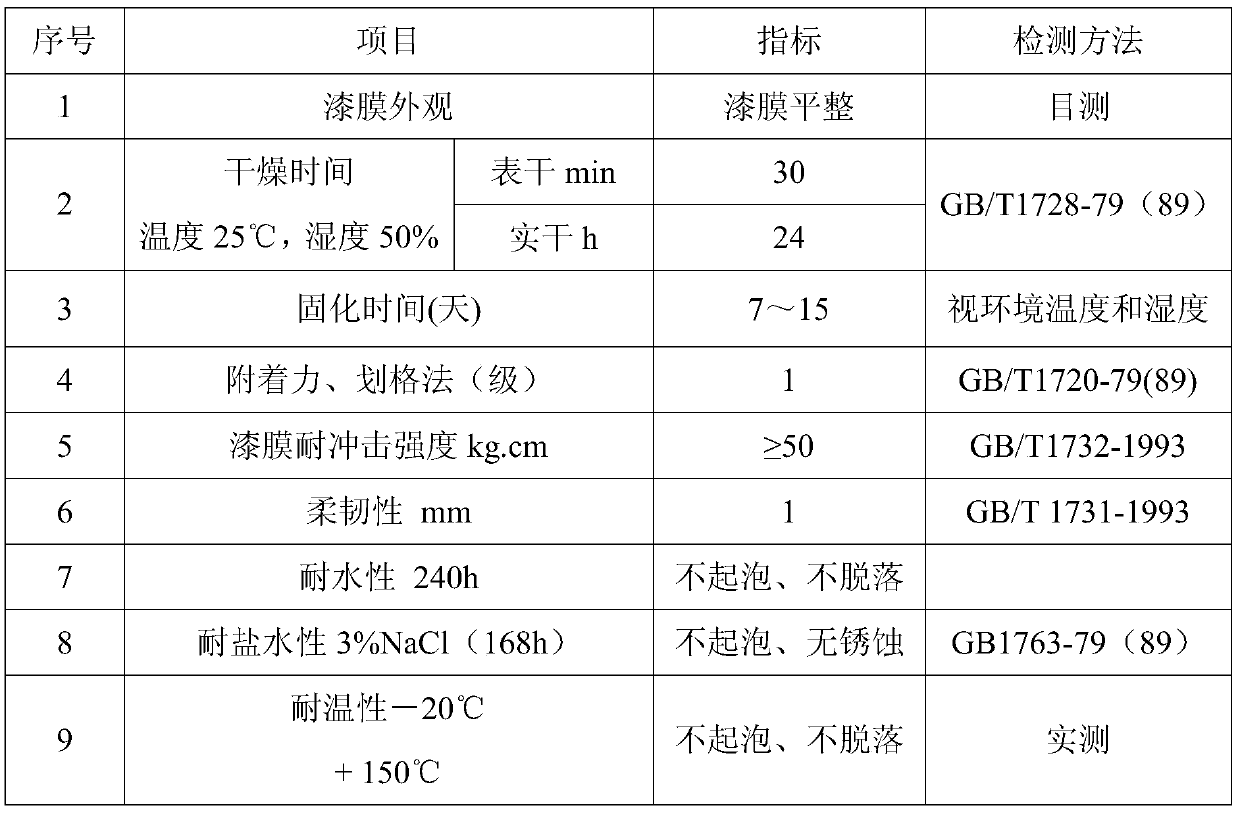

A kind of anticorrosion conductive coating for grounding grid and preparation method thereof

An anti-corrosion conductive and grounding mesh technology, applied in conductive coatings, anti-corrosion coatings, asphalt coatings, etc., can solve problems such as failure of galvanized coatings, and achieve easy dispersion, long-lasting anti-corrosion effect, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

