Transition metal oxide positive electrode material of lithium as well as preparation and application of transition metal oxide positive electrode material

A transition metal and cathode material technology, applied in the field of energy storage, can solve the problems of unsatisfactory high-rate cycle stability and high-temperature stability, difficulty in large-scale production, long synthesis cycle, etc., and achieve excellent cycle stability and high-temperature stability The effect of stability, easy large-scale production, and control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Add 0.5mmol Ni(Ac) 2 2H 2 O, 1.5mmol Mn(Ac) 2 2H 2 O mixing and ball milling for 8 hours;

[0043] (2) Heat treatment under natural ventilation: 1000°C for 1h, mix the obtained oxide with an excess of 10% LiAc·2H 2 O mixing and ball milling for 8 hours;

[0044] (3) Calcining the ball-milled mixture at 850°C for 12 hours in a tube furnace;

[0045] (4) Then flow the air at a flow rate of 10mL / min for 8 hours, and finally produce 0.97Li 1.02 Ni 0.5 mn 1.5 o 3.98 0.02Li 2 CO 3 ·0.01LiOH, the mass ratio of each component is measured by chemical titration and inductively coupled plasma emission spectrometry.

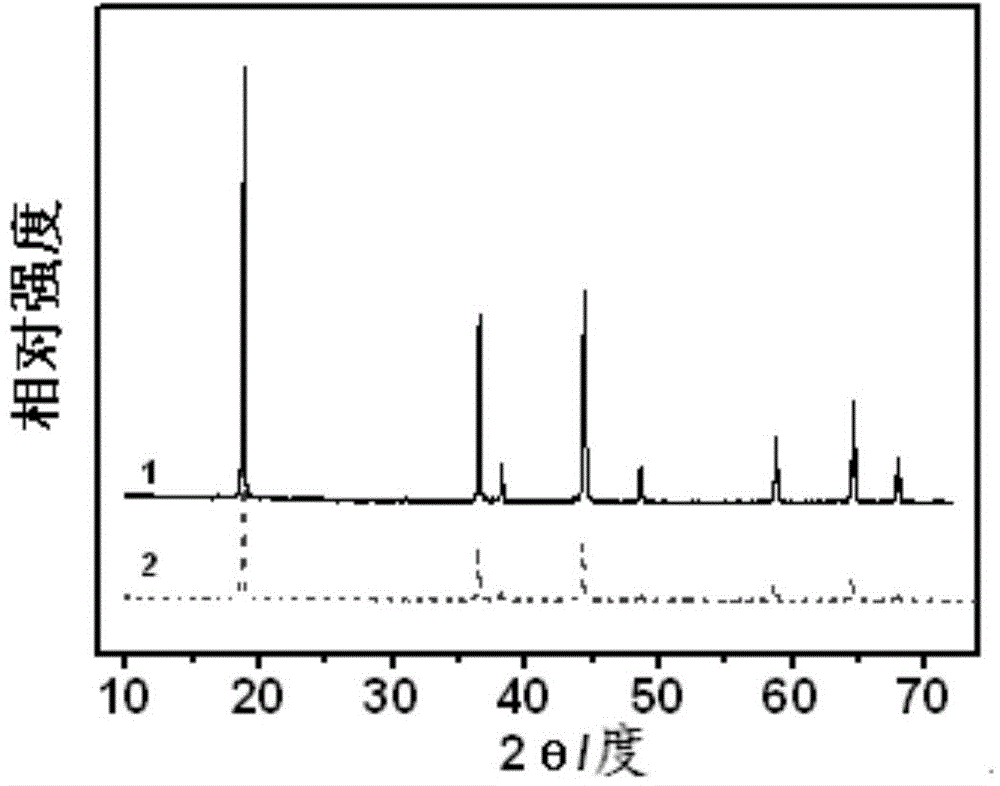

[0046] (5) Phase analysis: X-ray diffraction analysis was performed on the prepared material, as shown in the attached figure 1 The resulting material shown has a spinel structure belonging to the Fd-3m crystal form. The material has a high degree of crystallinity and only a few impurity Li x Ni 1-x O(0≦x≦0.5).

