A kind of preparation method of ultrahigh-strength hot forming steel for automobile

A hot stamping forming and ultra-high technology, applied in the field of high-strength steel, can solve problems such as the inability to use ordinary forming methods, and achieve the effects of thinning thickness, excellent plasticity, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] According to the chemical composition given in Table 1, it is smelted in a vacuum induction heating furnace, cast into a forging billet and then forged. The billet is heated to 1250°C and homogenized and annealed for 16 hours under atmosphere protection conditions.

[0033] Table 1 is the mass percent of each composition

[0034] Table 1

[0035]

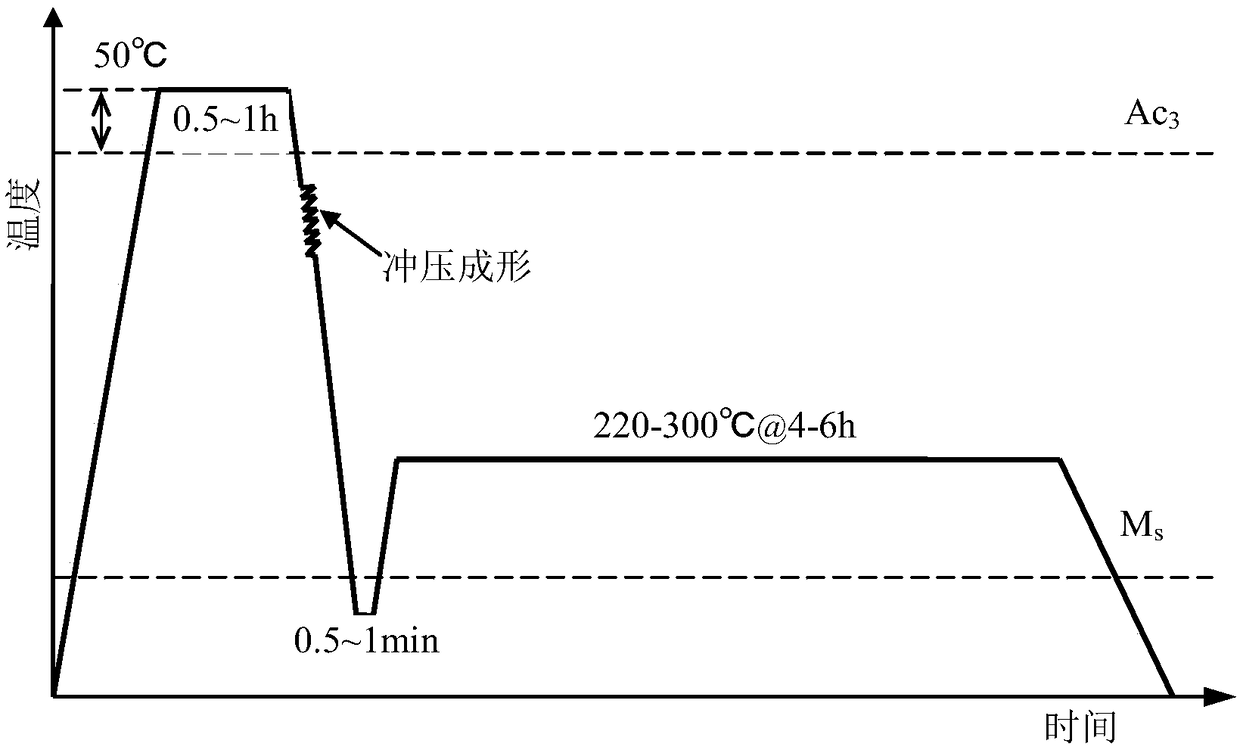

[0036] The hot-rolling process is to heat the billet to 1250°C for 2 hours, and hot-roll six passes on a 350mm two-roll mill to obtain a hot-rolled sheet with a thickness of about 3mm, with a total deformation of 85% to 90%. The final rolling temperatures were 1150°C and 1000°C respectively, and then cooled to room temperature with the furnace.

[0037] Heat the hot-rolled steel plate to 900°C in a resistance furnace, keep it warm for 0.5h, then quickly transfer it to a mold for hot stamping, and then put it into a salt bath furnace at 215°C to cool in a salt bath, and hold it for 60s, then move it into Insulate in a sal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com