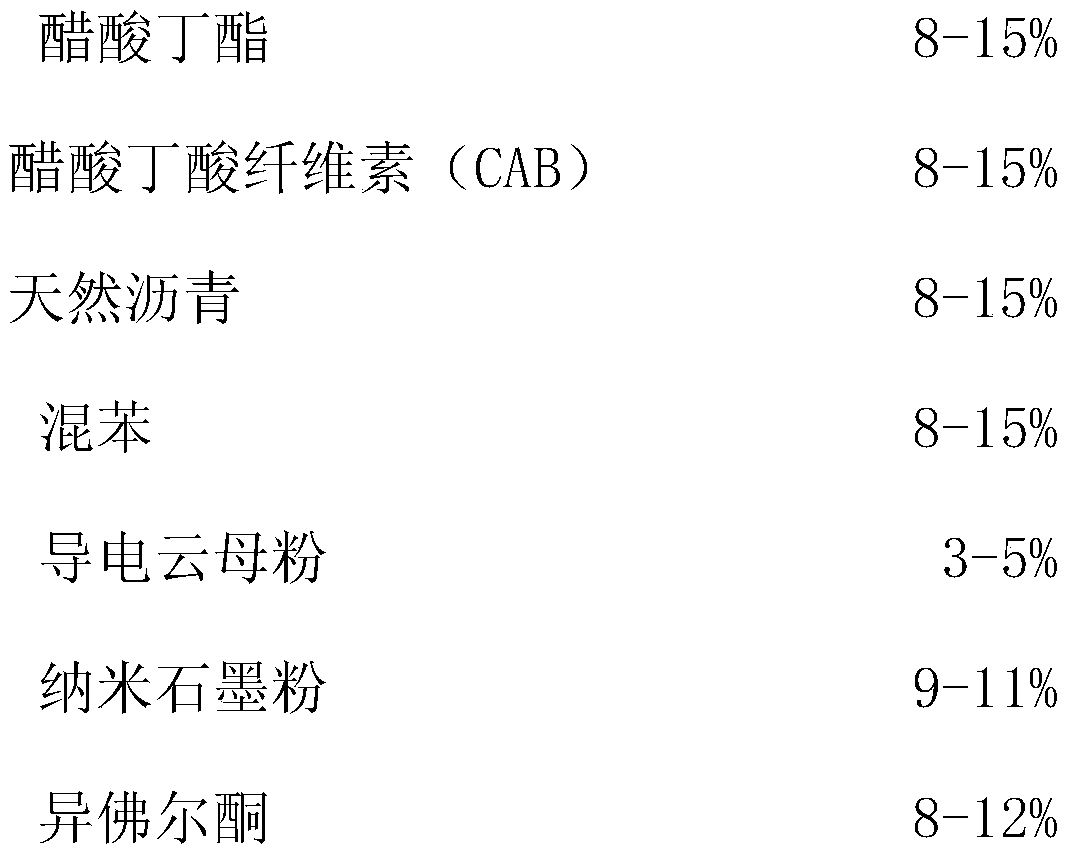

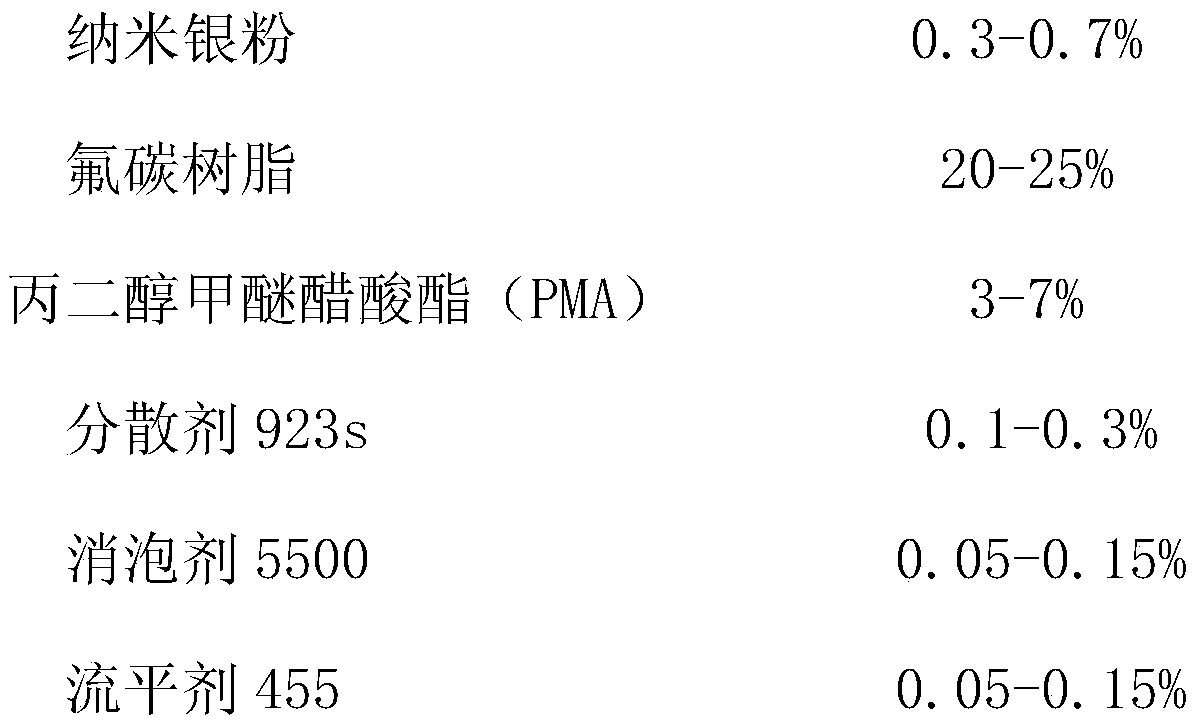

[0039] Embodiment one: a kind of preparation method of anticorrosion conductive paint for grounding net, it is characterized in that concrete steps are as follows:

[0040] (1) Take by weighing 12% butyl acetate and 11% cellulose acetate butyrate solution according to the mass percentage of component A in the above formula, and fully disperse after mixing to obtain a CAB solution;

[0041] (2) Take by weighing 12% natural asphalt and 12% mixed benzene according to the mass percentage of component A in the above formula, mix and disperse, stir to obtain natural asphalt liquid;

[0042] (3) Take by weighing 8% isophorone and 0.5% nano-silver powder according to the mass percentage of component A in the above-mentioned formula, mix uniformly and disperse evenly with ultrasonic waves to obtain nano-silver paste;

[0043] (4) Weigh 25% of fluorocarbon resin, 3% of propylene glycol methyl ether acetate, 0.3% of dispersant 923s, 0.05% of defoamer 5500, 0.15% of fluid according to the...

Embodiment 2

[0047] Embodiment two: a kind of preparation method of anticorrosion conductive paint for grounding grid, is characterized in that concrete steps are as follows:

[0048] (1) Take by weighing 8% butyl acetate and 9% cellulose acetate butyrate solution according to the mass percentage of component A in the above formula, and fully disperse after mixing to obtain the CAB solution;

