Carbon fiber overhead conductor with optical fiber communication function

An optical fiber communication, overhead wire technology, applied in the direction of optical guide, fiber mechanical structure, power cables for overhead applications, etc., can solve the problems of affecting the service life of the wire, aging of the core surface, etc. Performance, space and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

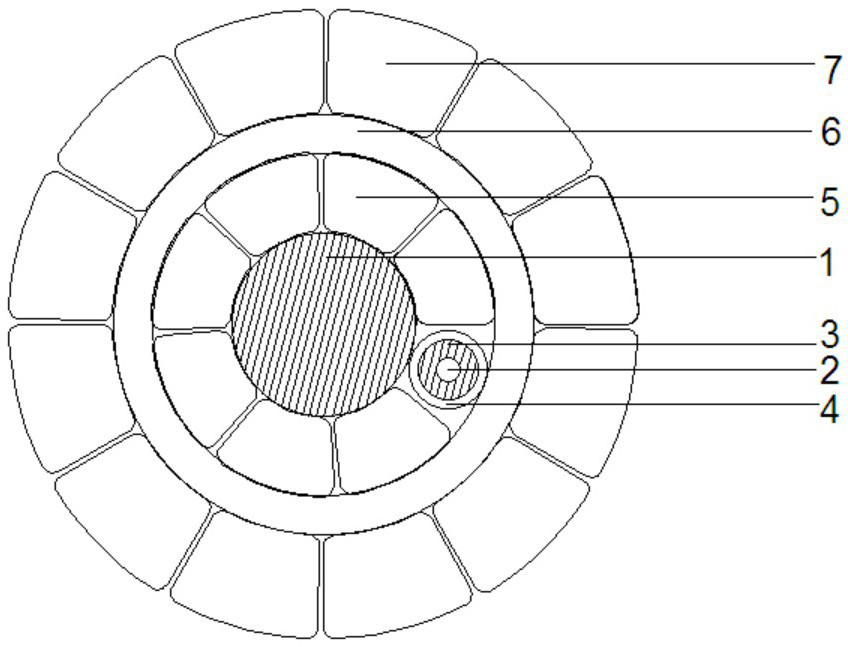

[0020] A carbon fiber overhead wire with optical fiber communication function, including a carbon fiber composite material core 1, an optical fiber 2, heat insulation cotton 3, an aluminum alloy tube 4, an inner aluminum layer 5, and a coated inner aluminum layer 5 and an aluminum alloy tube 4 from the inside to the outside The middle aluminum layer 6 and the outer aluminum layer 7.

[0021] As a preferred embodiment of the present invention, the inner aluminum layer 5 and the aluminum alloy tube 4 are in the same layer, tightly twisted on the carbon fiber composite material core 1, and the inner aluminum layer 5 is a single layer.

[0022] As a preferred embodiment of the present invention, the optical fiber 2 is passed through the center of the heat insulating cotton 3, and the heat insulating cotton 3 is filled in the aluminum alloy tube 4 to protect the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com