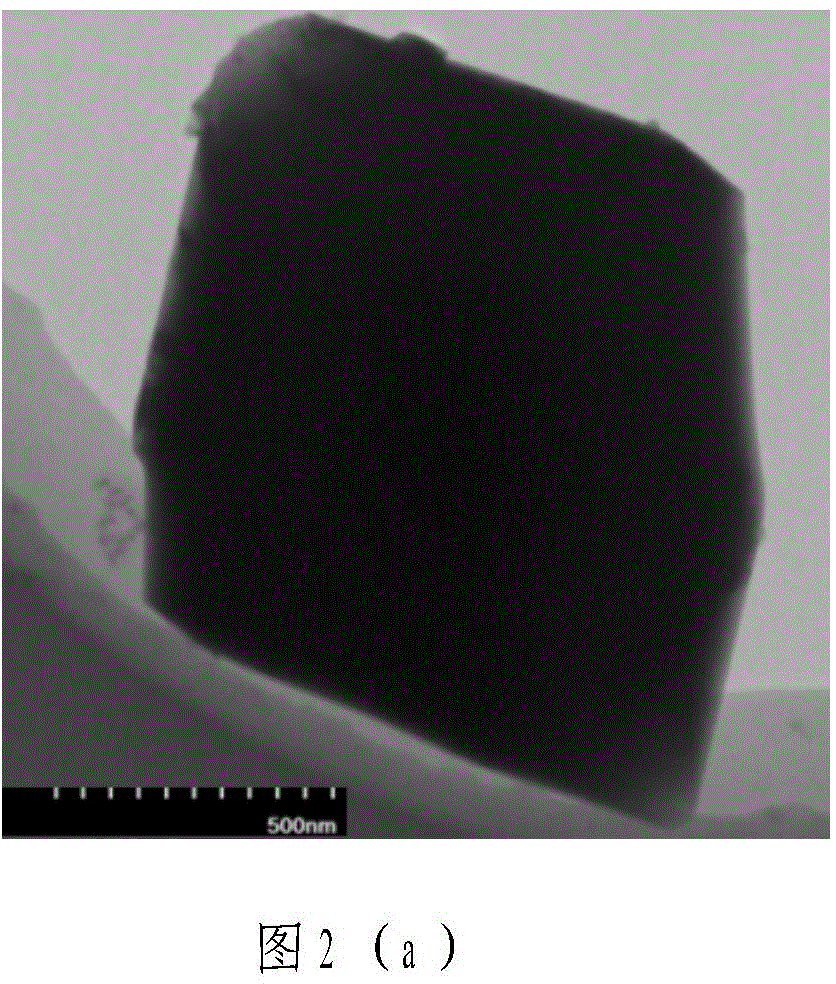

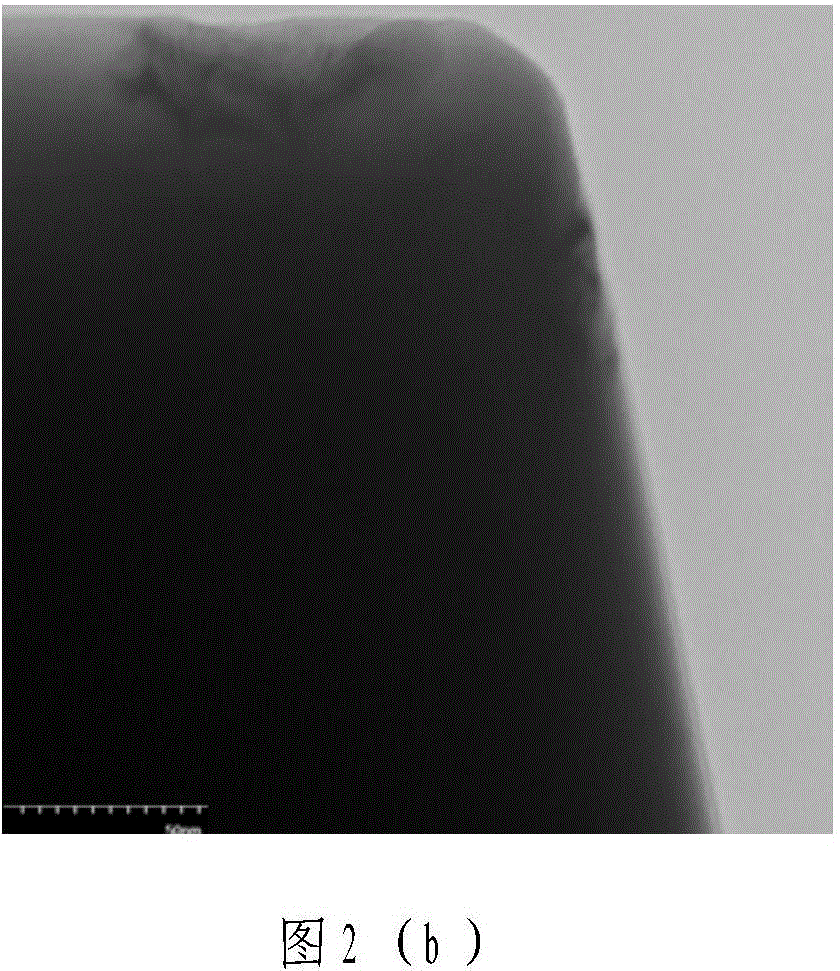

[0047] (6) Morphological characteri...

Embodiment 2

[0051] (1) Add 1.2mmol Cr 2 o 3 , 0.1mmol RuO 2 and 1.5 mmol MnC 2 o 4 2H 2 O mixing and ball milling for 12 hours;

[0052](2) Heat treatment: 400°C for 5h, the obtained oxide and an excess of 8.0% Li 2 C 2 o 4 2H 2 O mixing and ball milling for 8 hours;

[0053] (3) Calcining the ball-milled mixture at 900°C for 24 hours in a tube furnace;

[0054] (4) Then flow CO 2 , the flow rate is 80mL / min, the time is 1h, and finally 0.99Li 1.00 Cr 1.2 Ru 0.05 mn 0.75 o 3.98 0.01 Li 2 CO 3 .

[0055] (5) Phase analysis and morphology characterization: X-ray diffraction spectrum shows that the obtained material has a spinel structure and belongs to the Fd-3m crystal form, and the crystal structure of the material is not affected by the doping of Cr and Ru. The material has high crystallinity and no impurity Li x Ni 1-x O(0≦x≦0.5) exists. The microscopic morphology of the material was investigated on a Hitachi transmission electron microscope HT7700. The particle si...

Embodiment 3

[0059] (1) Dissolve 0.45mmol3,4,9,10-perylenetetracarboxylic anhydride in 14mL of 0.128M NaOH solution, add 0.2mmol Ni(Ac) 2 2H 2 O and 0.7mmol Mn(Ac) 2 2H 2 O was dissolved in 25 mL of water. Slowly add the perylene anhydride solution dropwise into the nickel-manganese mixed solution under vigorous stirring, and stir at room temperature for 0.5 h; transfer the prepared mother liquor into a reaction kettle, and hydrothermally crystallize at 100°C for 24 h;

[0060] (2) After centrifugation, washing, and drying, an orange-yellow precursor was obtained. The precursor was calcined at 600°C in an air atmosphere with a flow rate of 60mL / min for 1h to obtain nickel-manganese oxide.

[0061] (3) Mix nickel manganese oxide with an excess of 20% lithium source (Li 2 CO 3 :LiAc·2H 2 O=1:3) dispersed in acetone, ball milled for 12h;

[0062] (4) The ball-milled mixture was calcined at 850°C for 12 hours at a high temperature with a heating rate of 5°C / min;

[0063] (5) Then flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com