[0049] (2) Take by weighing 15% natural asphalt and 15% mixed benzene according to the mass percentage of component A in the above formula, mix and disperse, stir to obtain natural asphalt liquid;

[0050] (3) Take by weighing 12% isophorone and 0.7% nano-silver powder according to the mass percentage of component A in the above-mentioned formula, mix uniformly and disperse evenly with ultrasonic waves to obtain nano-silver paste;

[0051] (4) Weigh 23% of fluorocarbon resin, 5% of propylene glycol methyl ether acetate, 0.1% of dispersant 923s, 0.1% of defoamer 5500, and 0.1% of fluid according to th...

Embodiment 3

[0055] Embodiment three: a kind of preparation method of anticorrosion conductive paint for grounding grid, is characterized in that concrete steps are as follows:

[0056] (1) Take by weighing 15% butyl acetate and 15% cellulose acetate butyrate solution according to the mass percentage of component A in the above formula, and fully disperse after mixing to obtain a CAB solution;

[0057] (2) Take by weighing 9% natural asphalt and 9% mixed benzene according to the mass percentage of component A in the above formula, mix and disperse, stir to obtain natural asphalt liquid;

[0058] (3) Take by weighing 10% isophorone and 0.3% nano-silver powder according to the mass percentage of component A in the above-mentioned formula, mix evenly and disperse evenly with ultrasonic waves to obtain nano-silver paste;

[0059] (4) Weigh 20.3% of fluorocarbon resin, 7% of propylene glycol methyl ether acetate, 0.2% of dispersant 923s, 0.15% of defoamer 5500, and 0.05% of fluid according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com